Swing type stable tension buffering method and device for carbon fiber prepreg tape

A tension buffer device and carbon fiber prepreg technology, which is applied in transportation and packaging, winding strips, thin material processing, etc., can solve the problems of tension fluctuations in prepreg tapes and tension fluctuations during buffering, and achieve stable and low tension values. The effect of tension fluctuation and reasonable space allocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

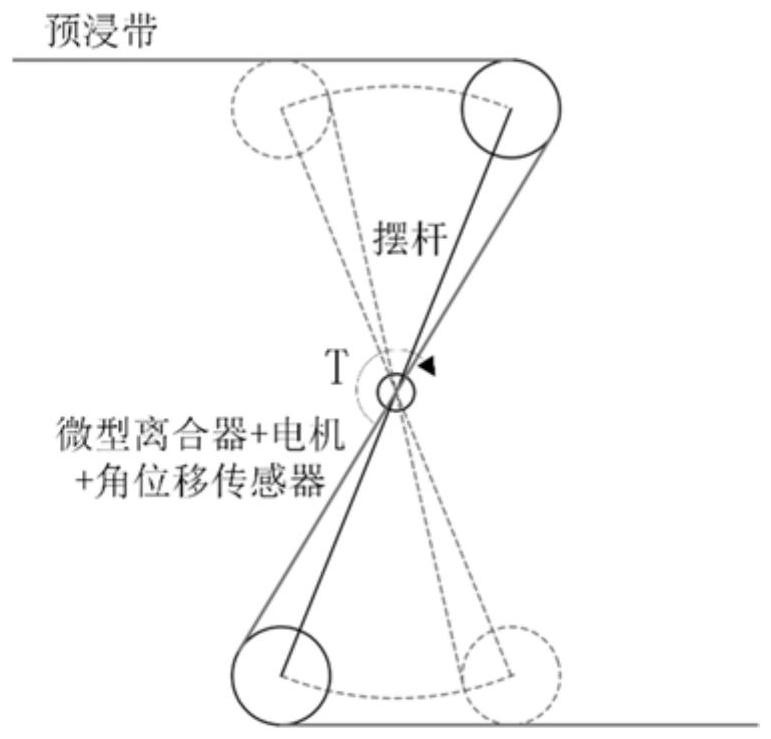

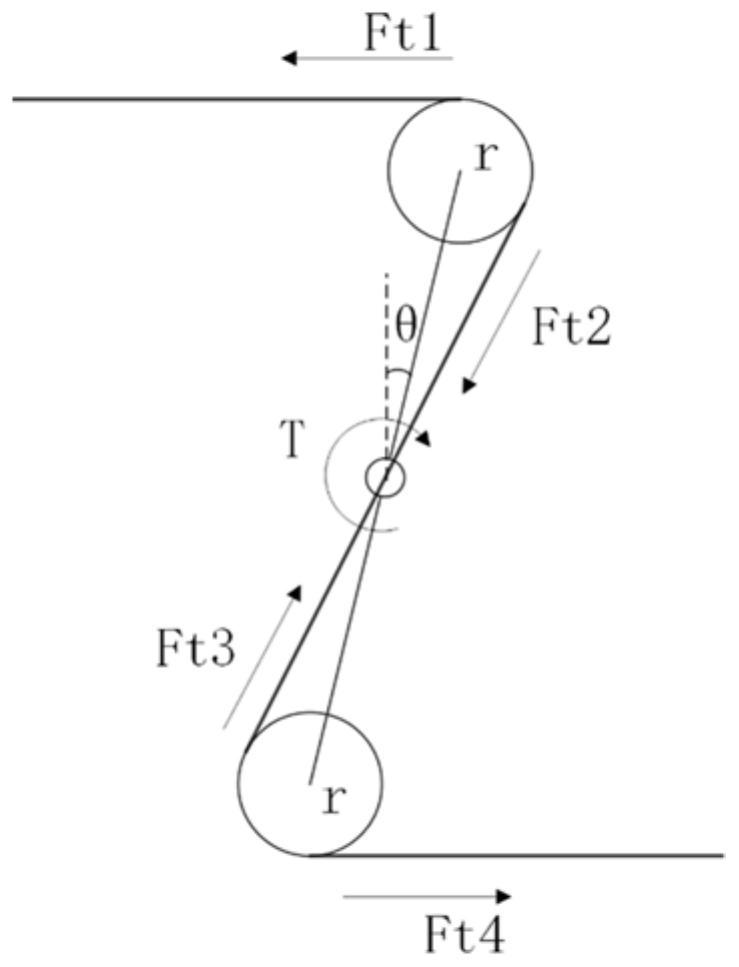

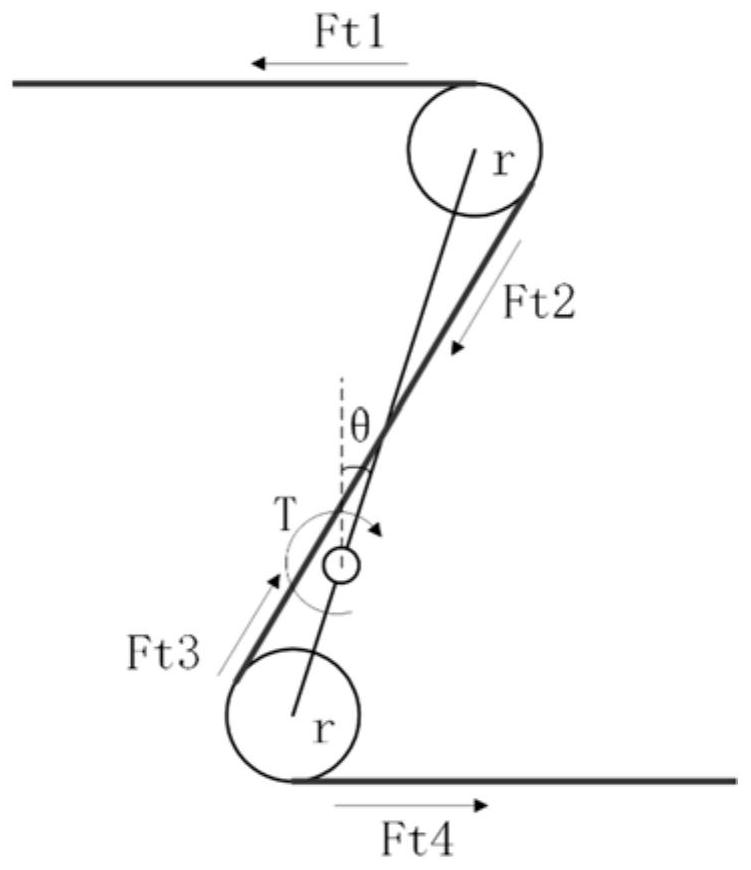

[0033] see figure 1 , the principle of a carbon fiber prepreg tape swing type small tension buffering method of the present invention is as follows: the buffering motor continues to rotate at a constant speed, drives the clutch or coupling to maintain a slipping state, and transmits a stable clockwise driving torque to the swing rod , the prepreg tape bypasses the guide wheels at both ends of the pendulum in a Z form. Due to the tension of the prepreg tape, the prepreg tape exerts a counterclockwise torque on the pendulum. This torque and the driving torque are mutually balanced torques. , the driving torque remains stable, and the tension of the prepreg tape remains stable.

[0034] When laying, if the laying speed of the prepreg tape is inconsistent with the feeding speed, it usually shows that the laying speed exceeds the feeding speed. Due to the speed differenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com