Patents

Literature

91 results about "Screen techniques" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoelectric devices and methods for making the same

InactiveUS6121539AMaximize heat flowMaximize flowThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsScreening techniquesThermal energy

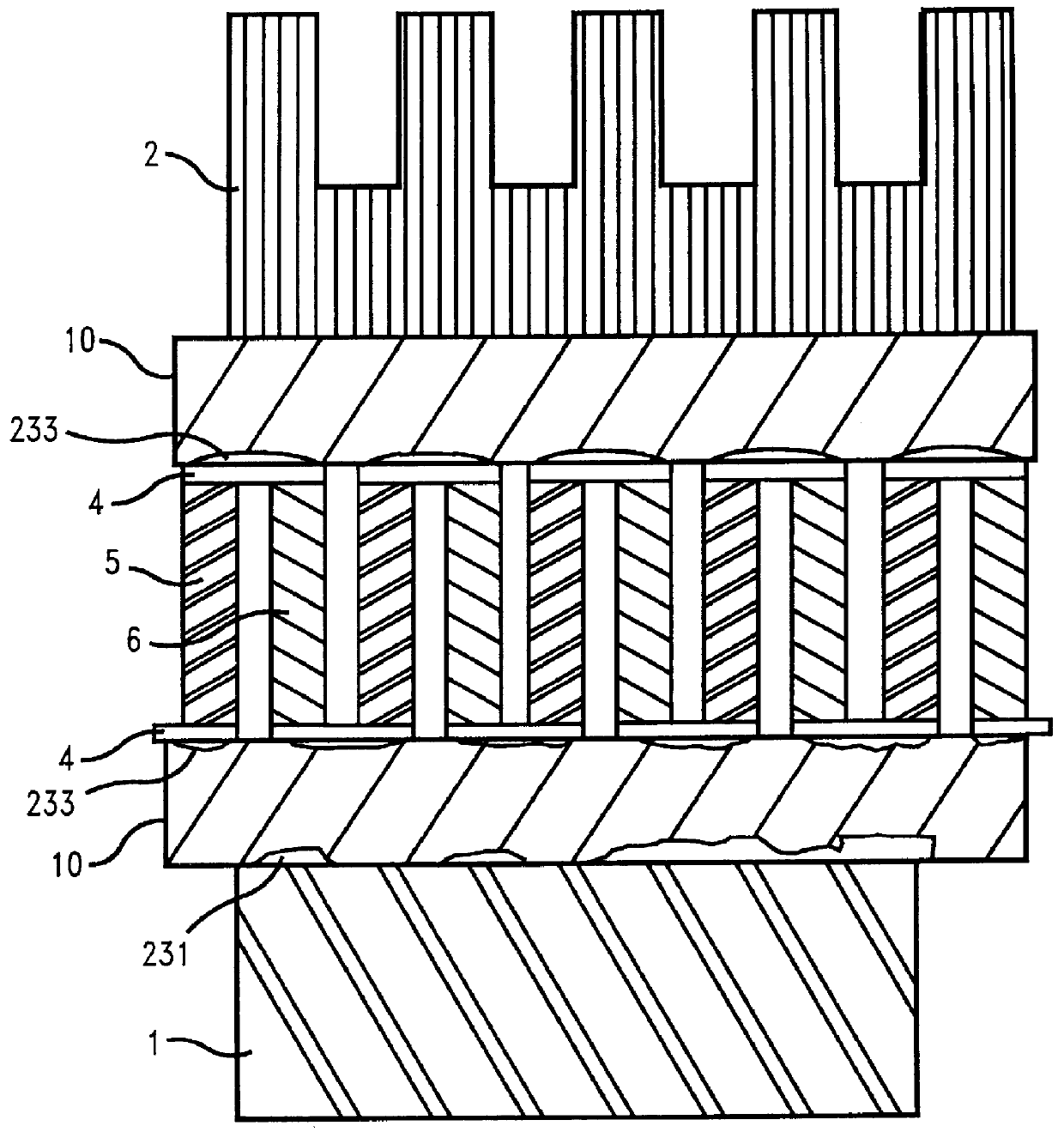

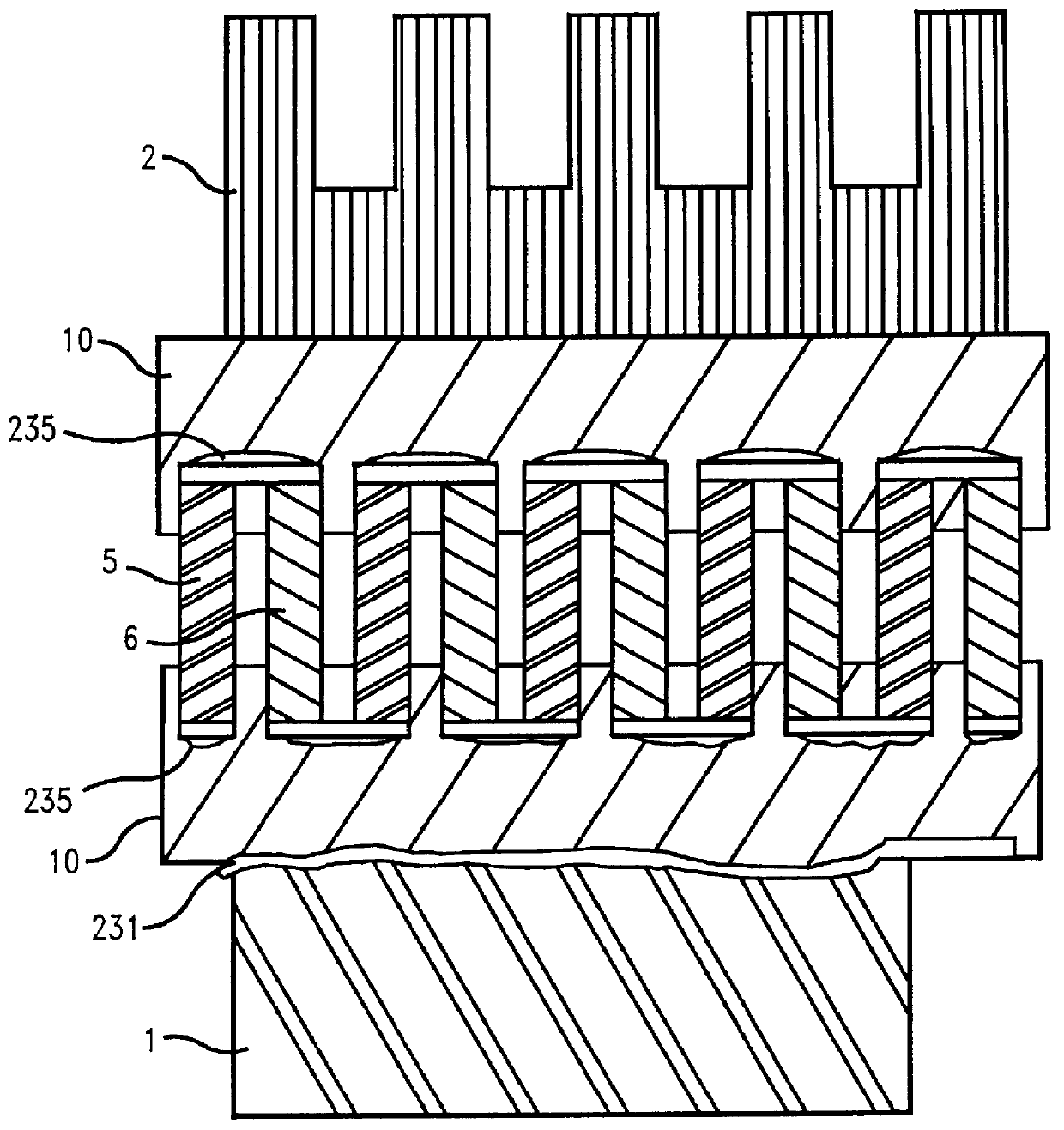

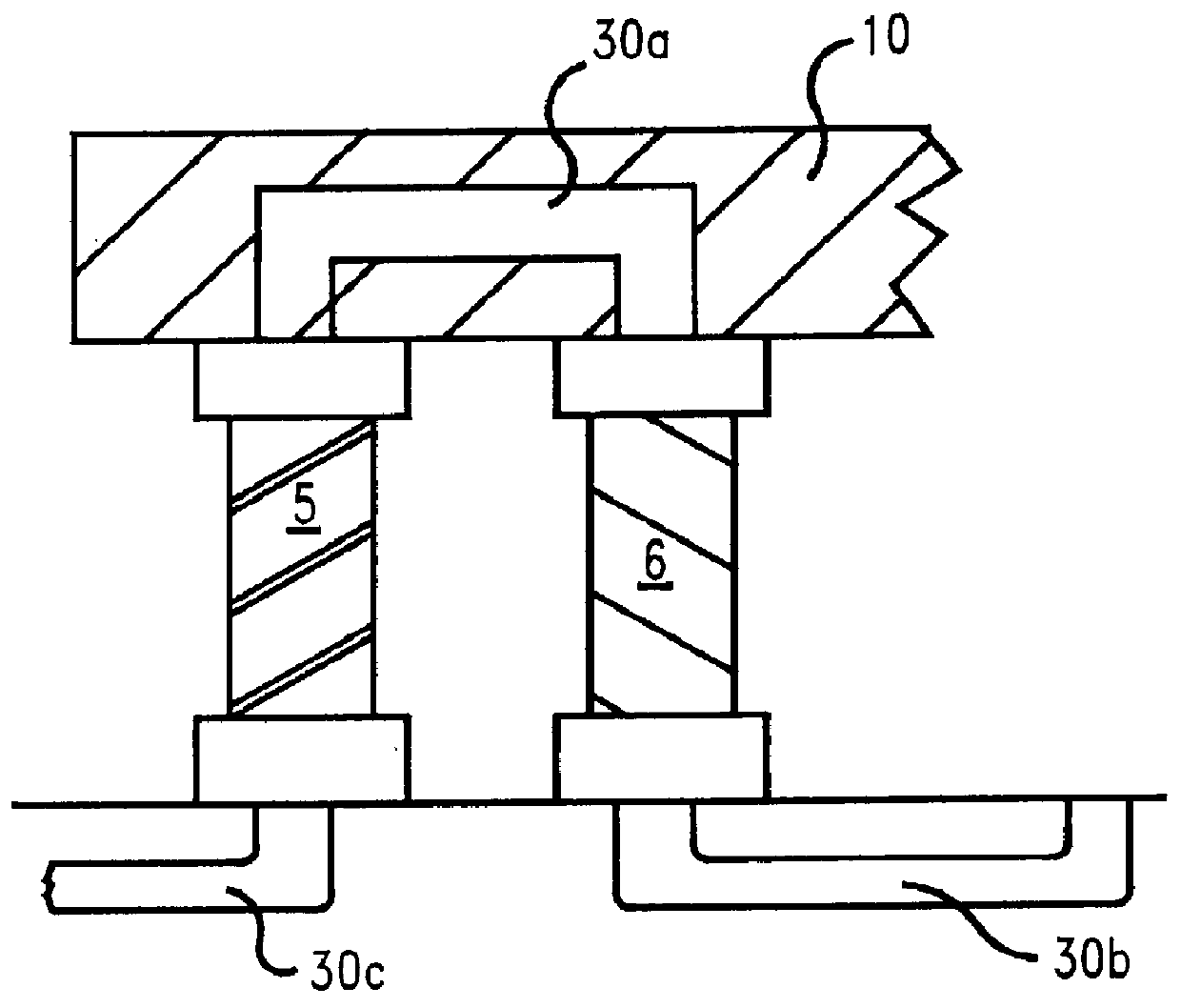

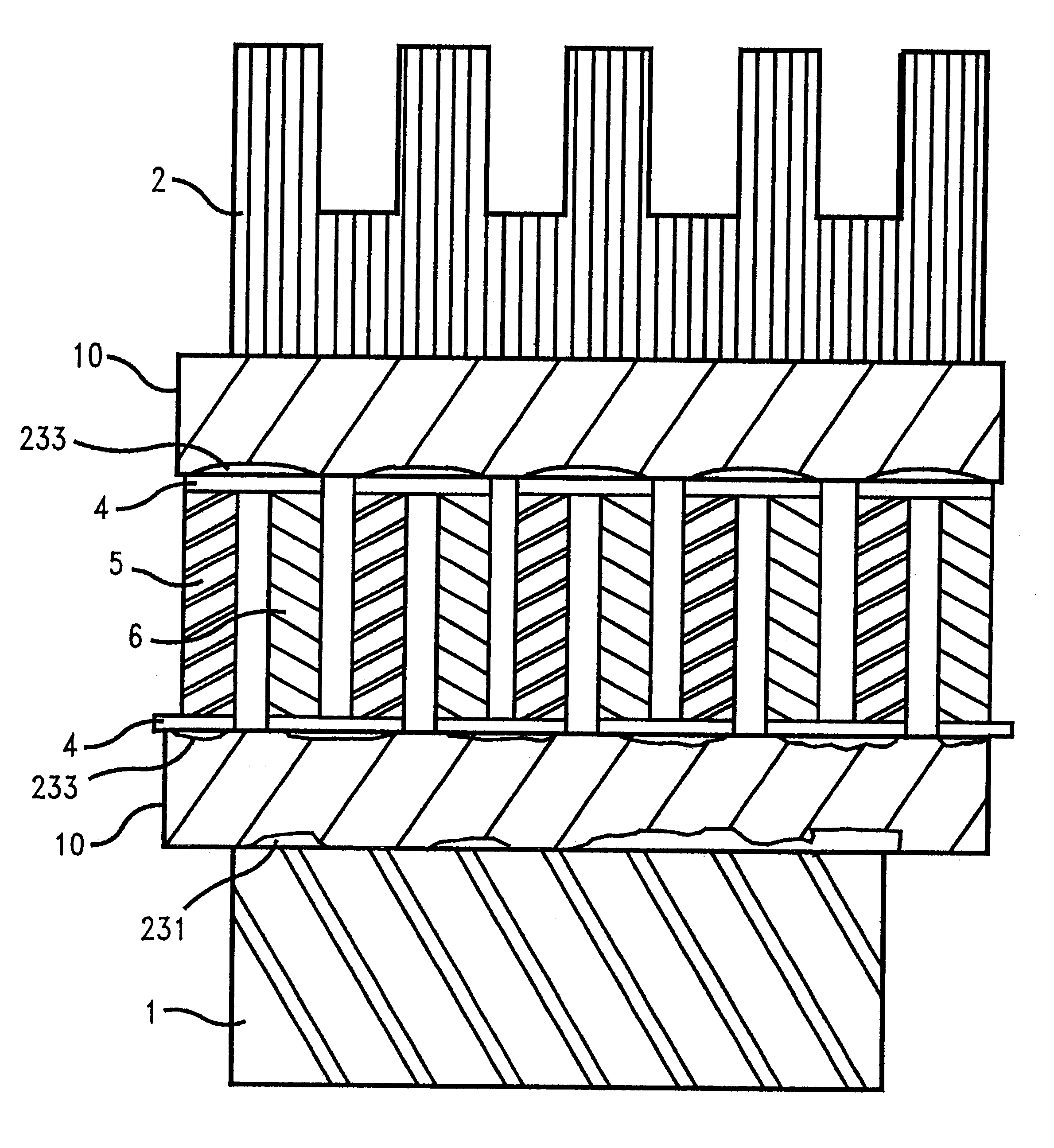

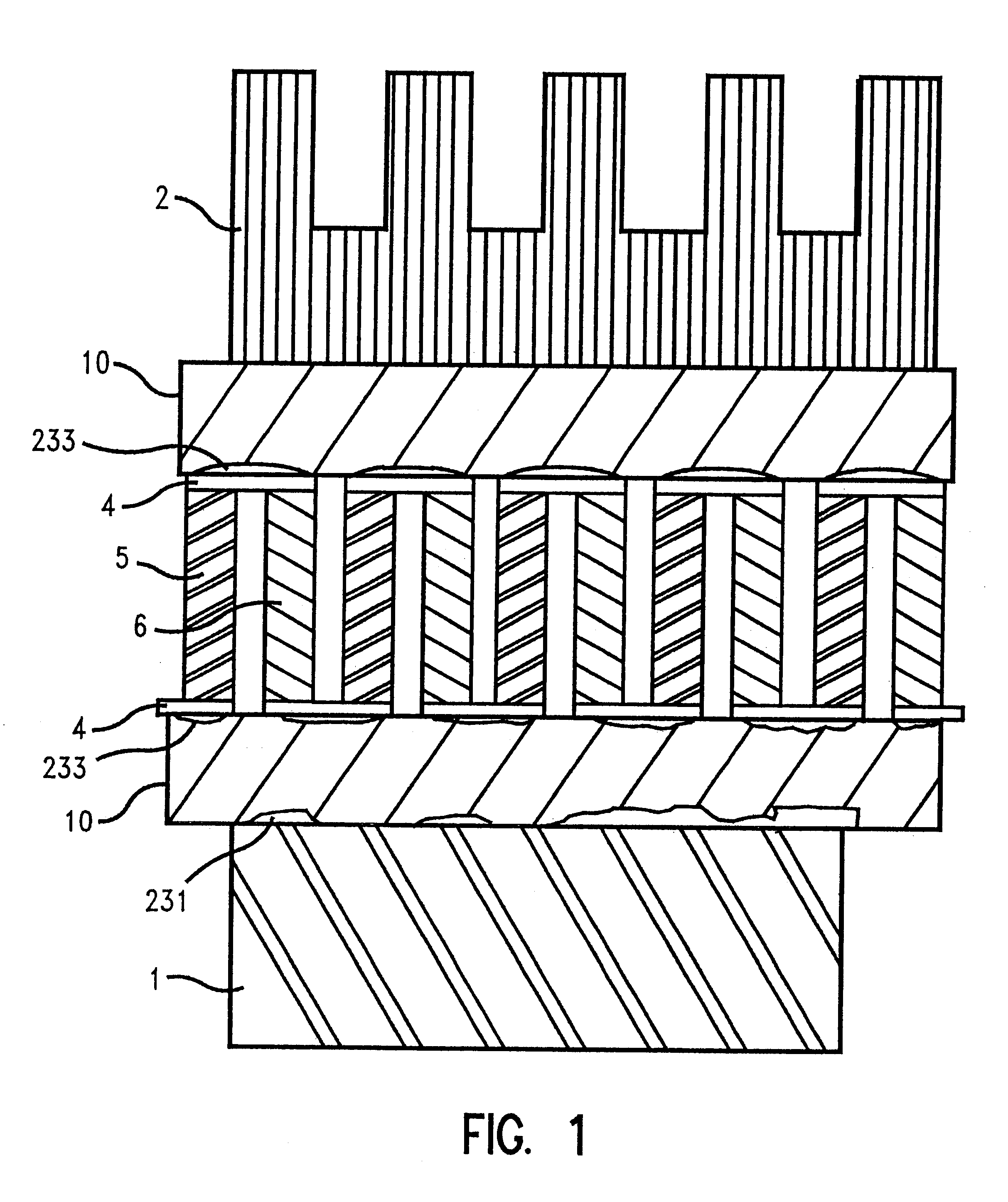

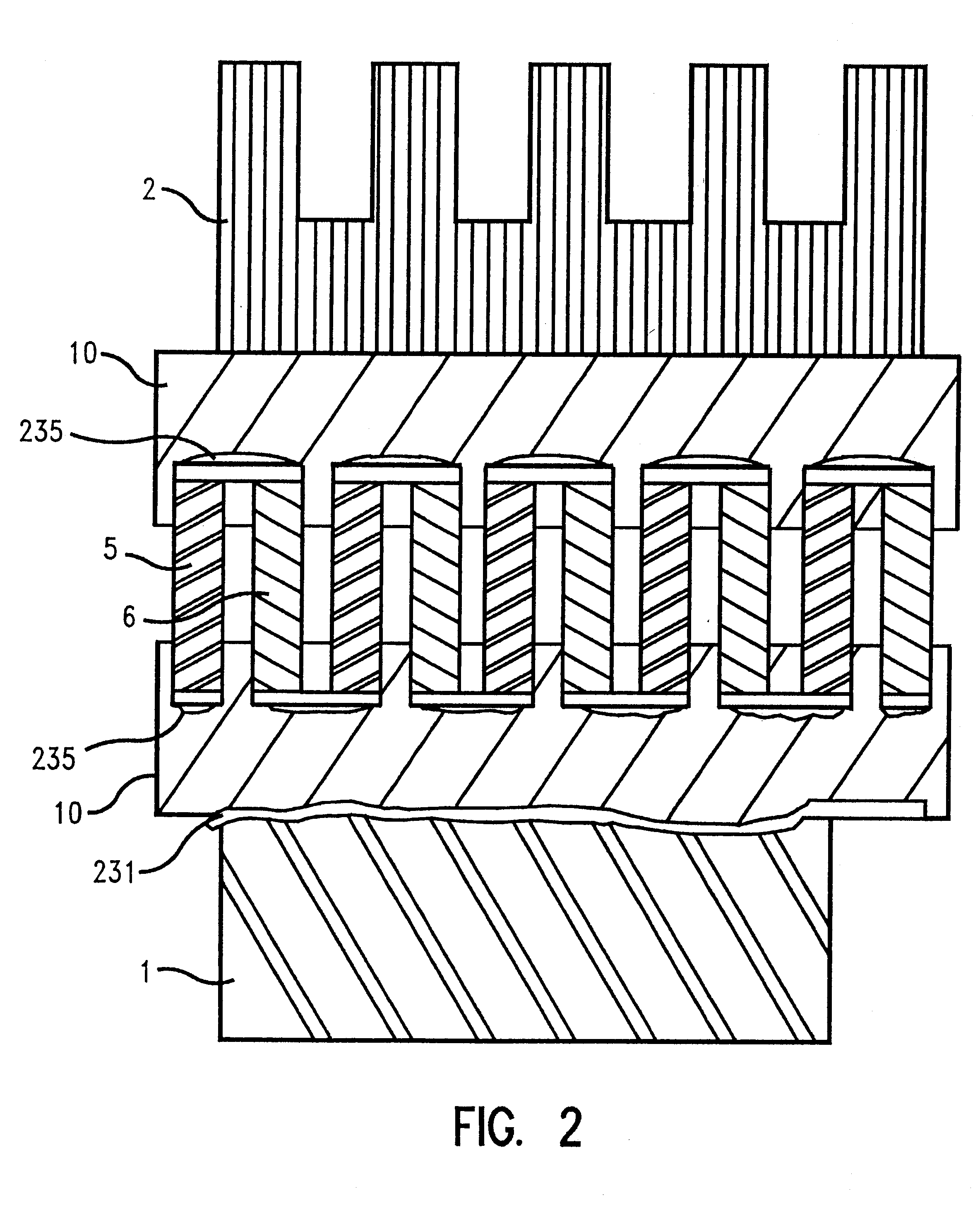

Thermoelectric devices having enhanced thermal characteristics are fabricated using multilayer ceramic (MLC) technology methods. Aluminum nitride faceplates with embedded electrical connections provide the electrical series configuration for alternating dissimilar semiconducting materials. Embedded electrical connections are formed by vias and lines in the faceplate. Methods are employed for forming tunnels through lamination and etching. A portion of the dissimilar materials are then melted within the tunnels to form a bond. Thermal conductivity of the faceplate is enhanced by adding electrically isolated vias to one surface, filled with high thermal conductivity metal paste. A low thermal conductivity material is also introduced between the two high thermal conductivity material faceplates. Alternating semiconducting materials are introduced within the varying thermal conductivity layers by punching vias within greensheets of predetermined thermal conductivity and filling with n-type and p-type paste. Alternating semiconducting materials may also be patterned in linear or radial fanout patterns through screening techniques and lamination of wire structures. A liquid channel within the faceplate is used to enhance thermal energy transfer. Thermoelectric devices are physically incorporated within the IC package using MLC technology.

