Patents

Literature

40results about How to "No change in length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

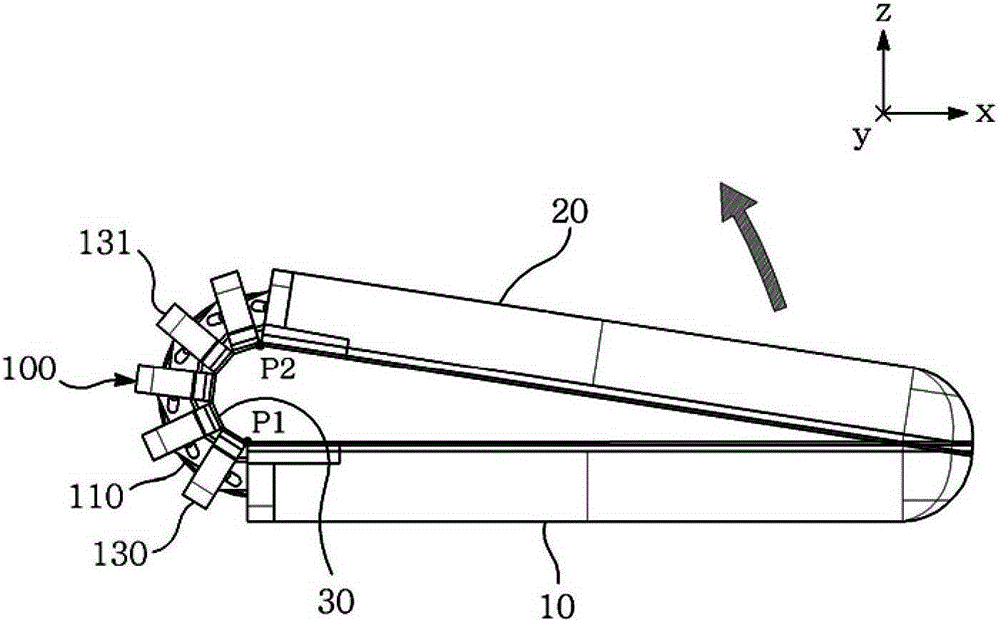

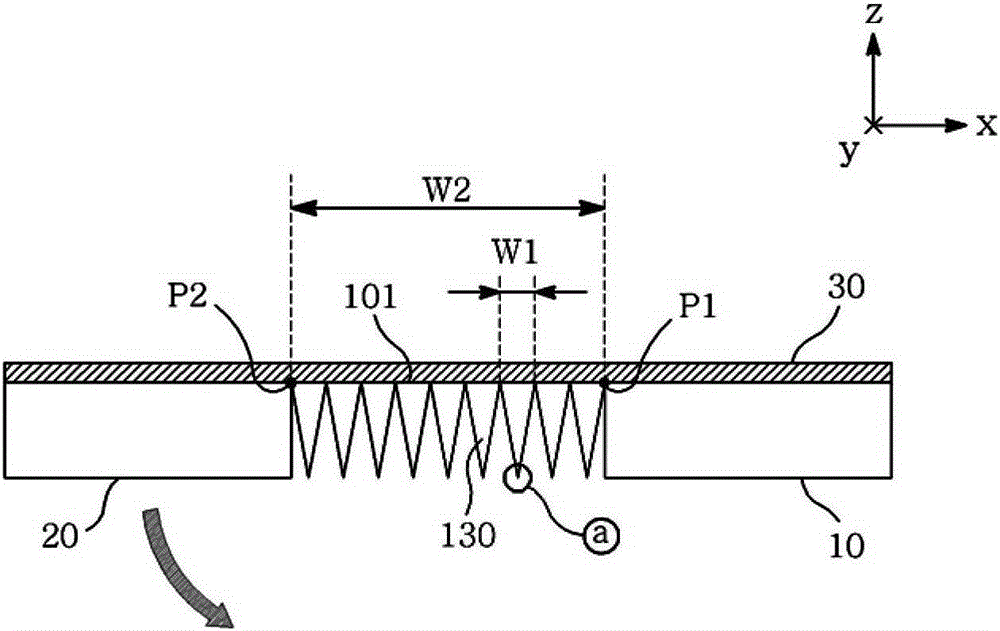

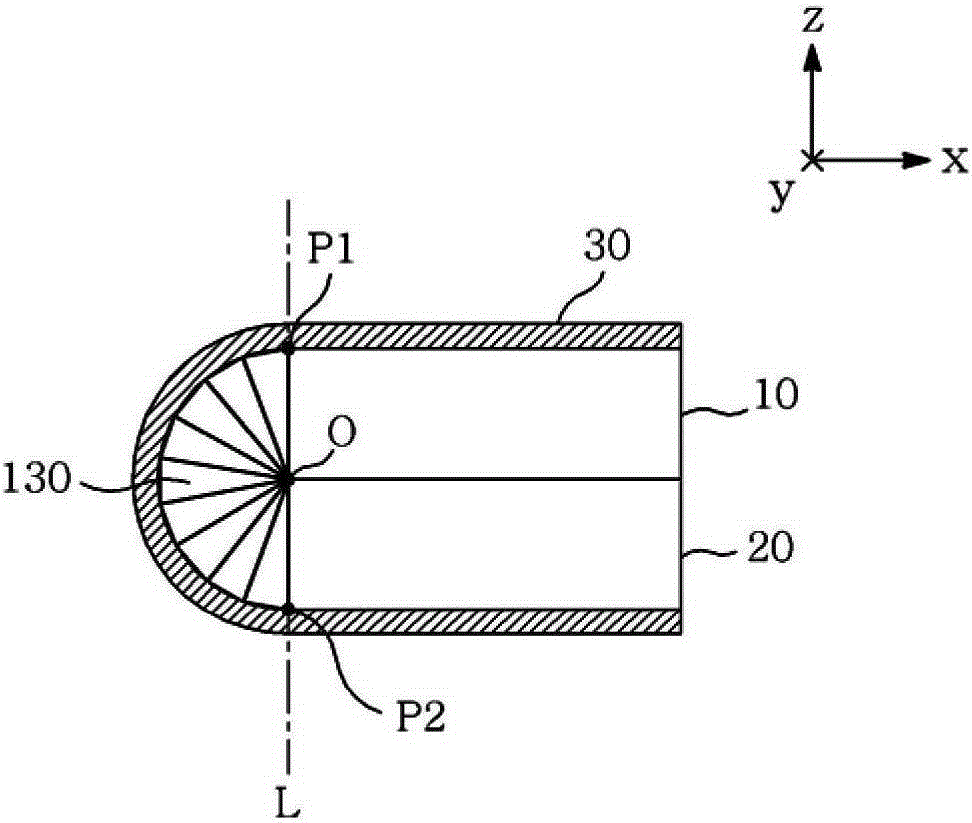

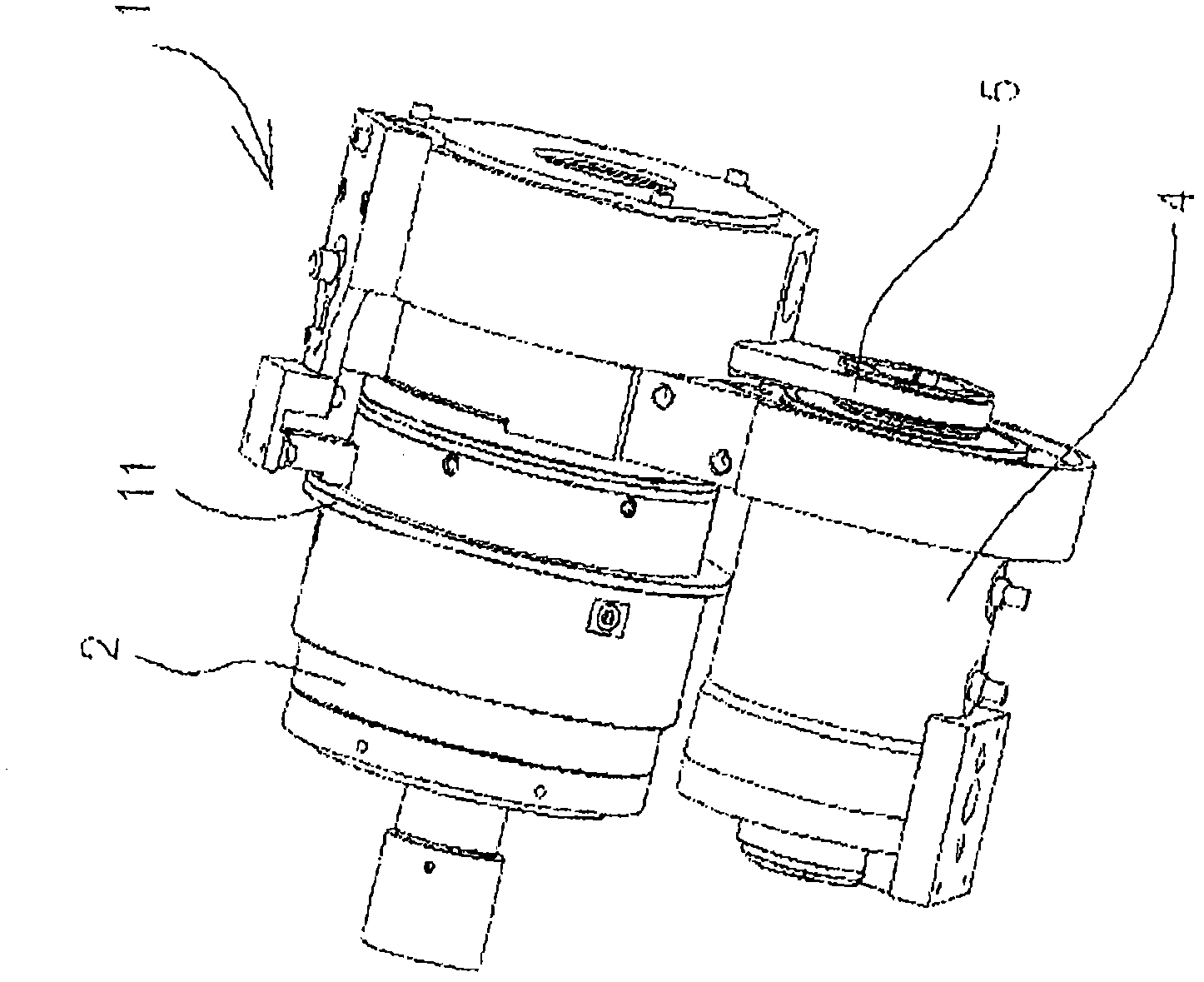

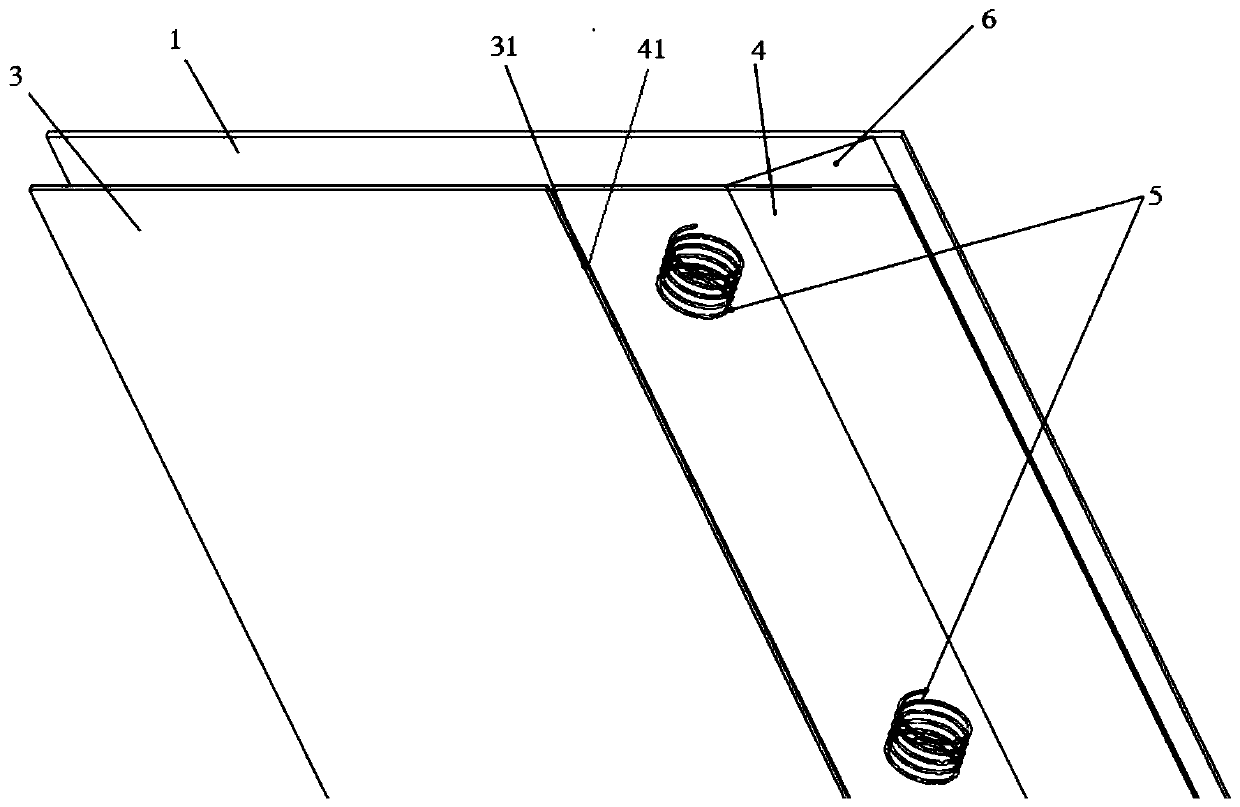

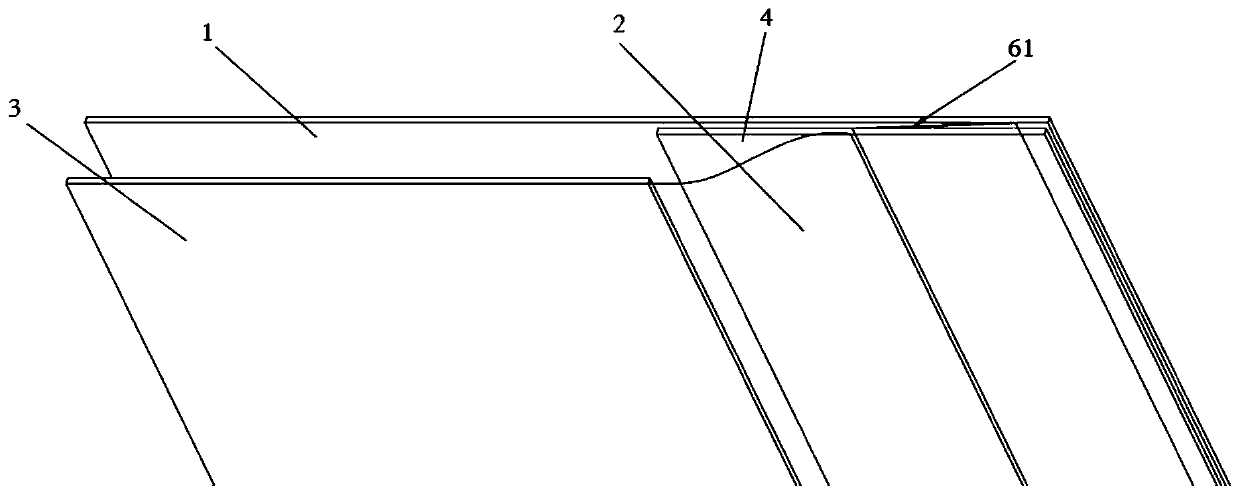

Hinge device

ActiveCN105605084ANo change in lengthAvoid damageWing accessoriesShaftsMechanical engineeringHinge angle

Owner:SENEKA

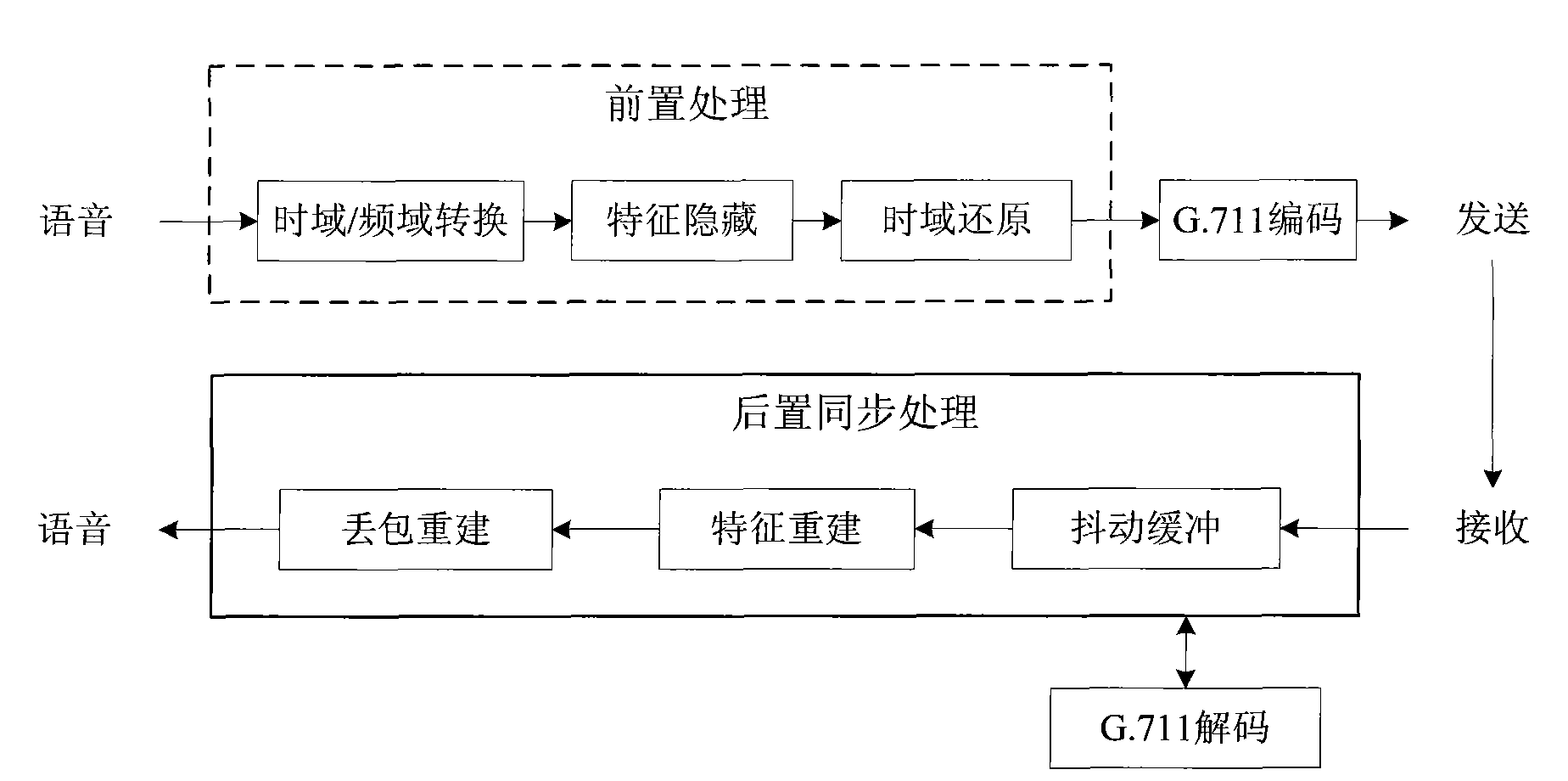

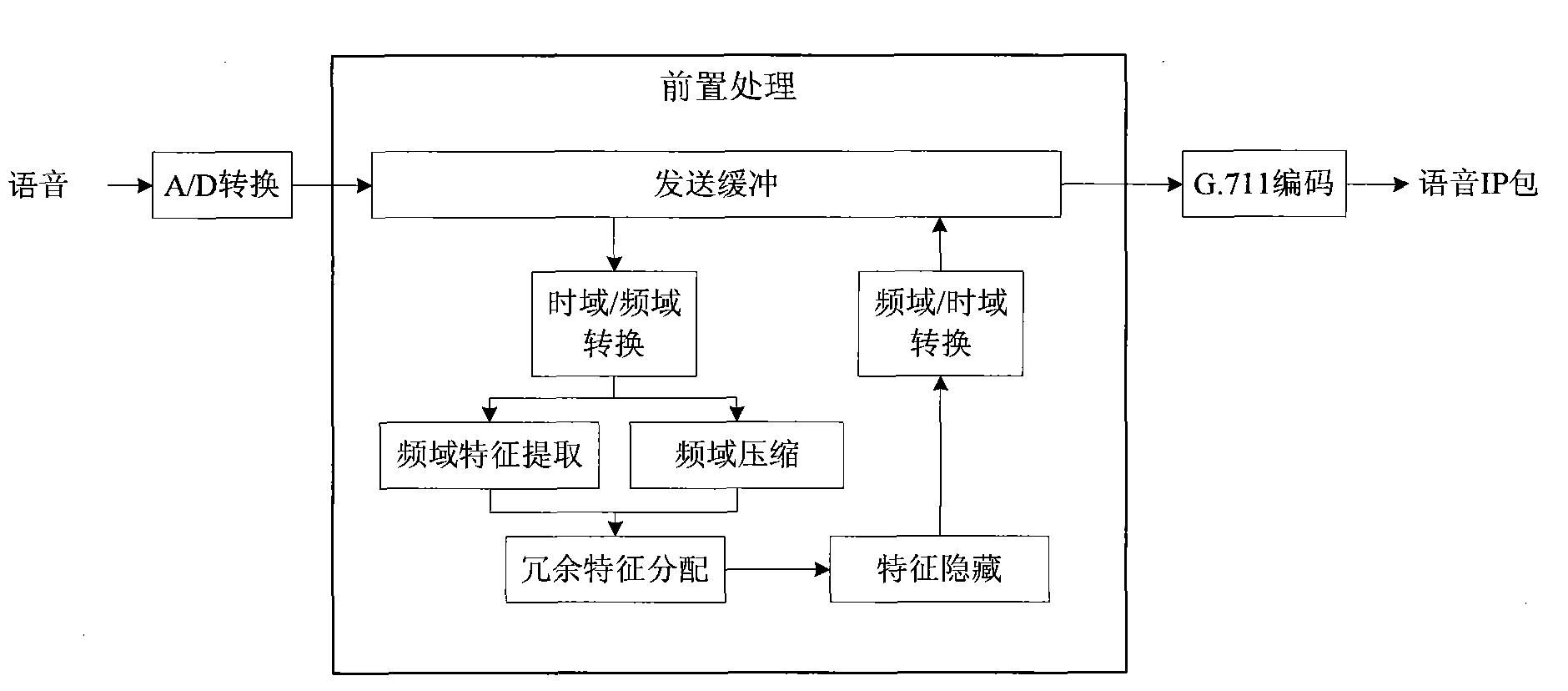

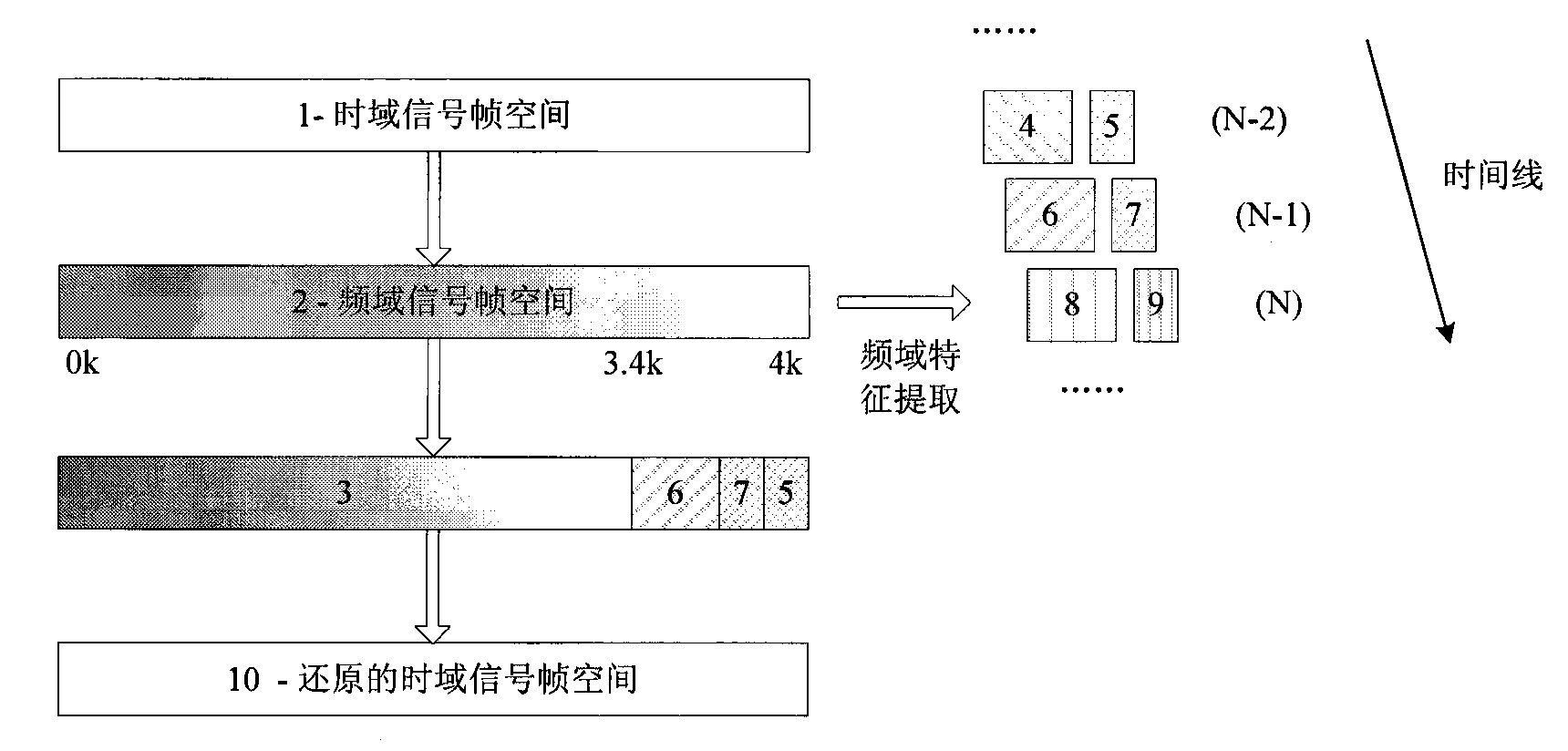

Method for hiding redundant information in G.711 phonetic coding

ActiveCN101604523ANo change in lengthPreserve sound detailsSpeech analysisCommunication qualityTelecommunications

The invention provides a method for hiding redundant information in G.711 phonetic coding. Pre-treatment is carried out before a phonetic packet is coded so that the phonetic packet is provided with hidden information insensitive to human ears, the information contains main features of adjacent other phonetic packets, then normal G.711 mode is used for coding and sending, the same back propagation is carried out for decoding and post-treatment at a receiving end, thus obtaining the original phonetic information. When the data packet is lost, the main phonetic features of the lost packet can be obtained from the adjacent data packets, thus restoring the main phonetic data of the lost packet. While for the device not knowing the hidden algorithm, normal G.711 mode can be directly used for decoding to obtain phonetics approaching the original state, thus the system can be compatible with G.711 code, and can greatly improve the capability of packet losing resistance of phonetic communication and improve communication quality.

