Deicing snow-melting agent

A technology of ice melting and formate, applied in other chemical processes, chemical instruments and methods, etc., can solve the corrosion of cadmium-plated parts, aircraft landing gear, corrosion of cadmium-plated parts of connectors, and can not reflect the real situation of aircraft parts environment and other problems, to achieve the effect of low corrosion, good environmental performance and strong water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

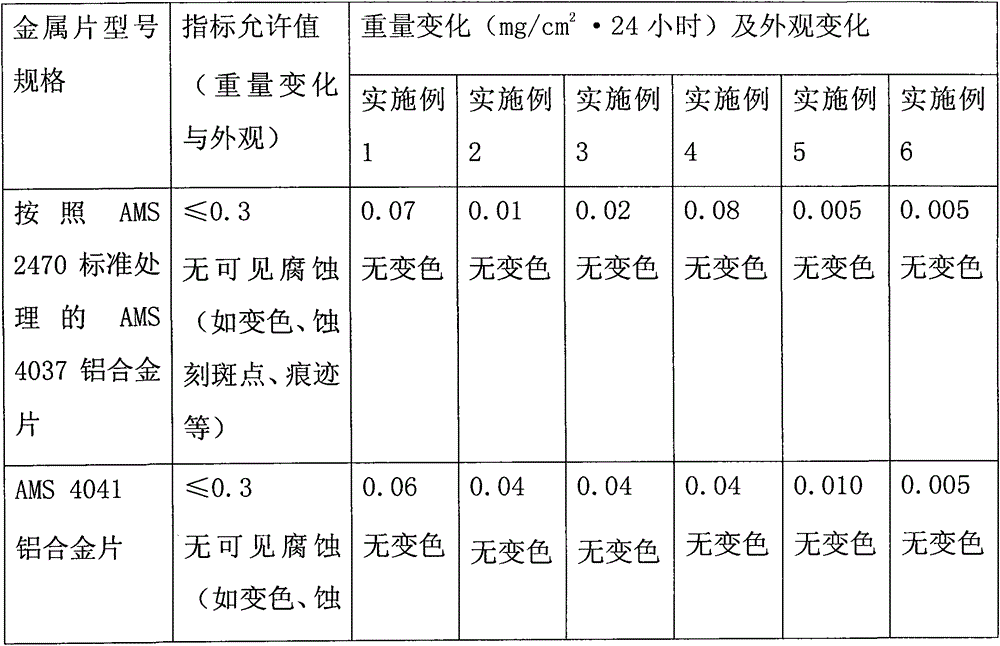

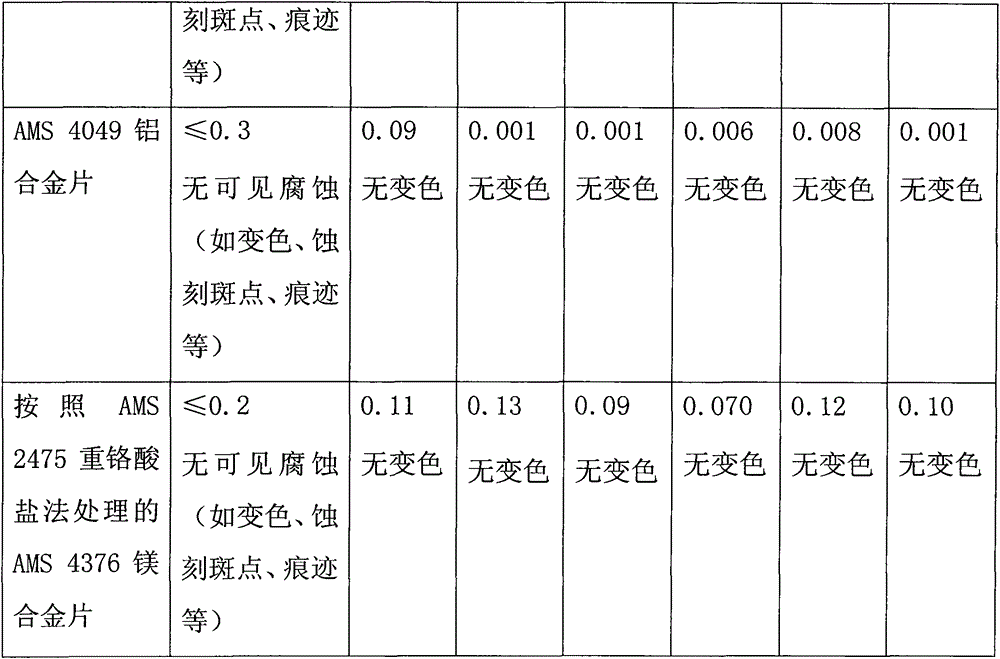

[0032] Perform full immersion corrosion test on Examples 1 to 6

[0033] ① For Examples 1-6, follow the ASTM test standard in "American Aviation Material Technical Specifications-About Flight Runway and Slideway Deicing / Anti-Icing Solid Containment" (AMS1431D Compound, Solid Runway and Taxiway Deicing / Anti-Icing) F483 standard conducts full immersion corrosion test.

[0034] ②The ASTM F483 standard measurement procedure is to take a metal piece with a size of 50.8×25.4×1.6mm and place it in a test solution of a specified concentration (15%) made of deicing agent, under one atmosphere of pressure and at a constant temperature of 38±3℃ , Soak for 24 hours, record the weight change and appearance corrosion and discoloration of the metal sheet before and after soaking, the unit of the test result is mg / cm 2 ·24 hours.

[0035] ③The test results are shown in Table 2 below:

[0036] Table 2 Test results of full immersion corrosion test

[0037]

[0038]

[0039] It can be seen from the abov...

Example Embodiment

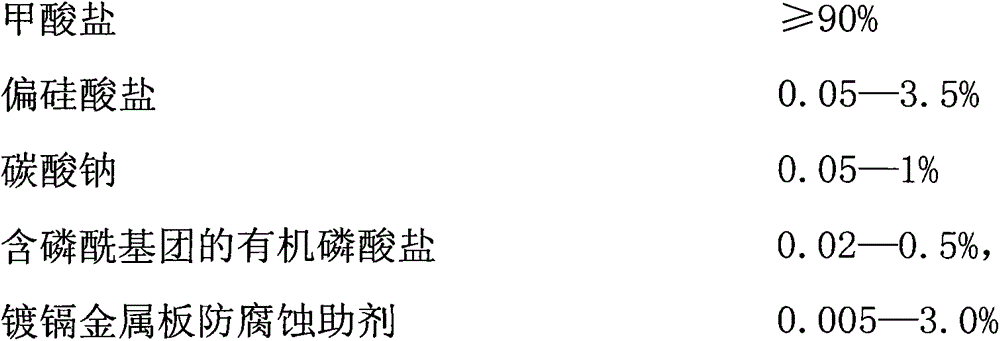

[0061] Example 7

[0062] A deicing and snow melting agent, the weight percentage of each component is:

[0063]

[0064] The production method is: take each component according to weight percentage, crush, mix and stir evenly, extrude into 2-6mm particles, dry, and get it.

Example Embodiment

[0065] Example 8

[0066] A deicing and snow melting agent, the weight percentage of each component is:

[0067]

[0068] The production method is the same as in Example 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com