Owner:IBM CORP

Thermoelectric devices and methods for making the same

InactiveUS6262357B1Maximize heat flowMaximize flowThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsThermal energyScreening techniques

Thermoelectric devices having enhanced thermal characteristics are fabricated using multilayer ceramic (MLC) technology methods. Aluminum nitride faceplates with embedded electrical connections provide the electrical series configuration for alternating dissimilar semiconducting materials. Embedded electrical connections are formed by vias and lines in the faceplate. Methods for forming tunnels through lamination and etching are employed. A portion of the dissimilar materials are then melted within the tunnels to form a bond. Thermal conductivity of the faceplate is enhanced by adding electrically isolated vias to one surface, filled with high thermal conductivity metal paste. A low thermal conductivity material is also introduced between the two high thermal conductivity material faceplates.Alternating semiconducting materials are introduced within the varying thermal conductivity layers by punching vias within greensheets of predetermined thermal conductivity and filling with n-type and p-type paste. Alternating semiconducting materials may also be patterned in linear or radial fanout patterns through screening techniques and lamination of wire structures. A liquid channel within the faceplate is used to enhance thermal energy transfer.Thermoelectric devices are physically incorporated within the IC package using MLC technology.

Owner:INT BUSINESS MASCH CORP

Digital positioner for electric controlled valve and method thereof

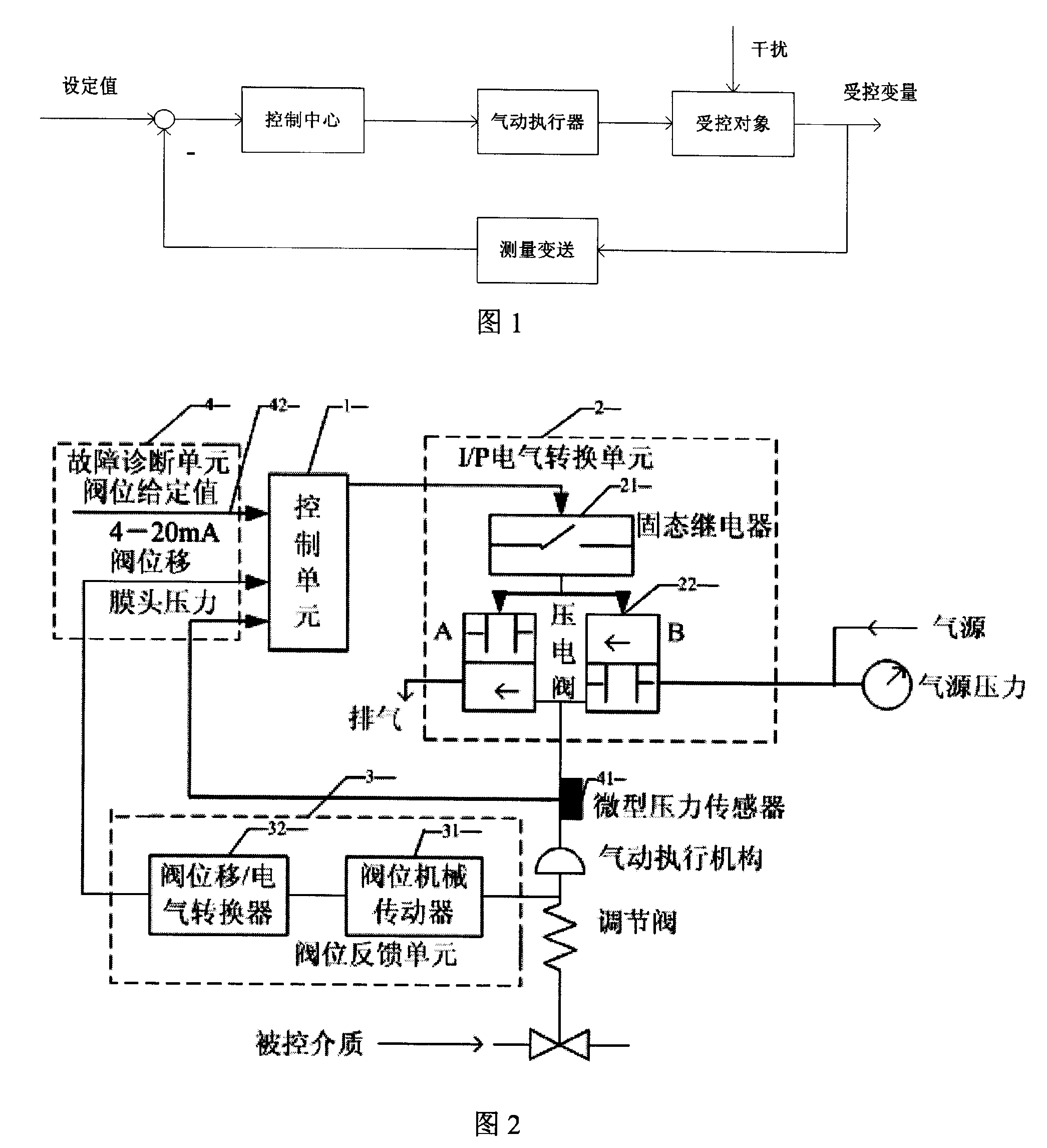

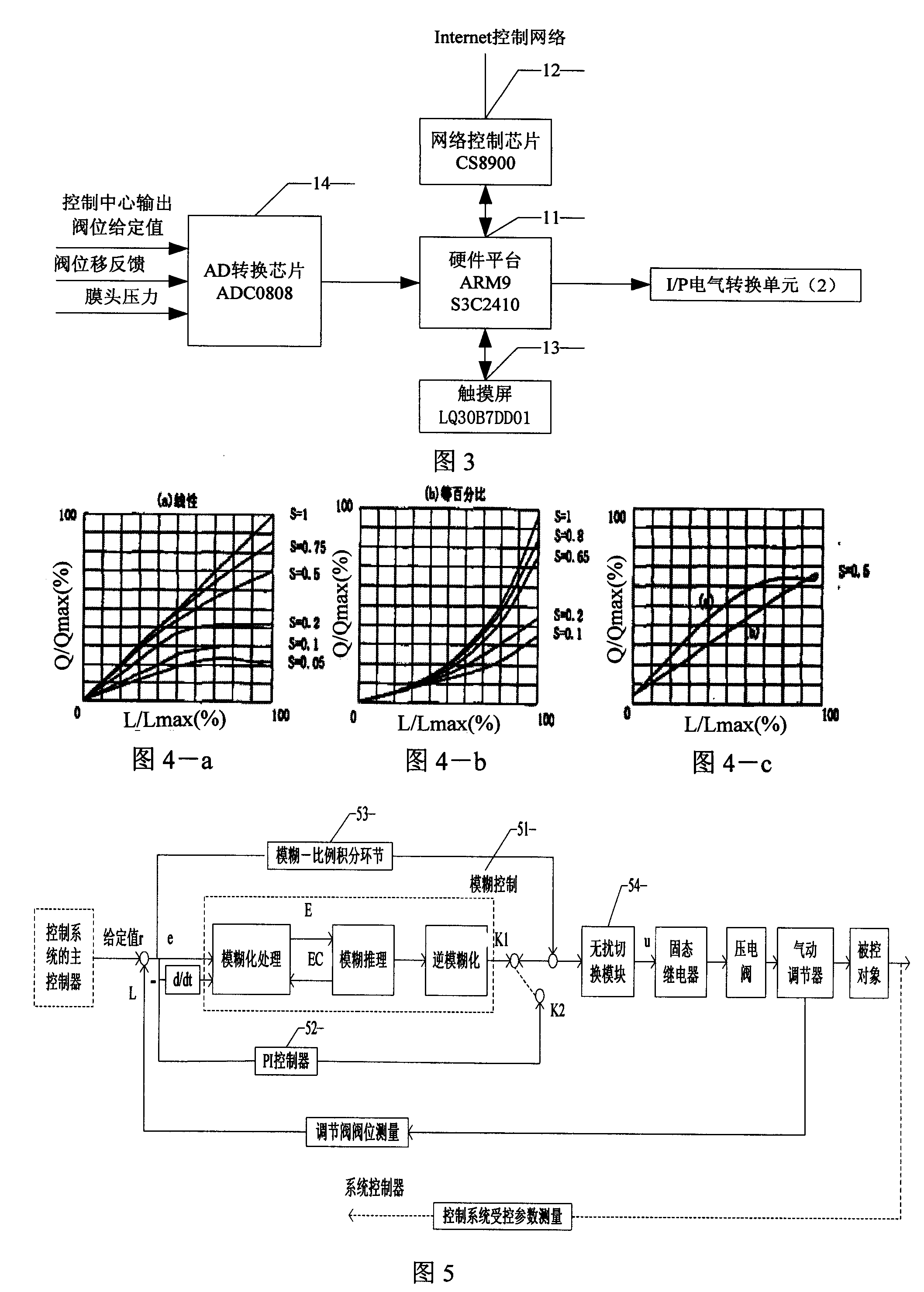

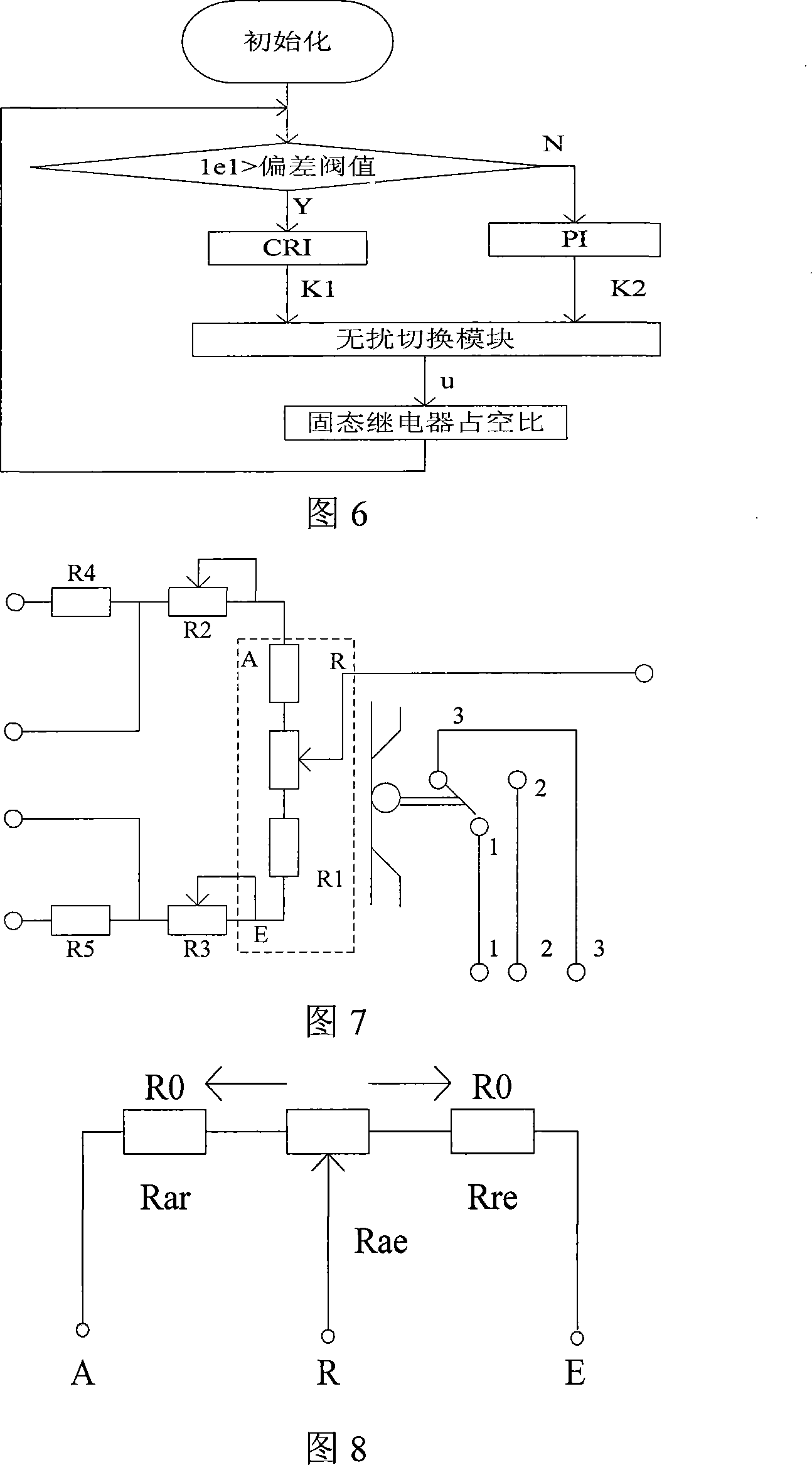

InactiveCN101245871AImprove qualityWon't interfereOperating means/releasing devices for valvesControl using feedbackDual modeEngineering

The invention discloses a digital electric valve positioner and a method thereof. The positioner consists of a control unit, an I / P electric conversion unit, a valve position feedback unit and a malfunction diagnosis unit. By the configuration of the flux characteristic parameters of the positioner, the working flux characteristic aberration which is caused by the factors such as a change of the pressure drop ratio of the adjusting valve, etc. is corrected, which is based on that a plurality of flux characteristics and action directions of the adjusting valve integration are provided. The control to the valve position of the adjusting valve is based on a Fuzzy-PI dual-mode no-interference shifting algorithm. Depending on the internal relationship between the valve position given value, the valve position feedback value and the valve film head pressure which are arranged by a control center and applying a rule-based knowledge reasoning, the malfunction diagnosis is realized through that the user selects to release or partly release the valve film head pressure during the stuck freeing operation. The valve displacement / electric conversion of the valve position feedback unit depends on a non-contact magnetic sensitive potentiometer. The man-machine interaction adopts a touch screen technique, and the control unit is accessed in a control network by an Ethernet interface.