Owner:网经科技(苏州)有限公司

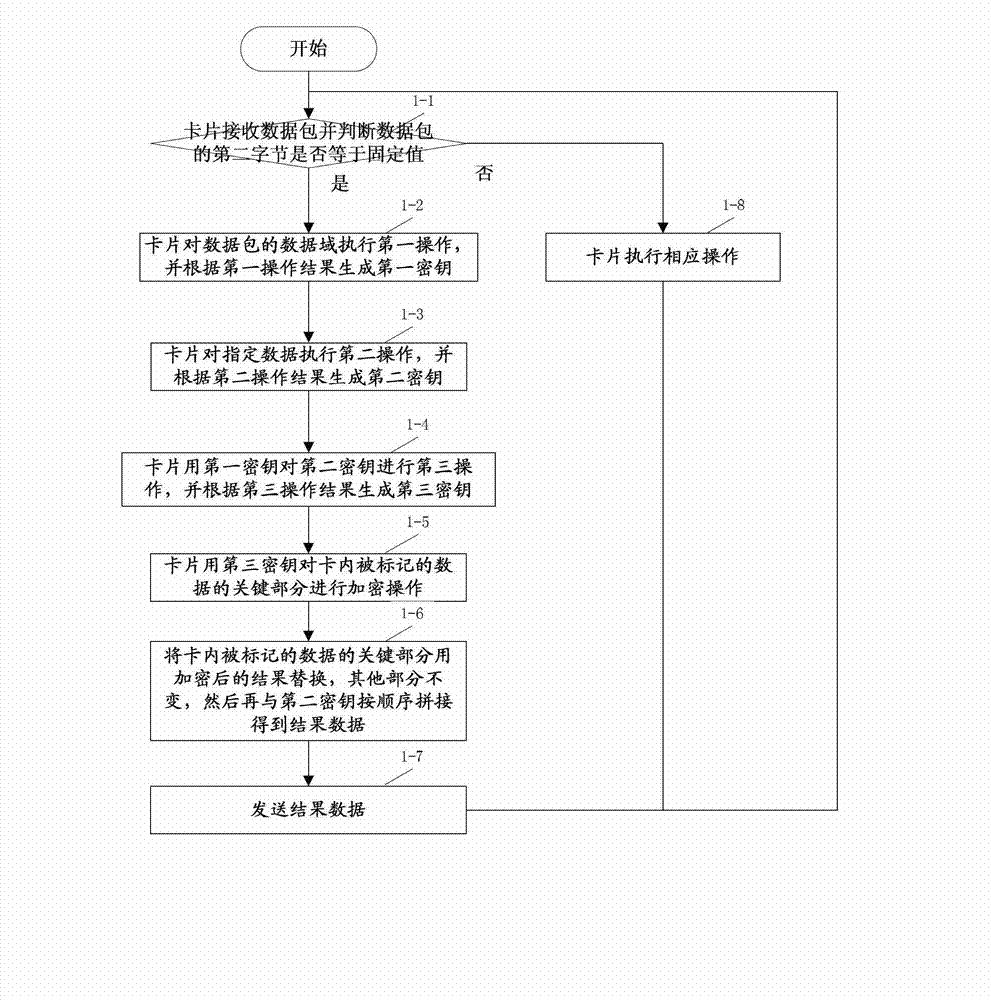

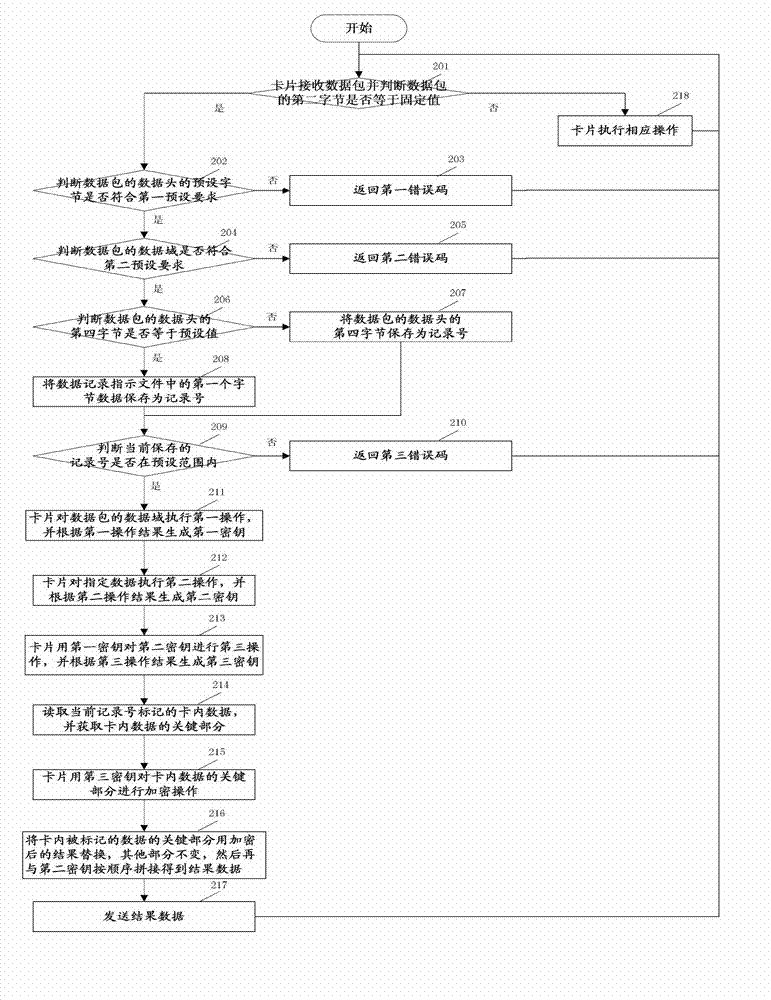

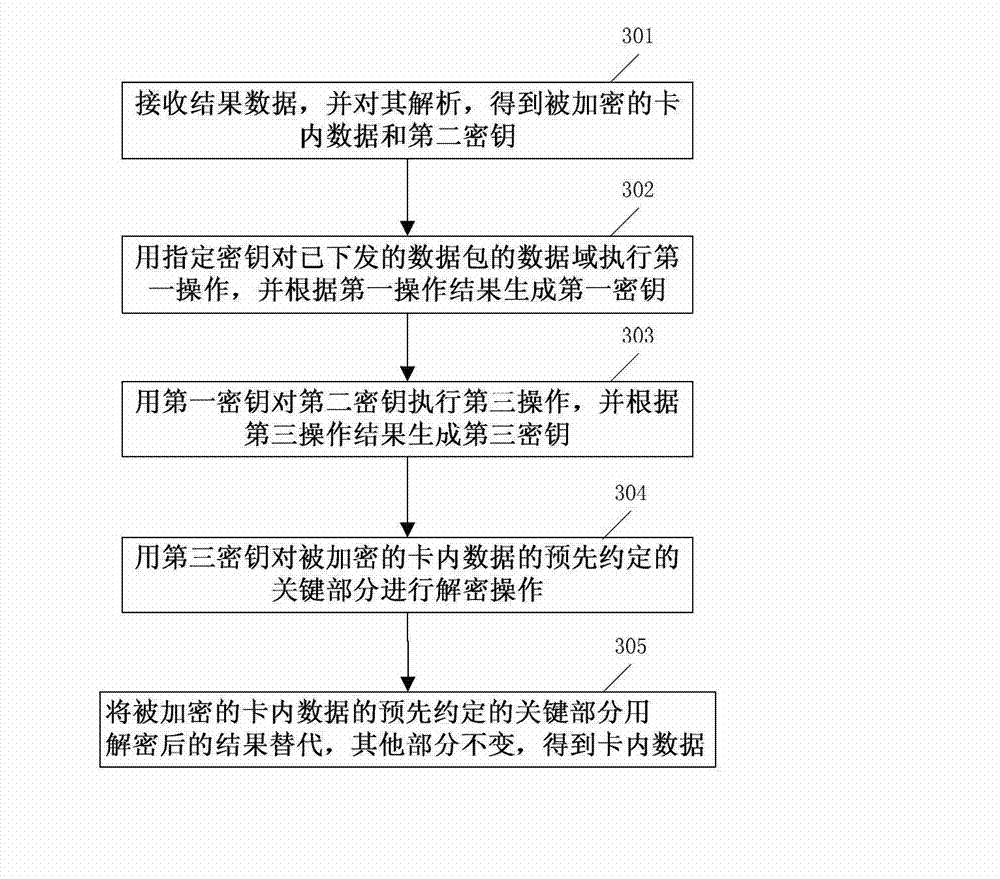

Method for securely transmitting equipment information

ActiveCN102739406AChange lengthSecure transmissionKey distribution for secure communicationUser identity/authority verificationSecure transmissionNetwork packet

The invention discloses a method for securely transmitting equipment information, relating to the filed of information security. By the method, a data packet is integrally encrypted after a CPU (Central Processing Unit) card receives the data packet and an adopted encryption key is readable outside the CPU card, thereby solving the problem that the information security of the CPU card is low. The method comprises the following steps: receiving the data packet and judging whether the second byte of the data packet is equal to a fixed value by the card; carrying out corresponding operation if the second byte of the data packet is not equal to the fixed value; carrying out the first operation on the data field of the data packet to generate a first key if the second byte of the data packet is equal to the fixed value; then carrying out the second operation to generate a second key; carrying out the third operation on the second key by using the first key to generate a third key; carrying out encryption operation on the key part of the data marked in the card by using the third key; substituting the key part of the data marked in the card by using the encrypted result, wherein other parts are not changed; and then splicing with the second key in sequence to obtain result data, and sending the result data.

Owner:FEITIAN TECHNOLOGIES

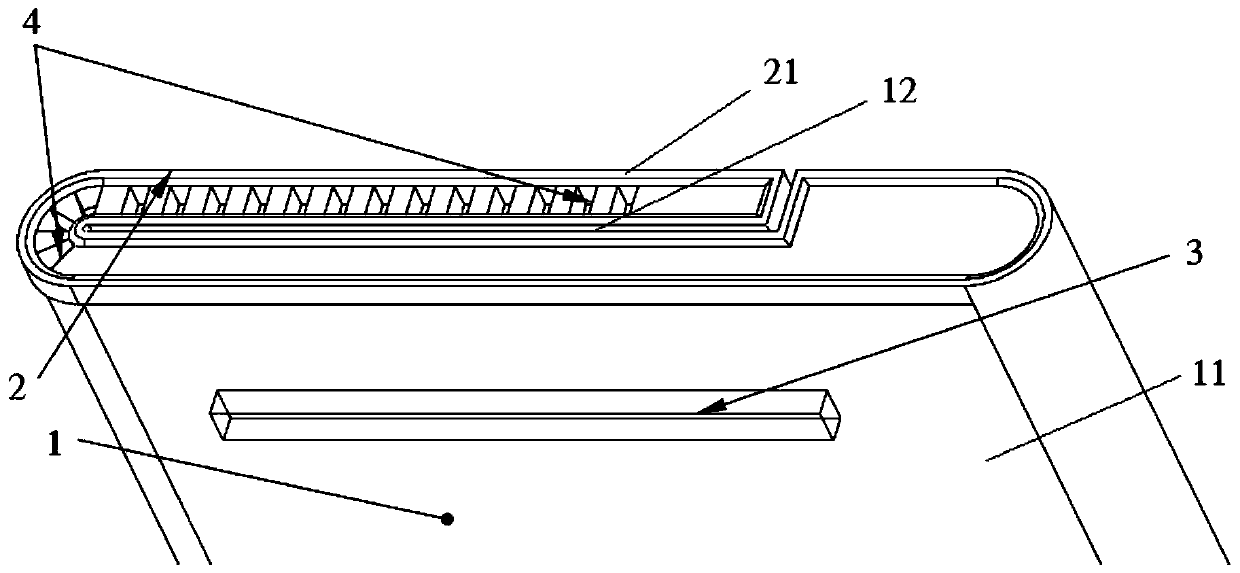

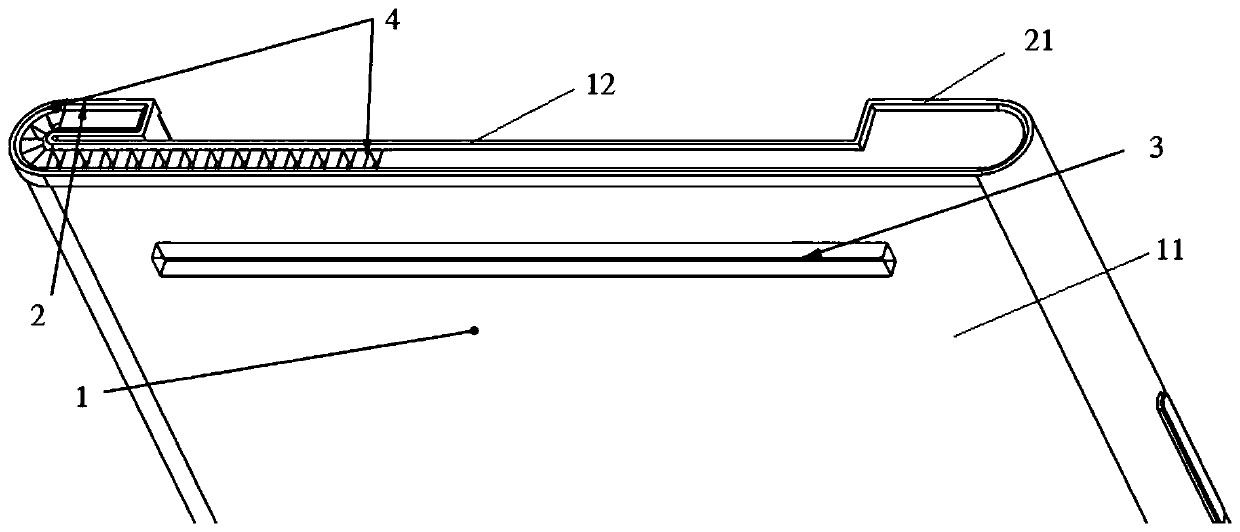

Mobile terminal

PendingCN110545342ATroubleshoot extended technical issuesIncrease diversityTelephone set constructionsScreen techniquesMultimedia

The invention provides a mobile terminal. Flexible screen techniques are used, and the invention provides a mobile terminal with two display areas capable of sliding relatively. When the two display areas are in a common display state or in mutual back-to-back arrangement, the two display areas can display different display contents independently; or one of the display areas is in a storage state,and when one of the display areas slides to the surface where the other display area is located, the display areas are combined into an extended screen, and a unified and complete content is displayed in the screen, so that the effect of extending the display screen is achieved, and excellent terminal practical experience is brought to a user.

Owner:SHENZHEN TRANSSION HLDG CO LTD

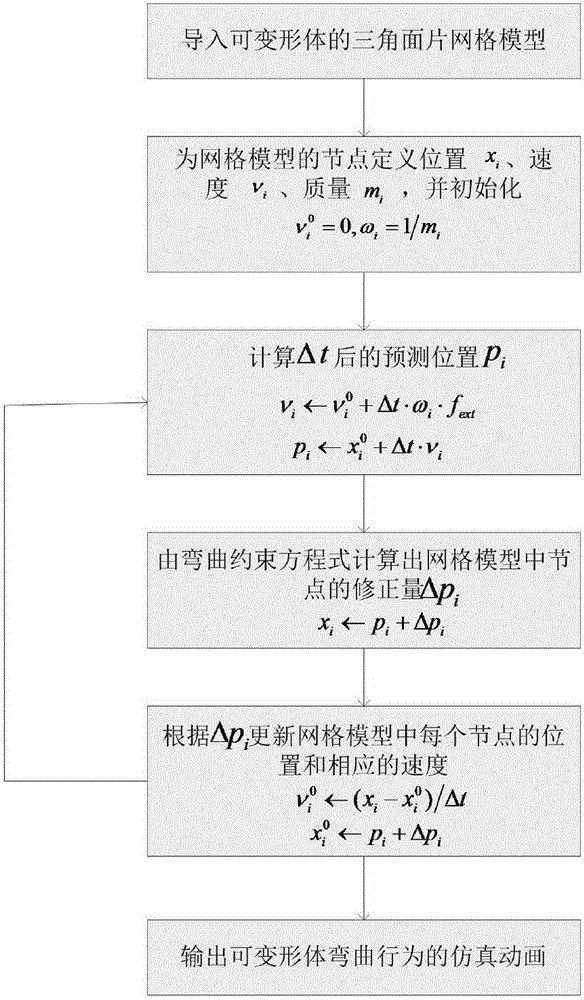

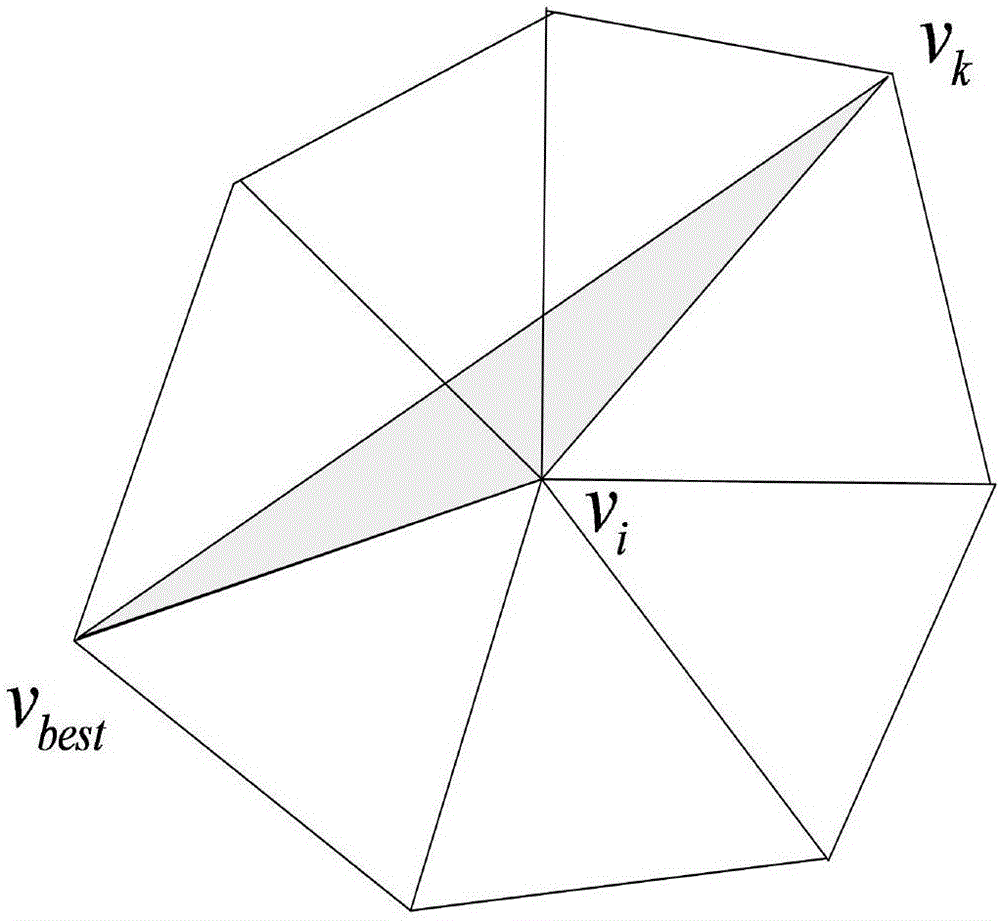

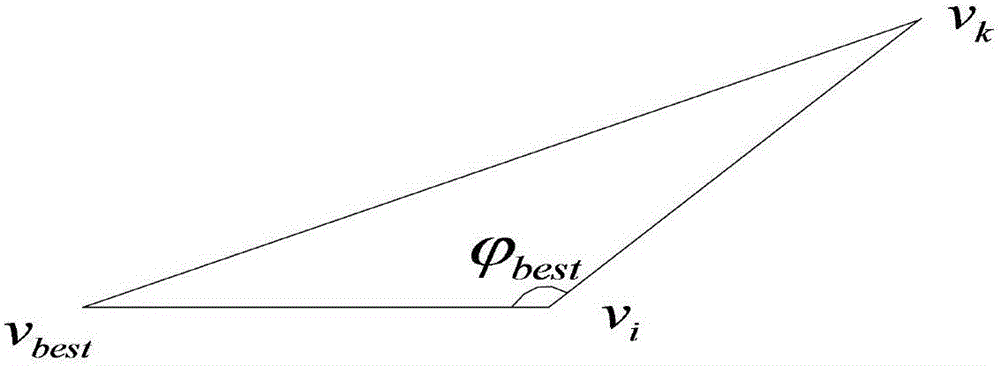

Method of simulating angle bending model using position based dynamics

InactiveCN104268305AReduce complexityReduce computational costSpecial data processing applicationsPosition based dynamicsAnimation

The invention relates to a method of simulating angle bending model using position based dynamics. The method includes the steps of 1, making a grid model file of a deformable body to be simulated, and importing the grid model file into a deformable body simulation system; 2, defining variants of the grid model file of the deformable body; 3, according to Newton's second law and theorem of motion for particles, calculating a node prediction position p of a deformable body grid model after the deformable body grid model experiences an external force f<ext> for a time step Deltat; 4, building an angle bending model among nodes of the deformable body grid model; 5, outputting an image of the deformable body grid model at a node accurate position x, and using the node accurate position x as a node initial position of a next time step; 6, repeating the steps 3 to 5, and sequentially outputting images of frame of the deformable body grid model until simulation animation of bending deformation of the deformable body is obtained. The method has the advantages that the calculating process is easier, and calculation cost is reduced.

Owner:XIDIAN UNIV

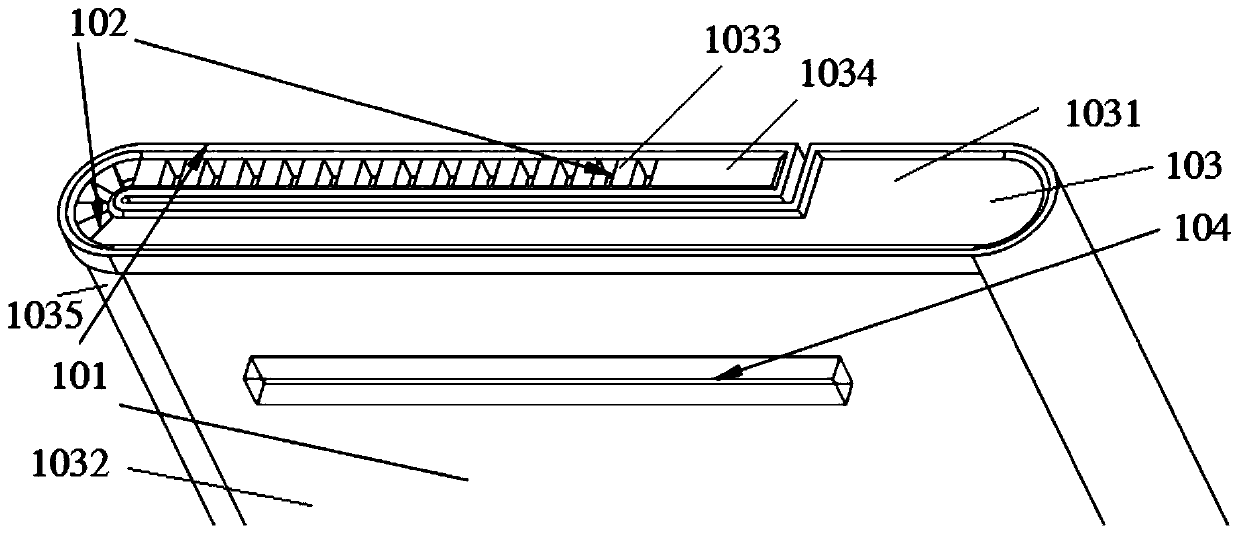

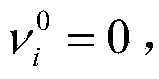

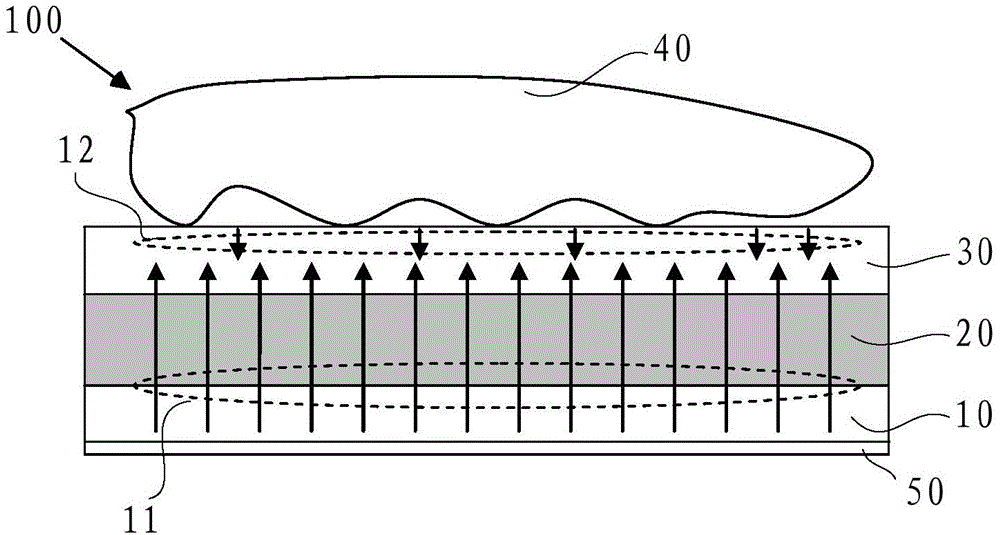

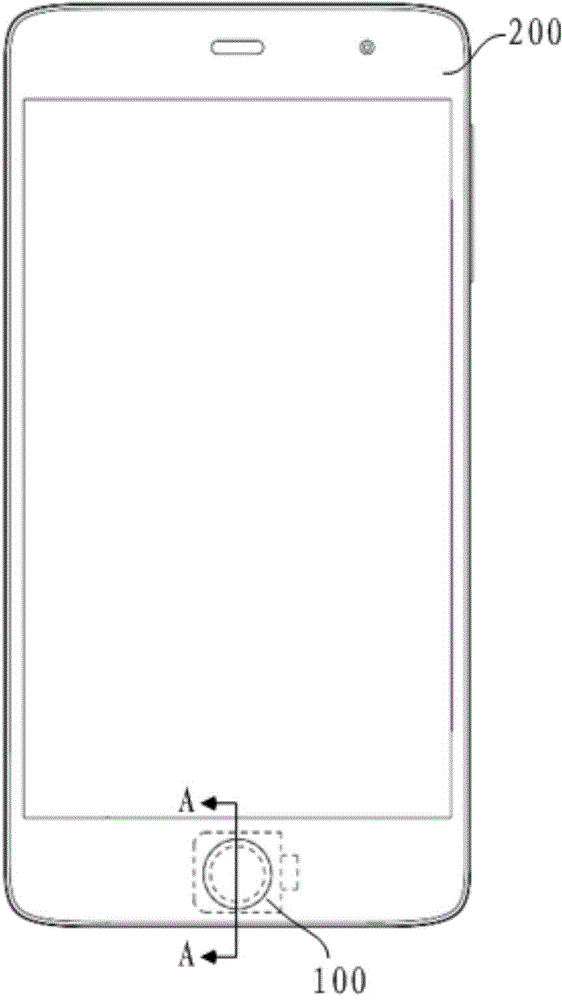

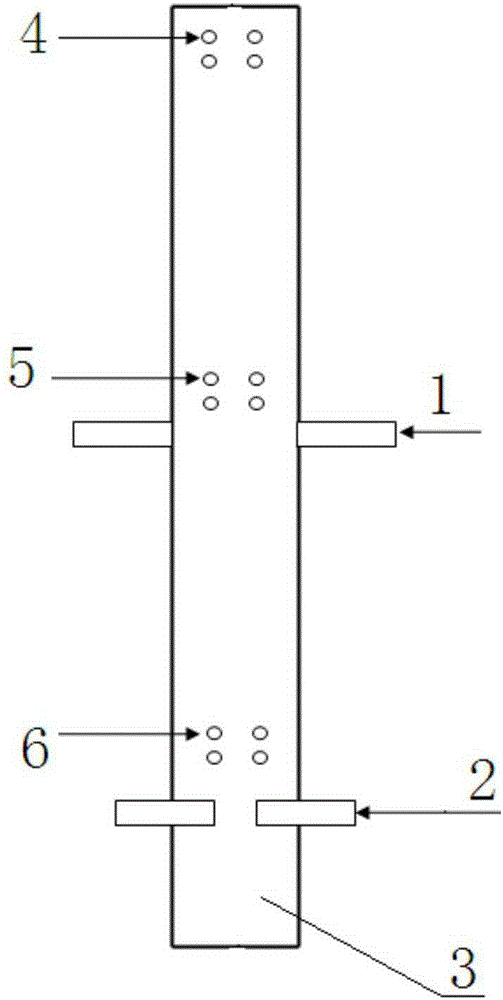

Mobile terminal with fingerprint recognition system

InactiveCN105786102ASave materialEasy to disassembleDigital data processing detailsCharacter and pattern recognitionFingerprintFront cover

The invention provides a mobile terminal with a fingerprint recognition system. The mobile terminal comprises a mobile terminal shell which includes a front cover board and a middle shell parallel to the front cover board; the front cover board includes a display area and a button area, and the front cover board is provided with a first hole, wherein the first hole is located in the button area; the middle shell is provided with a second hole, and one side of the middle shell facing to the front cover board is provided with a display module, wherein the display module is opposite to the display area; and the first hole and the second hole are matched to form a hole used for installing a fingerprint imaging module, wherein the fingerprint imaging module is installed at one side of the middle shell back to the front cover board and penetrates through the second hole and the first hole in sequence. The fingerprint imaging module and the display module of the mobile terminal with the fingerprint recognition system provided by the invention are respectively installed on the middle shell and the front cover board, the size of the fingerprint imaging module is not limited by the size of the display module and the overall dimension can be larger, and the length of a mobile phone can be remained unchanged.

