Manufacturing method of variable cross-section pipe fitting

A manufacturing method and variable cross-section technology, applied in the field of variable cross-section pipe fittings, can solve the problems of surface cracks, troubles, shortened service life, etc., and achieve the effect of no change in length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] The manufacturing method of variable cross-section pipe fittings according to the present invention, plate blanking→heating→die extrusion→welding extruded slabs into variable cross-section pipe fittings→heat treatment→checking shape and trimming and grinding→rough machining→flaw detection→adjustment Quality→finishing→inspection→delivery, where the blanking of the sheet is to cut the sheet into two slabs, and the upper mold and the lower mold are used in the die extrusion step, after the slab is placed in the lower mold, the upper mold The slab exerts a downward force so that the slab is squeezed between the upper die and the lower die until the half wall of the variable section pipe is formed.

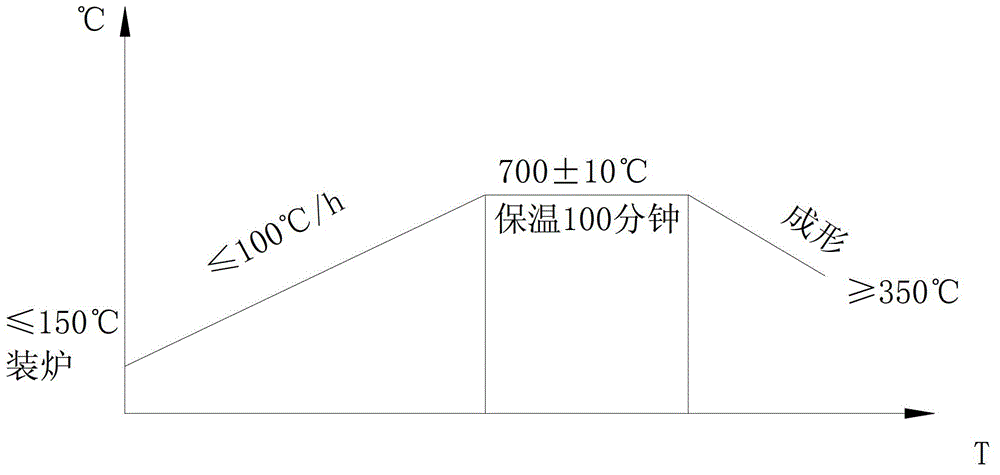

[0012] like figure 1 As shown, the slab is heated in a furnace below 150°C, heated to 700±10°C at a heating rate of ≤100°C / hour and kept for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com