Non-chlorine snow melting agent, and preparation method thereof

A snow-melting agent, non-chlorine technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of shortened service life of buildings, difficulty in large-scale storage, poor snow-melting ability, etc., achieve small friction attenuation coefficient and reasonable processing cost , The effect of strong snow melting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a preparation method of a deicing agent composition, which comprises sugar and C selected from one or both of sucrose and reducing sugar 1 -C 8 The salts of organic acids are mixed and spray-dried to obtain a granular product.

[0027] In the present invention, "granular product" has no special requirements on the diameter of the particles, as long as the product is granular, it belongs to the scope of "granular".

[0028] When molasses is used instead of sucrose and / or reducing sugar, its preparation method includes: heating molasses at 35-60°C, stirring to make the ingredients fully mixed; then adding 0.8%-1.5% of liquid alkali (based on the weight of molasses, where The concentration of medium alkali is 35%-40%), mix evenly, enter the reaction kettle for hydrolysis reaction; then add acid to the reacted reaction solution to adjust the pH of the reaction solution to 8.0-8.5; cool down, add 1%-4% hydrogen peroxide (based on the wei...

Embodiment 1

[0041] Embodiment 1: Contrast of application amount of deicing agent of the present invention and commercially available deicing agent in snow melting test on snowy road surface

[0042] The detection method of the snow melting ability of the snow melting agent in the present invention follows the national standard GB / T23851-2009, and the method is as follows: take two 150ml porcelain crucibles with the same diameter and height, add 100ml of water, and place them in a low-temperature constant temperature box at -10°C ± 1°C until freezing. Pipette 20% deicing agent solution of the present invention and 20% sodium chloride solution of 25ml, move respectively in the 50ml beaker, be placed in the low temperature thermostat of-10 ℃ ± 1 ℃, standby after 12 hours. Take out the porcelain crucible with ice cubes from the low-temperature constant temperature box, wipe off the water and ice on the outer wall, and weigh it quickly, accurate to 0.1g. Quickly pour the deicing agent solutio...