Owner:SHANGHAI OXI TECH

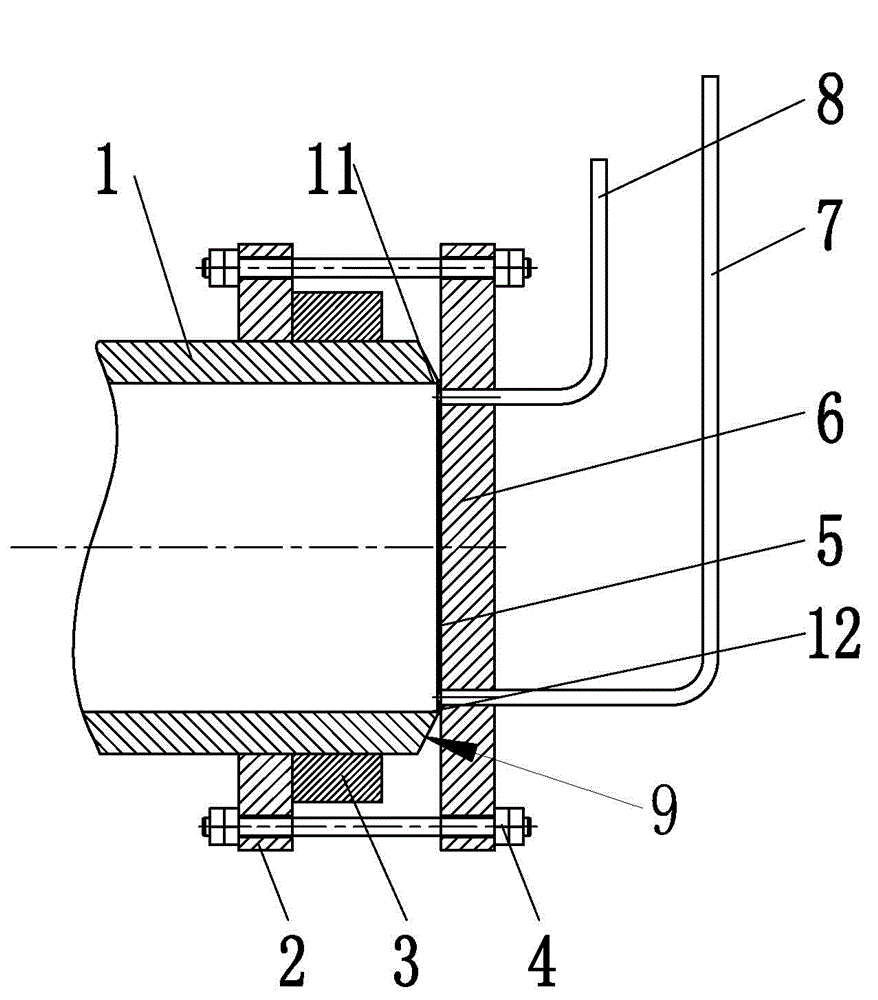

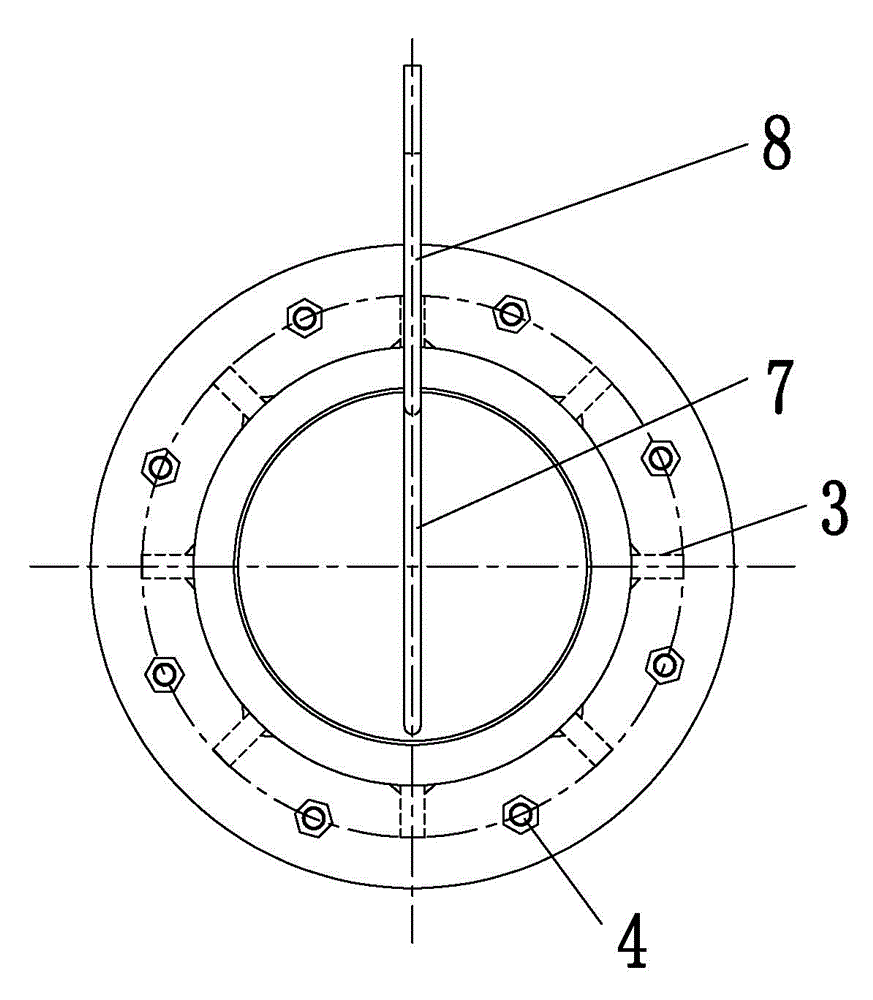

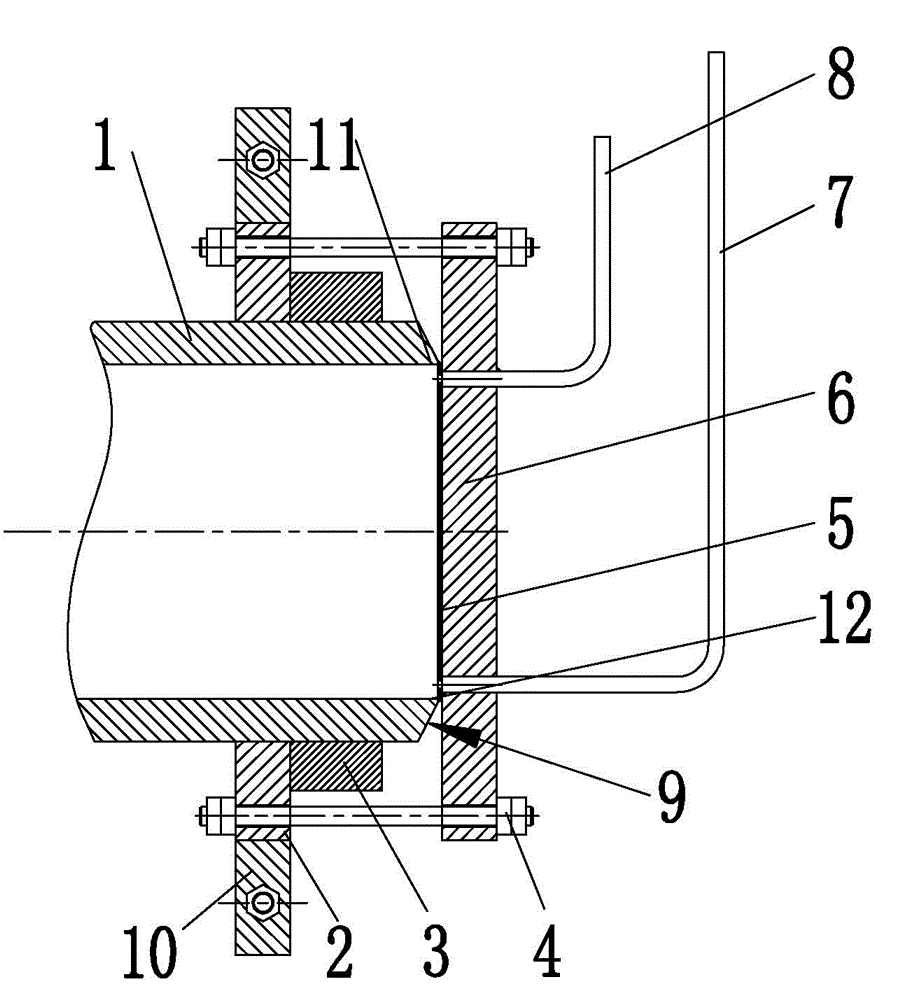

Pressure testing tool for opening connecting tubes without flange seal

ActiveCN102721605AReduce the amount of sandingChange lengthMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesLine tubingEngineering

A pressure testing tool for opening connecting tubes without flange seal comprises a pressure testing ring, a sealing sheet, a blind flange, an exhaust pipe, a water inlet pipe and a plurality of fixing rib plates. The pressure testing ring is sleeved on the outer wall of a pipe, the sealing sheet is welded at a pipe orifice, the blind flange is in close compression joint with the sealing sheet and is connected with the pressure testing ring by locking parts, one end of the exhaust pipe is penetratingly arranged on the blind flange and the sealing sheet and is communicated with an inner cavity of the pipe, the other end of the exhaust pipe is bent upwards, one end of the water inlet pipe is penetratingly disposed on the blind flange and the sealing sheet and is communicated with the inner cavity of the pipe, the other end of the water inlet pipe is bent upwards, and the fixing rib plates are peripherally arranged along the outer wall of the pipe and used for supporting the pressure testing ring. Compared with the prior art, the pressure testing tool is low in welding load, cutting and grinding workload for the pipe orifice is low after pressure testing, a groove is not damaged, the length of the pipe is ensured to be unchanged, and the pressure testing tool is particularly applicable to pressure tests for equipment and pipelines with machined grooves and opening connecting pipes made of pure materials.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

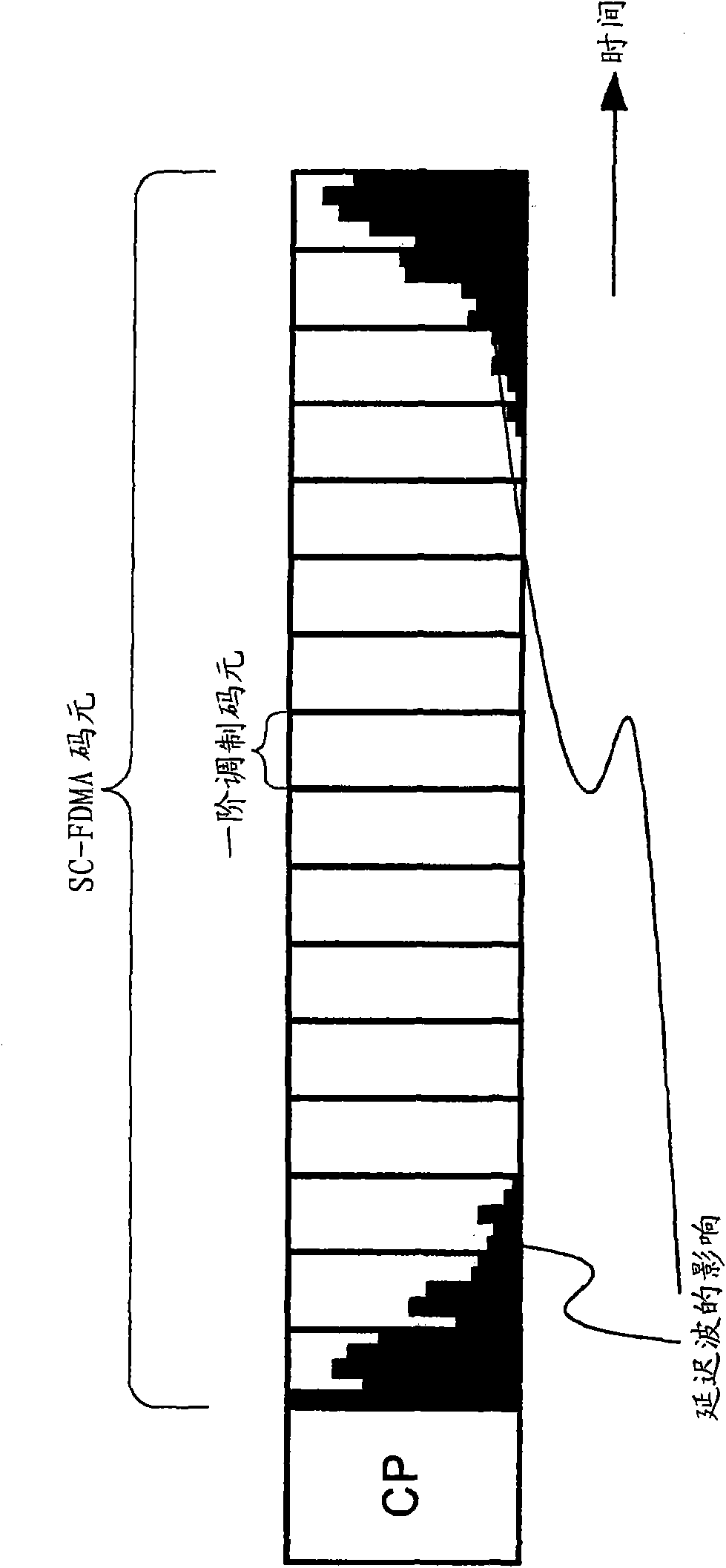

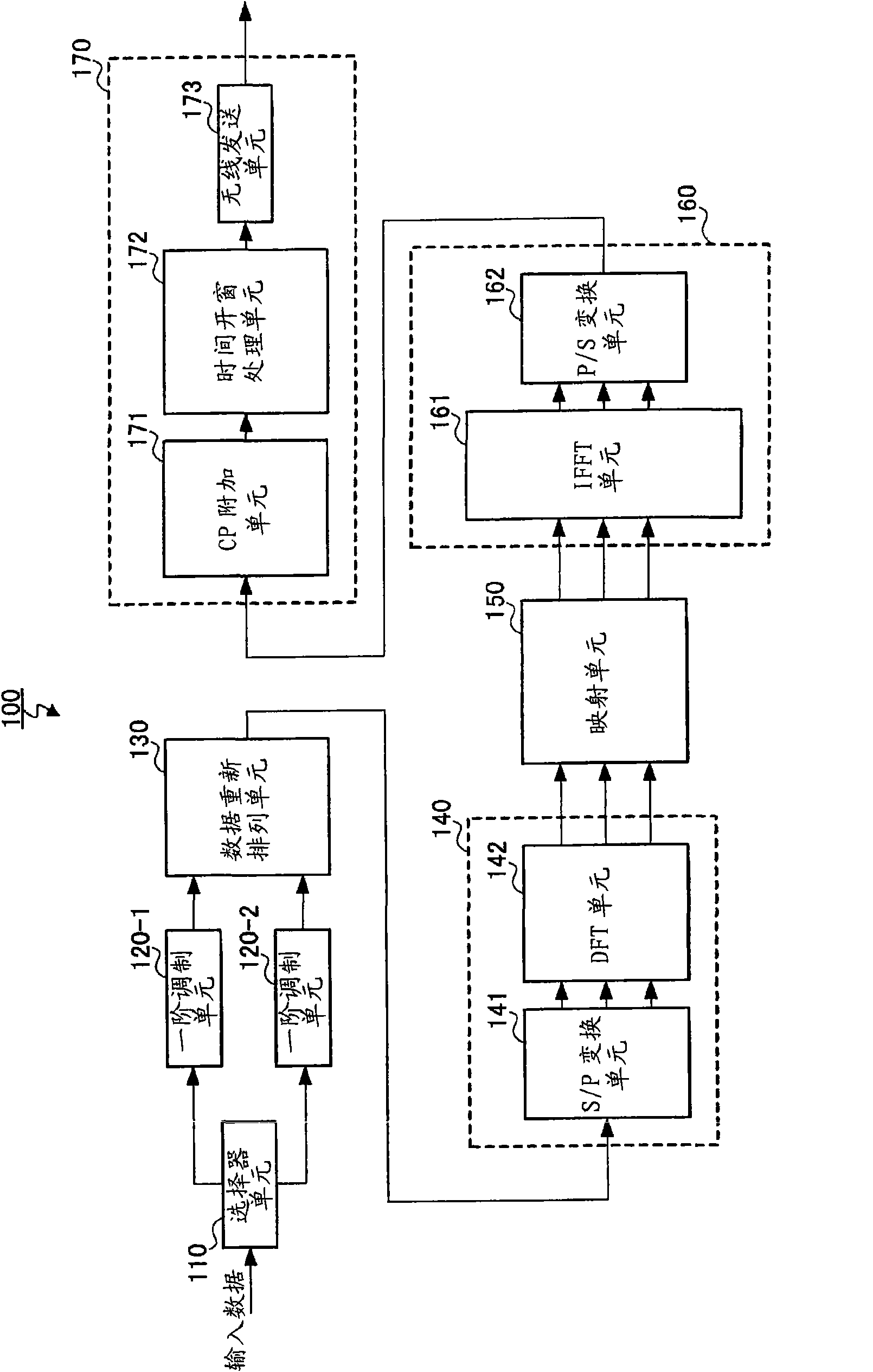

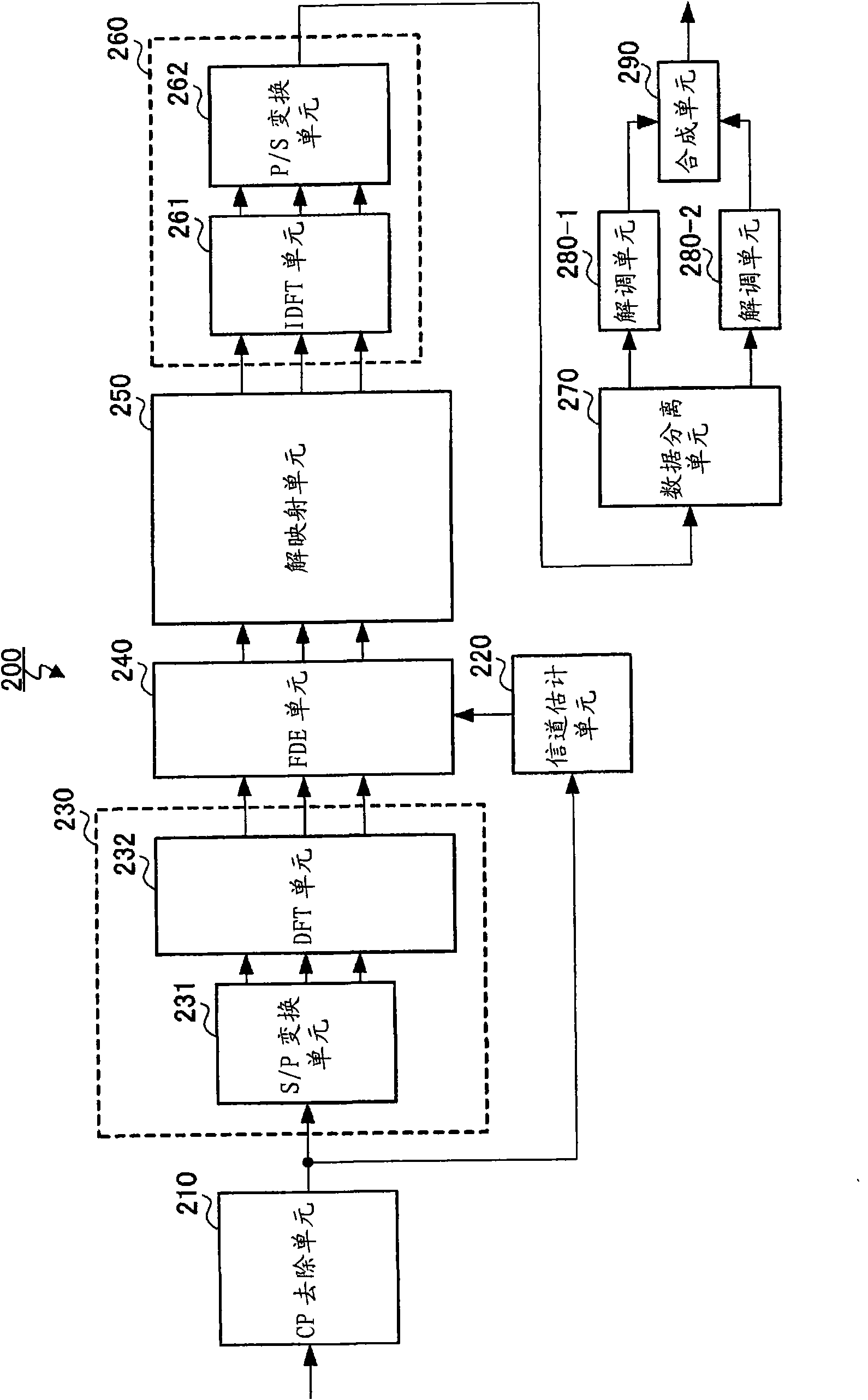

Transmitter, transmitting method, receiver, and receiving method

InactiveCN101689951ANo change in lengthNo reduction in transmission efficiencyTransmission path divisionCriteria allocationTime domainTransmitter

Owner:PANASONIC CORP

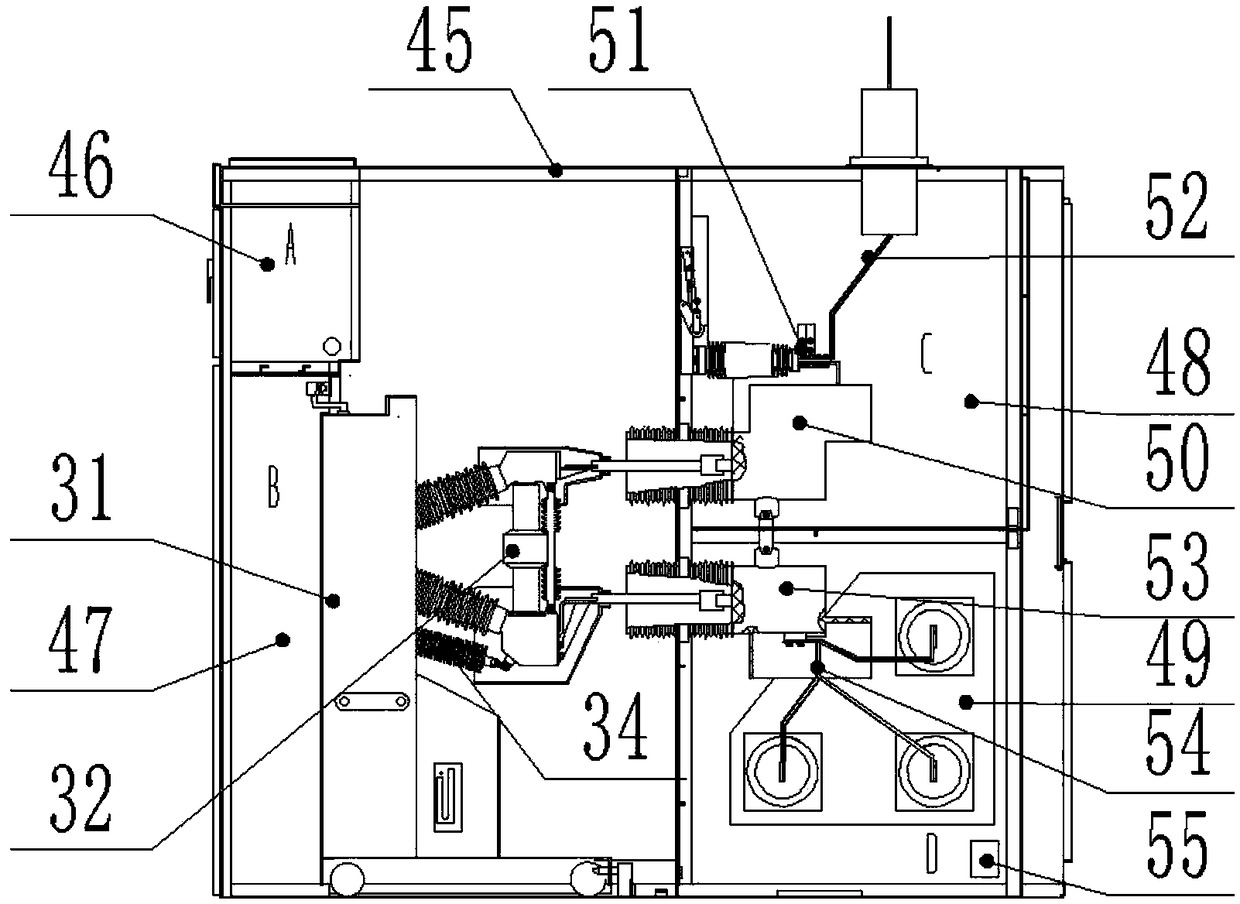

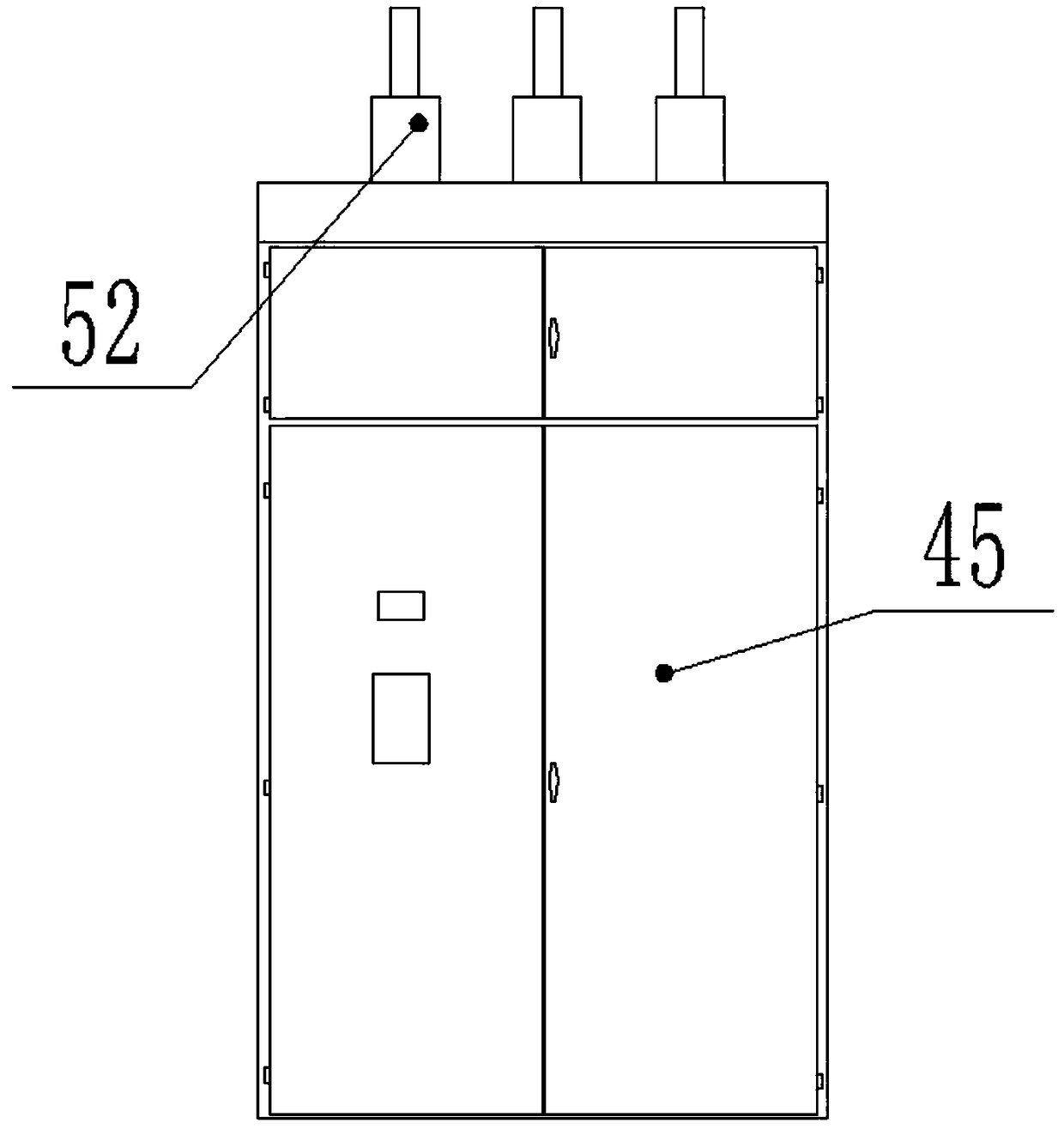

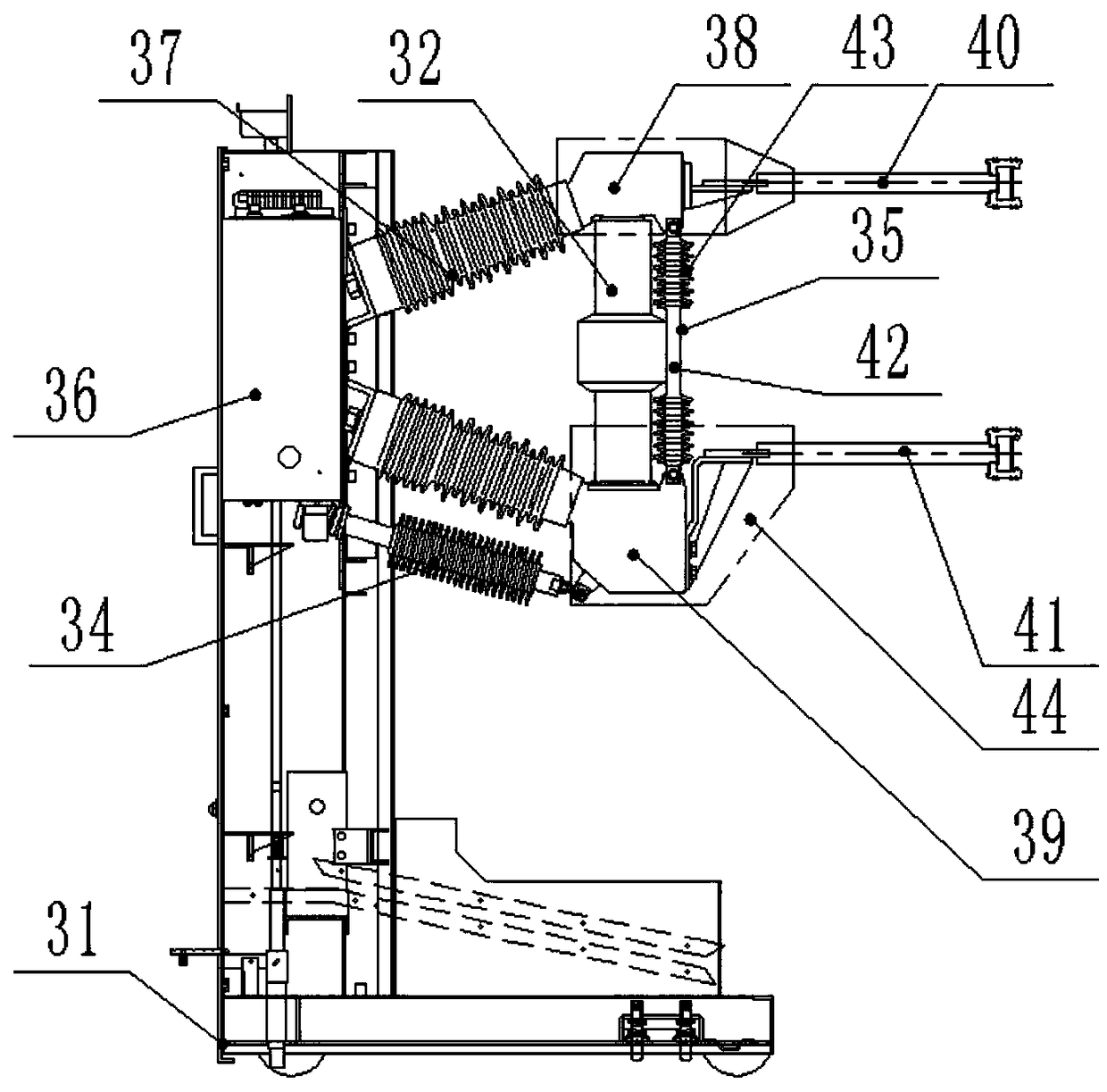

40.5kV switch equipment system

ActiveCN108767726AImprove insulation performanceAvoid compromising operational safetyBus-bar/wiring layoutsSwitchgear detailsFeeder lineSwitchgear

The invention discloses a 40.5kV switch equipment system. The system comprises a switch cabinet; an instrument chamber, a handcart chamber, a feeder line chamber and a bus chamber are formed in the switch cabinet; the feeder line chamber is arranged above the bus chamber, the handcart chamber is arranged at the left side of the feeder line chamber and the bus chamber, the instrument chamber is arranged at the left upper corner of the handcart chamber, and a circuit breaker module is arranged in the handcart chamber; an upper conductive connector on the circuit breaker module is connected withan upper contact box type current transformer outlet arranged at the feeder line chamber, the inlet of the upper contact box type current transformer is connected with an upper branch bus connector through a grounding switch; a lower conductive connector on the circuit breaker module is connected with a lower contact box type current transformer outlet arranged at the bus chamber, and the lower contact box type current transformer inlet is connected with a lower branch bus connector; and the circuit breaker module comprises a frame, a vacuum arc extinguish chamber, an operating mechanism, a connecting insulation pull rod and an insulating brace rod.