Owner:ZHEJIANG UNIV

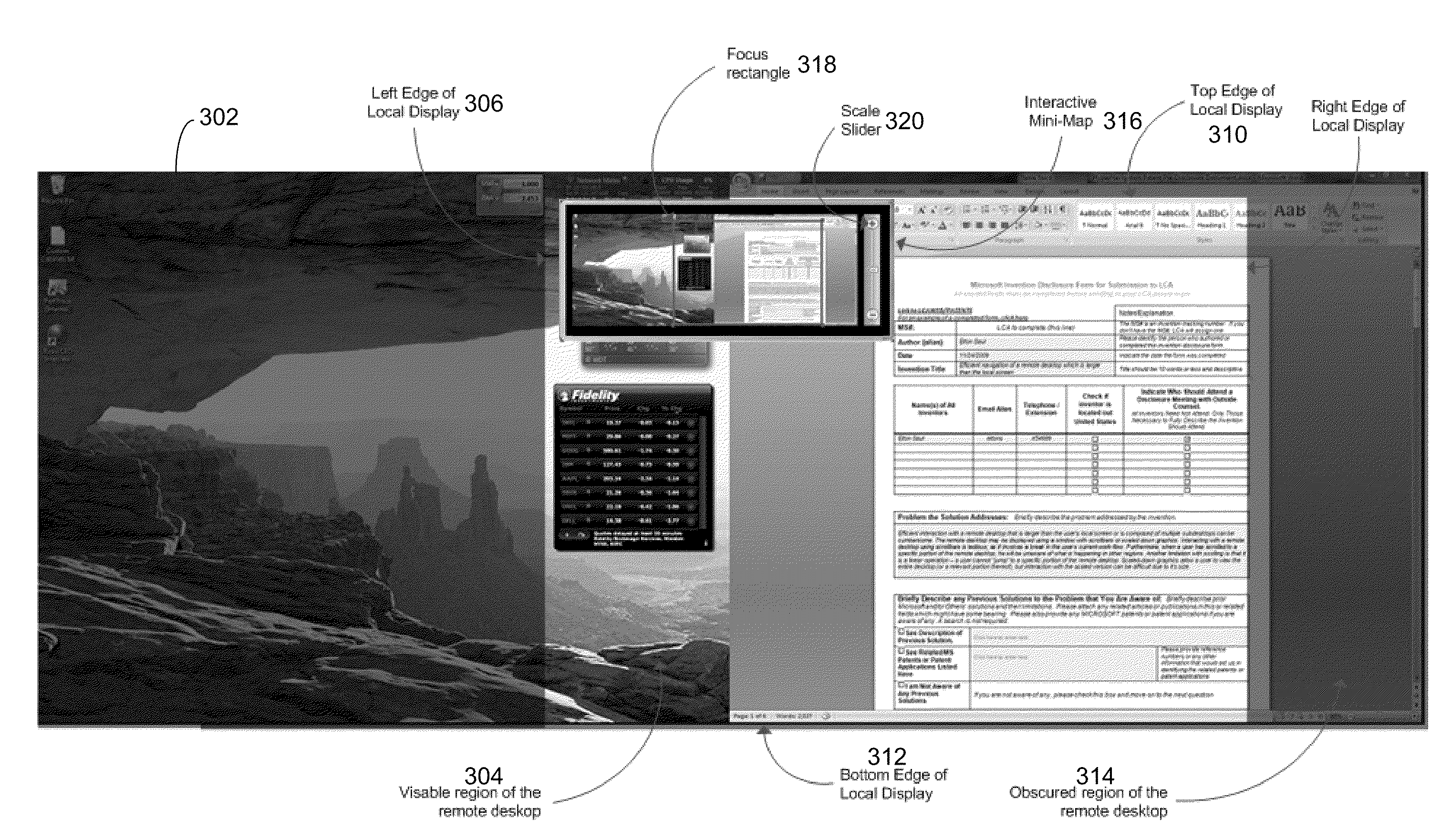

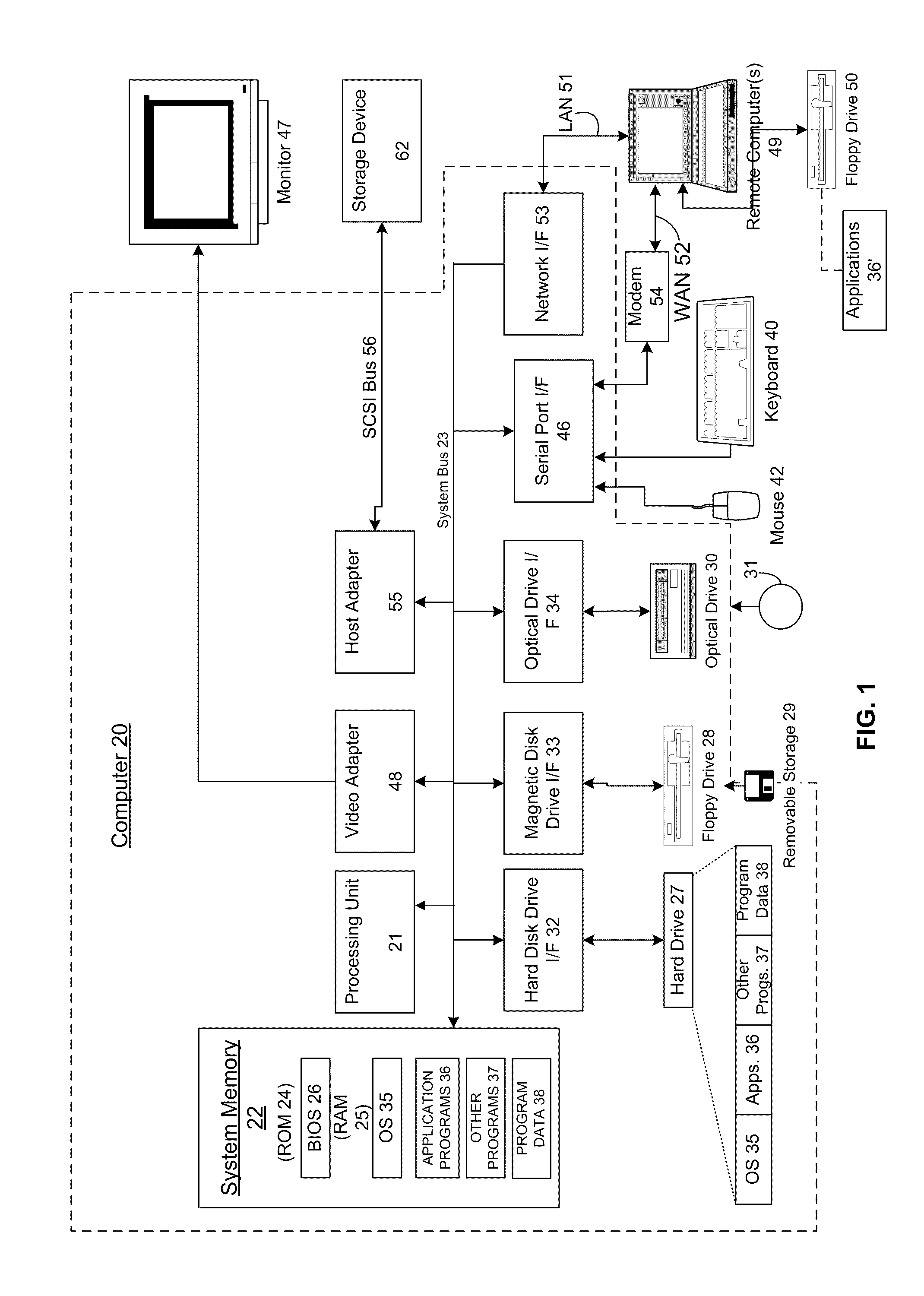

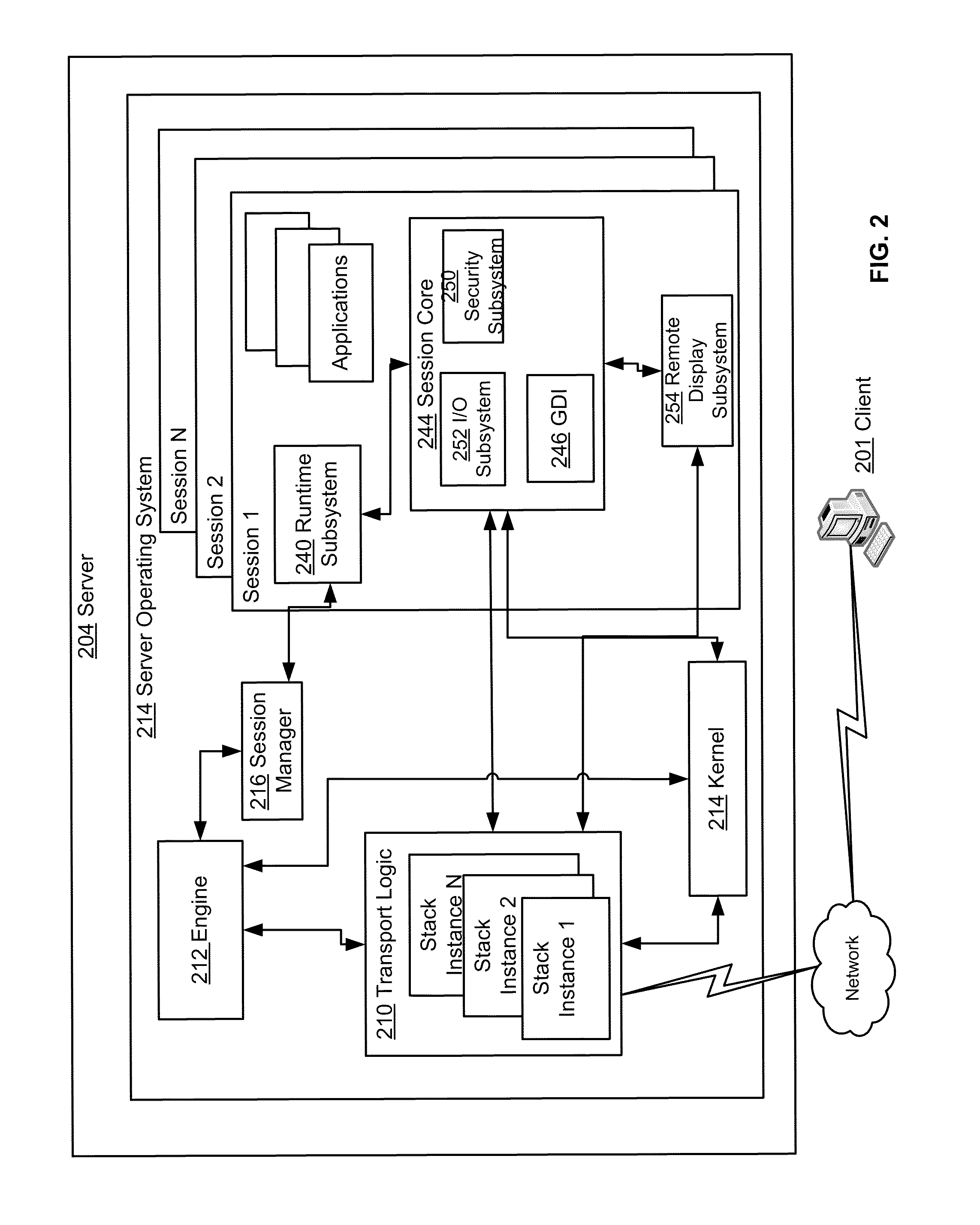

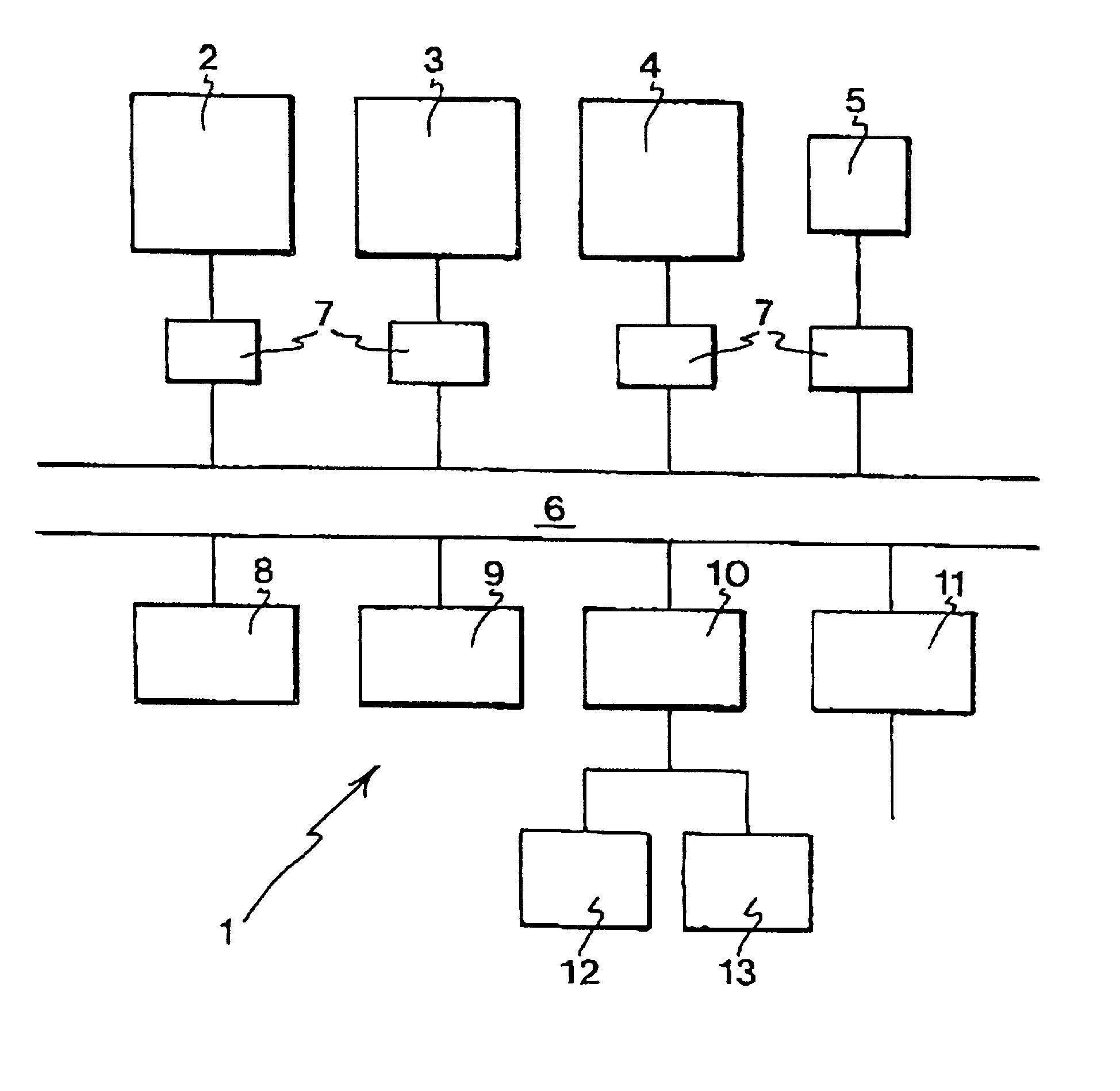

Efficient navigation of and interaction with a remoted desktop that is larger than the local screen

InactiveUS20110214063A1Input/output for user-computer interactionStatic indicating devicesRemote desktopClient-side

Techniques are disclosed for the efficient navigation of and interaction with a remoted desktop that is larger than the local viewing area. In an embodiment, a client displays both a portion of the remoted desktop in its native size, as well as a “mini-map”—a scaled-down view of the entire remoted desktop that may be used for navigation of the natively displayed portion of the remoted desktop. In an embodiment, the natively displayed portion of the remoted desktop is indicated in the mini-map. In an embodiment, use of a computer mouse and / or multi-touch gestures is used as input to navigate the natively displayed portion of the remoted desktop.