Embodiment 2

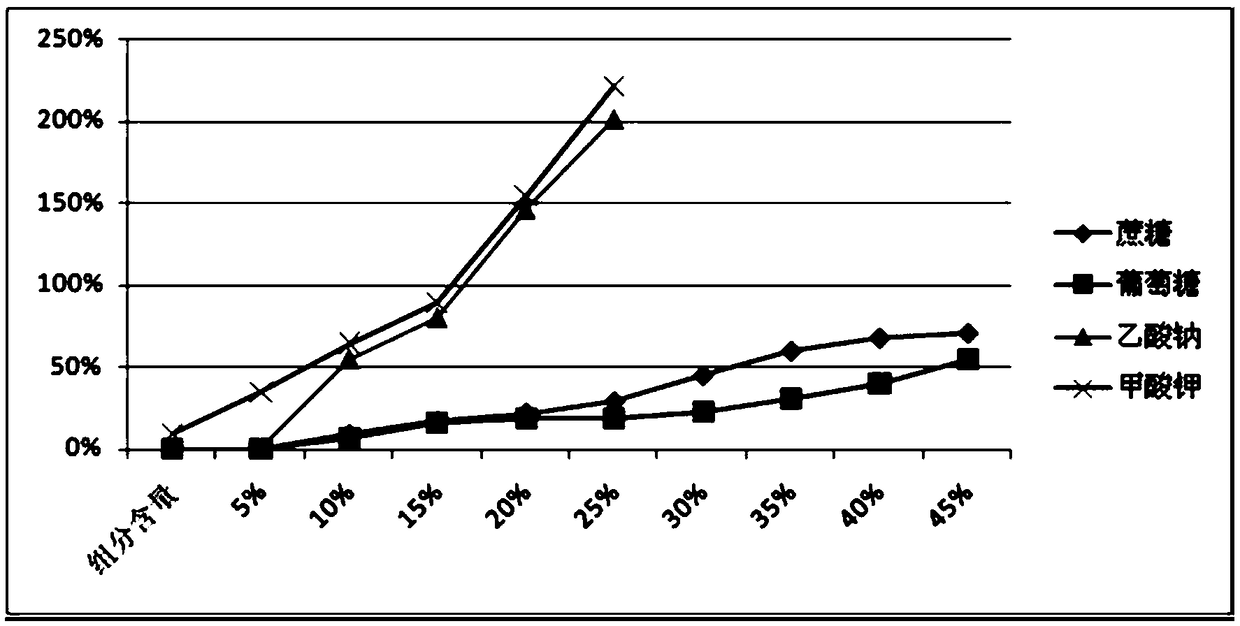

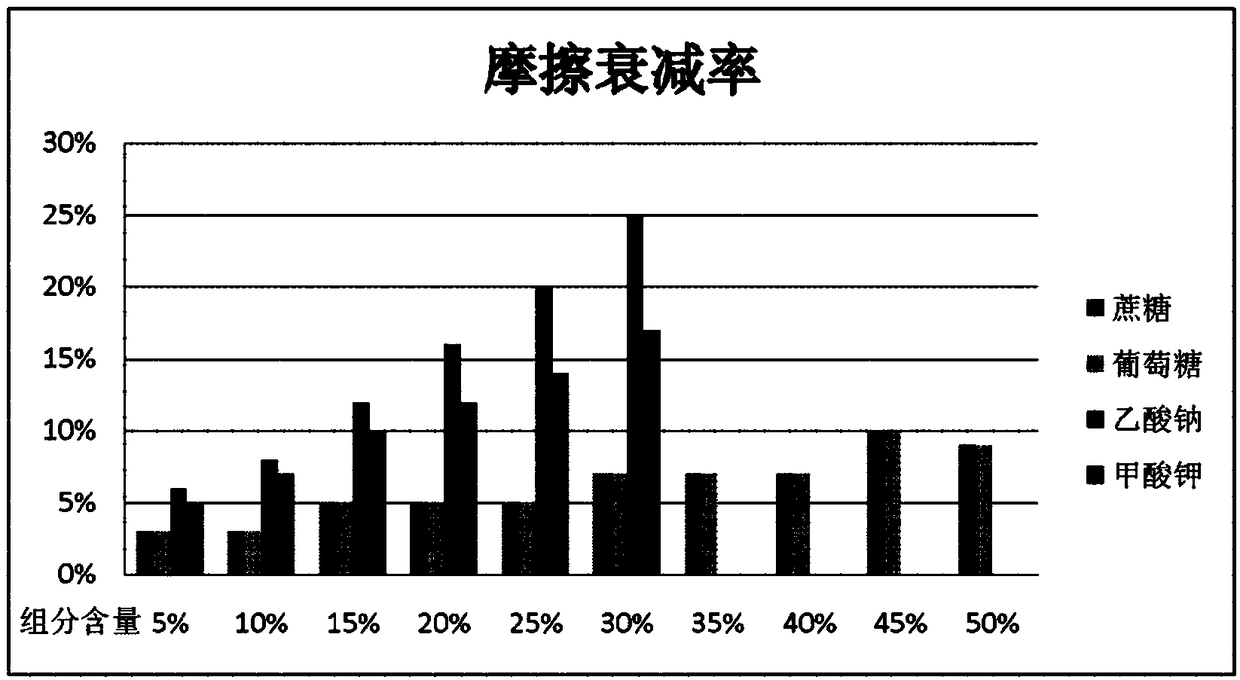

[0059] Example 2: Snow-melting and ice-melting ability experiment of a single component

[0060] The snow melting effect test was carried out according to the national standard GB / T23851-2009, and the test method was the same as in Example 1. The test results are listed in Table 2 below, wherein the amount of the active ingredient is expressed as a percentage concentration in the aqueous solution:

[0061] Table 2 Snow-melting effect of single-component snow-melting agent

[0062]

[0063]

[0064]

[0065]

[0066]

[0067] It can be seen from the above table that under the condition of -10°C required by the national standard, sucrose and glucose alone do not have snow-melting ability when the content is less than 10%, and sodium acetate alone does not have snow-melting ability when the content is less than 10%. Snow-melting ability, while the ice-melting ability of potassium formate is relatively prominent when the content is less than 10%. In addition, unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com