Owner:四川电器集团股份有限公司

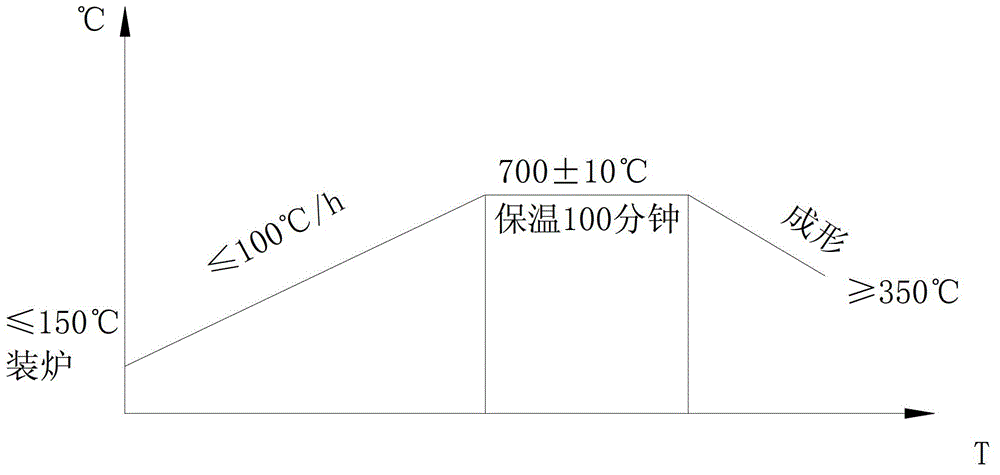

Manufacturing method of variable cross-section pipe fitting

The invention discloses a manufacturing method of a variable cross-section pipe fitting, which comprises the steps of blanking a plate sheet, heating, performing mould extrusion, allowing extruded plate blanks to be welded into the variable cross-section pipe fitting, and performing heat treatment, appearance inspection, finishing, grinding, rough processing, flaw detection, hardening and tempering, finish turning, inspection and delivery, wherein in the step of blanking the plate sheet, the plate sheet is cut into two plate blanks, and in the step of the mould extrusion, an upper mould and a lower mould are adopted, and after the plate blanks are placed in the lower mould, the upper mould applies a downward force on the plate blanks, so that the plate blanks are extruded between the upper mould and the lower mould till half pipe walls of the variable cross-section pipe fitting are formed. The manufacturing method has the advantages that with the adoption of the manufacturing method, the interior of the produced variable cross-section pipe fitting does not collapse; the length of the variable cross-section pipe fitting is not changed; the variable cross-section pipe fitting is not distorted; and the surface of the variable cross-section pipe fitting is smooth and clean without folds, cracks or other forging defects.

Owner:张家港海陆重型锻压有限公司

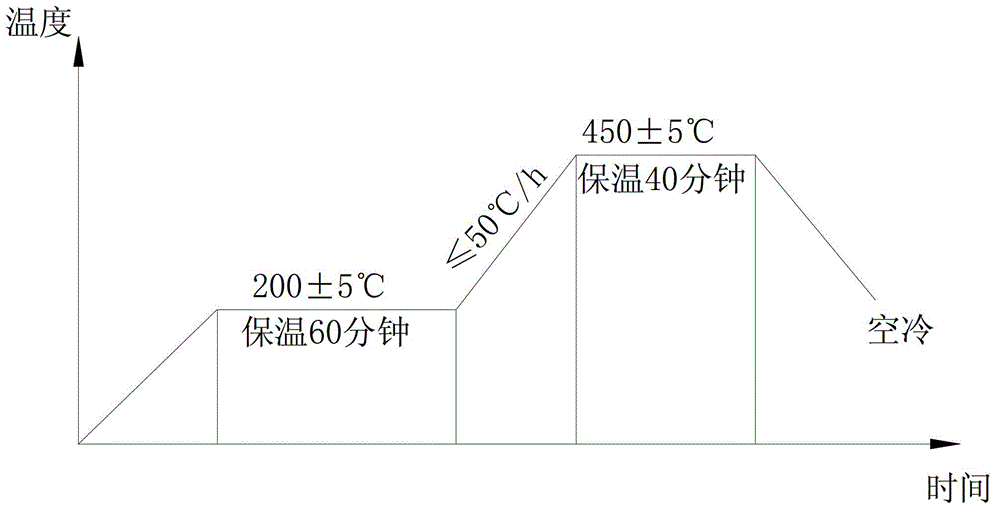

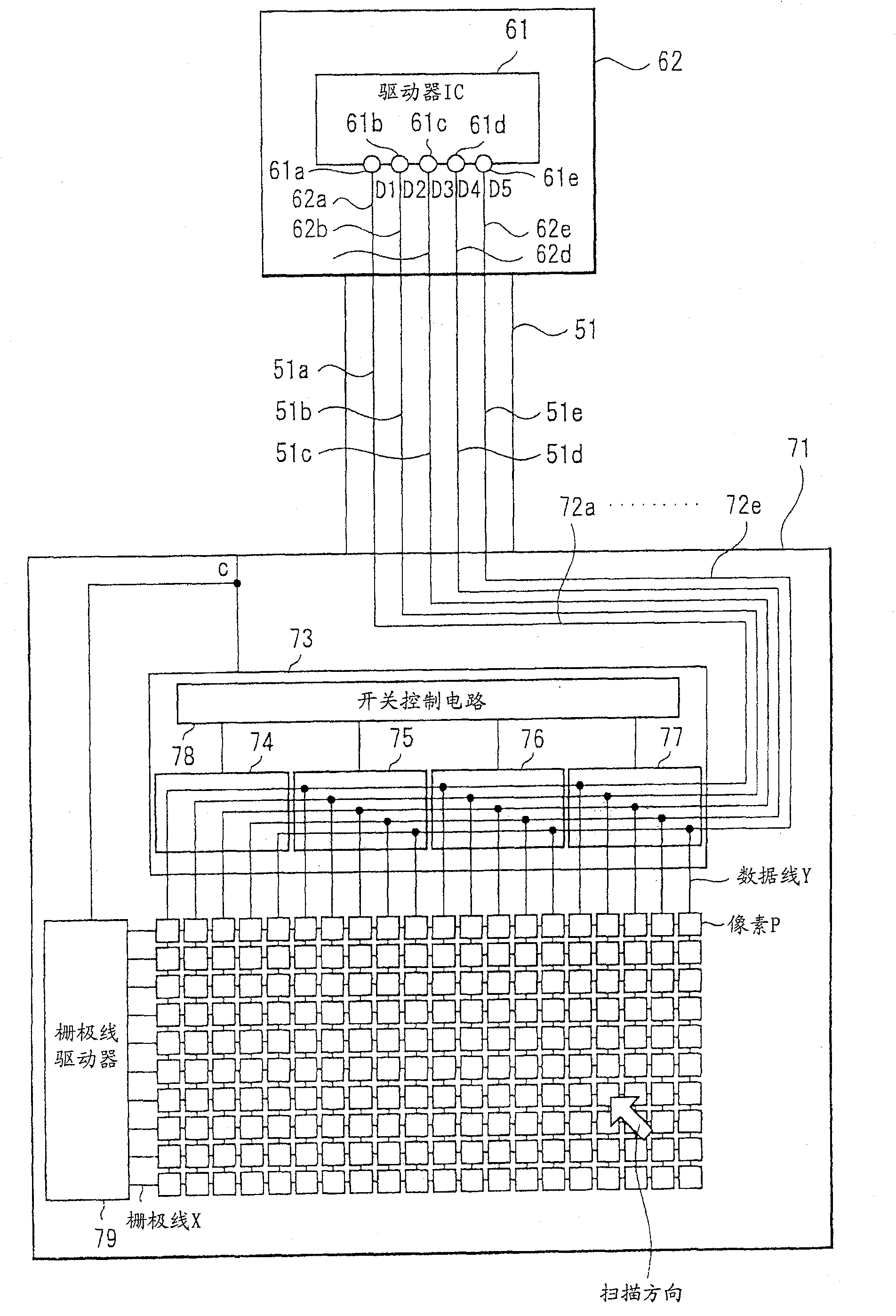

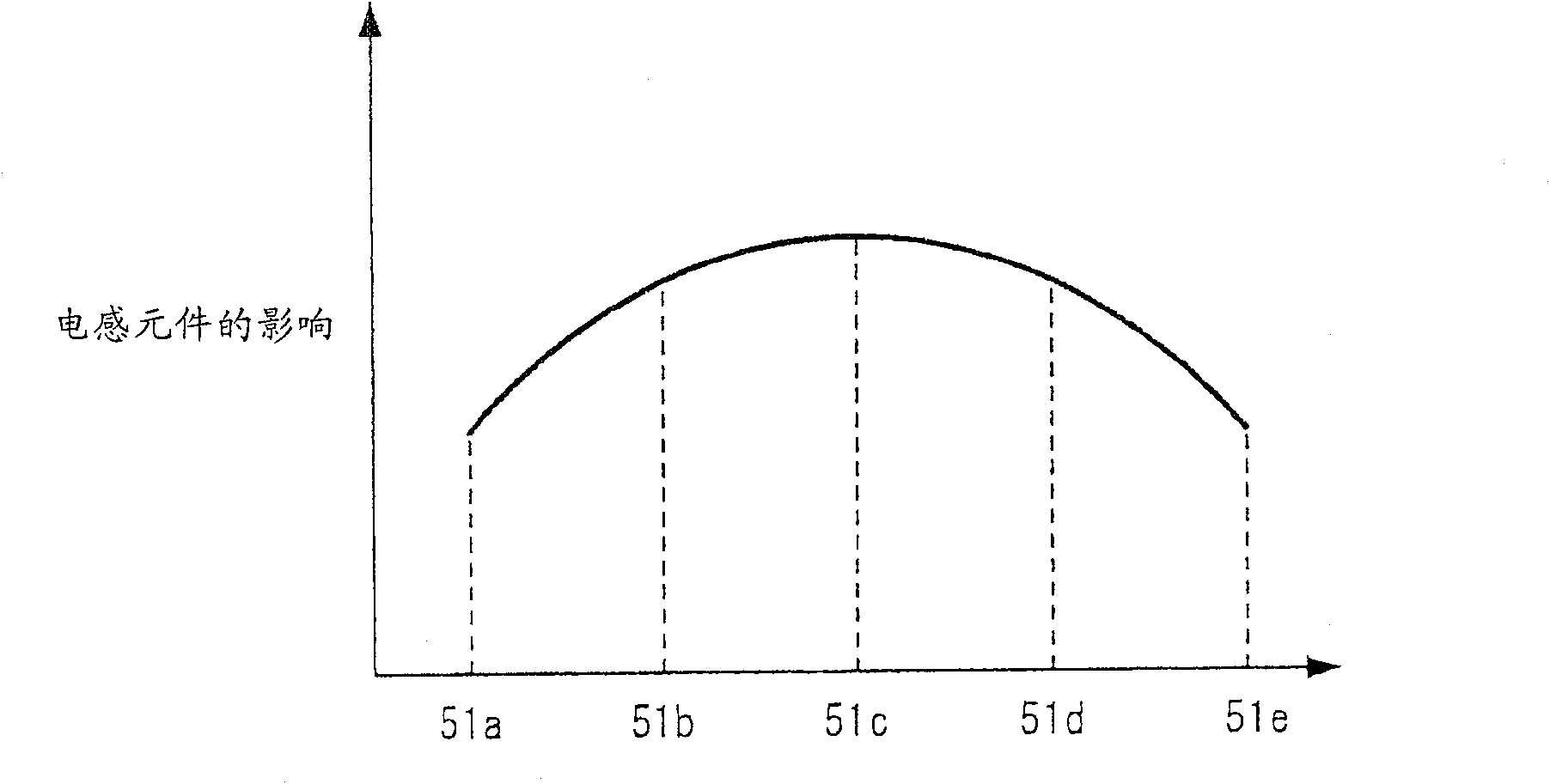

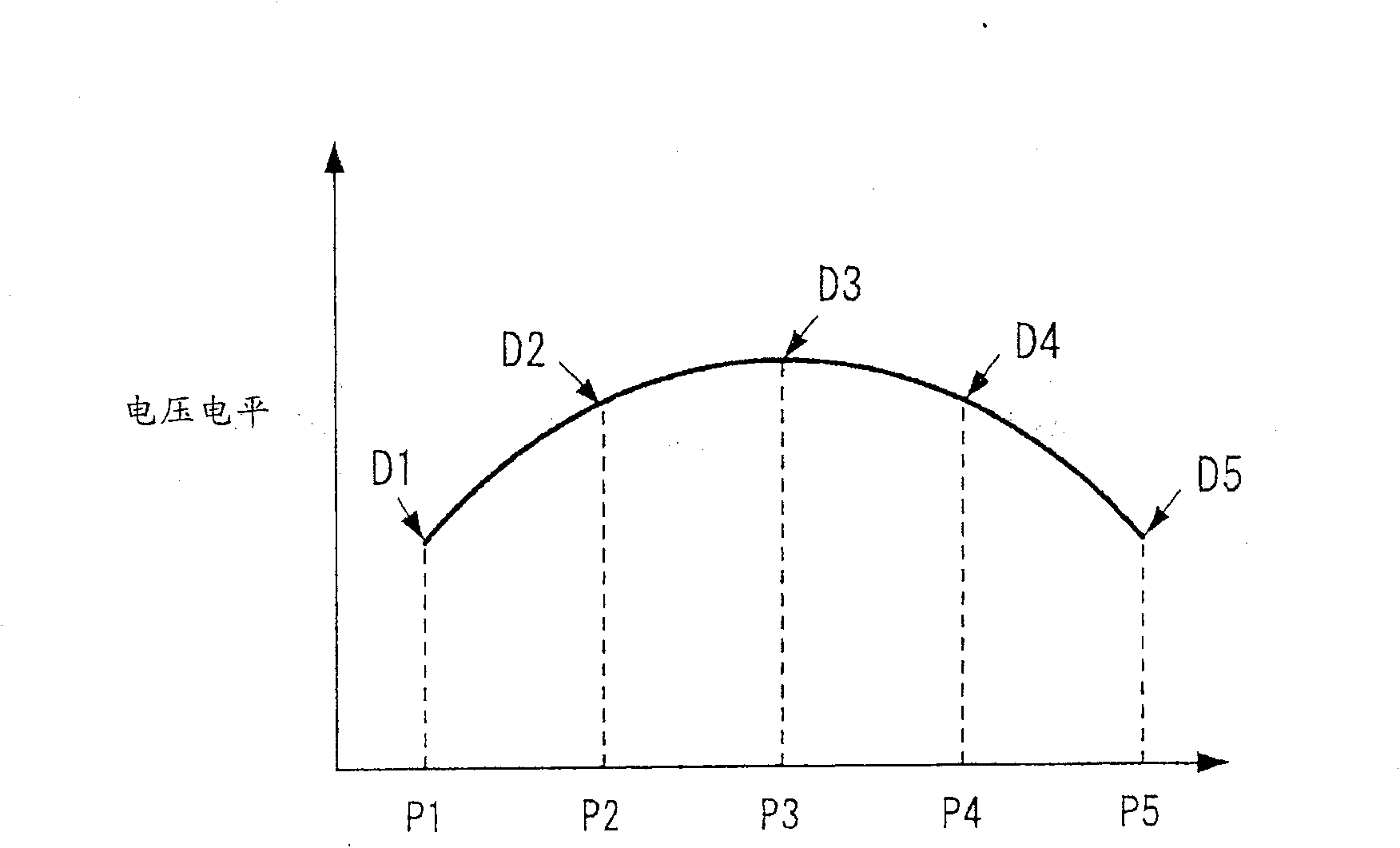

Interconnect structure for display device and projection display apparatus

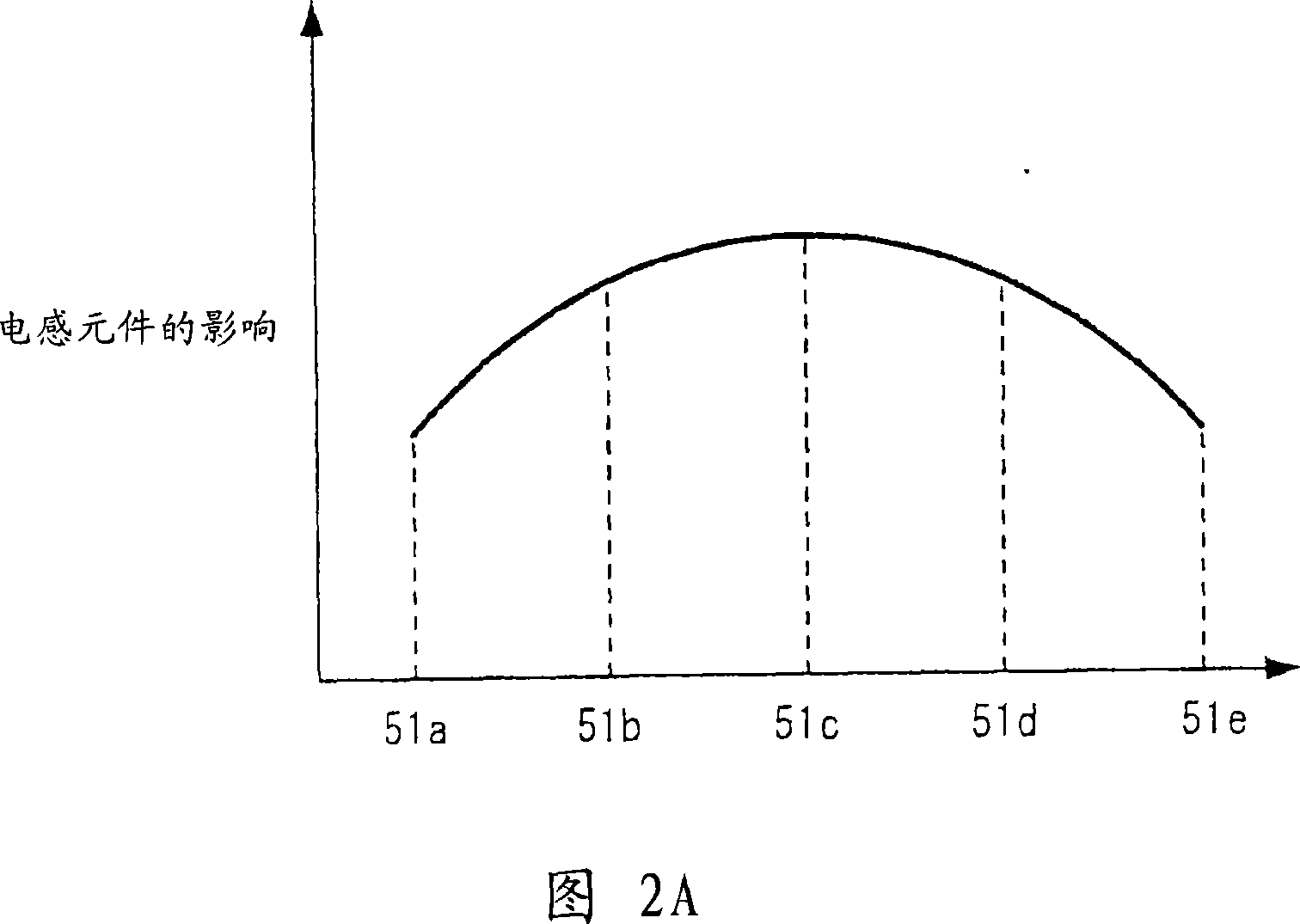

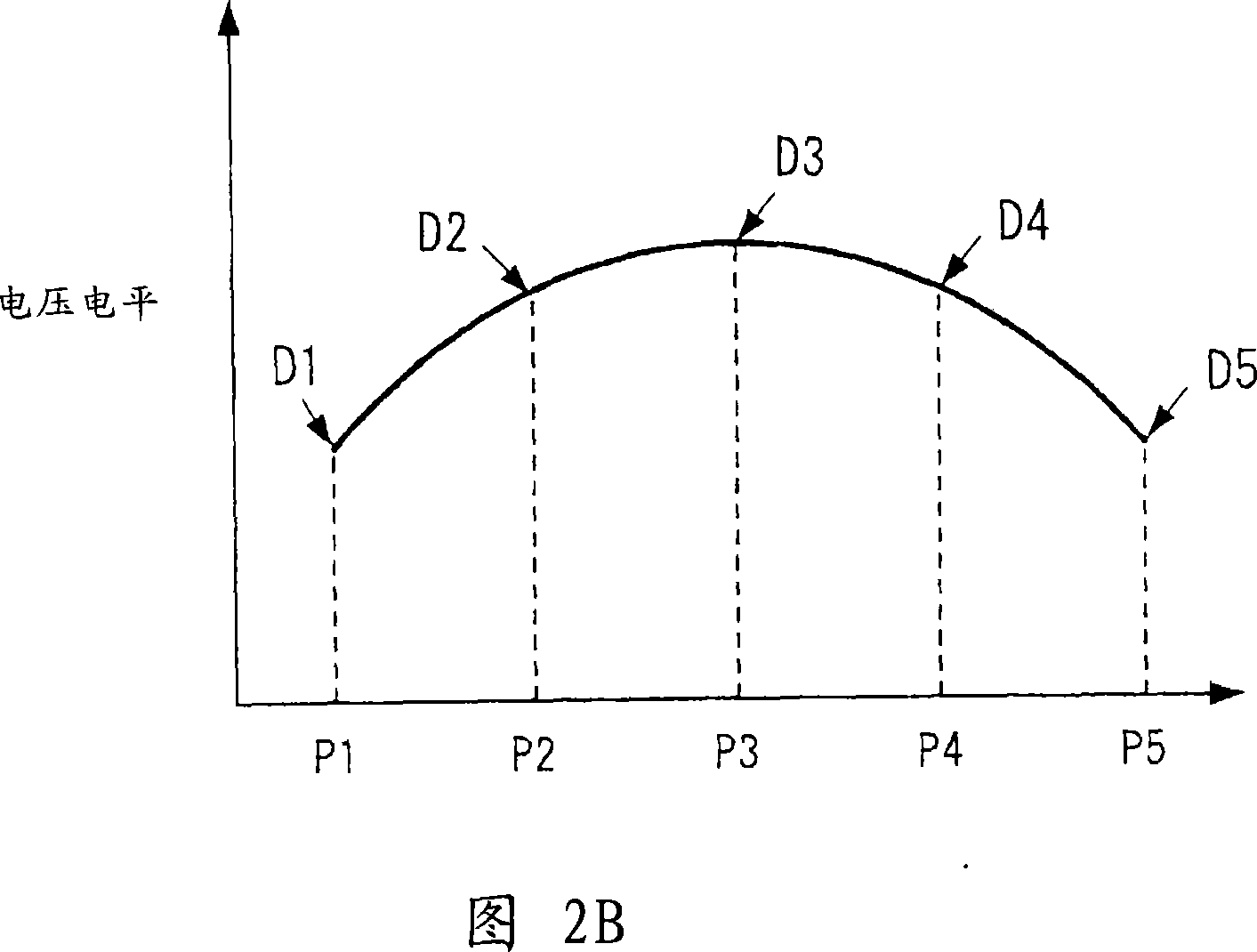

InactiveCN101078825ANo change in current drive capabilityNo change in lengthStatic indicating devicesProjectorsDisplay deviceComputer science

An interconnect structure for a display device includes a driver from which display data are supplied, and an interconnect material having a plurality of signal lines disposed in parallel through which the display data are supplied from the driver. In the interconnect structure for a display device, the signal lines from which the display data are transmitted via the interconnect material are rearranged such that the display data via the signal lines having a comparatively larger effect of the inductance components and the display data via the signal lines having a comparatively smaller effect of the inductance components in the interconnect material are alternately supplied to adjacent pixels or groups of pixels of the display device. As a result, an image is displayed based on the luminance suitable for the display data.

Owner:SONY CORP

A New Radiator Core Support Plate

The invention relates to a novel radiator core support plate. Two inclined slots are arranged on the support plate, and the inclined slots respectively extend from both sides of the support plate to the middle of the support plate and do not pass through the support plate. The present invention has beautiful appearance, simple structure and good strength. A chute is directly set on the surface of the support plate, without changing the length of the raw material, and can well control the total length of the support plate. Forming mold saves production cost.