Owner:MICROSOFT TECH LICENSING LLC

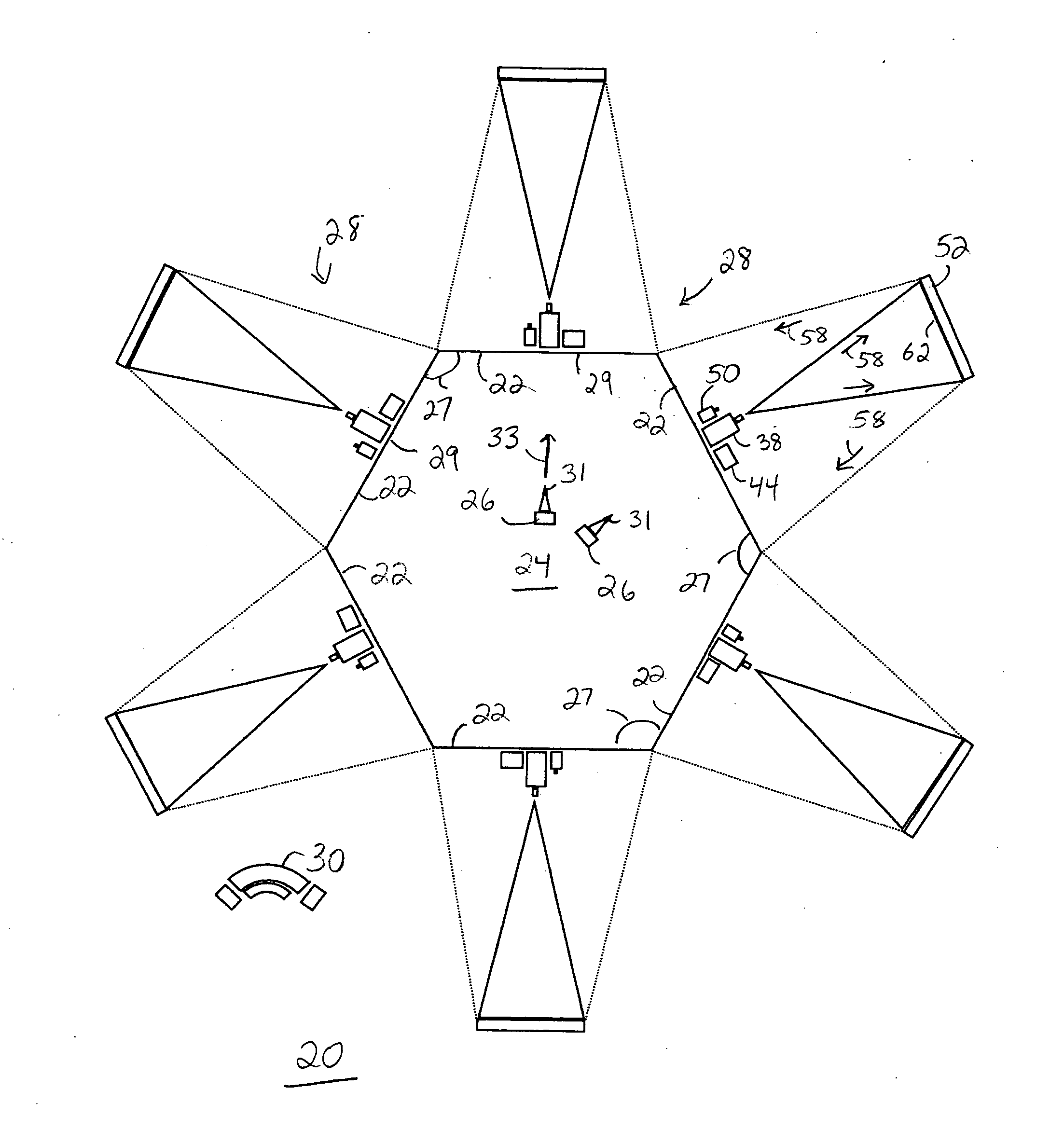

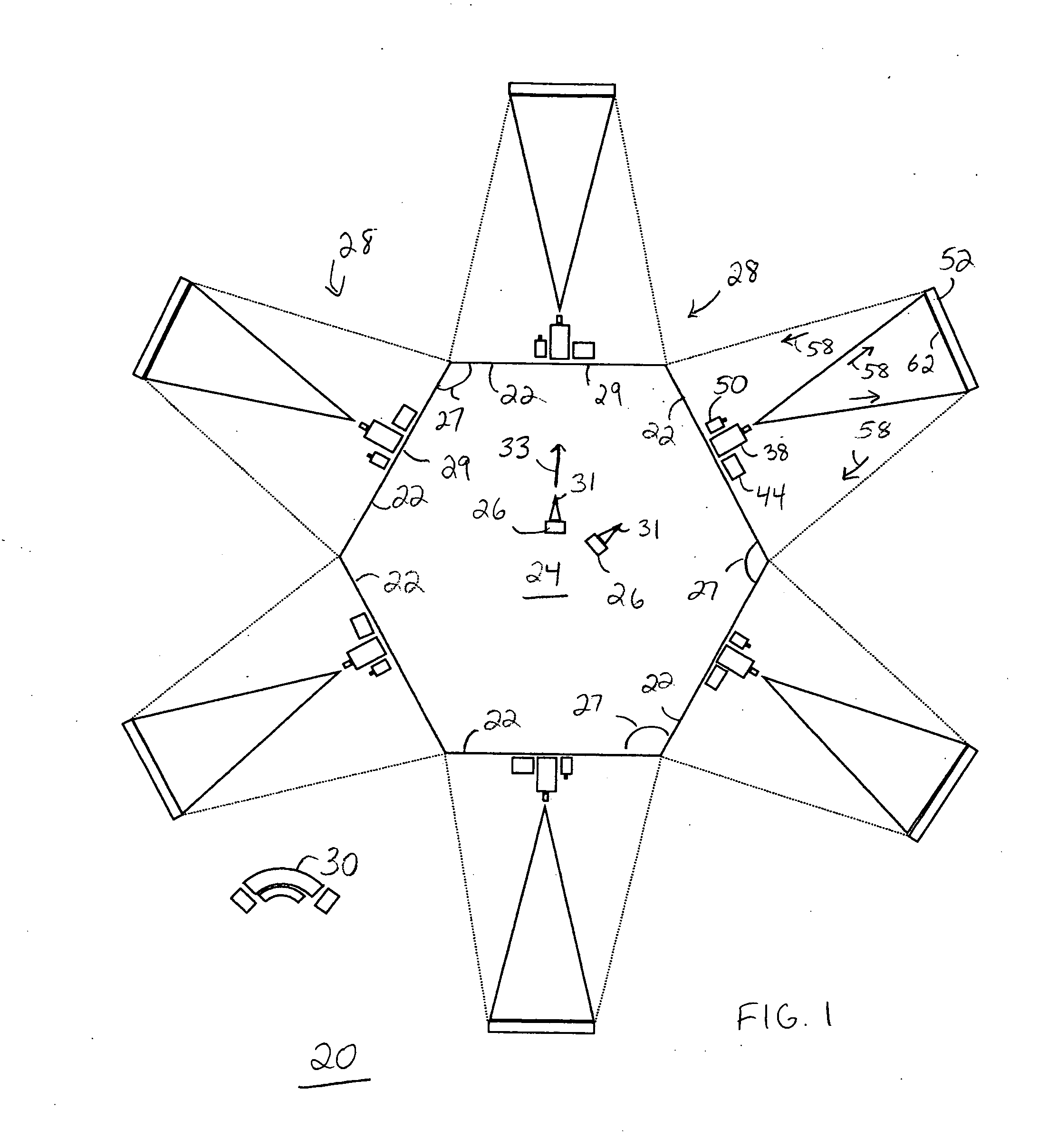

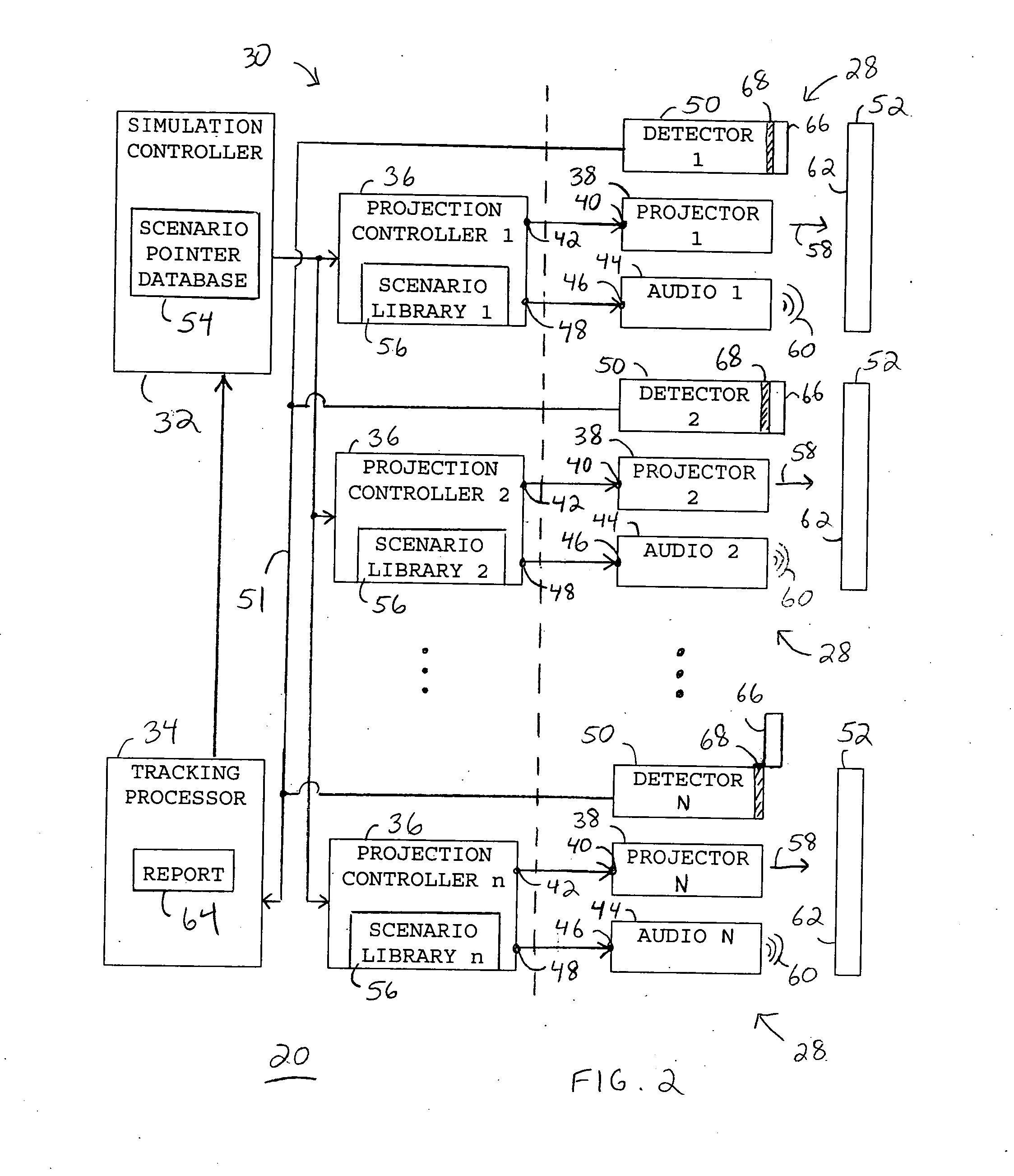

Method and program for scenario provision in a simulation system

InactiveUS20060105299A1Easy to useEncouraging teamworkTraining adaptationTeaching apparatusComputer graphics (images)Background image

A simulation system (20) facilitates training for trainees (26) subject to multi-directional threats. A method for providing a scenario (211) for use in the simulation system (20) utilizes a scenario provision process (202) executable on a computing system (26). The process (202) calls for choosing a background image (234) for the scenario (211), and selecting a video clip(s) (386) of one or more actors (266) from a database (203) of video clips (386). The video clip(s) (386) are filmed using a green or blue screen technique, and include a mask portion (394) of the actor (266) and a transparent portion (396). The video clip(s) (386) are combined with the background image (234) to create the scenario (211), with the mask portion (394) forming a foreground image over the background image (234). The scenario (211) is displayed on a display of the simulation system (20).

Owner:VIRTRA INC

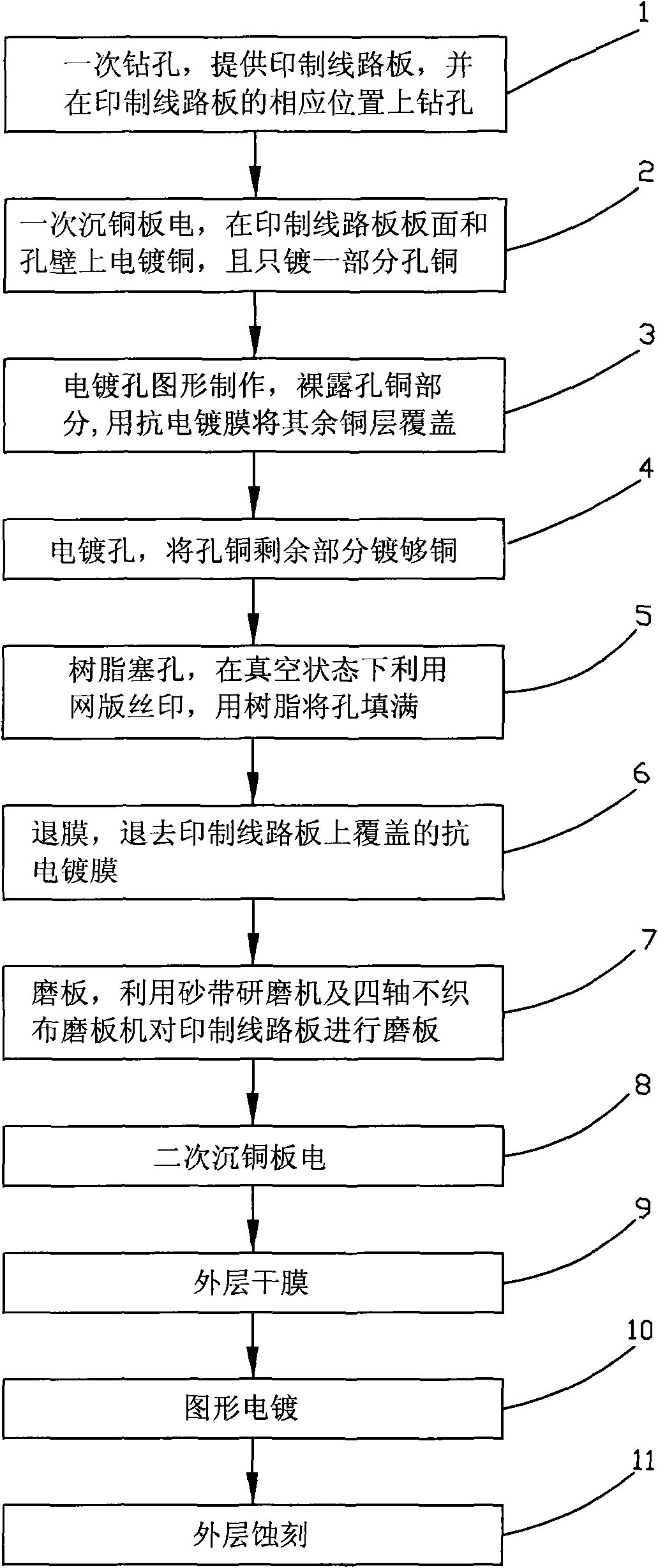

Manufacturing method for printed wiring board with dense disk holes

InactiveCN101662893ASolve grinding difficultiesResolve Resin DepressionPrinted element electric connection formationLine widthEngineering

The invention relates to a manufacturing method for a printed wiring board with dense disk holes, comprising the steps of: 1 once boring a hole, 2 once plating copper on the board surface and a wall of a hole of a printed wiring board and only partially plating the wall of the hole, 3 making a pattern of plating hole, 4 plating copper on the part of the hole which is not plated, 5 filling the holewith resin by adopting silk-screen in vacuum, 6 withdrawing a film, 7 grinding a printed wiring board with an abrasive band grinding machine and a four-axle unwoven cloth graining machine, 8 secondarily plating copper on the board, 9 drying a film on the outer layer, 10 plating the pattern and 11 etching the outer layer. The invention manufactures the products with dense disk holes with a line width and line-spacing of 4 / 4mil, by once plating copper on a 10um hole. The problems of partially filled tap-hole, hollow resin, resin foam, etc., are efficiently solved by adopting the vacuum silk-screen technique and the problems of difficult grinding of resin, sunken resin, unevenly cutting of the copper on the board surface, etc., are efficiently solved by grinding with abrasive band and four-axle unwoven cloth graining technique.

