Monitoring block for real-time soundness evaluation of power plant hydraulic actuators during operation

A hydraulic actuator and sound technology, applied in the field of monitoring blocks, can solve problems such as large costs and inability to diagnose faults, and achieve the effects of ensuring reliability, saving time and costs, and simplifying connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 4 example

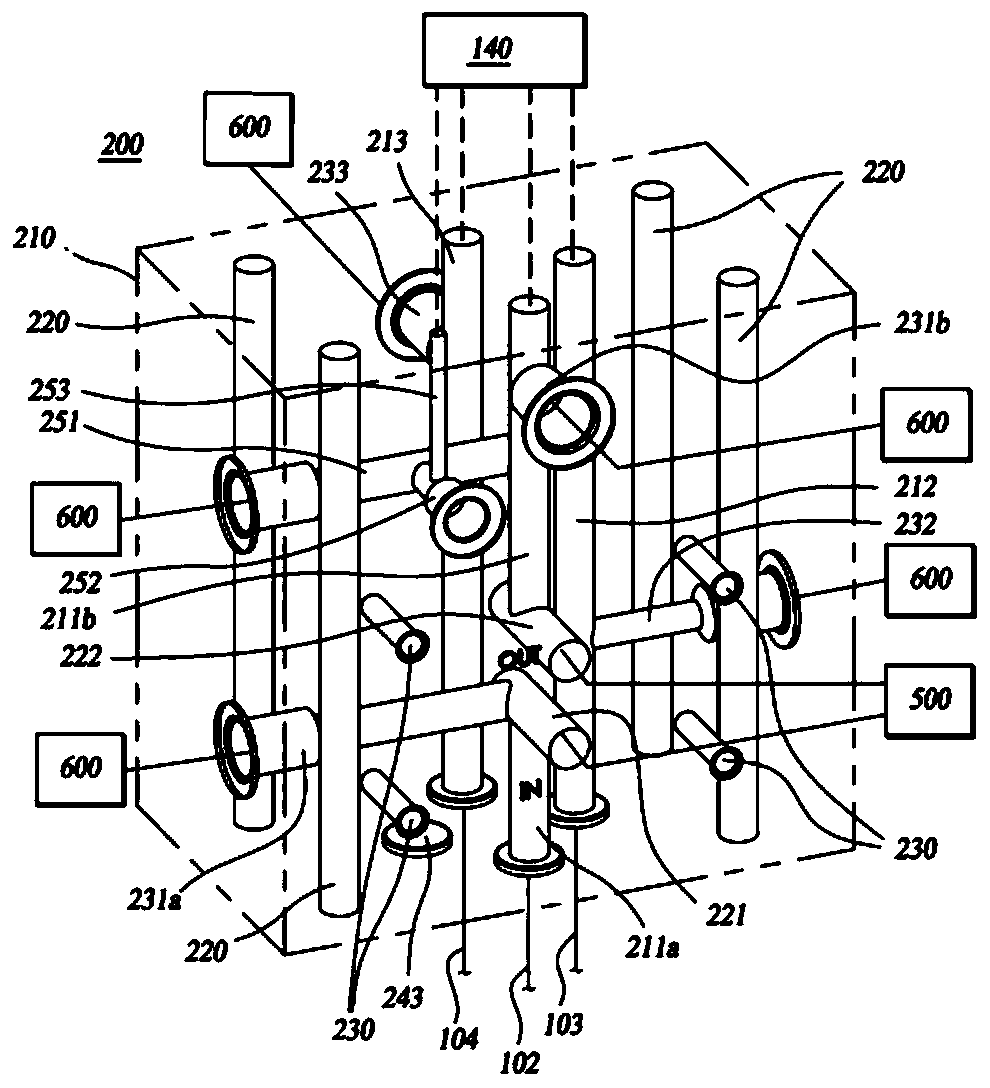

[0157] According to the fourth embodiment of the present invention, the detailed structure of the driving monitoring block 200 is the same as that of any one of the first to third driving monitoring blocks 200 of the present invention, so the description thereof is omitted.