Owner:扬州英谛车材实业有限公司

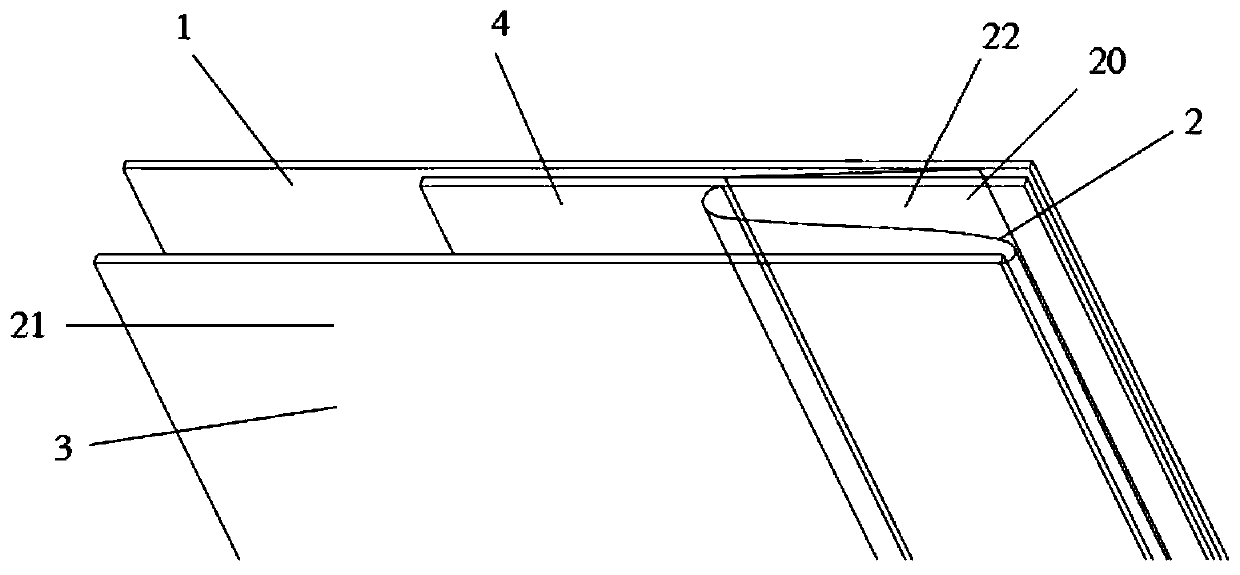

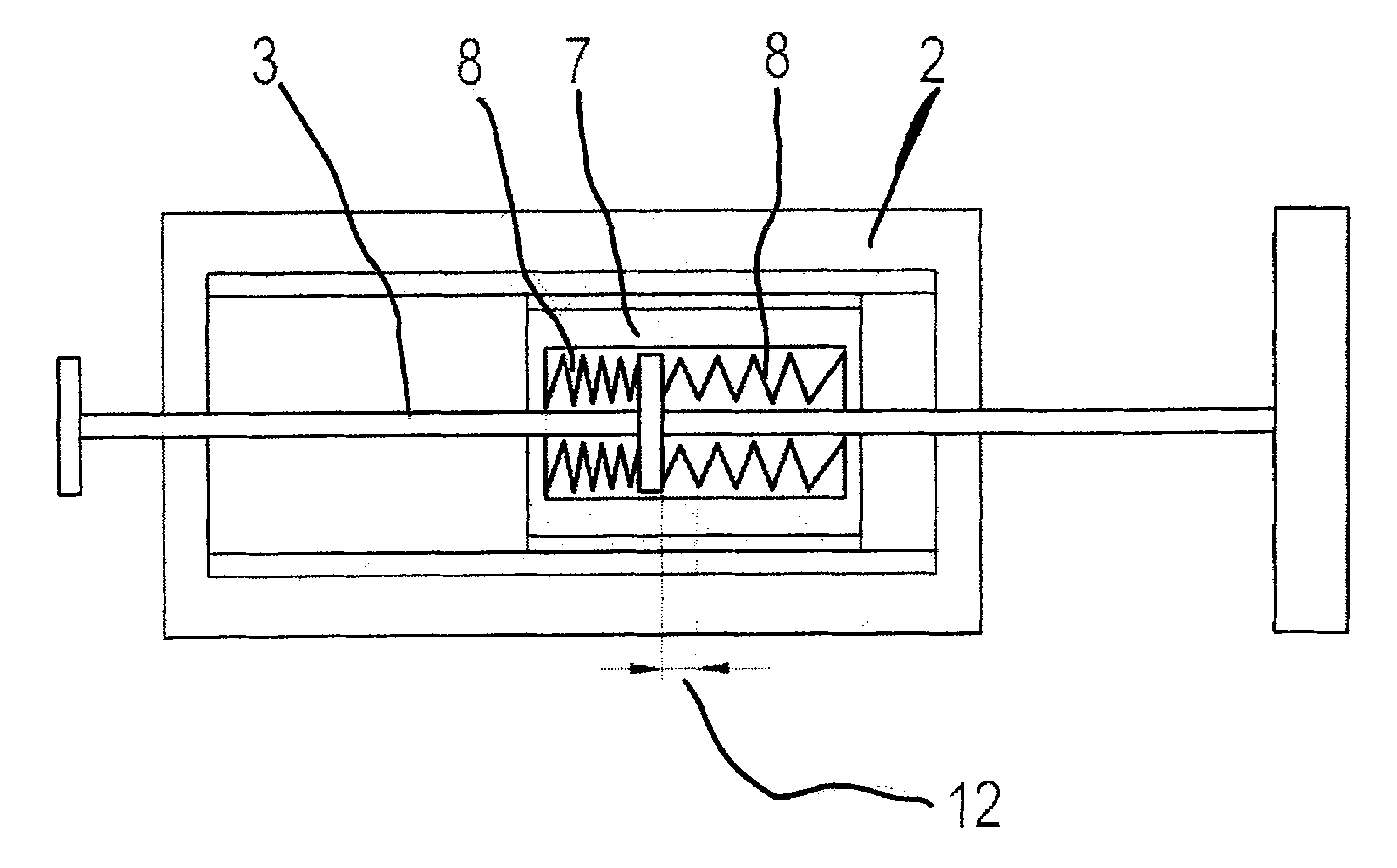

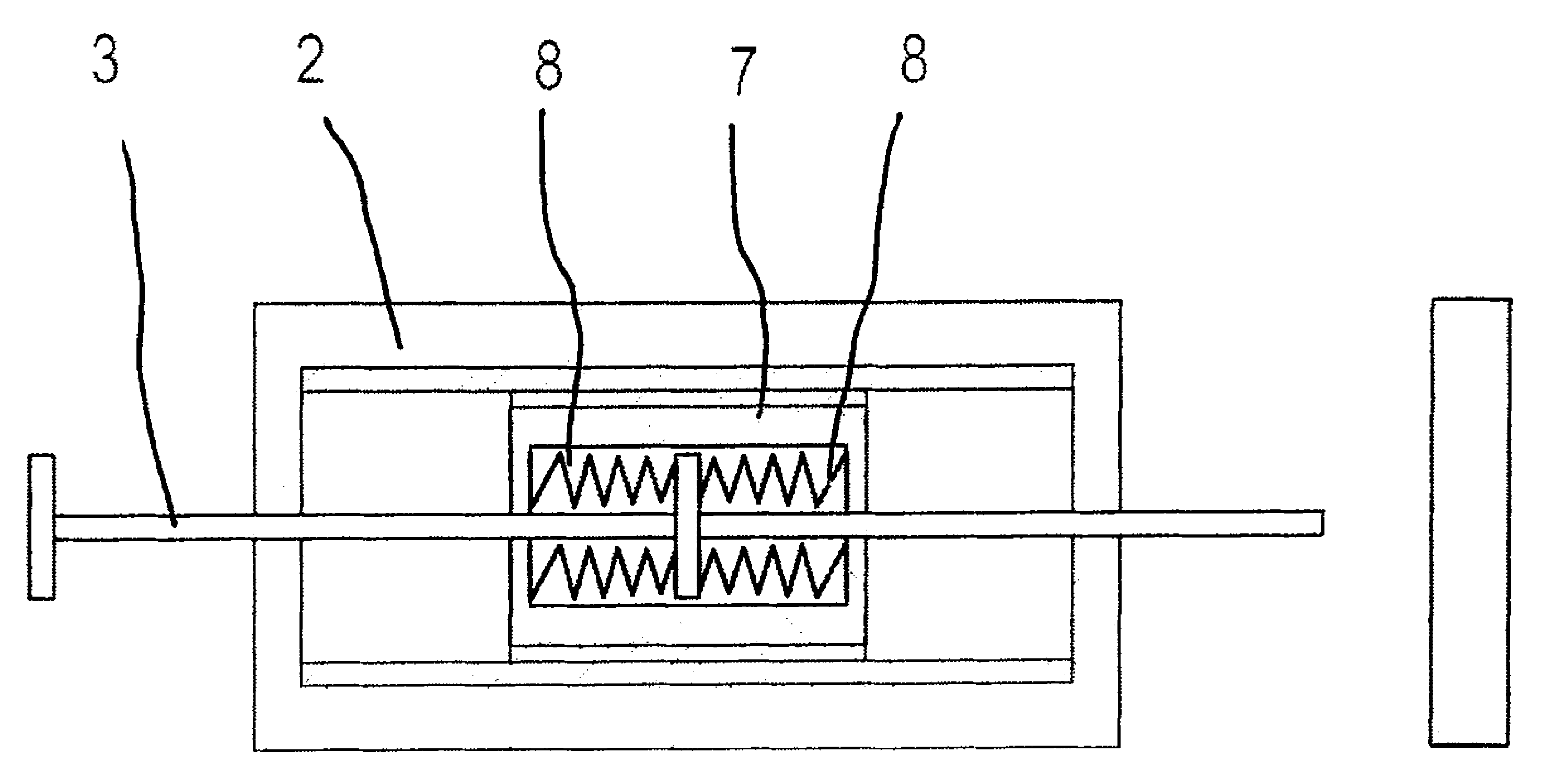

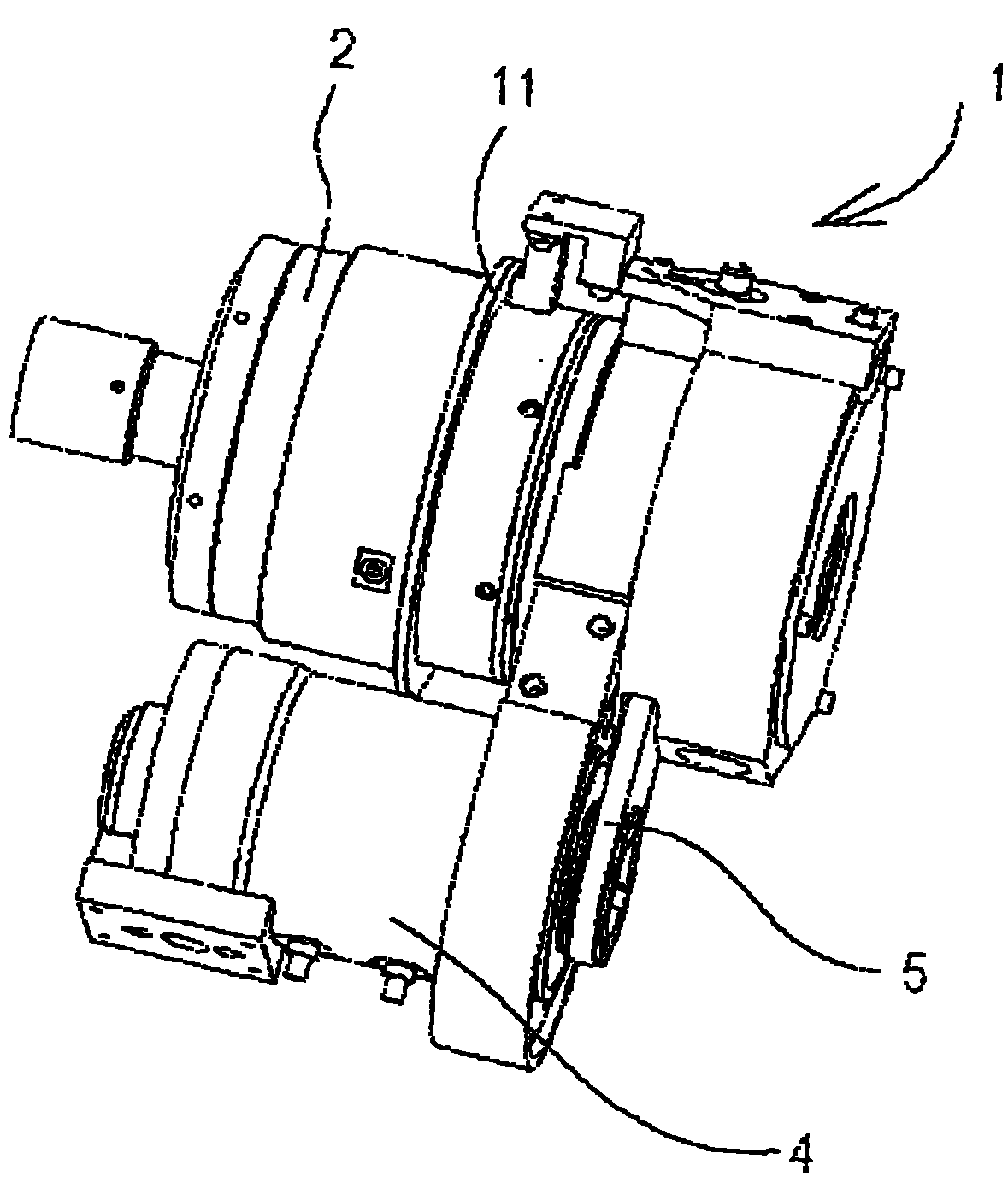

Method for clamping a tool or a workpiece and device for performing the method

InactiveCN102548693AHigh clamping reliabilitySimple structureSleeve/socket jointsPrecision positioning equipmentDrive wheelAxial force

Owner:ROHM CO LTD

Mobile terminal

PendingCN110620835ATroubleshoot technical issues with screen extensionsAchieve hiddenTelephone set constructionsLarge screenLarge screen display

The invention provides a mobile terminal, a flexible screen technology is also utilized, the mobile terminal capable of realizing at least two display states is provided, and the two display states comprise common screen display and large screen display. According to the technical scheme, by means of the supporting mechanism, the flexible screen and the like which are arranged in the stacked mode,conversion between common screen display and large screen display is achieved, unified and complete content can be displayed in the large screen state, the effect of expanding the display screen is achieved, and excellent terminal practical experience is brought to users.

Owner:SHENZHEN TRANSSION HLDG CO LTD

A Simulation Method of Angle Bending Model Based on Position Dynamics

InactiveCN104268305BReduce complexityReduce computational costSpecial data processing applicationsPosition based dynamicsAnimation

The invention relates to a method of simulating angle bending model using position based dynamics. The method includes the steps of 1, making a grid model file of a deformable body to be simulated, and importing the grid model file into a deformable body simulation system; 2, defining variants of the grid model file of the deformable body; 3, according to Newton's second law and theorem of motion for particles, calculating a node prediction position p of a deformable body grid model after the deformable body grid model experiences an external force f<ext> for a time step Deltat; 4, building an angle bending model among nodes of the deformable body grid model; 5, outputting an image of the deformable body grid model at a node accurate position x, and using the node accurate position x as a node initial position of a next time step; 6, repeating the steps 3 to 5, and sequentially outputting images of frame of the deformable body grid model until simulation animation of bending deformation of the deformable body is obtained. The method has the advantages that the calculating process is easier, and calculation cost is reduced.

Owner:XIDIAN UNIV

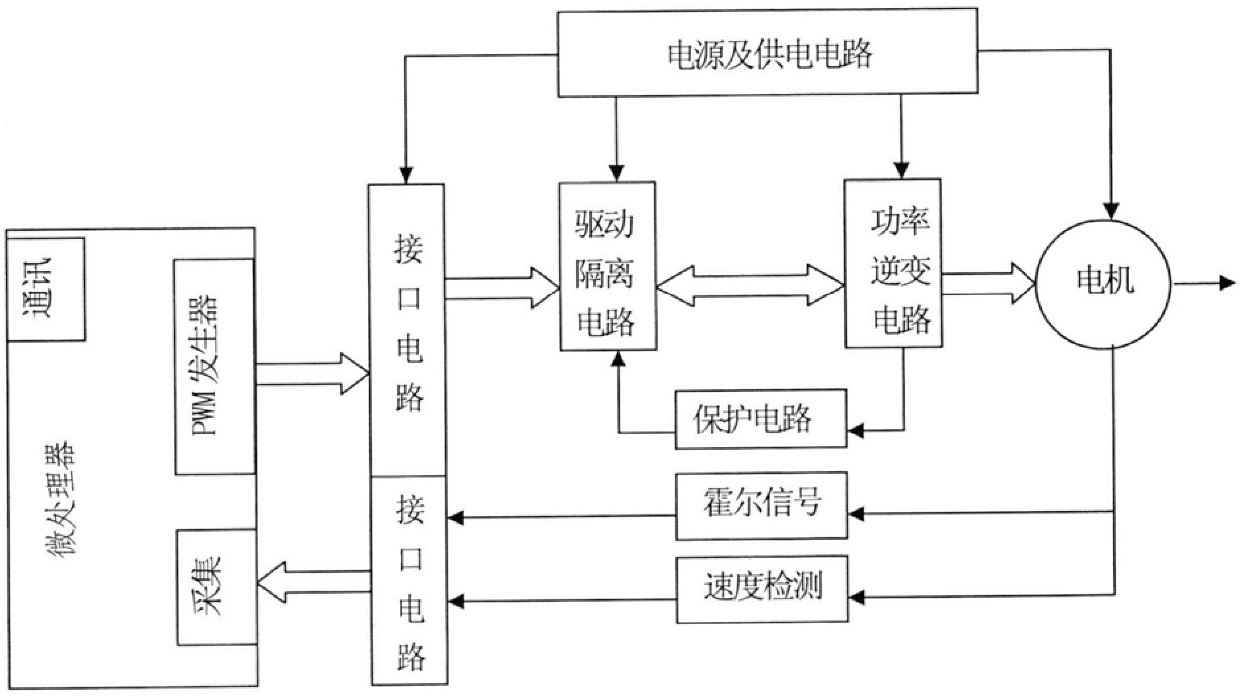

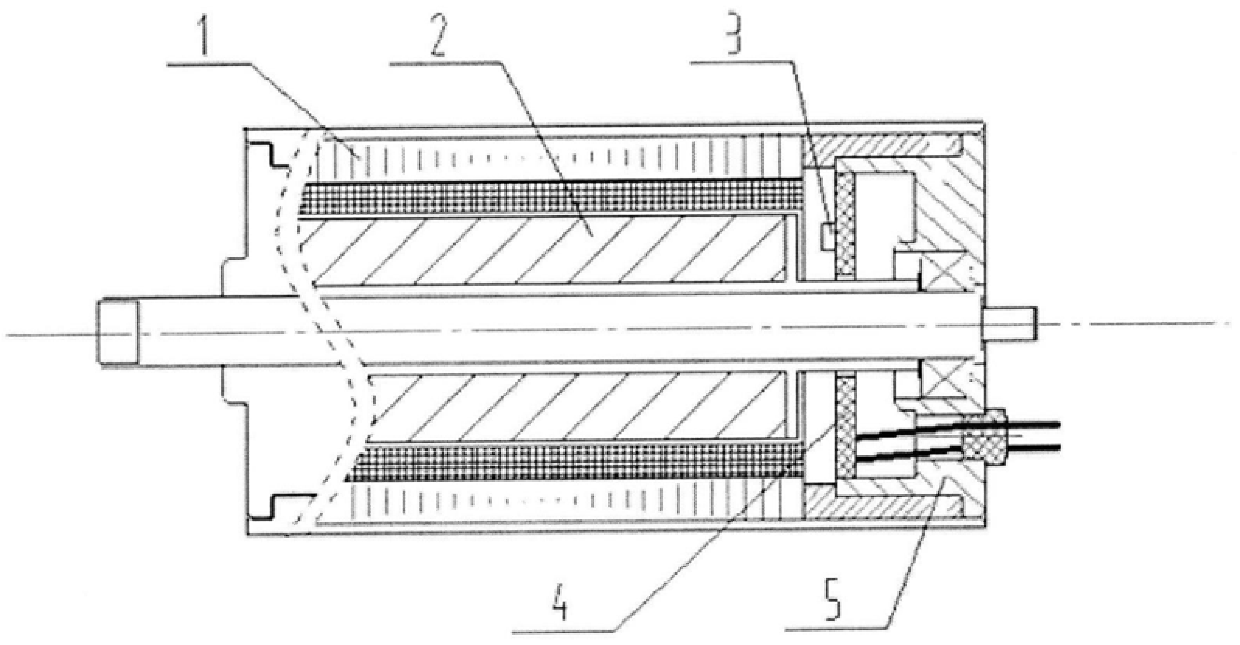

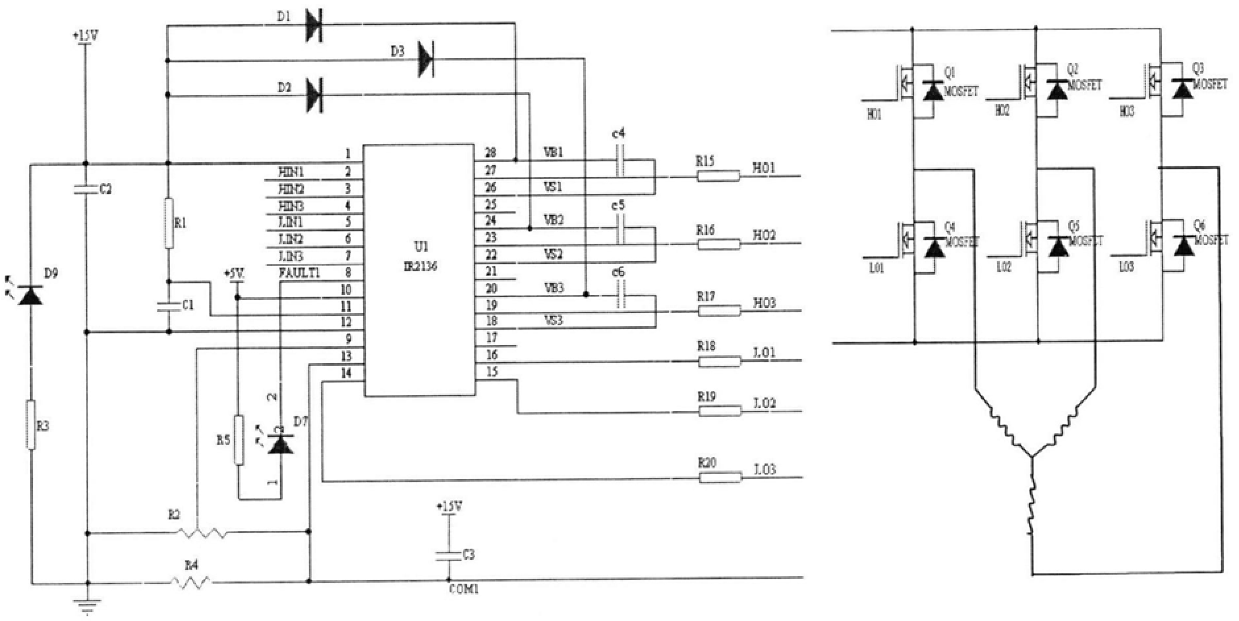

Brushless DC motor sinusoidal drive

InactiveCN106342389BReduce weightWeight increaseSingle motor speed/torque controlLow noiseCarrier signal

The invention discloses a sinusoidal drive device for a brushless DC motor, which comprises: a microprocessor and an interface circuit, a power supply circuit, a drive isolation circuit, a power inverter circuit and a protection circuit; the drive isolation circuit is connected to the microprocessor and the protection circuit respectively. The interface circuit is connected with the power inverter circuit; the power inverter circuit is connected with the brushless DC motor, the microprocessor and the interface circuit are connected with the output terminal of the Hall circuit board in the motor, and the periodic sinusoidal signal output by the Hall integrated circuit is collected, according to The rotor signal sensed by the linear Hall integrated circuit and the phase relationship of the stator winding obtain the rotor position information and the sinusoidal modulation wave of each stator winding energized. The sine modulation wave and carrier modulation are used to generate SPWM waves to supply power to the stator windings. The power supply current of the motor windings is a sine wave, and the torque fluctuation of the motor is small. It solves the problems of increased motor weight, lengthened length or complex process under the existing technical conditions, and has the advantages of low noise, fast start and stop, reliable operation and the like.

