A semi-automatic laminating machine with a laminating degree guarantee device

A semi-automatic and laminating technology, which is applied to the assembly of printed circuits, electrical components, electrical components, etc. with electrical components, can solve the problems of affecting the quality of finished products, low printing efficiency, and insufficient automation, so as to achieve the effect of ensuring the quality of lamination

Active Publication Date: 2019-10-01

江苏珍世味食品有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During the processing of mylar sheet + rubber dome, it needs to be laminated. For the lamination equipment of Mylar sheet + rubber dome, the current equipment requires many steps of manual operation, and the degree of automation It is not high enough, the printing efficiency is low, and it is necessary to improve it; and in the lamination process, the corresponding accuracy of the Mylar sheet and the rubber dome is very important, which affects the quality of the subsequent finished product

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

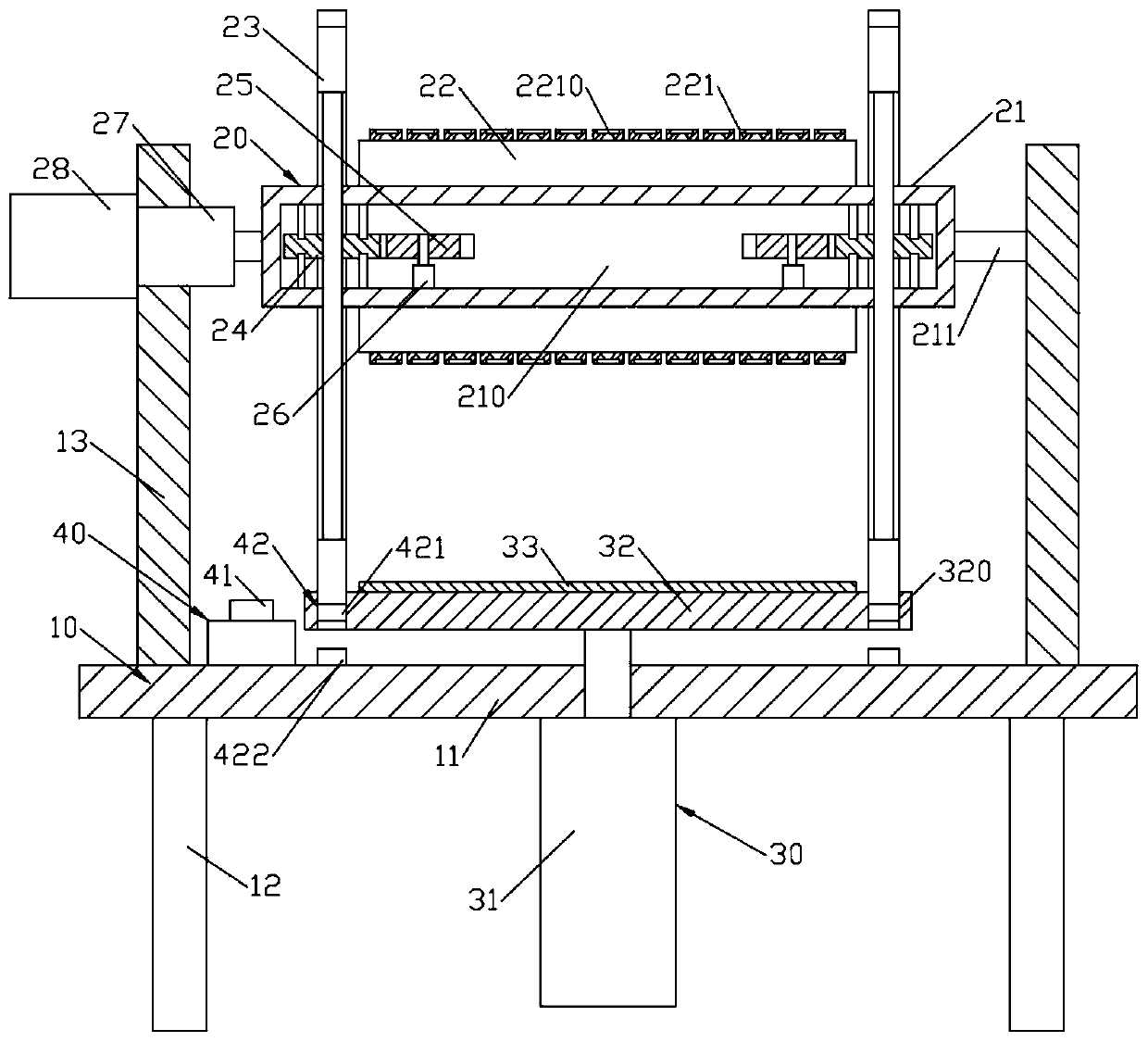

The invention discloses a semi-automatic laminator with a lamination degree guaranteeing device. The laminator comprises a support, a lamination support unit, a lamination driver and a central controller; the support comprises a horizontal shoe plate; a pair of vertical shoe plates in left-right symmetry is molded in the upper end surface of the horizontal shoe plate; the lamination support unit is arranged in the upper portions of the pair of vertical shoe plates; the lamination support unit comprises a central support plate and a pair of laminating support plates; the laminating support plates are fixed in the upper and lower end surfaces of the central support plate; the lamination driver comprises a laminating driving top plate; the laminating driving top plate is arranged below the lamination support unit in an elevating manner; guide posts are arranged on the central support plate in the elevating manner; and guiding through holes which are through in the vertical direction and cooperated with the guide posts respectively are formed in the upper surface of the laminating driving top plate. The condition that lamination is not qualified due to inaccurate force application direction can be avoided, and the mylar and rubber dome laminating quality is ensured.

Description

technical field The invention relates to the technical field of circuit board processing equipment, in particular to a semi-automatic laminating machine with a lamination guarantee device. Background technique During the processing of mylar sheet + rubber dome, it needs to be laminated. For the lamination equipment of Mylar sheet + rubber dome, the current equipment requires many steps of manual operation, and the degree of automation It is not high enough, the printing efficiency is low, and it is necessary to improve it; and in the lamination process, the corresponding accuracy of the Mylar sheet and the rubber dome is very important, which affects the quality of the subsequent finished product. Contents of the invention The purpose of the present invention is to provide a semi-automatic laminating machine with a lamination guarantee device for the deficiencies of the prior art, including a bracket, a lamination support unit, a lamination drive device and a central cont...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H05K3/30H05K13/04

Inventor 王文庆

Owner 江苏珍世味食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com