A New Radiator Core Support Plate

A new type of radiator and support plate technology, applied in heat exchanger shells, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of increasing production costs, weakening strength, and the impact of core height, saving production costs, Beautiful appearance and simple structure

Inactive Publication Date: 2011-11-30

扬州英谛车材实业有限公司

View PDF11 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Automobile radiator manufacturers generally use expansion joints when producing radiator core support plates. The so-called expansion joints are a preventive measure to prevent the support plate from being damaged by the thermal stress caused by the thermal expansion and contraction of the radiator core. At present, the easiest way is to cut off the finished support plate, that is, to saw an opening on the surface of the support plate. This structure will not only cause the product appearance of the support plate to deteriorate, but also weaken the strength, and it will easily cut off the heat dissipation if the operation is careless. With a core, waste products are produced; another method is to symmetrically punch out pits on both sides of the surface of the support plate, so that the support plate has the function of stretching and contracting under the action of thermal stress. This structure requires an additional set of blanking dies and forming dies , which greatly increases the production cost, and after the support plate is sunken, the length of the finished product is not easy to control, and it is easy to affect the core height of the product

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

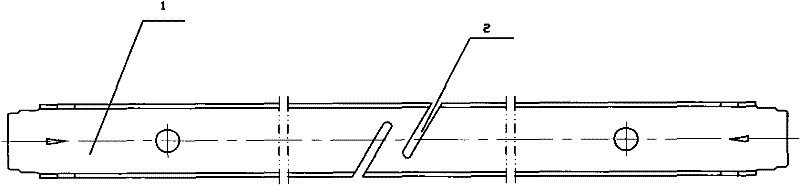

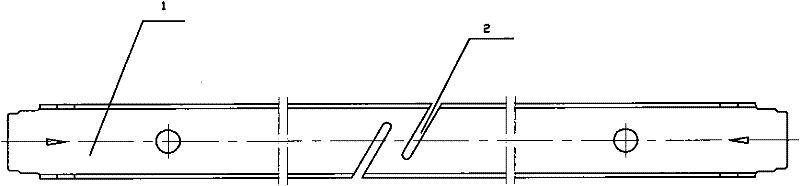

[0008] A new radiator core support plate, the support plate 1 is provided with two chute 2, the chute 2 extends from both sides of the support plate 1 to the middle of the support plate 1 and does not pass through the support plate 1 , the two chutes 2 are arranged parallel to each other.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a novel radiator core support plate. Two inclined slots are arranged on the support plate, and the inclined slots respectively extend from both sides of the support plate to the middle of the support plate and do not pass through the support plate. The present invention has beautiful appearance, simple structure and good strength. A chute is directly set on the surface of the support plate, without changing the length of the raw material, and can well control the total length of the support plate. Forming mold saves production cost.

Description

technical field [0001] The invention relates to an automobile radiator core support plate, in particular to a novel radiator core support plate. Background technique [0002] Automobile radiator manufacturers generally use expansion joints when producing radiator core support plates. The so-called expansion joints are a preventive measure to prevent the support plate from being damaged by the thermal stress caused by the thermal expansion and contraction of the radiator core. At present, the easiest way is to cut off the finished support plate, that is, to saw an opening on the surface of the support plate. This structure will not only cause the product appearance of the support plate to deteriorate, but also weaken the strength, and it will easily cut off the heat dissipation if the operation is careless. With a core, waste products are produced; another method is to symmetrically punch out pits on both sides of the surface of the support plate, so that the support plate ha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F28F9/007

Inventor 翁文锺毛霞牧野张敦虎纪长伟王定刘斌

Owner 扬州英谛车材实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com