Owner:XIAN AEROSPACE PROPULSION TESTING TECH RES INST

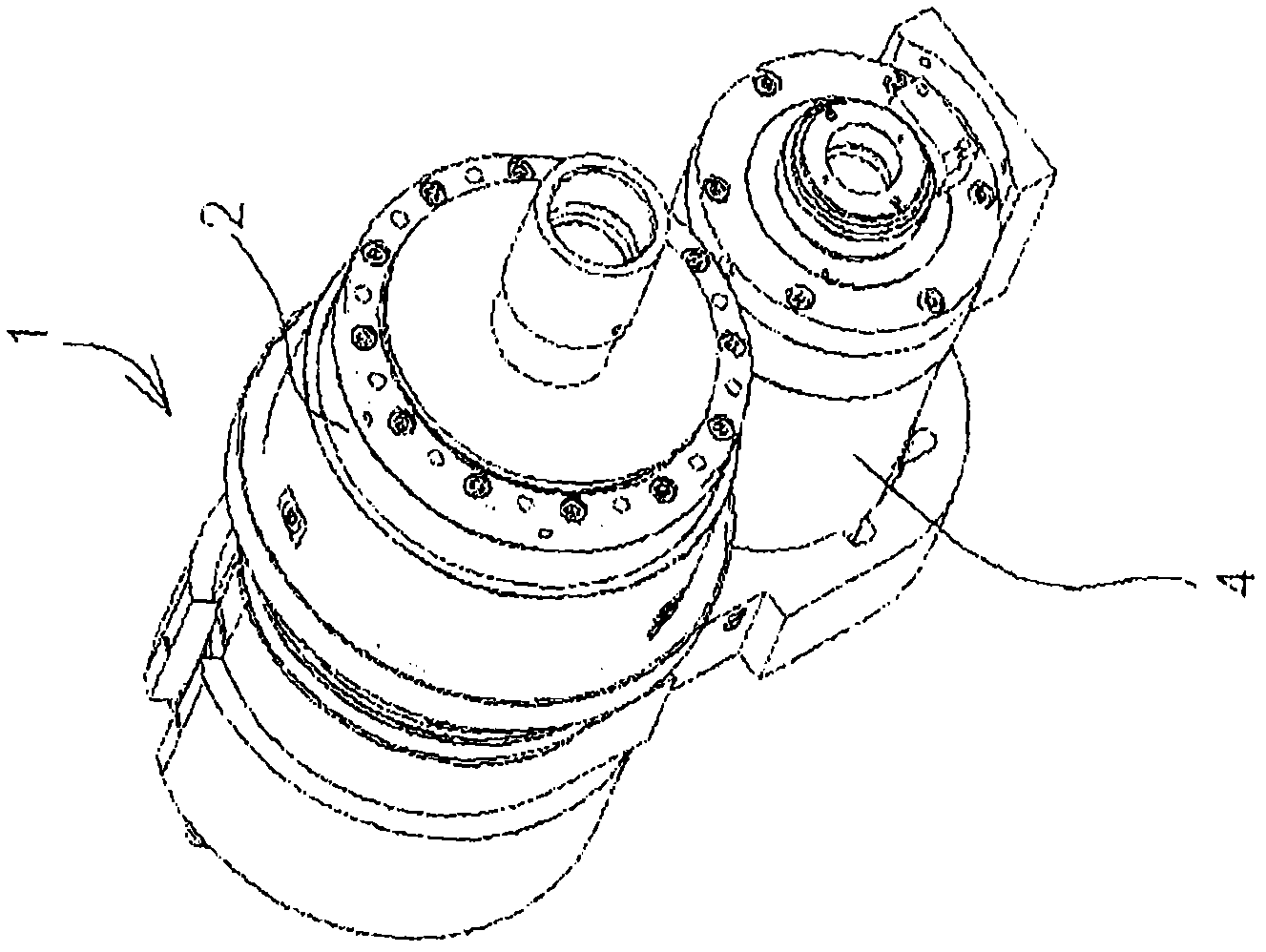

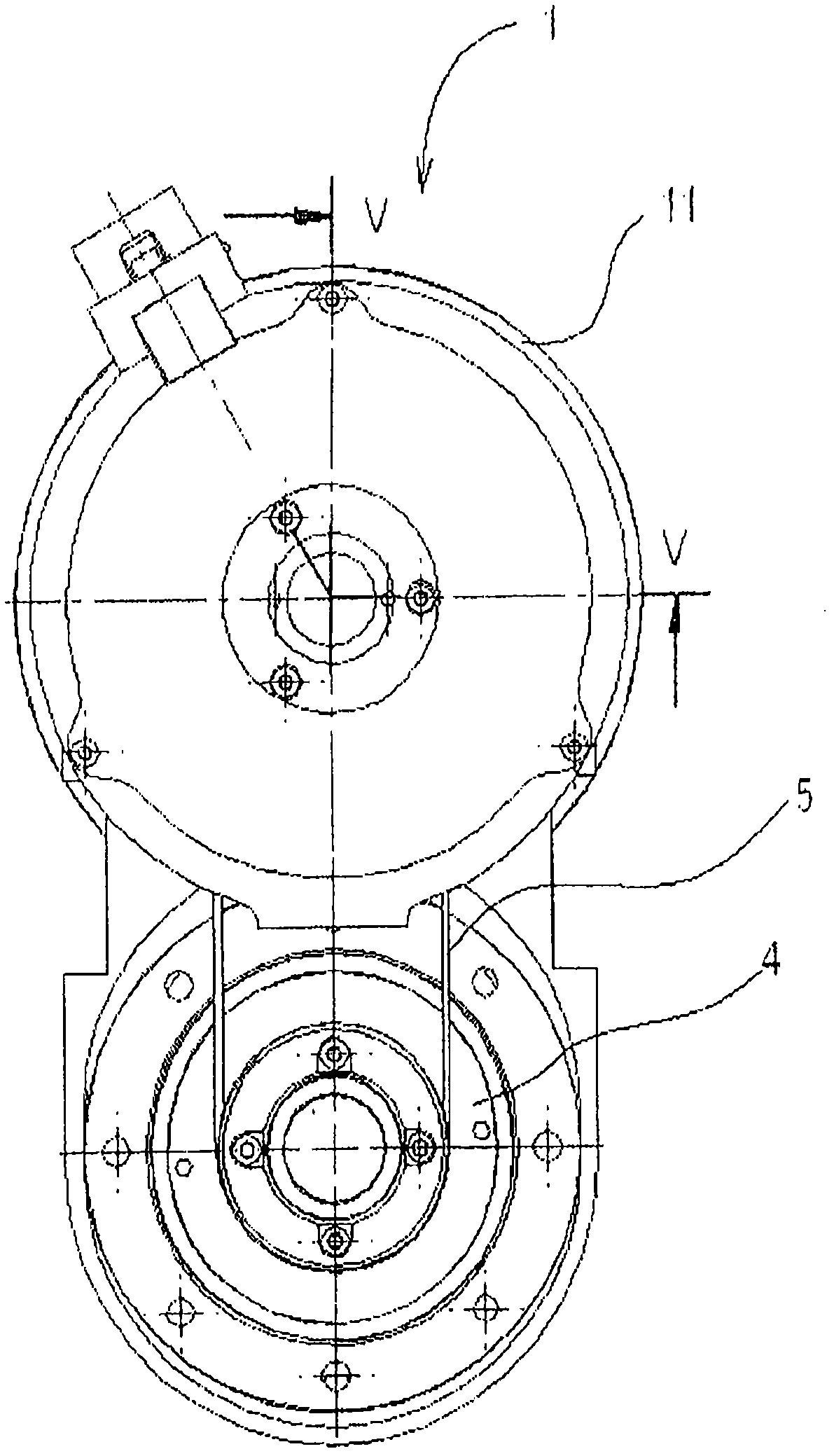

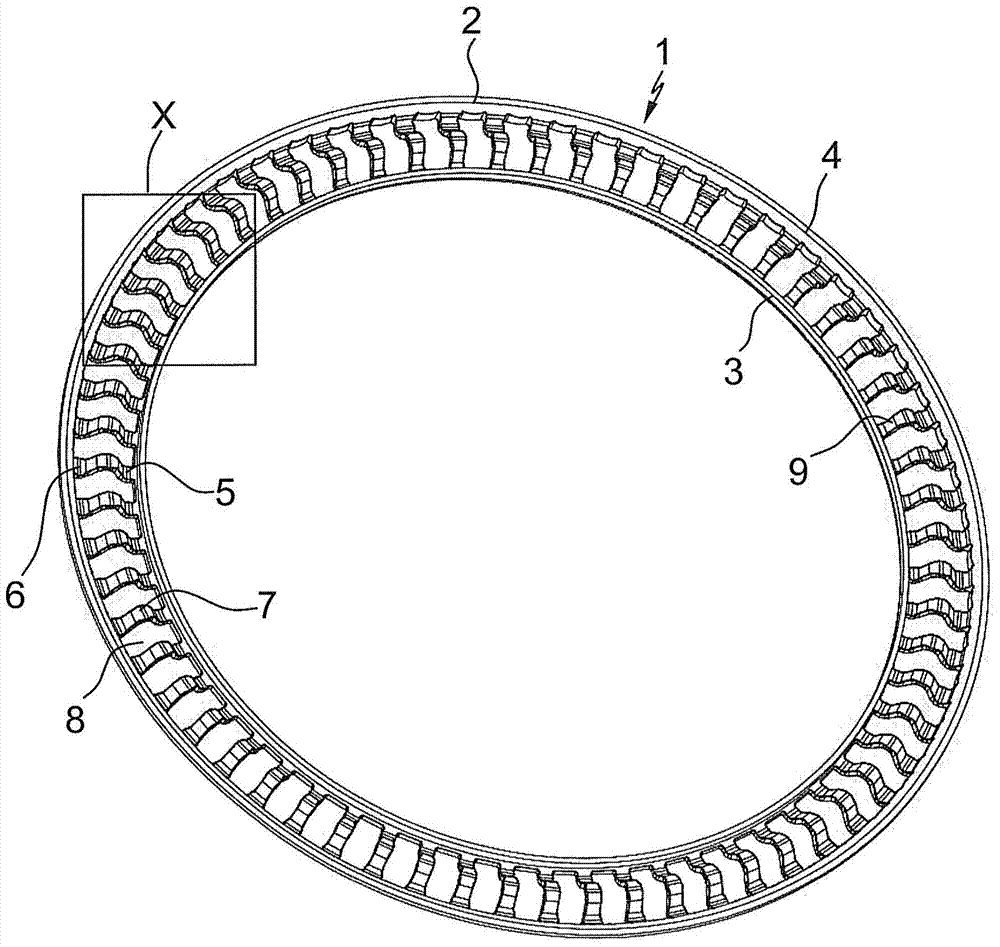

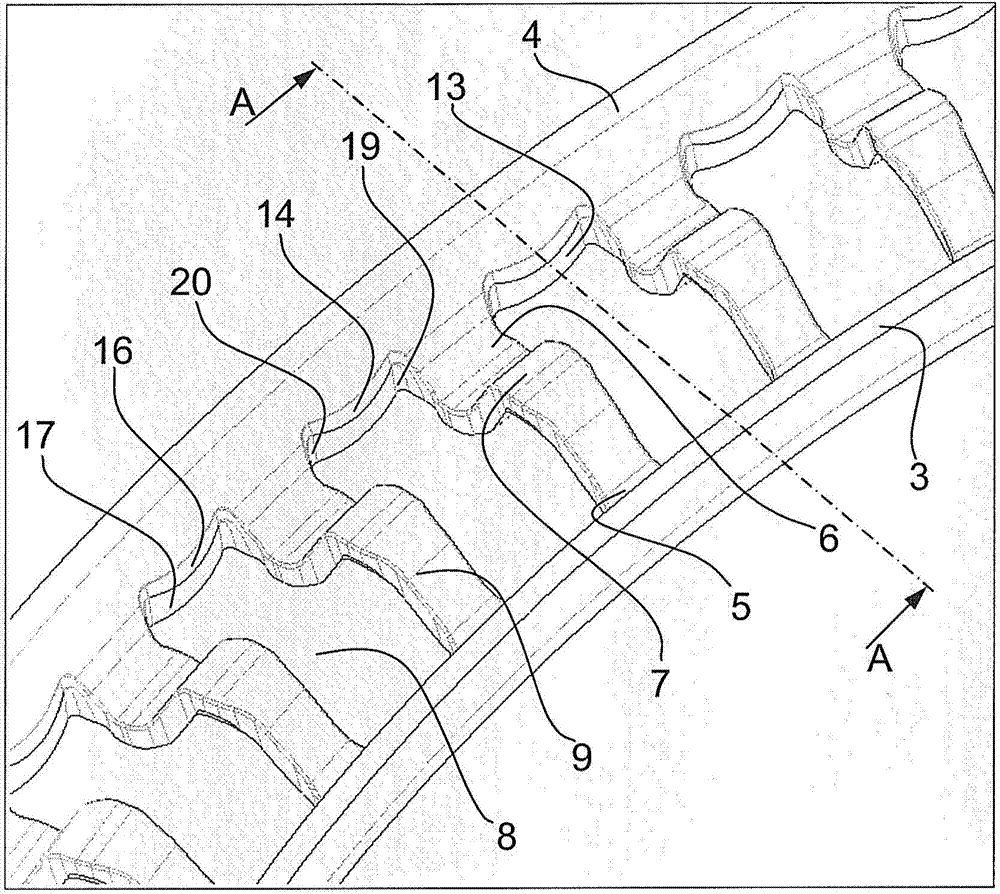

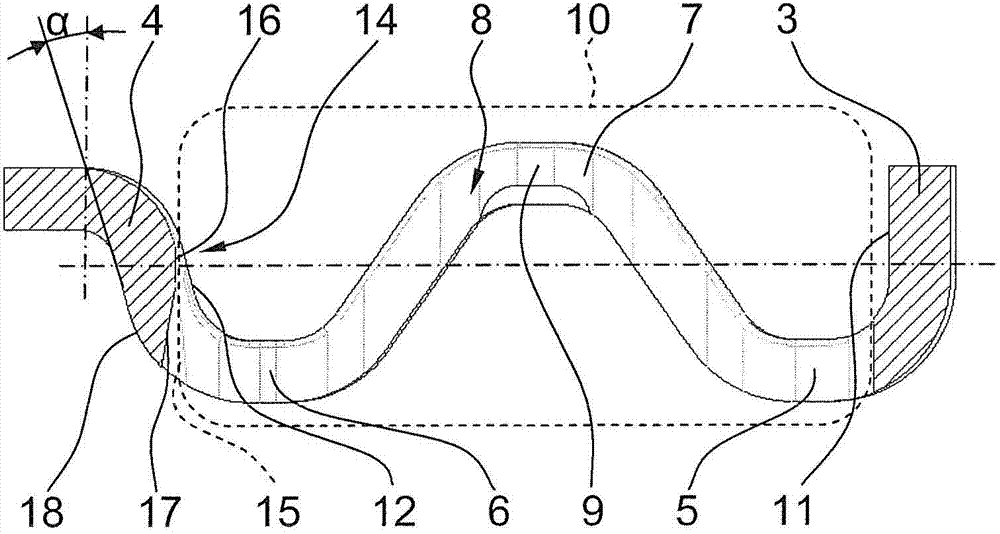

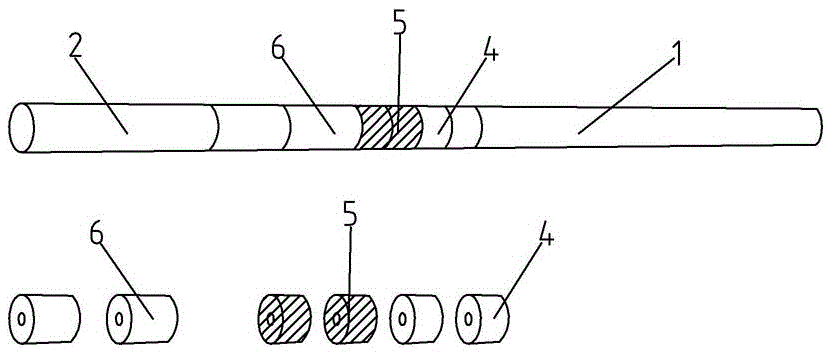

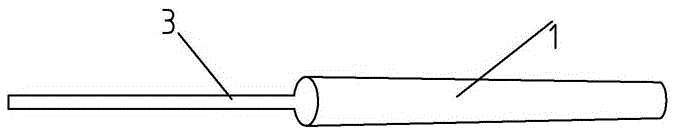

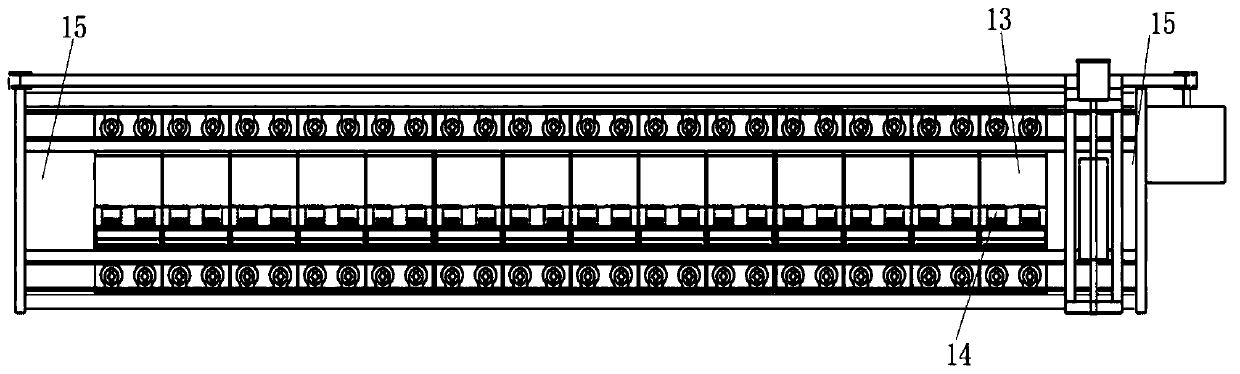

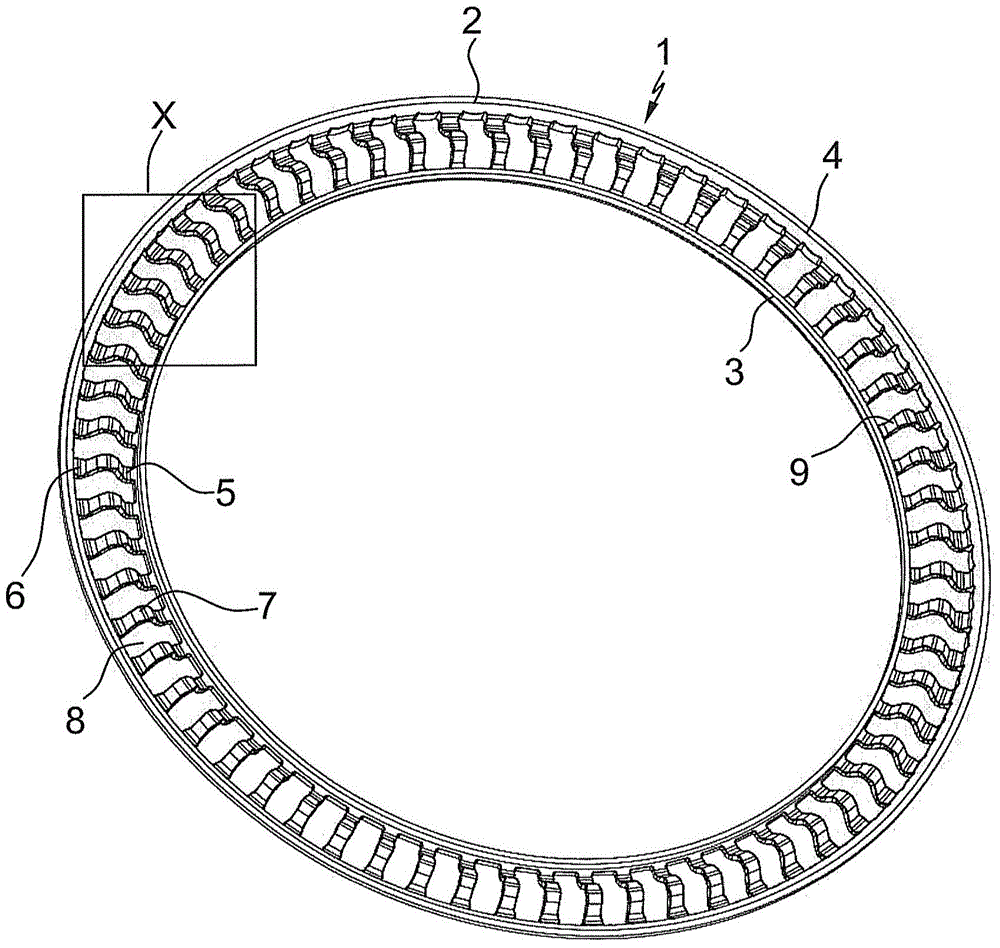

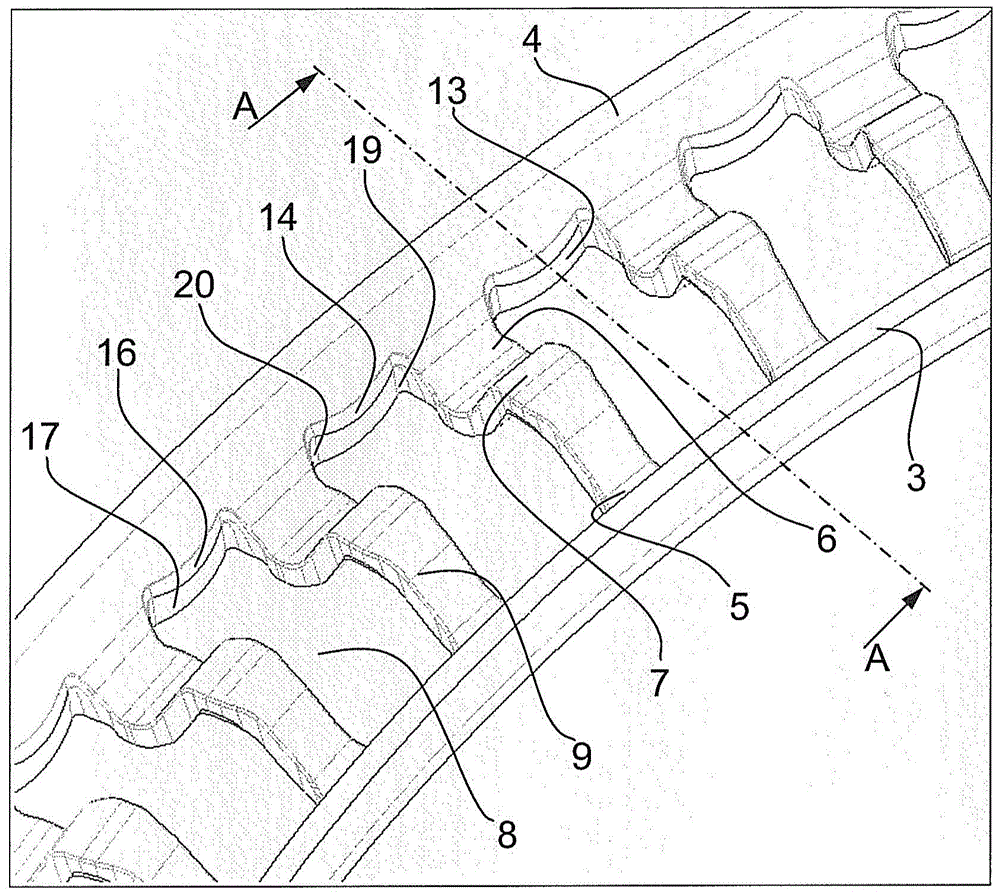

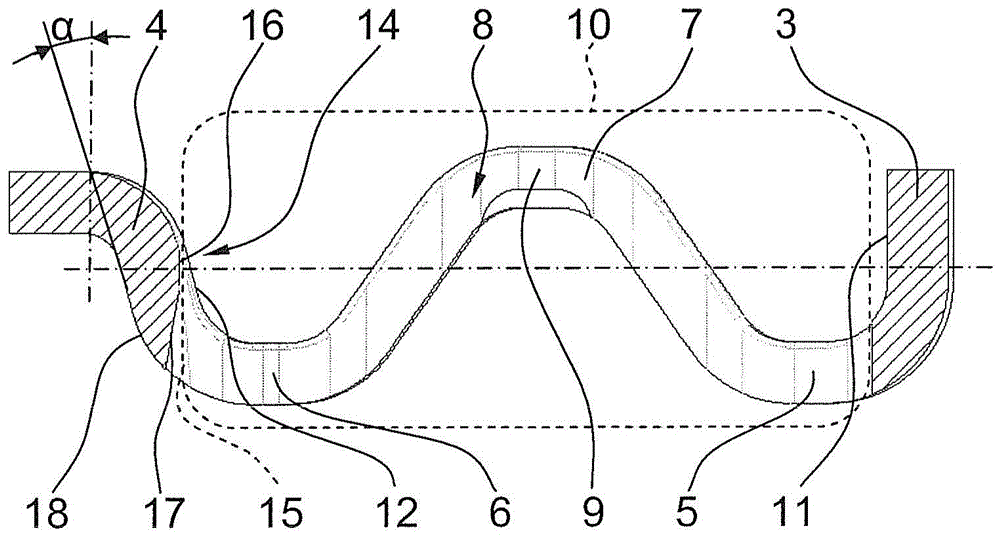

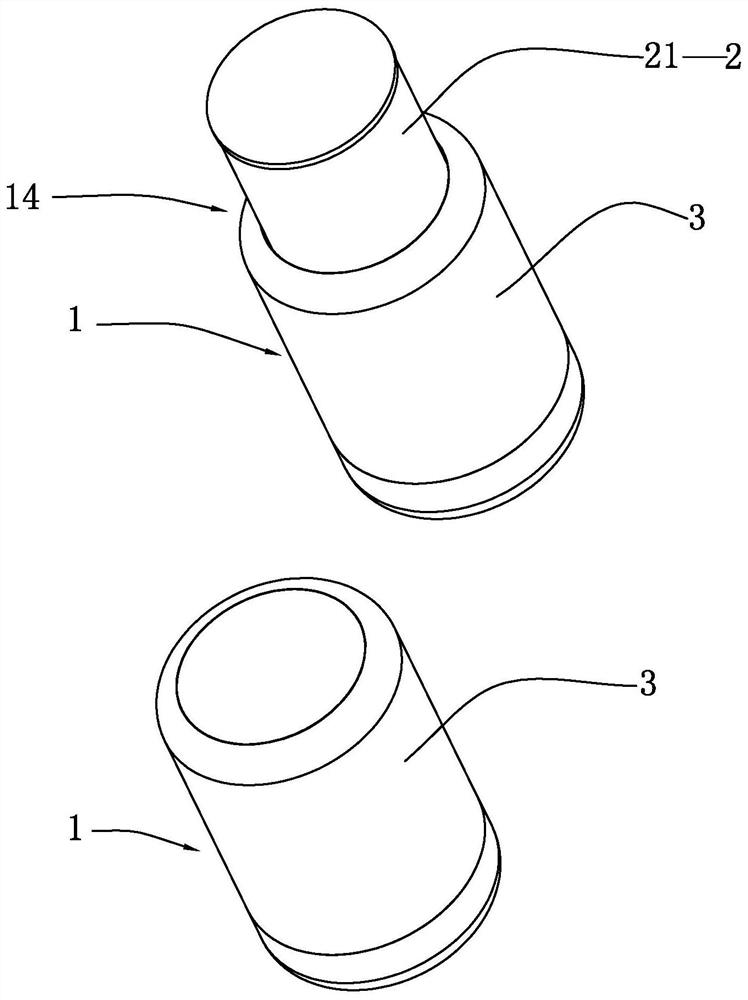

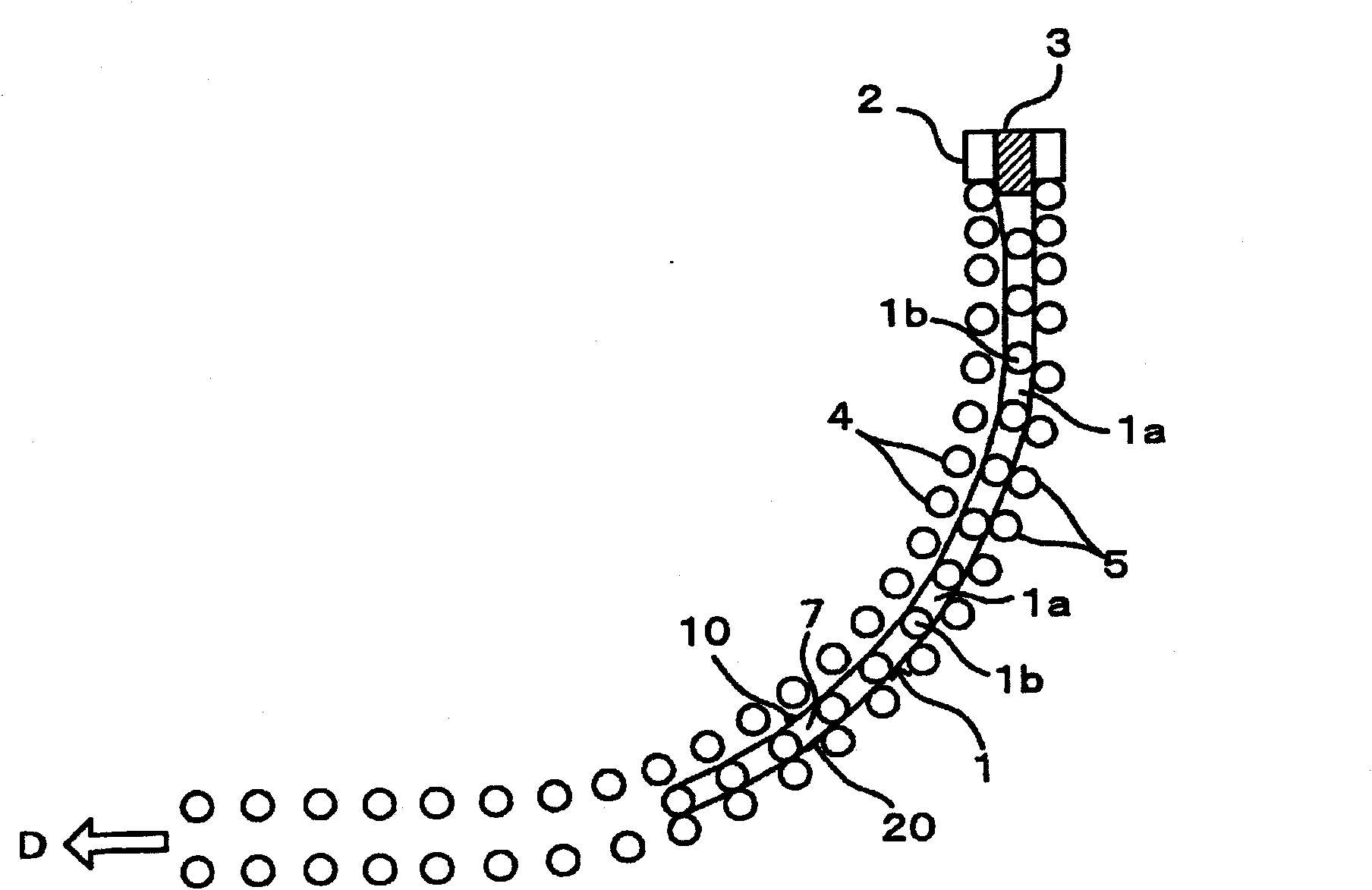

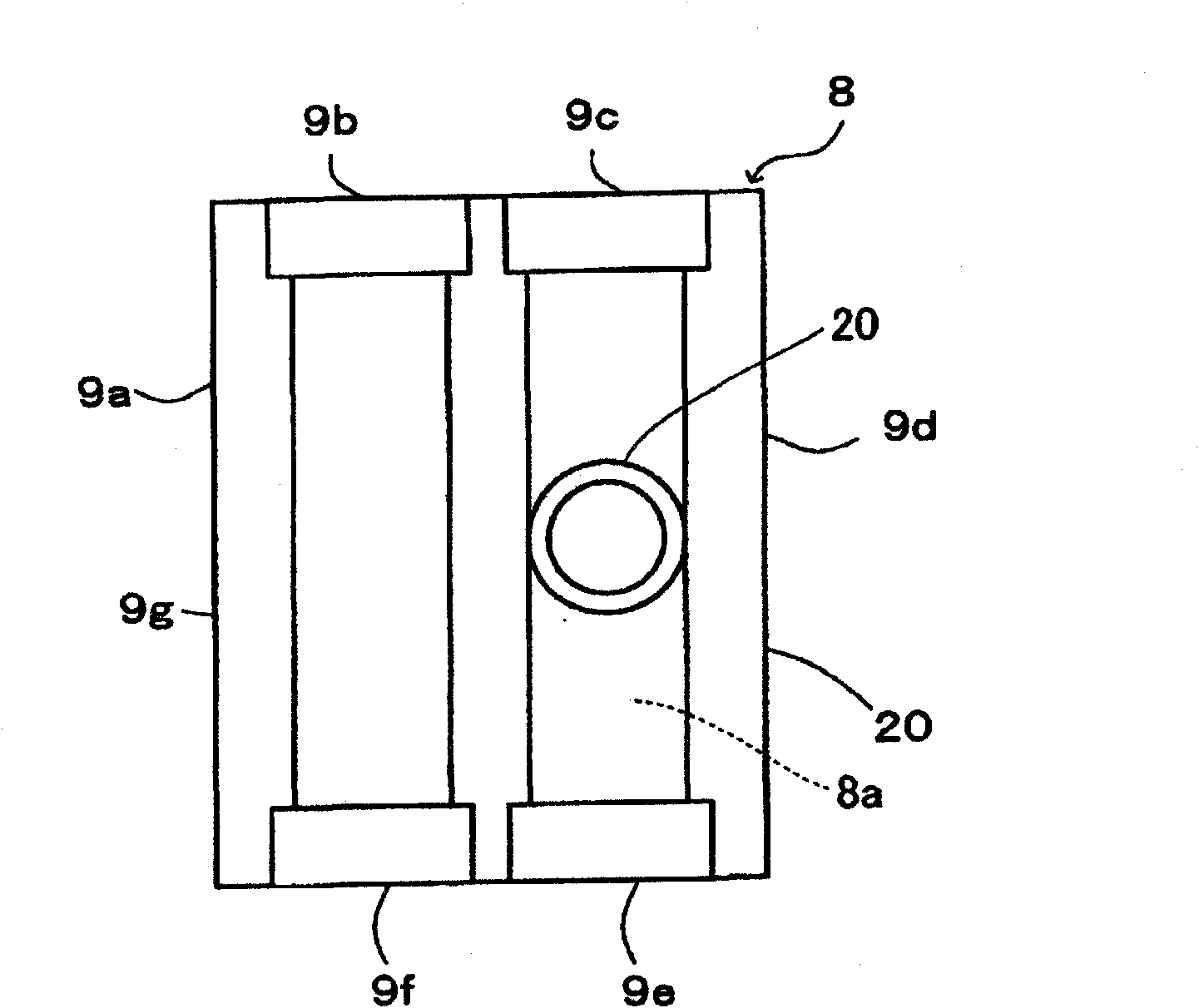

Axial cage for cylindrical rolling bodies

ActiveCN104854357ANo change in lengthAvoid drillingRoller bearingsBearing componentsEngineeringAxial distance

an axial cage (1) for cylindrical rolling bodies which substantially is formed of a thin-walled washer (2) with a W-shaped profile, the individual profile legs of which are formed by an inner radial rim (3) formed on the inner edge of the washer (2), an outer radial rim (4) formed on the outer edge of the washer (2) and a U-shaped center crimp (7) connected by way of inner and outer axial profile sections (5, 6) to the radial rims (3, 4) and having the same radial extent as the rims (3, 4). A number of evenly spaced rectangular cage pockets (8) are cut from the central crimp (7) and the adjacent axial profile sections (5, 6), between which pockets an equal number of pocket webs (9) are formed connecting the rims (3, 4) with one another, by which webs the cylindrical rolling bodies (10) are retained in the cage pockets (8) at uniform distances from one another and are also guided in the circumferential direction. According to the invention, this axial cage (1) is characterized in that the outer radial rim (4) is formed with an inclination (α) facing away from the central U-shaped crimp (7) and the cage pockets (8) have an axial length greater than the smallest axial distance between the inner sides (11, 12) of the inner and the outer radial rim (3, 4) such that the cage pockets (8) extend at least into the outer radial rim (4) of the axial cage (1) and, because of a crowned formation of the outer face sides (13) towards the center of the pocket on the outer radial rim (4) of the axial cage (1) at the height of the roll axes of the rolling bodies (10), form a rounded thrust lug (14) for the outer end faces (15) of the rolling body (10).