Owner:DONGGUAN MEADVILLE CIRCUITS

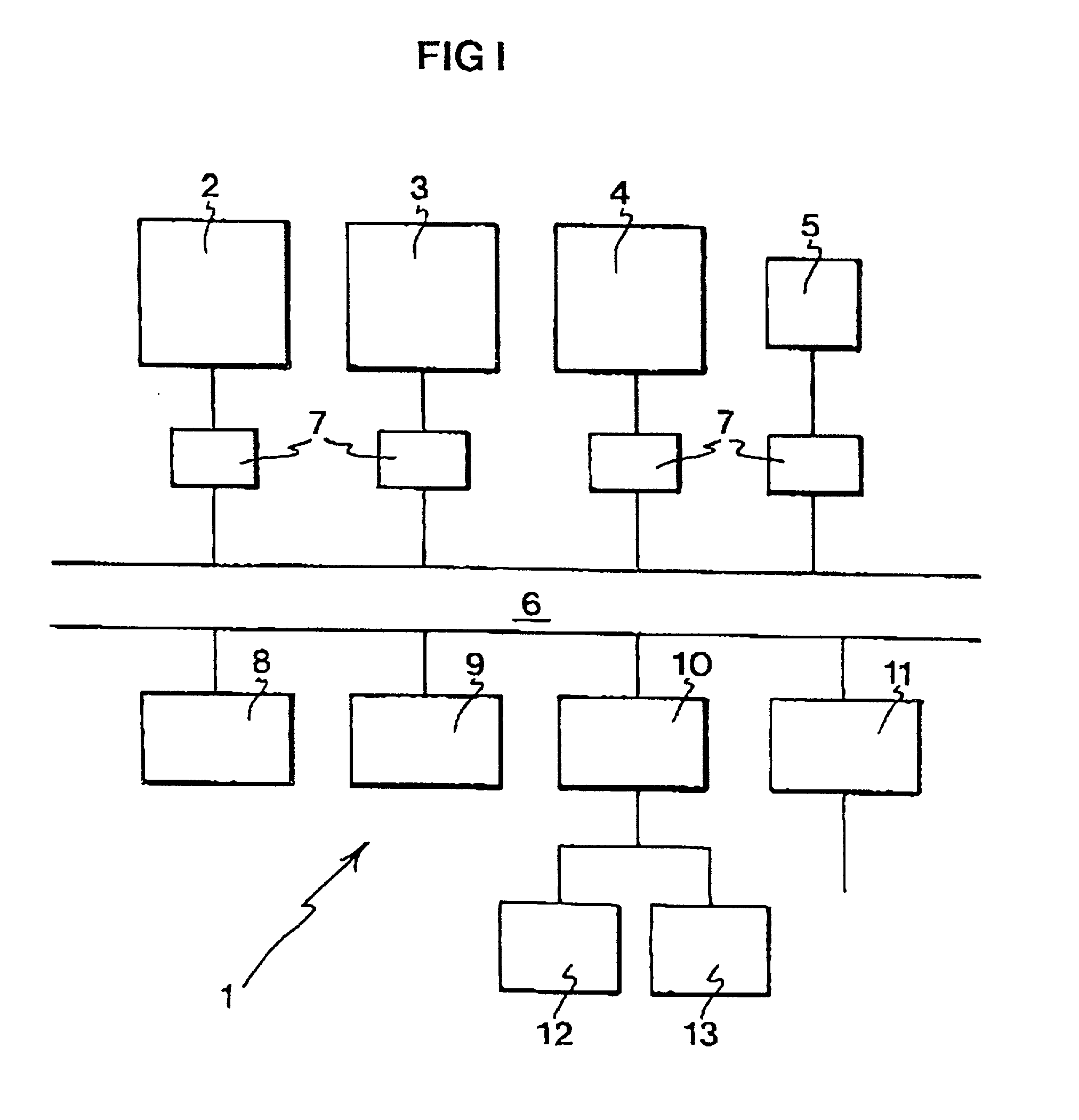

Computer including at least two displays

InactiveUS20020067319A1Easy to adaptEasy to implementCathode-ray tube indicatorsDetails for portable computersDisplay deviceTouchscreen

