Axial cages for cylindrical rolling elements

An axial retaining and rolling element technology, applied in rolling contact bearings, rotating bearings, roller bearings, etc., can solve the problem of increasing the manufacturing cost of the axial cage, increasing the structural space of the axial cage, and increasing the axial retention. rack manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

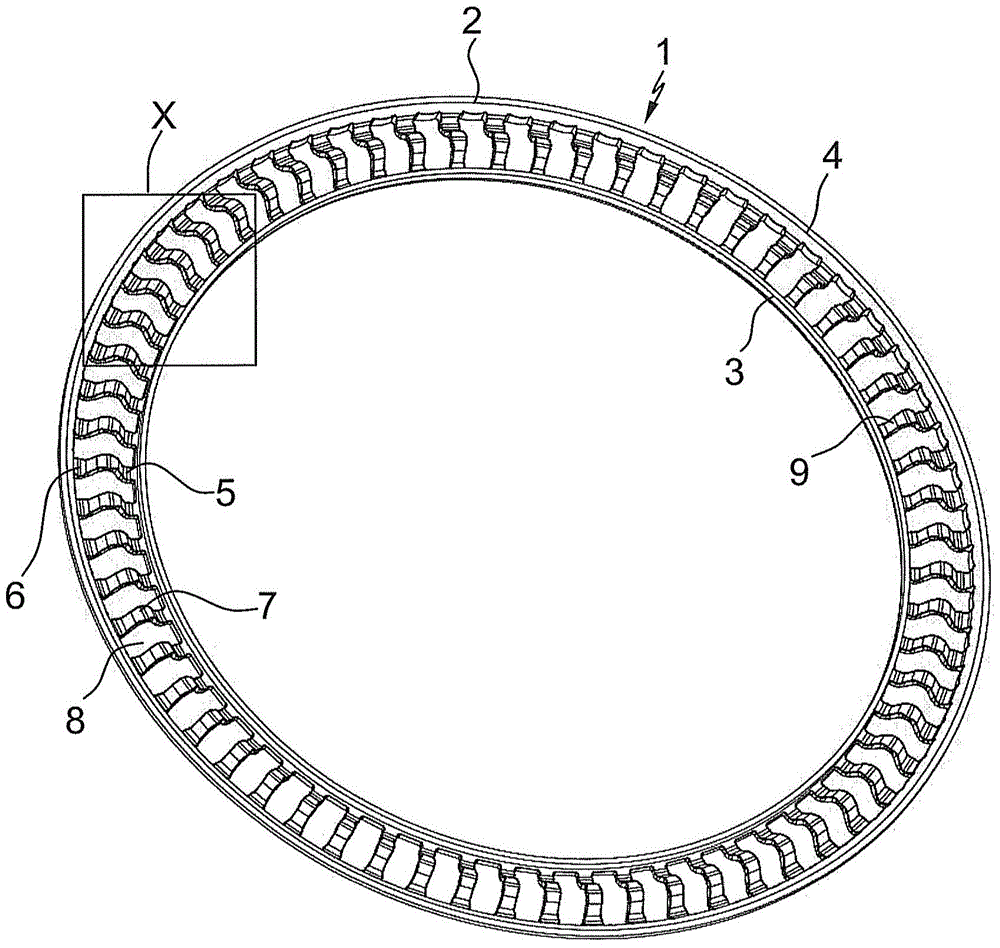

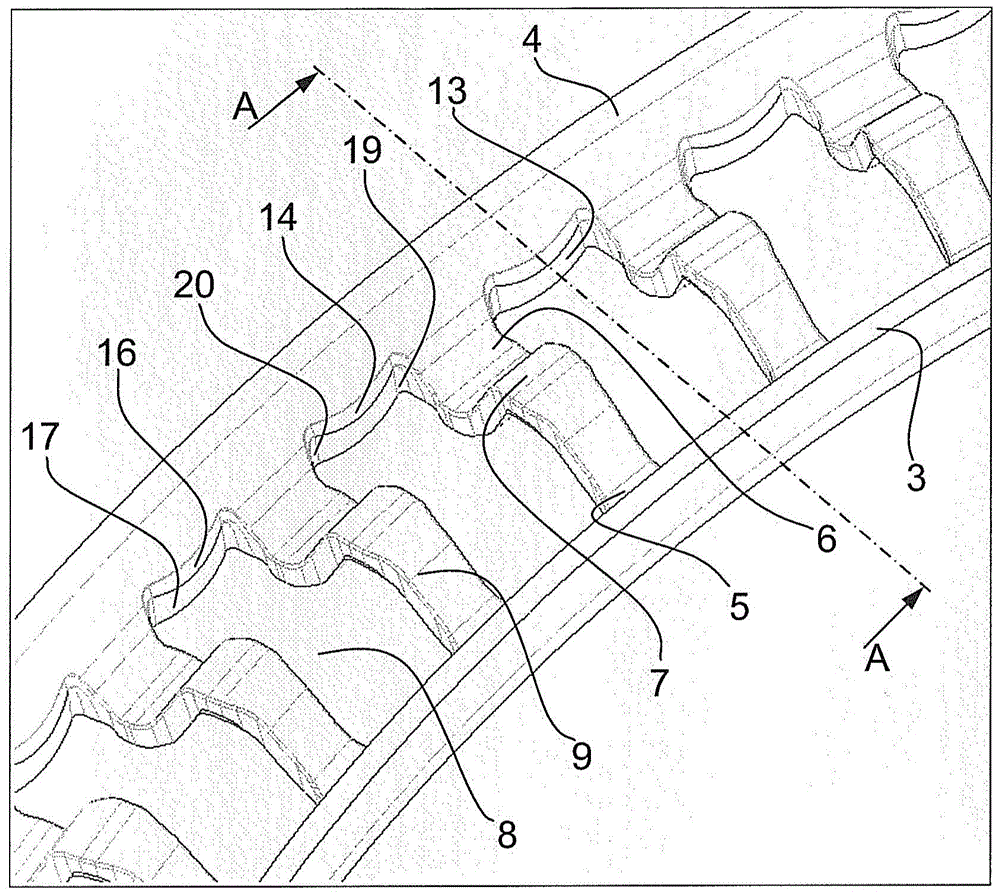

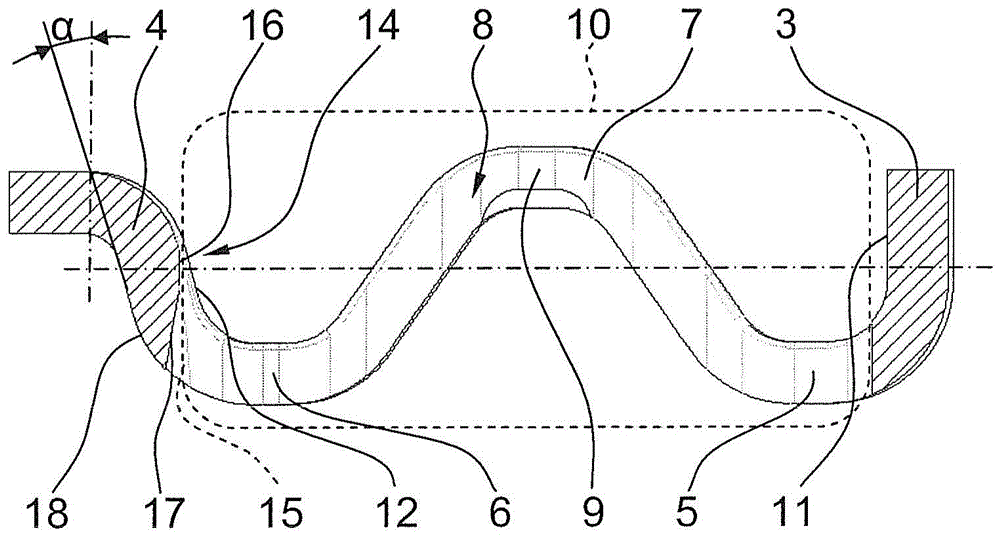

[0019] Depend on figure 1 An axial cage 1 suitable for an axial needle roller bearing is obtained, which substantially consists of a thin-walled annular disk 2, like in particular image 3 As clearly shown, the annular disk has a W-shaped profile cross-section. In addition, in figure 1 In combination image 3It can be seen that from the inner radial edge 3 formed on the inner edge of the annular disk 2, the outer radial edge 4 formed on the outer edge of the annular disk 2 and by the inner axial contour section 5 and the outer axial The individual profile sections of the axial cage 1 are formed by the U-shaped turnup 7 of the profile section 6 connected to the rims 3 , 4 , which U-shaped turnup has the same radial extension as the rims 3 , 4 . In addition, by figure 1 and figure 2 It is evident that the bead 7 and the adjoining axial profile sections 5 , 6 result in a plurality of rectangular cage pockets 8 evenly spaced from one another, between which cage pockets an eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com