Bi-directional anti-seepage lead bush

A bushing and taper bushing technology, which is applied in the field of two-way anti-seepage lead bushing and lead bushing, can solve the problems of incomplete anti-seepage and achieve the effect of improving anti-seepage ability and large degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with examples of implementation.

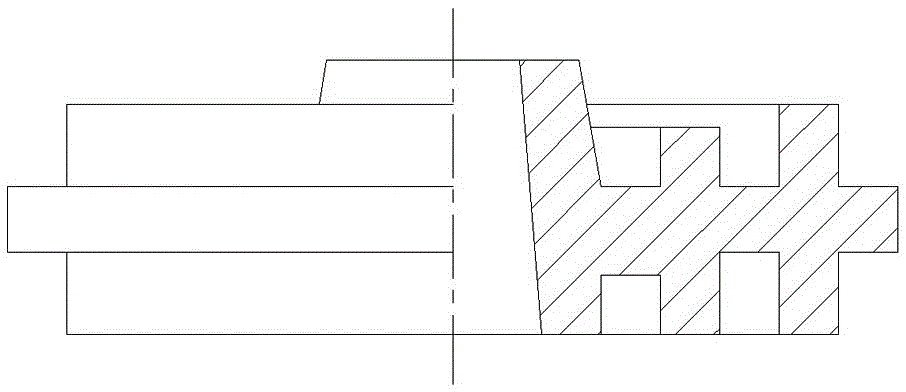

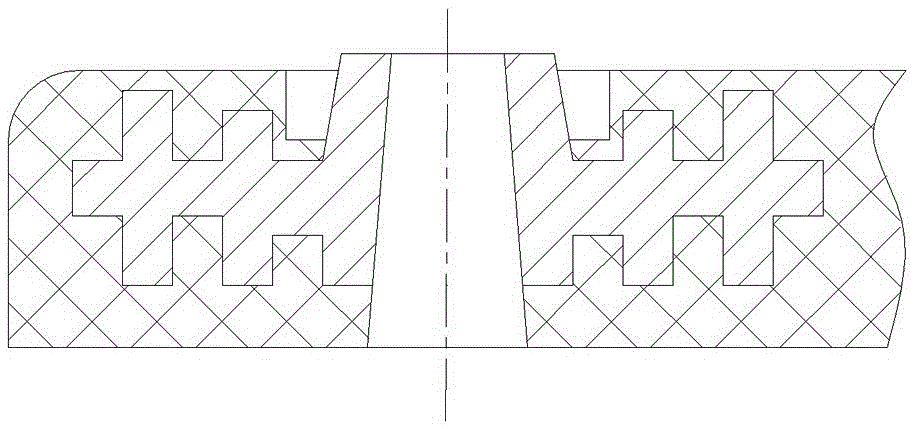

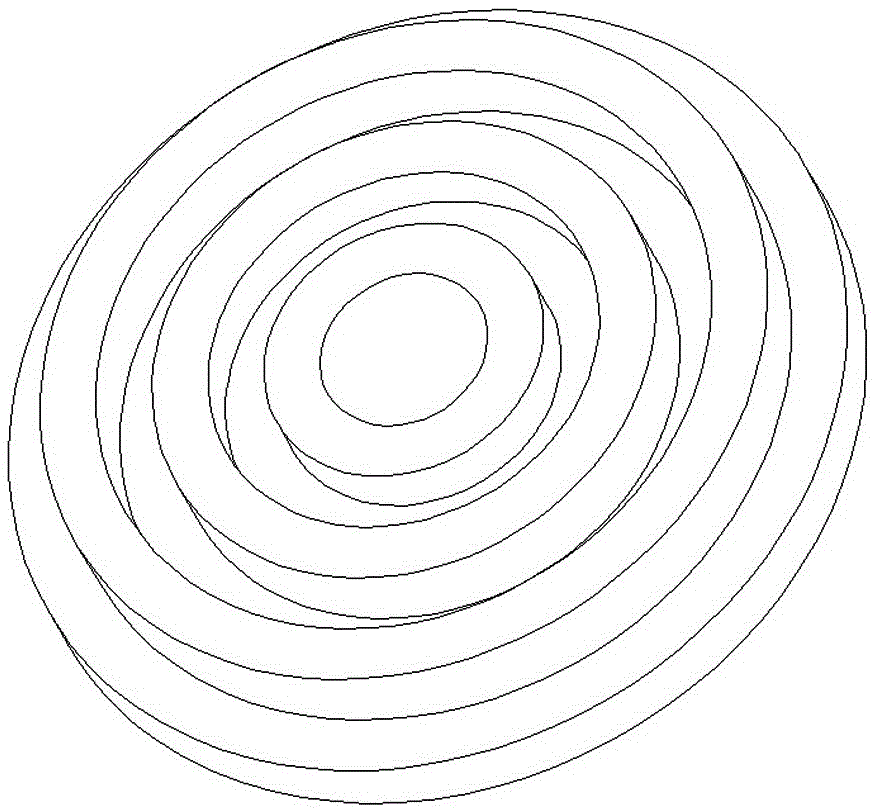

[0016] The two-way anti-seepage lead bushing shown in the attached figure is a part to ensure the airtightness of the lead-acid battery. This part is implanted in the housing for positioning and installation of the terminals. The lead bushing is a flange-shaped component, with an axial taper sleeve in the center, and a radially protruding round edge connected to the taper sleeve, and integrated concentric circular shoulders with alternating concave and convex on the upper and lower end faces of the round edge. In this embodiment, due to the relatively small specifications of the supporting lead-acid battery, the upper and lower ends of the round edge are only provided with such figure 1 As shown in the two integrated concentric circular shoulders, a radially protruding circular shoulder is provided on the outer wall of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com