Owner:HENSEL MARTIN

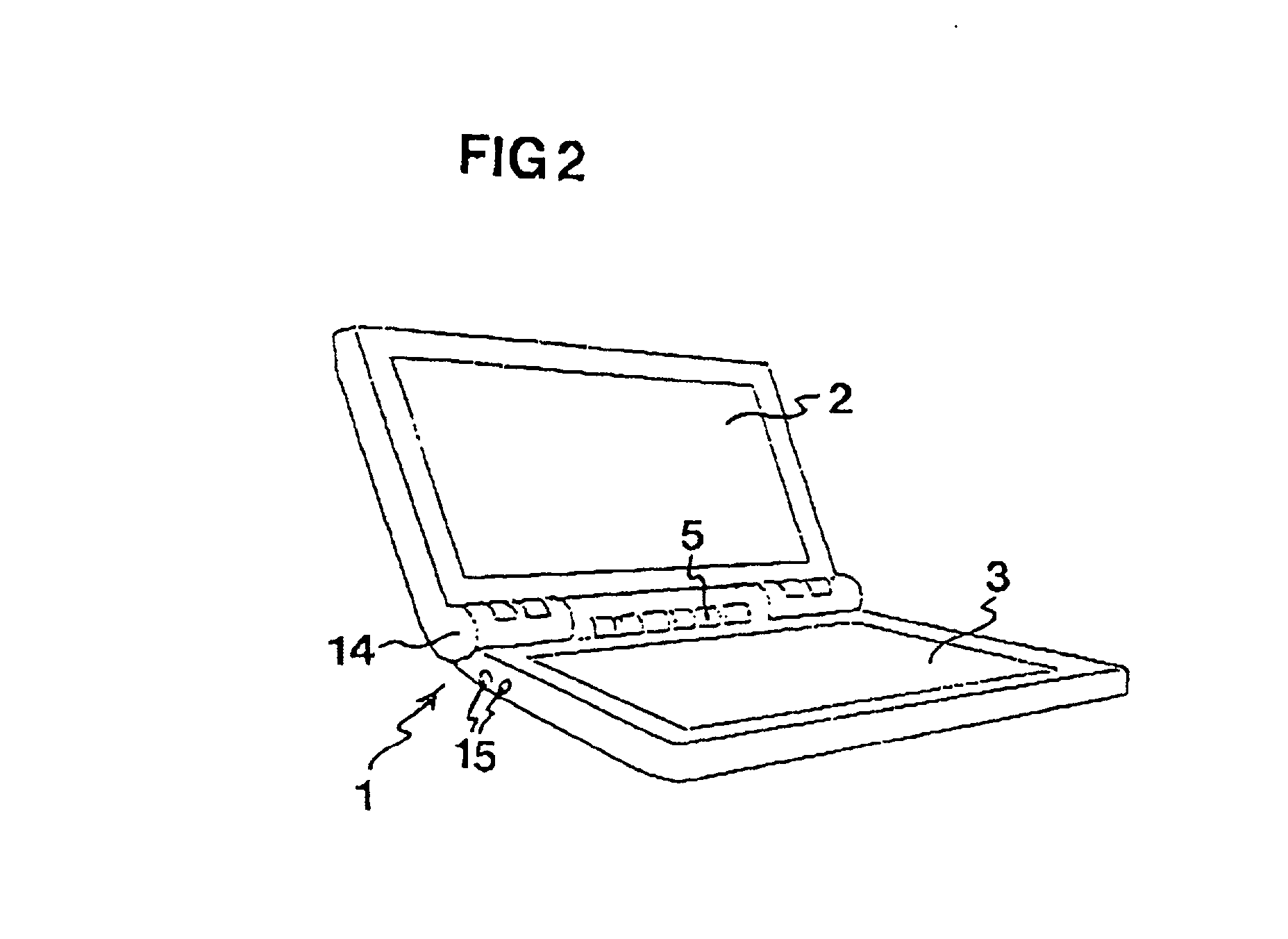

Grid driving circuit, grid line driving method and displaying device

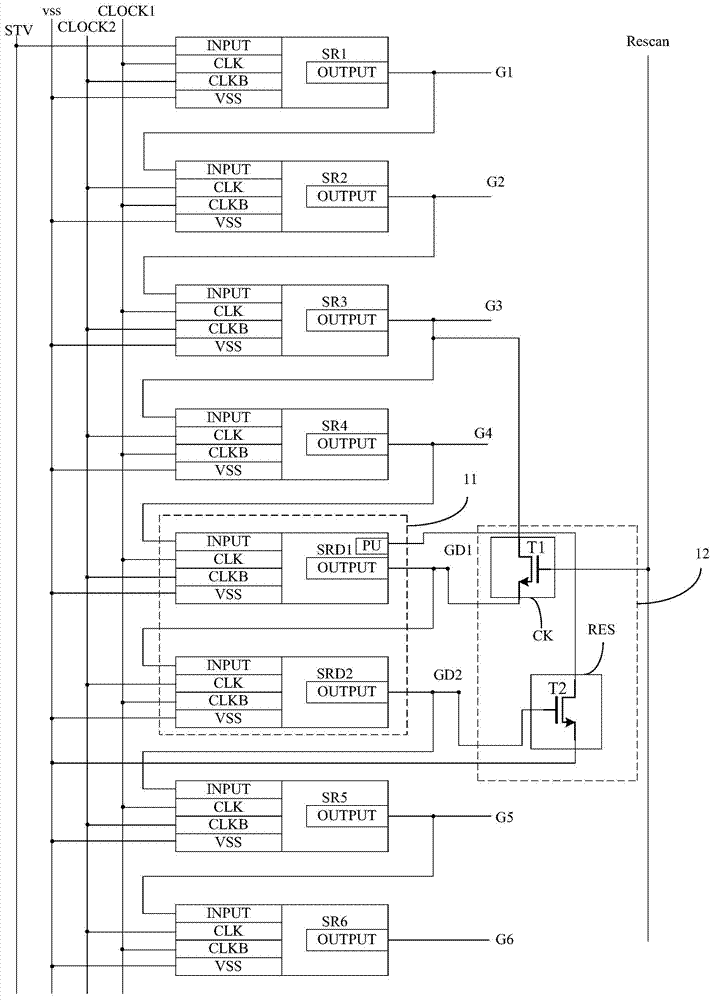

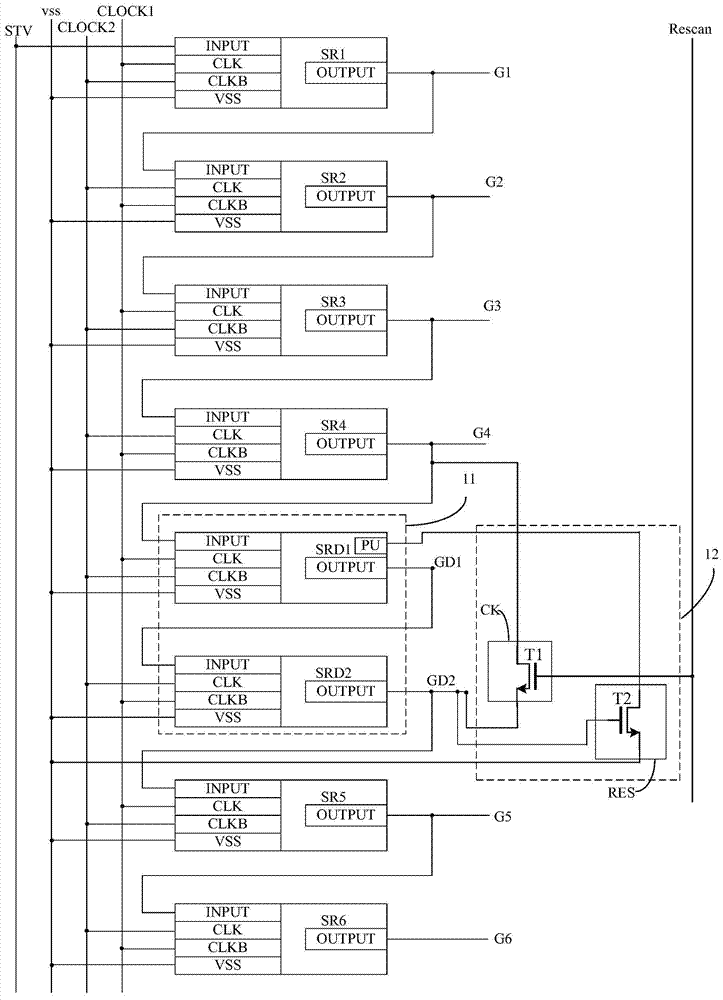

InactiveCN103489391AImprove the display effectStatic indicating devicesDigital storageShift registerComputer module

An embodiment of the invention provides a grid driving circuit, a grid line driving method and a displaying device and relates to the technical field of displaying. The problem of poor displaying caused by scanning signal interruption in a time-share driving touch screen technique is solved. The grid driving circuit comprises a plurality of shifting register units which are in serial connection. A displacement delay module is in serial connection between the jth grade shifting register unit and the (j+1)th grade shifting register unit, the jth grade shifting register unit and the (j+1)th grade shifting register unit are adjacent to each other, the displacement delay module is connected with the output end of the jth grade shifting register unit and the input end of the (j+1)th grade shifting register unit, the displacement delay module is further connected with a repetition output module, and the repetition output module is connected with the output end of the (j-n+1)th shifting register unit and the control end of a clock. An embodiment of the grid driving circuit is applied to manufacturing displayers.

Owner:BOE TECH GRP CO LTD +1

Array substrate, manufacturing method of array substrate and display device

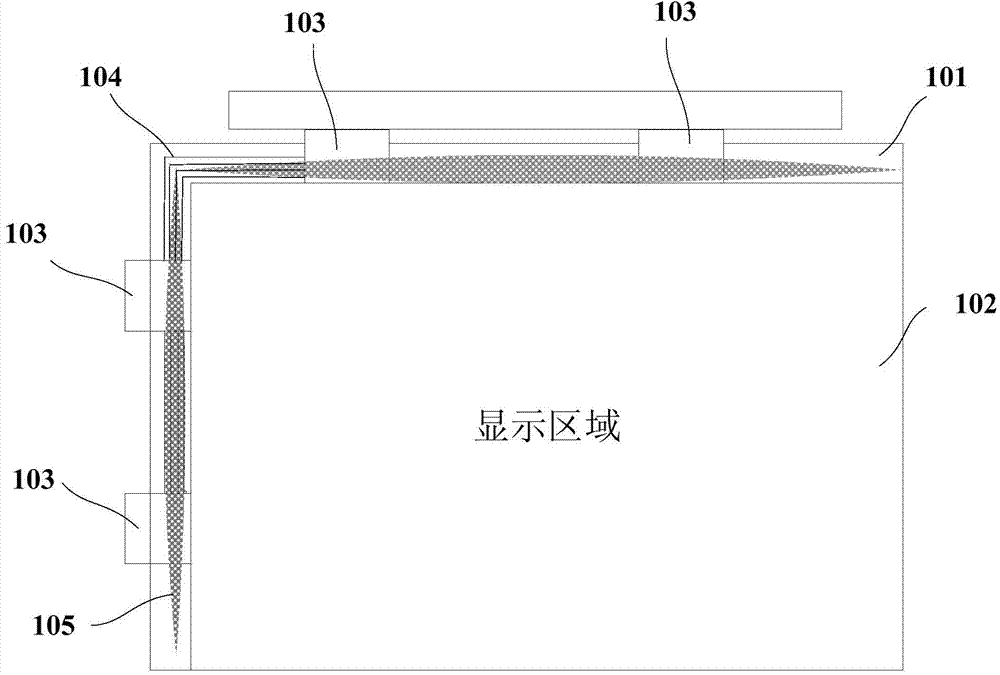

