A pre-aligned semi-automatic laminating machine

A laminating machine and semi-automatic technology, applied in the field of circuit board processing equipment, can solve the problems of affecting the quality of finished products, low printing efficiency, and insufficient automation, and achieve the effect of ensuring laminating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

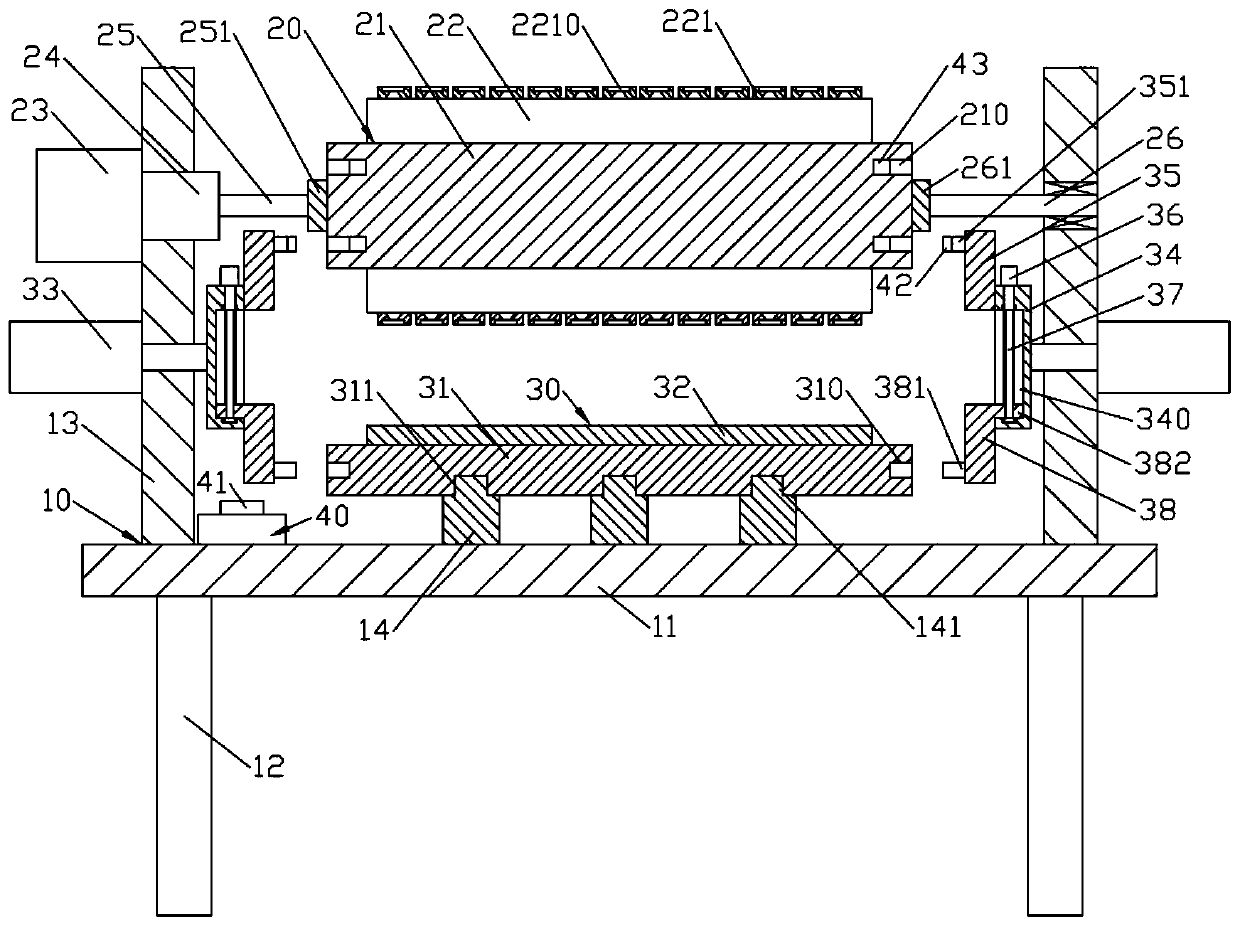

[0013] like figure 1 As shown, a pre-aligned semi-automatic laminating machine includes a bracket 10, a laminating support unit 20, a laminating drive device 30 and a central controller 40; the bracket 10 includes a horizontal support plate 11; the lower end surface of the horizontal support plate 11 A number of evenly distributed support feet 12 are formed on the top; a pair of vertical support plates 13 symmetrically arranged on the left and right are formed on the upper end surface of the horizontal support plate 11; the fitting support unit 20 includes a central support plate 21 and a pair of fitting support plates 22; The central support plate 21 is detachably pivoted on a pair of first vertical support plates 13; the fit support plate 22 is fixed on the upper and lower end faces of the center support plate 21; the fit driving device 30 includes a fit driving top plate 31 and a The alignment lifting unit that is symmetrically arranged on the left and right; the alignment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com