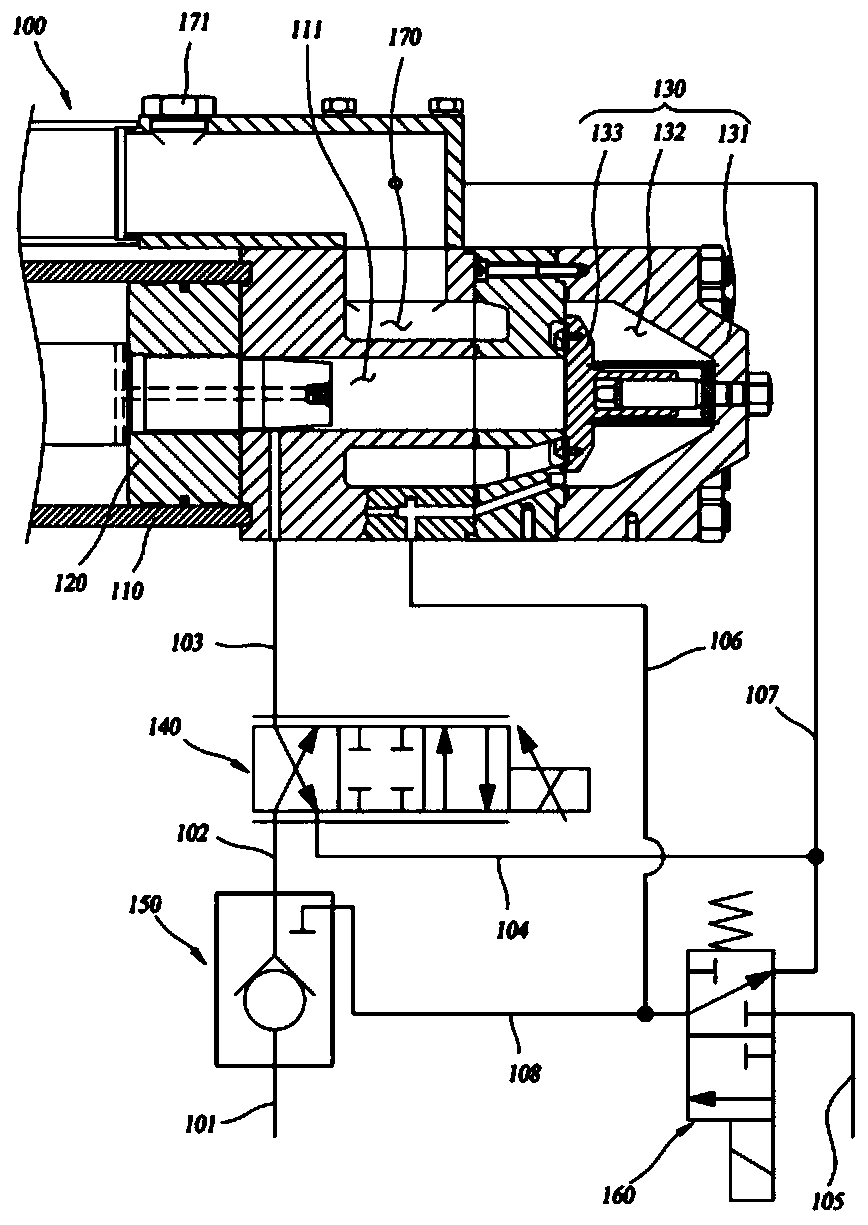

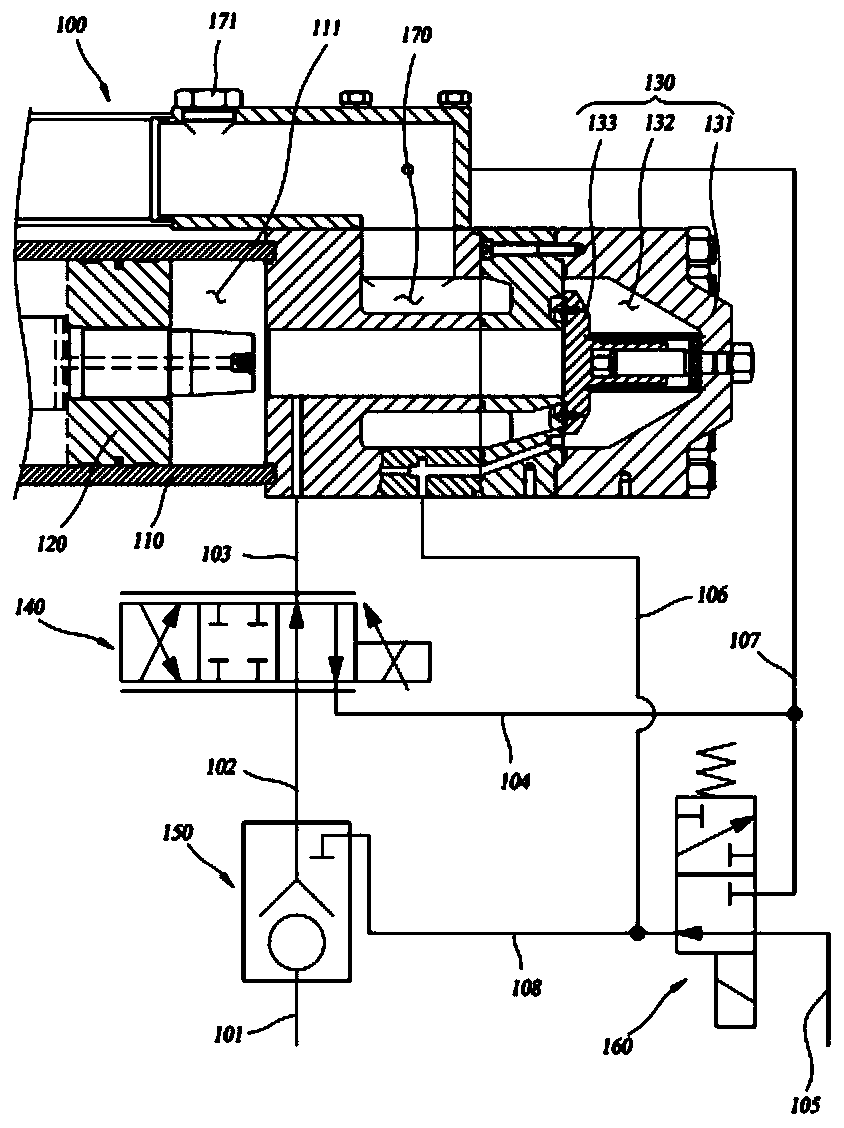

[0158] If so, according to the fourth embodiment of the present invention, the lower side of the driving body unit 210 is combined with the hydraulic actuator 100, the upper side of the driving body unit 210 is combined with the driving valve 200, and the module fastening part 230 is arranged on the right side of the driving body unit 210. , the right side of the driver unit 210 is combined with the flow sensing module 500 . Furthermore, the hydraulic sensing module 600 is combined with any of the front, back and both sides of the driving body unit 210 in order not to dry the hydraulic actuator 100 , the driving valve 140 , and the flow sensing module 500 .

[0159] According to the fourth embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com