Owner:SCHAEFFLER TECH AG & CO KG

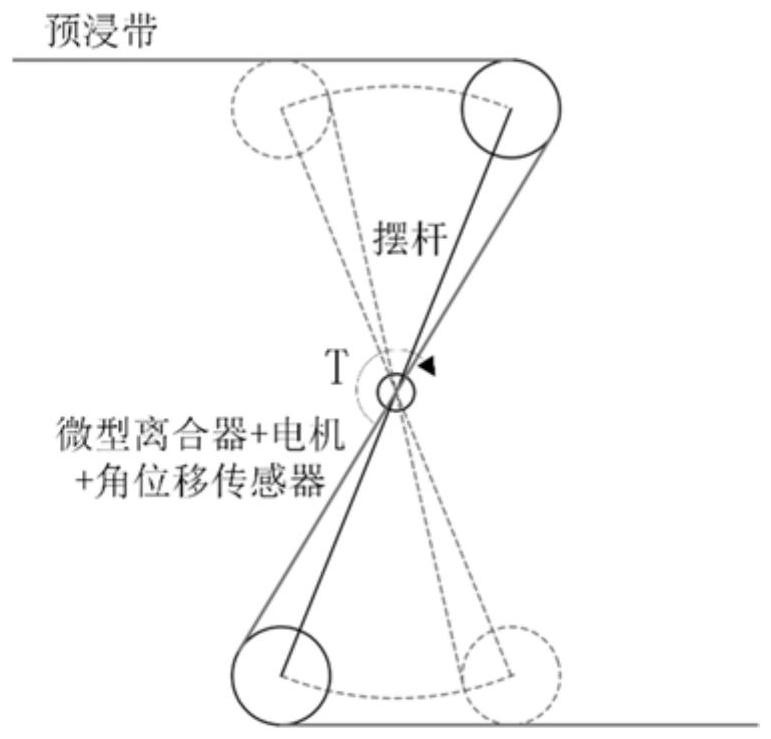

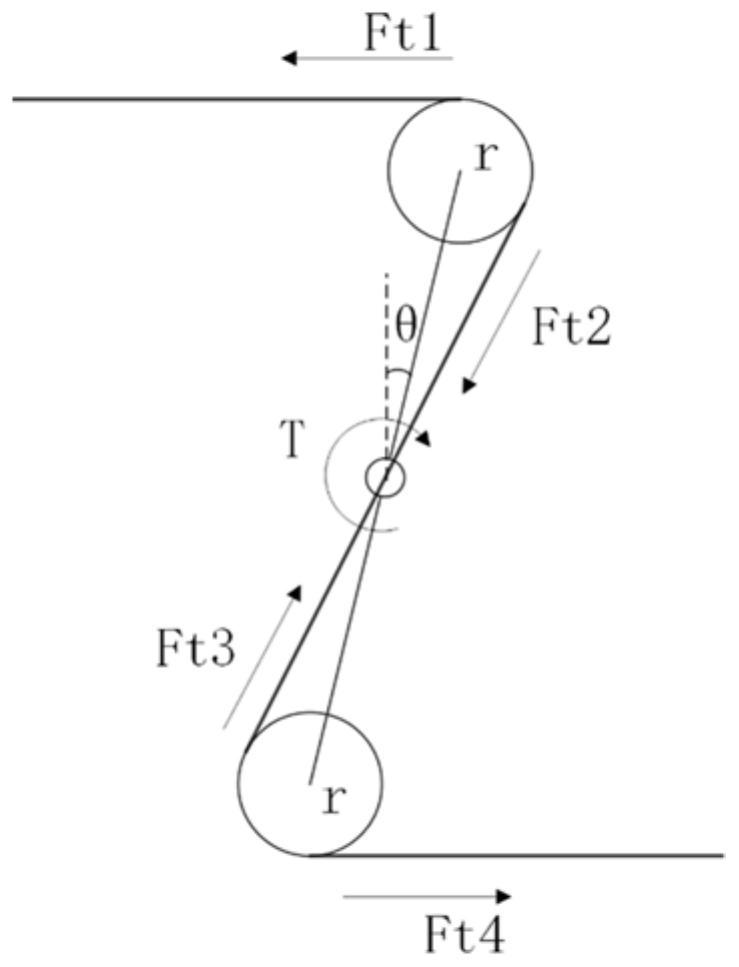

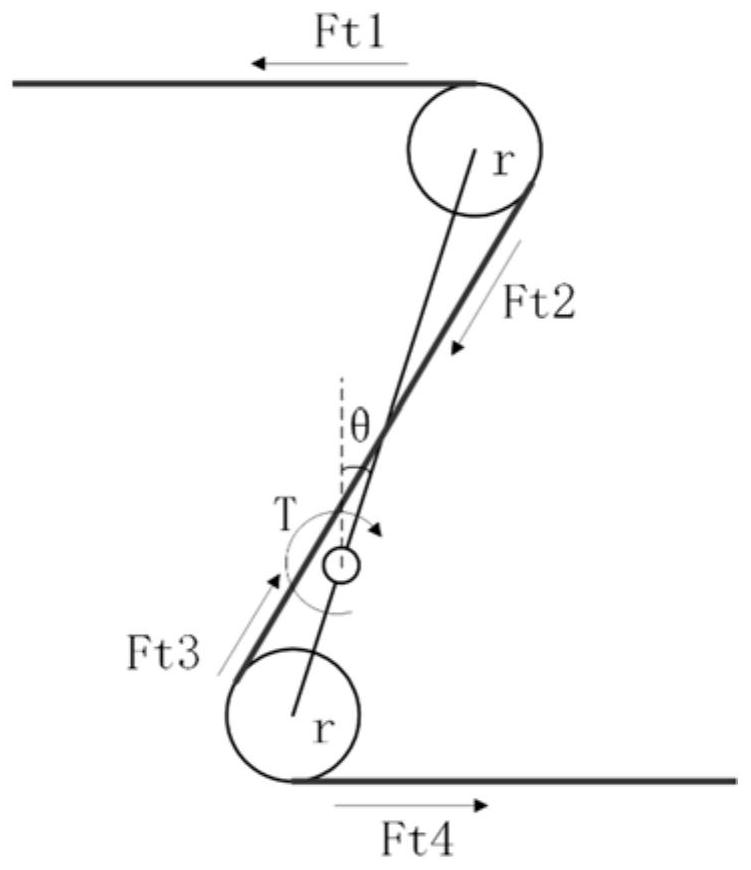

Swing type stable tension buffering method and device for carbon fiber prepreg tape

The invention relates to a swing type stable tension buffering method and device for a carbon fiber prepreg tape. The swing type stable tension buffering device comprises a buffering motor and a buffering device main shaft, a swing rod and a micro clutch are arranged on an output shaft of the buffering motor in a sleeving manner, the swing rod is connected with the micro clutch, the two ends of the swing rod are respectively provided with swing rod guide wheels, and the prepreg tape is wound around the two swing rod guide wheels in a Z shape. According to the swing type stable tension buffering method and device, the swing rod is used as a buffer element, so that tension fluctuation caused by inertia of the buffer element in the buffer process is reduced; the micro clutch is adopted as a tension control element, a motor drives the clutch to transmit stable driving torque to the swing rod, the torque is balanced with the torque of the swing rod under the tension action of the prepreg tape, so that the prepreg tape keeps stable tension; and the tension value of the prepreg tape can be adjusted by controlling the output torque of the clutch, the tension value is stable and can be verysmall, and the stable tension of the prepreg tape can be maintained in the buffering process.

Owner:西安华晟复材科技有限公司

A billiard cue that adjusts weight and length with rings of different specifications and combinations

InactiveCN103301628BIncrease or decrease weightNo change in lengthBilliardsVolumetric Mass DensityComputer science

Owner:饶涛

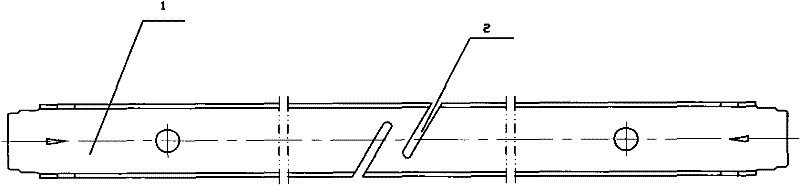

Interconnect structure for display device and projection display apparatus

InactiveCN100555035CNo change in current drive capabilityNo change in lengthStatic indicating devicesProjectorsData signalInductor

An interconnection structure for a display device includes a driver providing display data, and an interconnection material having a plurality of signal lines arranged in parallel through which the driver provides display data. In the interconnection structure for the display device, rearrange the signal lines that transmit the display data via the interconnection material, so that the display data via the signal line having a relatively large inductance element influence in the interconnection material, and The display data of the signal lines affected by the small inductive elements are alternately supplied to adjacent pixels or groups of pixels of the display device. As a result, an image is displayed according to a brightness suitable for the display data.

Owner:SONY CORP

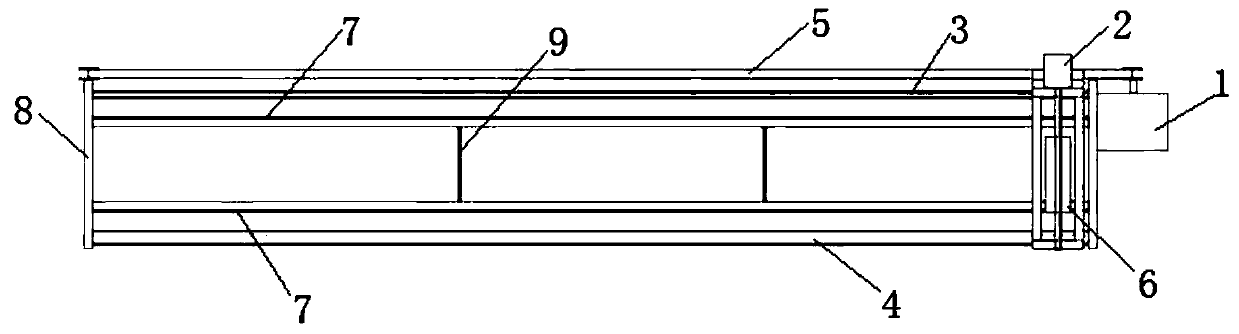

Remote opening and closing device for circuit breakers in row and working method thereof

PendingCN110223890AChange lengthSmall footprintProtective switch operating/release mechanismsCircuit breakerRemote communication

The present invention discloses a remote opening and closing device for circuit breakers in row and a working method thereof. The device comprises: a first linear guide rail and a second linear guiderail are disposed in parallel along with direction in which the circuit breakers are arranged in a row; the first linear guide rail and the second linear guide rail are disposed above an end surface of the circuit breakers with a switch, and projection of the two linear guide rails on the end surface is distributed on both sides of the switch. The device has a function of remote communication, andcan realize remote automatic opening and closing control of any one of the circuit breakers in the row, without affecting realization of manual opening and closing.

Owner:SHANDONG UNIV +1

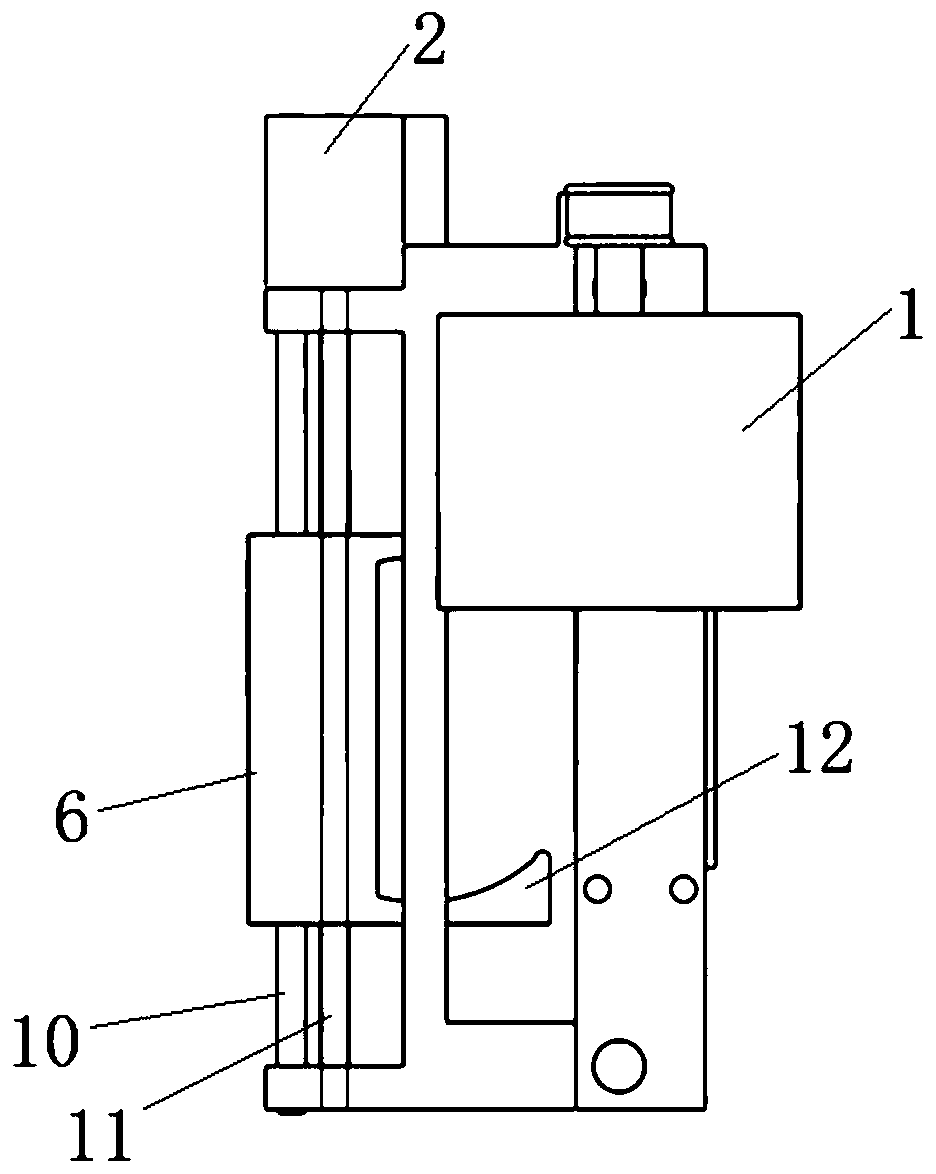

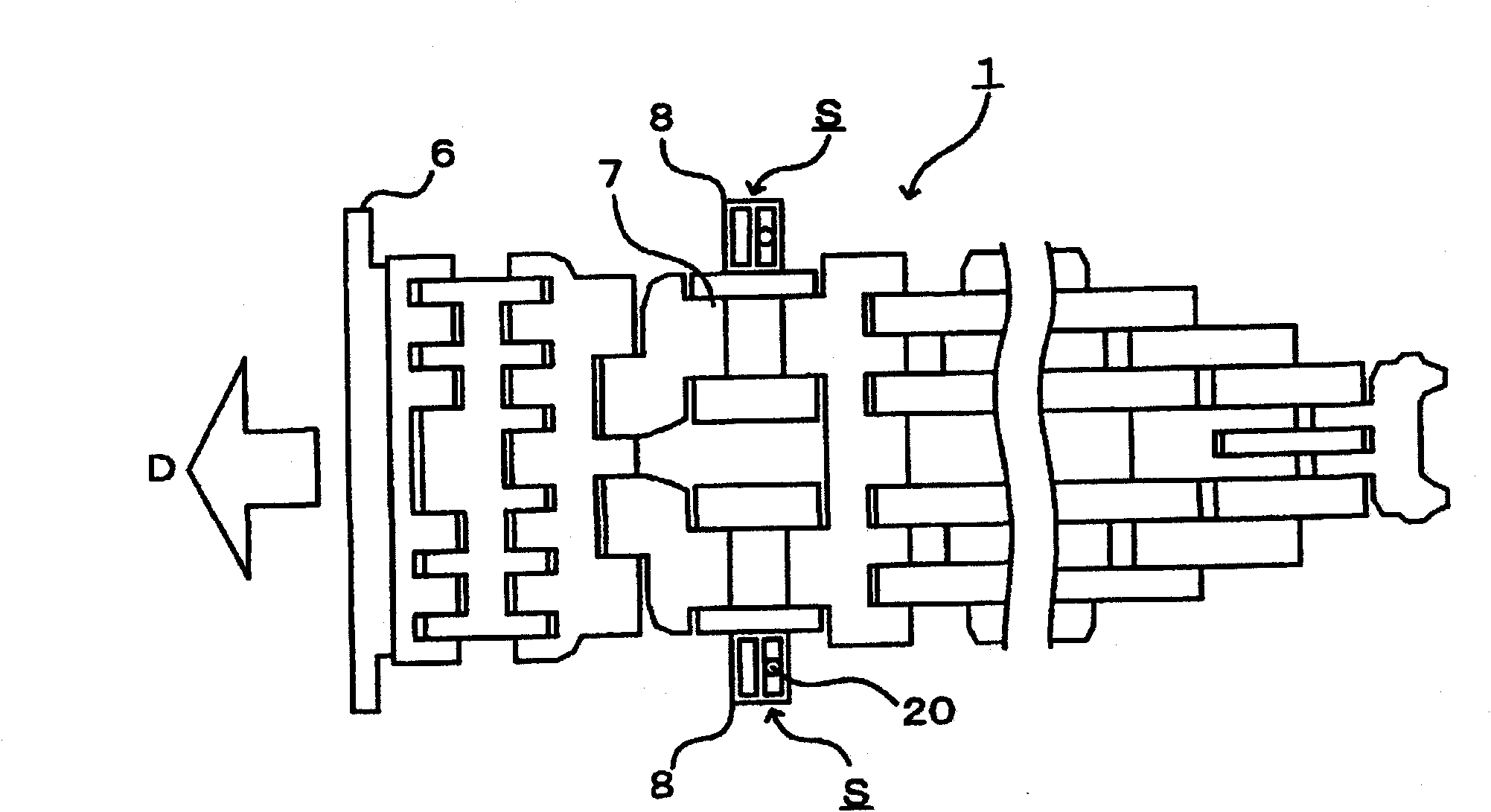

Method for clamping a tool or a workpiece and device for performing the method

InactiveCN102548693BHigh clamping reliabilitySimple structureSleeve/socket jointsPrecision positioning equipmentDrive wheelMoving jaw

The invention relates to a method of clamping a tool or a workpiece, using an electric actuator (1) having a housing (2) attached to a work spindle of a machine tool and in which a threaded spindle (3) for moving jaws of a chuck is axially displaceable, and an electric servomotor (4) having a rotor connected with a drive wheel (6) that moves a nut (7) on the threaded spindle (3), a first sensor being associated with the threaded spindle (3) for detecting the axial position thereof, and a second sensor being associated with the spindle nut (7) for detecting the axial position thereof, and including the method step of determining the position of the threaded spindle (3) by the first sensor when a slight axial force occurs due to contact of the clamping jaws with the tool or the workpiece, and continued movement of the spindle nut (7) until a specified sensor difference (12) between the first sensor and the second sensor is determined by the second sensor. The invention further relates to an apparatus for carrying out the method.

Owner:ROHM CO LTD

Axial cages for cylindrical rolling elements

ActiveCN104854357BIncrease axial lengthNo change in lengthRoller bearingsBearing componentsEngineeringAxial distance

The invention relates to an axial cage (1) for cylindrical rolling elements, which consists essentially of a thin-walled annular disk (2) with a W-shaped profile cross-section, formed to an annular The inner radial edge (3) on the inner edge of the disc (2), the outer radial edge (4) formed onto the outer edge of the annular disc (2) and through the inner axial profile section and the outer axial profile section (5,6) The central U-shaped crimp (7) connected to the radial rim (3,4) and having the same radial extension as the rim (3,4) forms the axial cage contour segments of . In this case, a plurality of rectangular cage pockets (8) evenly spaced from one another result from the central bead (7) and the adjoining axial profile sections (5, 6), between which cage pockets Form the same number of pocket webs (9) connecting the edges (3, 4) to each other, which hold the cylindrical rolling elements (10) at an even distance from each other in the cage pockets (8) , and guide these cylindrical rolling elements in the direction of rotation. According to the invention, the axial cage (1) is characterized in that the outer radial edge (4) is configured with an angle of inclination (α) pointing away from the central U-shaped curl (7), and that the cage pockets (8) have an axial length greater than the minimum axial distance between the inner side (11, 12) of the inner radial edge and the outer radial edge (3, 4), so that the cage pocket (8) is at least Extends into the outer radial edge (4) of the axial cage (1) and is formed in the axial cage ( 1) is formed on the outer radial edge (4) at the height of the rolling axis of the rolling element (10) with a rounded thrust projection (14) for the outer end side (15) of the rolling element (10) ).

Owner:SCHAEFFLER TECH AG & CO KG

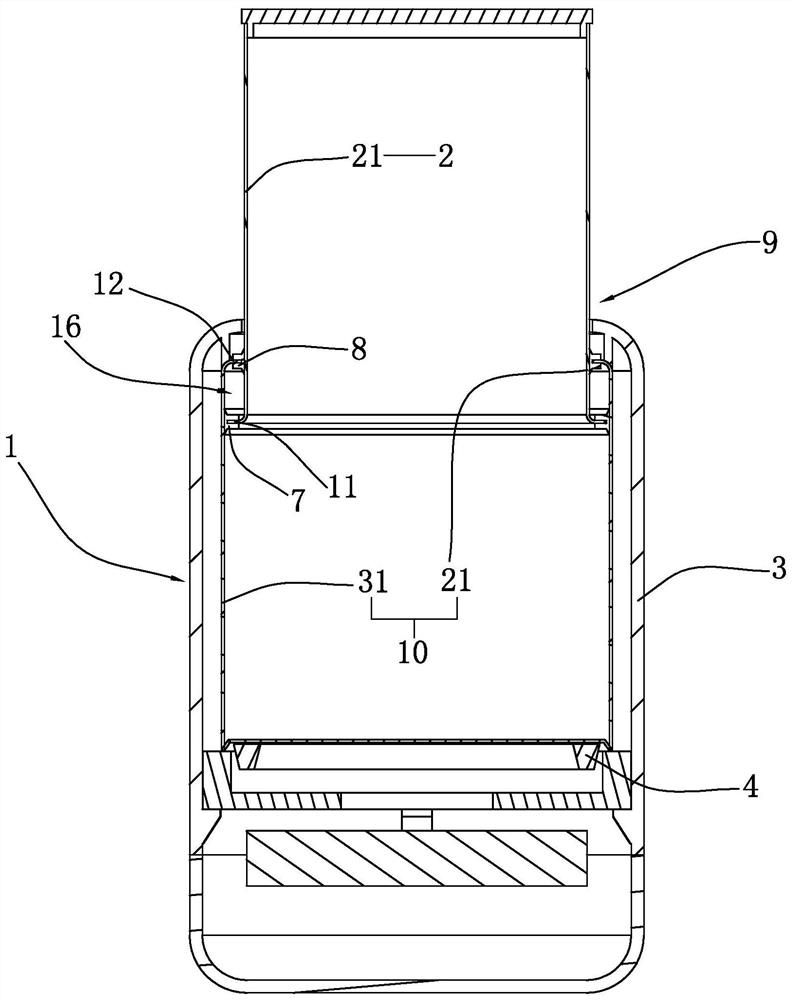

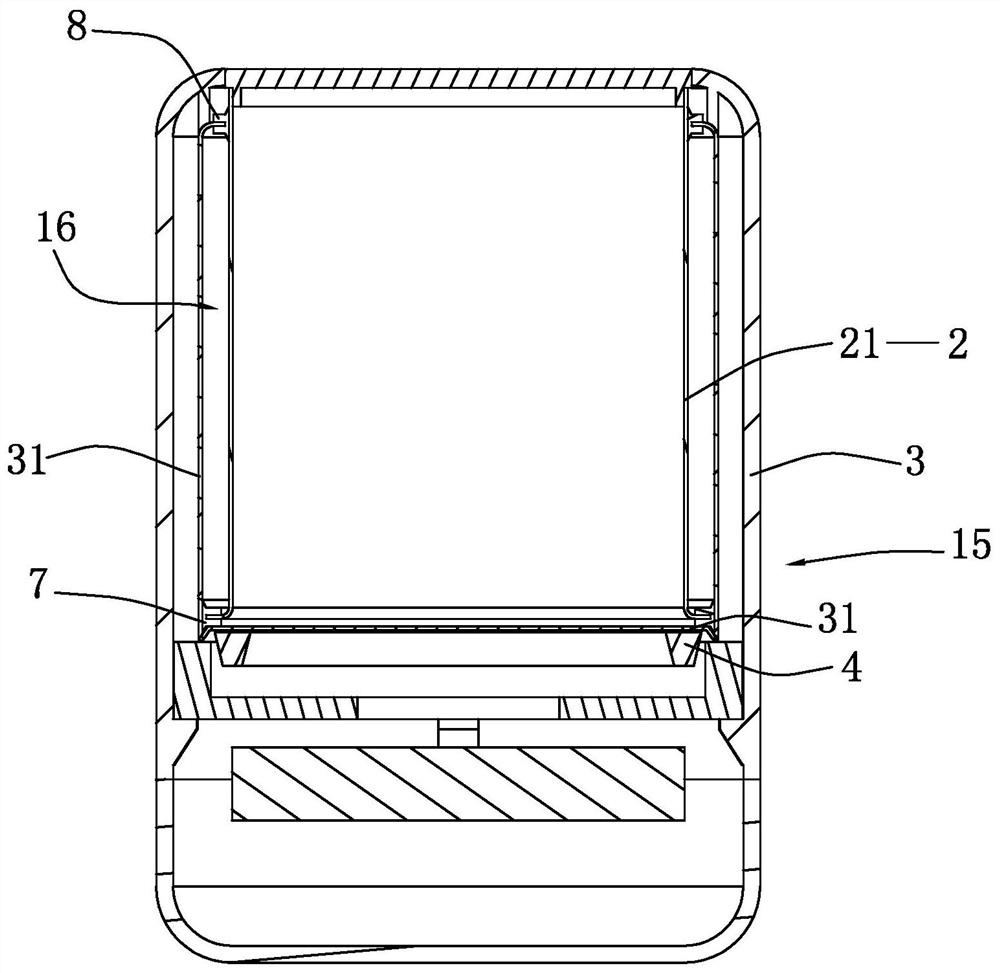

Liquid heating container

PendingCN113647810AImprove user experienceImprove reliabilityWater-boiling vesselsPhysicsEngineering

The invention discloses a liquid heating container, which comprises a telescopic kettle body and a heating assembly arranged on the kettle body, and is characterized in that the kettle body comprises an upper kettle body and a lower kettle body movably sleeved on the upper kettle body, a supporting structure is arranged on the kettle body, the supporting structure is positioned between the upper kettle body and the lower kettle body, when the kettle body is opened, the kettle body extends, the supporting structure is not exposed and limits the upper kettle body to move towards the lower kettle body. When the kettle body is opened, the supporting structure is located between the outer side wall of the upper kettle body and the inner side wall of the lower kettle body. The supporting structure is shielded by the upper kettle body, is invisible in the appearance, and the user experience is improved. In addition, when the kettle body works, the supporting structure is protected by the upper kettle body and cannot be directly impacted or mistakenly touched, it is guaranteed that the supporting structure reliably supports the kettle body, and then the working reliability of the liquid heating container is improved.

Owner:JOYOUNG CO LTD

Heat-preserving time adjusting method for hot galvanizing unit alloying furnace

ActiveCN105177486AChange lengthDo not change running speedHot-dipping/immersion processesCold airEngineering

The invention relates to the technical field of hot-galvanizing unit alloying, in particular to a heat-preserving time adjusting method for a hot galvanizing unit alloying furnace. A plurality of gas sealing spraying nozzles are arranged in a vertical heating chamber in the length direction in which a hot galvanizing steel plate is placed. Circulation of vertical gas of the gas sealing spraying nozzles is sealed through cold gas sprayed out of the gas sealing spraying nozzles; rising of hot air is cut off; and a cooling spraying pipe is arranged on the upper portion of each gas sealing spraying nozzle in a matched manner and used for jetting cold air so that the hot galvanizing steel plate cutting off hot air can be cooled. According to the heat-preserving time adjusting method, the length of a heating chamber is not changed, and the running speed of the hot galvanizing steel plate is not changed; and due to the fact that cooling gas is added in the soaking zone of the hot galvanizing unit alloying furnace and used for sealing, when alloying products are produced, the heat preserving time of the soaking zone can be shortened while the temperature of a unit is lowered.

Owner:BENGANG STEEL PLATES

Roll-to-roll distance measuring device

ActiveCN102026748BStable and high-precision measurementNo change in lengthMechanical clearance measurementsUsing optical meansForeign matterEngineering

A roll-to-roll distance measuring device comprises a sensor device for measuring the distance between at least a pair of rolls disposed oppositely to each other on both sides of a cast piece passage in a continuous casting machine. The sensor device comprises a movable sensor head having a cylindrical body part, a head part which is arranged continuously with the upper end of the body part in a conical shape and the top of which is convexed toward the upper roll among the pair of rolls; and a cylindrical sensor housing for storing the sensor head. A reception part serving as a space for receiving foreign matters is formed between the bottom end outer peripheral surface of the head part and the upper end inner peripheral surface of the sensor housing when the bottom end of the head part is intruded into the sensor housing. The bottom part of the reception part is formed in an annular flat surface in the top plan view thereof.

Owner:NIPPON STEEL CORP +1

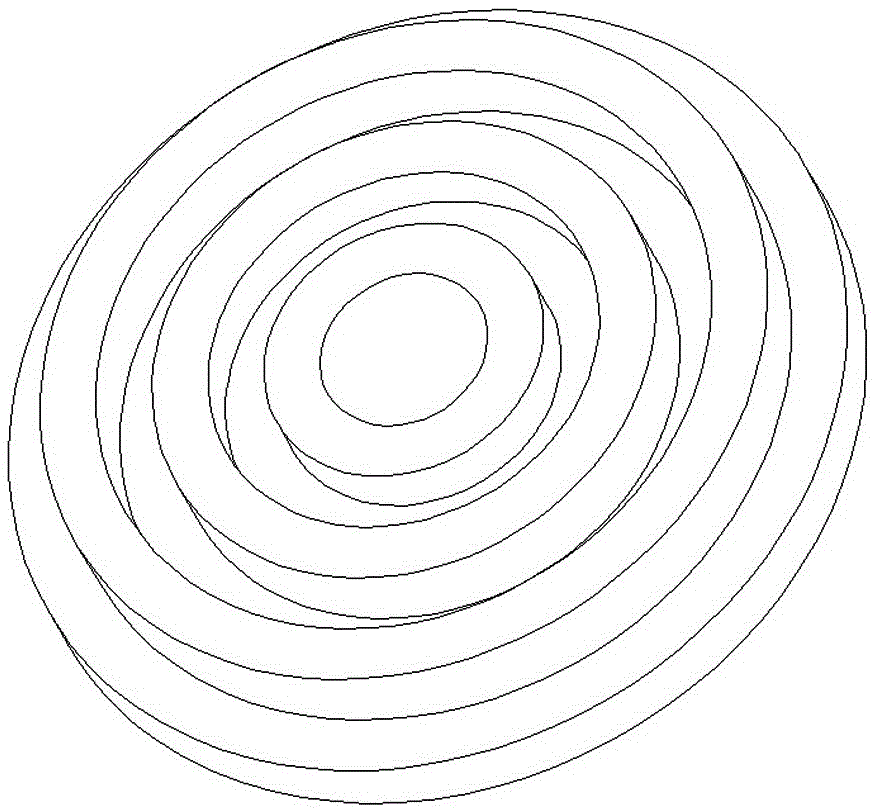

Bi-directional anti-seepage lead bush

The invention discloses a bi-directional anti-seepage lead bush which is a flange-shaped member. An axial taper sleeve is arranged in the center, a round edge extending radially is connected outside the taper sleeve, 2-5 concave and convex alternated integrated concentric circles are respectively formed on an upper end face and a lower end face of the round edge, and at least one radially extending integrated shoulder is arranged on an outer wall of the round edge, so that a structure integrating a double-end-face anti-seepage structure and an axial anti-seepage structure is formed. The bi-directional anti-seepage lead bush is structurally characterized in that a main anti-seepage structure is arranged on the end face, the position of the structure differs from the position of an axial anti-seepage structure in the prior art by 90 degrees, the most advantage of the position adjustment is that the anti-seepage structures are arranged on double faces, part of the axial anti-seepage structure is still remained, and the problem of acid seepage of a lead bush of a lead-acid battery shell is thoroughly solved under the actions of the double anti-seepage structures.

Owner:SHUANGDENG GRP

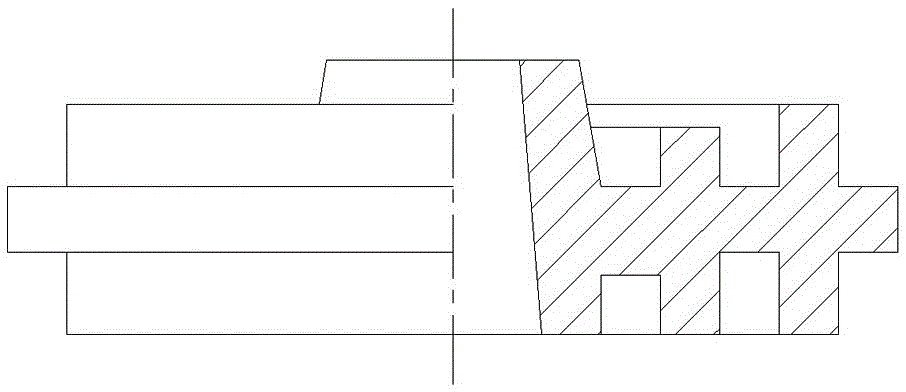

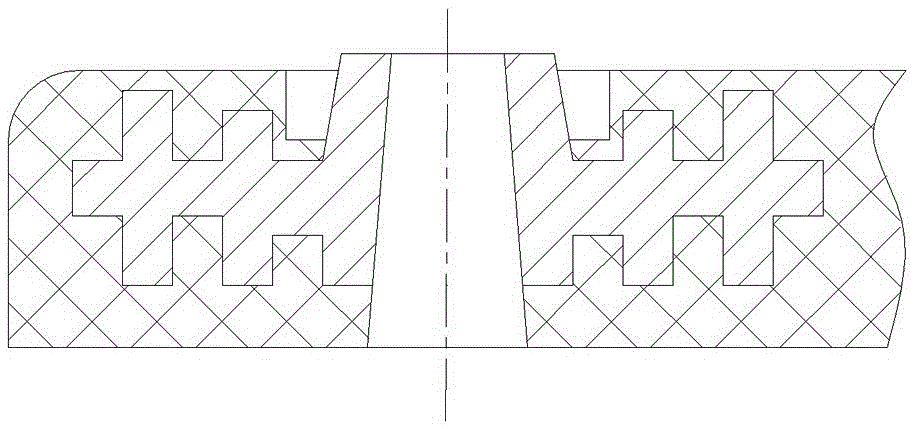

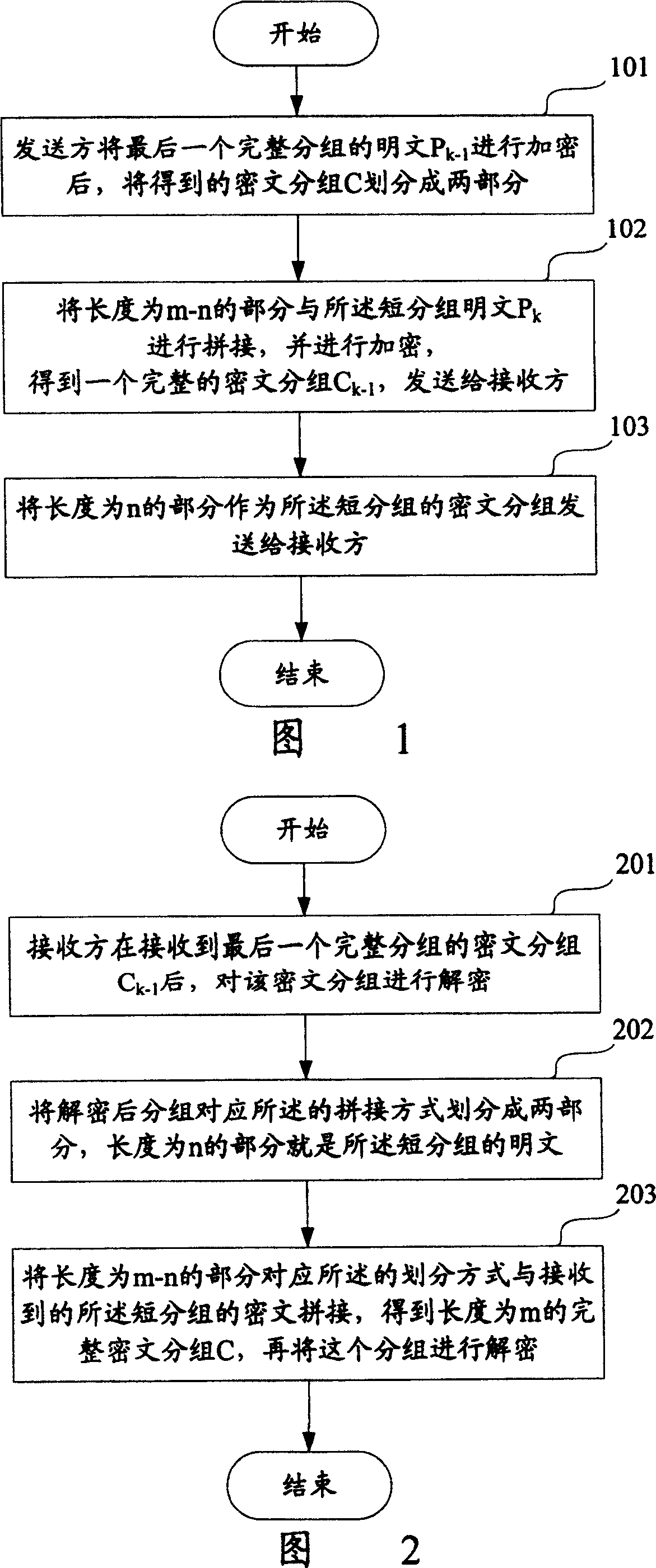

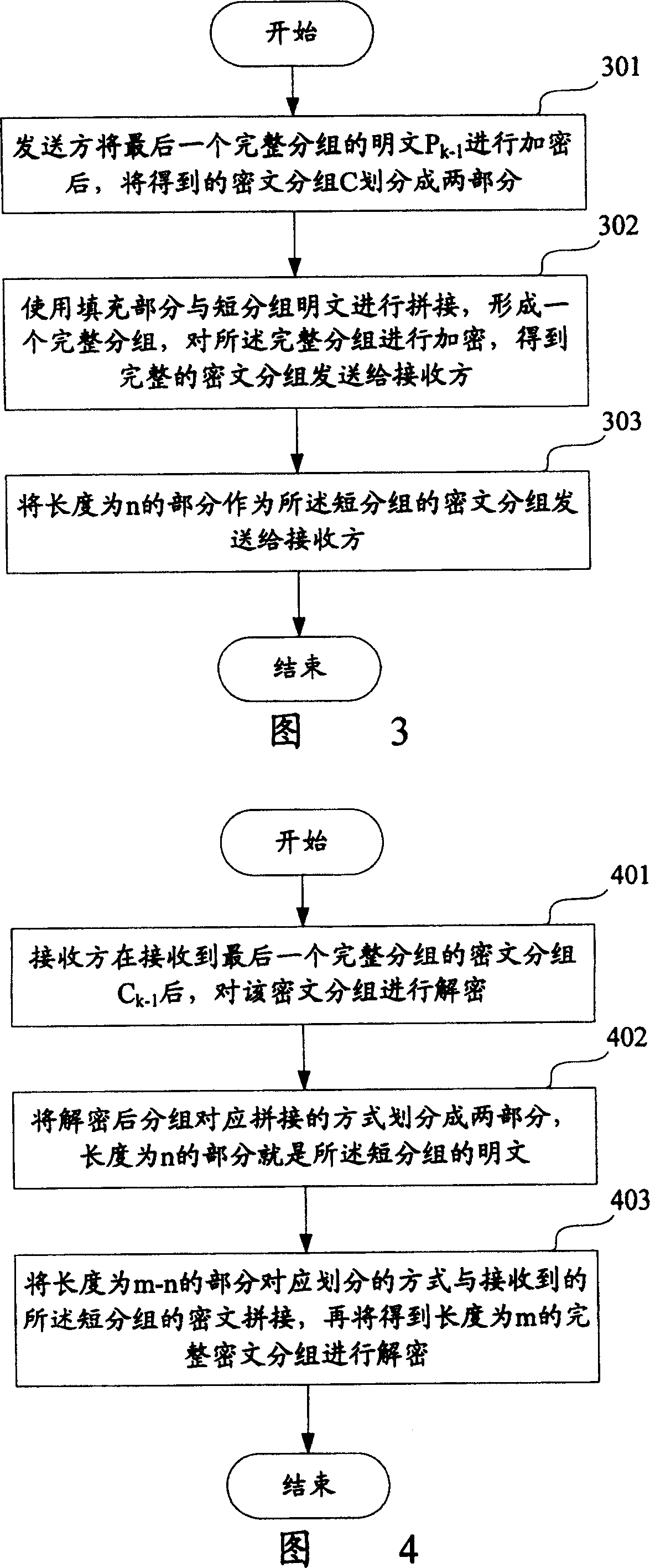

Short block processing method in block encryption algorithm

InactiveCN1323507CEnsure safetyGuaranteed transmission efficiencyEncryption apparatus with shift registers/memoriesPlaintextCiphertext

Owner:HUAWEI TECH CO LTD

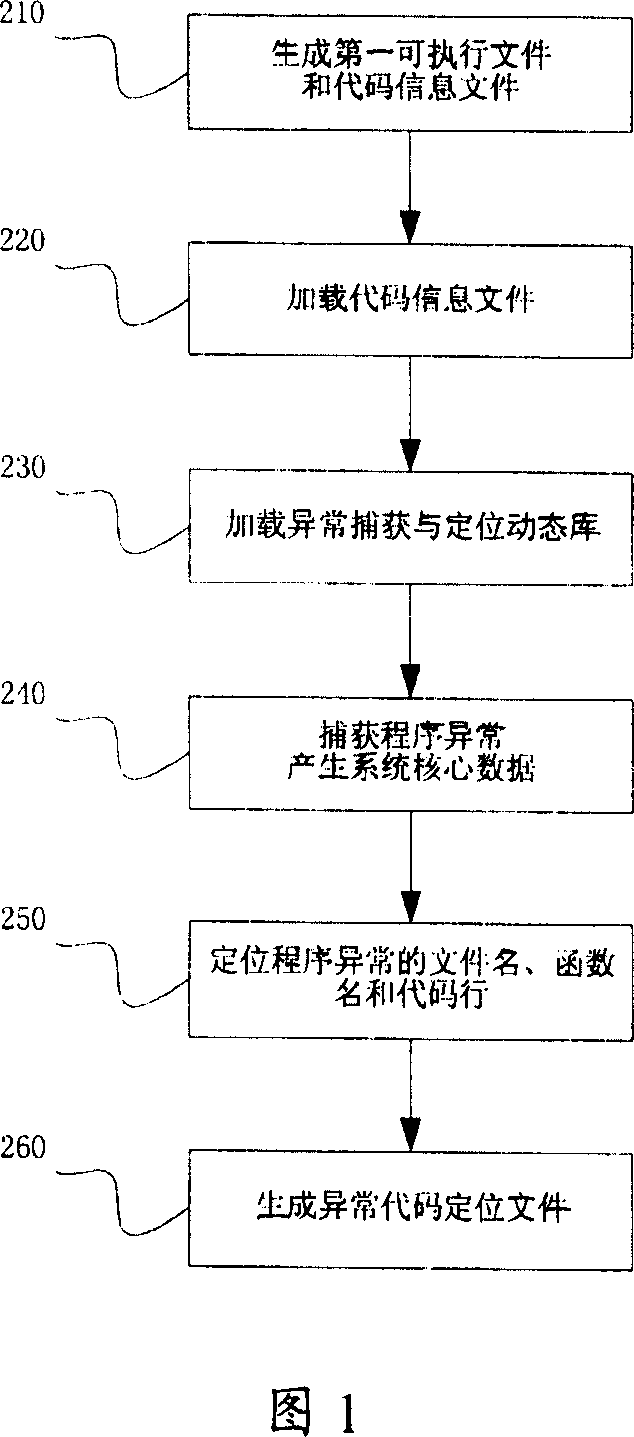

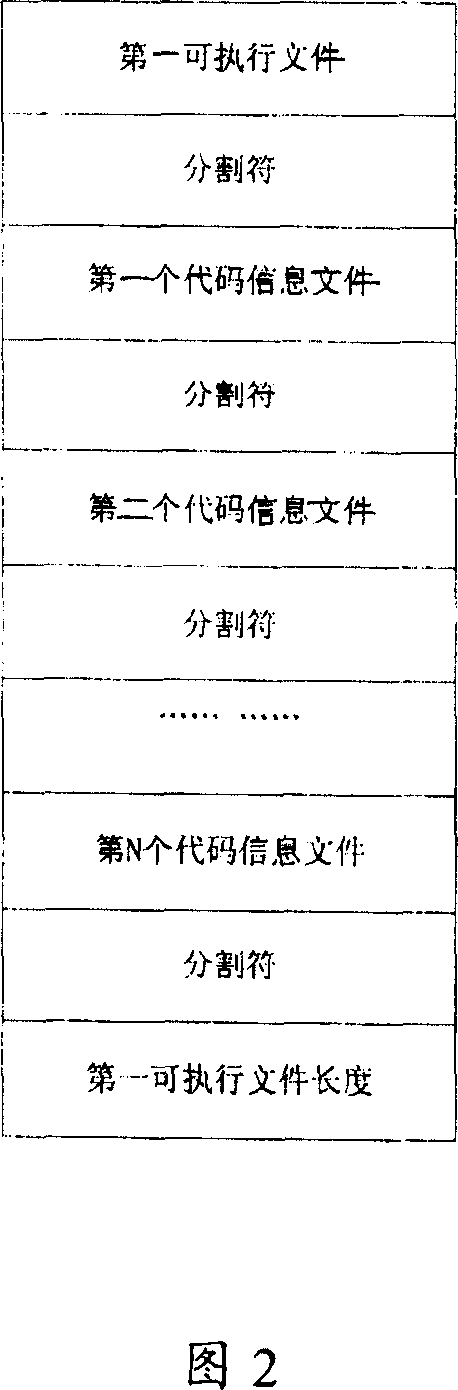

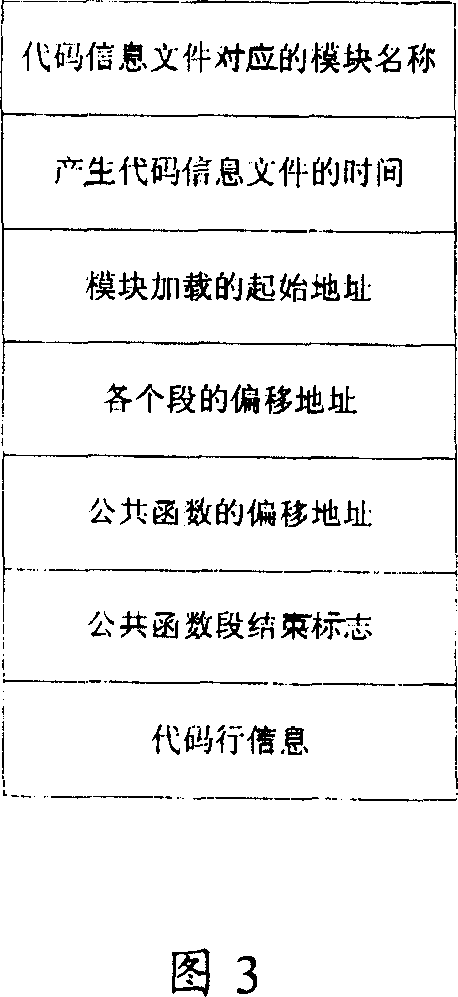

Method for locating program abnormity

InactiveCN1329836CImprove efficiencySimplified version management mechanismSoftware testing/debuggingMemory addressExecutable

Owner:HUAWEI TECH CO LTD

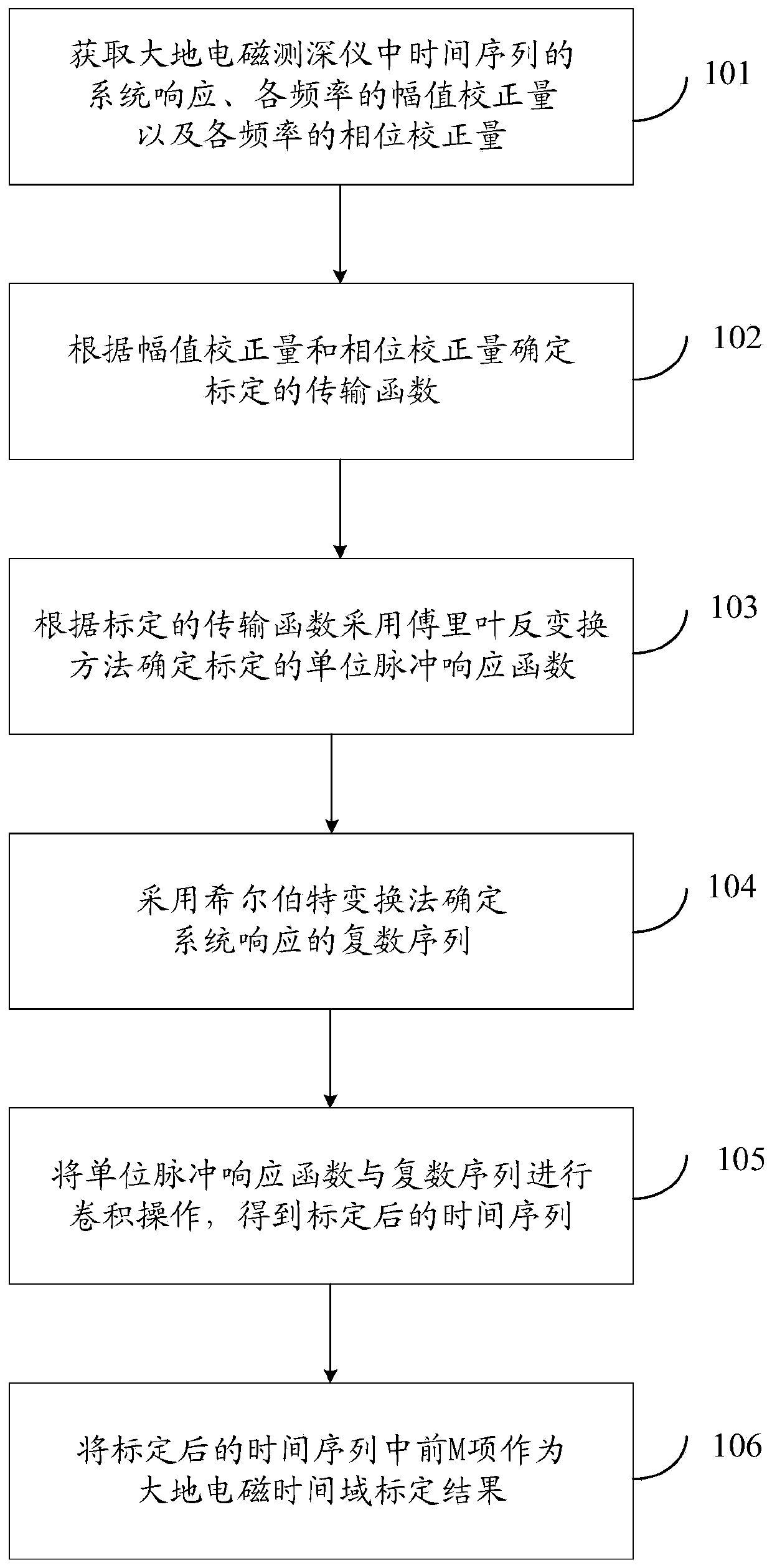

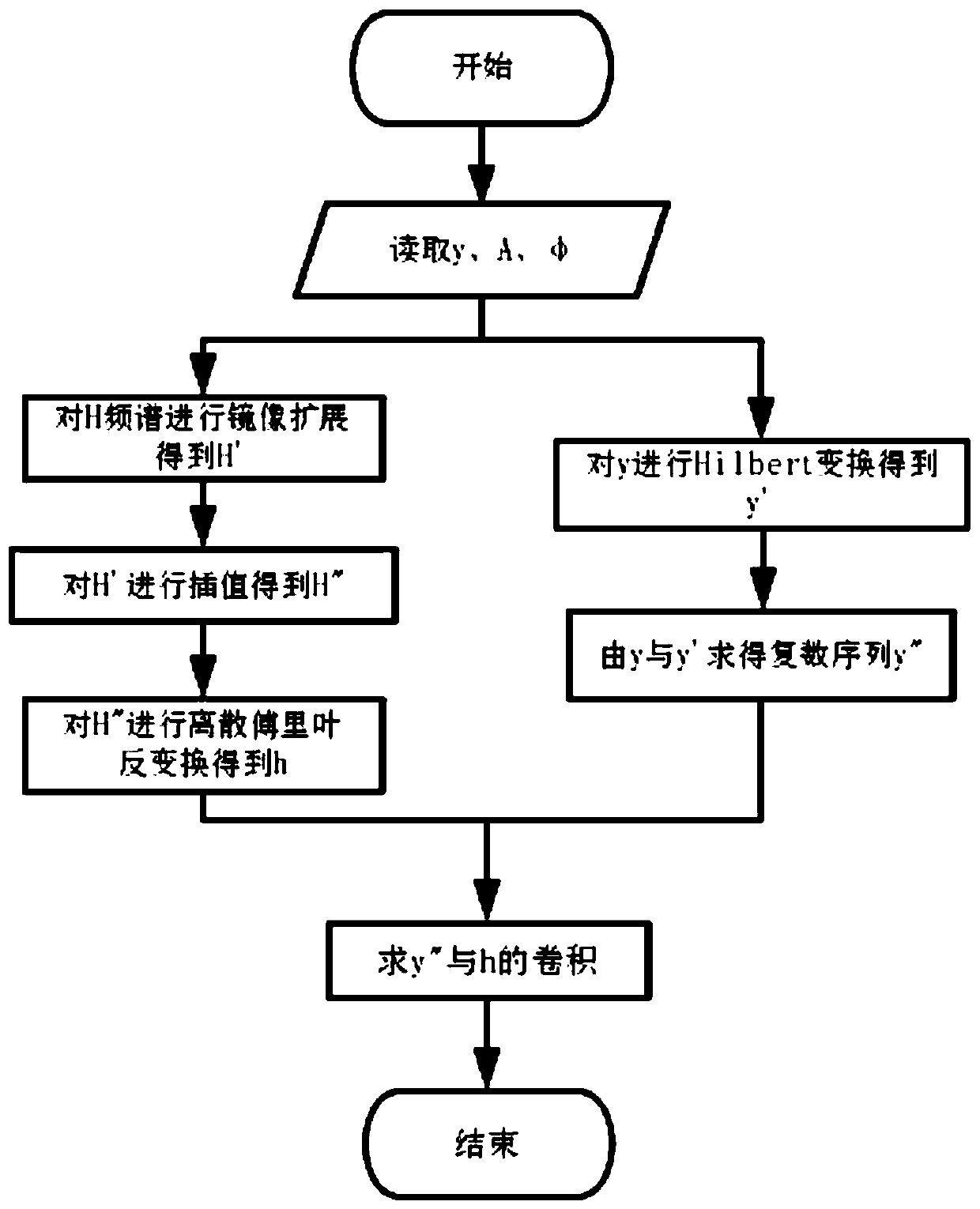

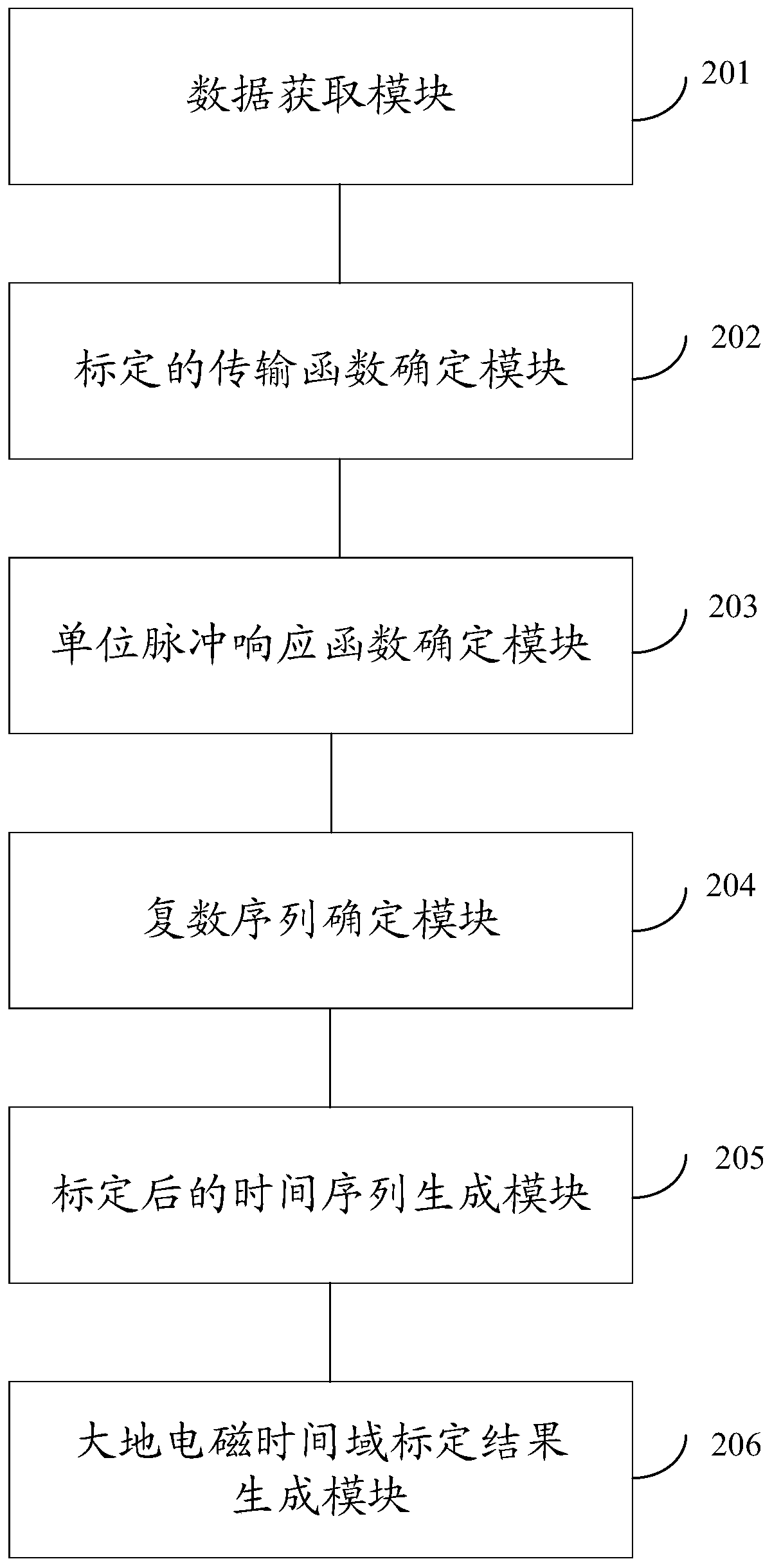

Magnetotelluric time domain calibration method and system

The invention discloses a magnetotelluric time domain calibration method and system. The method comprises the following steps: 1, ; the method comprises the following steps: acquiring a system response of a time sequence in the magnetotelluric depth finder, an amplitude correction value of each frequency and a phase correction value of each frequency; determining a calibrated transfer function according to the amplitude correction value and the phase correction value, determining a calibrated unit impulse response function by adopting an inverse Fourier transform method according to the calibrated transfer function, and determining a complex sequence of system response by adopting a Hilbert transform method; and performing convolution operation on the unit impulse response function and thecomplex sequence to obtain a calibrated time sequence. By adopting the method and the system provided by the invention, the time sequence can be directly calibrated, and the method and the system have the advantages of reducing the loss of effective signals and the residue of noise caused by filtering and enhancing the robustness of a time domain impedance estimation result.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com