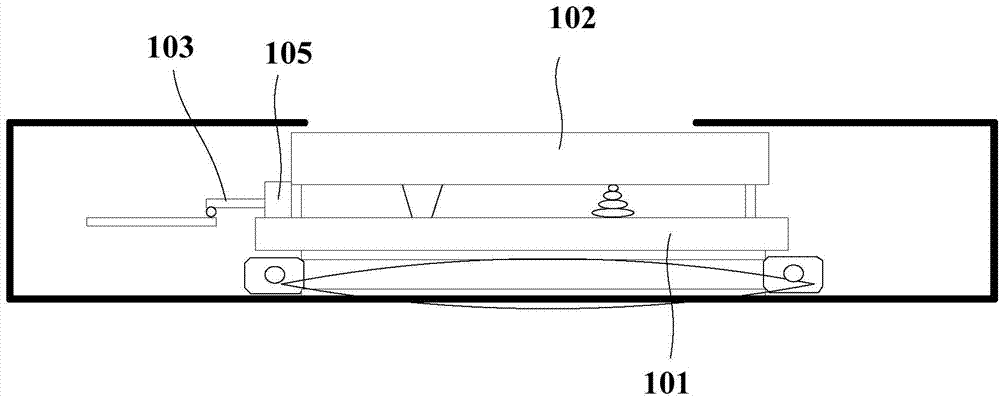

InactiveCN103901690AReduce widthReduce the risk of injurySemiconductor/solid-state device detailsSolid-state devicesDisplay deviceEngineering

The invention provides an array substrate, a manufacturing method of the array substrate and a display device. The array substrate comprises a display region, a non-display region and a plurality of signal connection wires, wherein the signal connection wires are located at the non-display region and used for being connected with a driving unit and comprise the first connection wires and the second connection wires, the first connection wires are electrically connected with the driving unit, the second connection wires are electrically connected with the first connection wires, the second connection wires are arranged in at least two layers, and each layer of the second connection wires is insulated from another layer of the second connection wires. By the adoption of the array substrate, the manufacturing method of the array substrate and the display device, the width of the part, occurred by the signal connection wires, of the non-display region of the array substrate can be reduced, and therefore the signal connection wires can be covered with silicon gel as much as possible, the risk of damage to the signal connection wires is reduced, the utilization rate of the array substrate can be increased, and the array substrate can be applied to the narrow bezel screen technology.

Owner:BOE TECH GRP CO LTD +1

Method and system of displaying a popping-screen

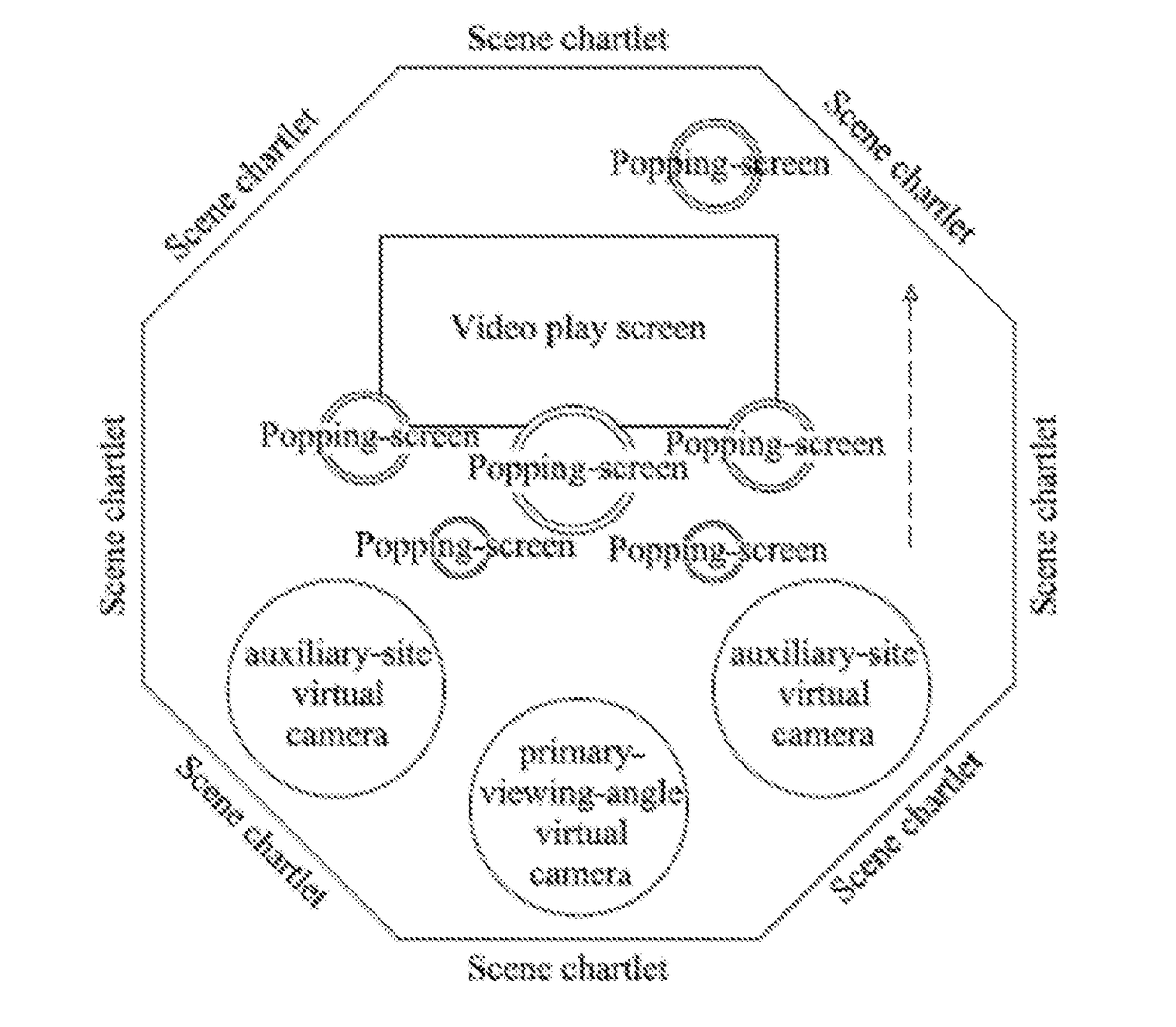

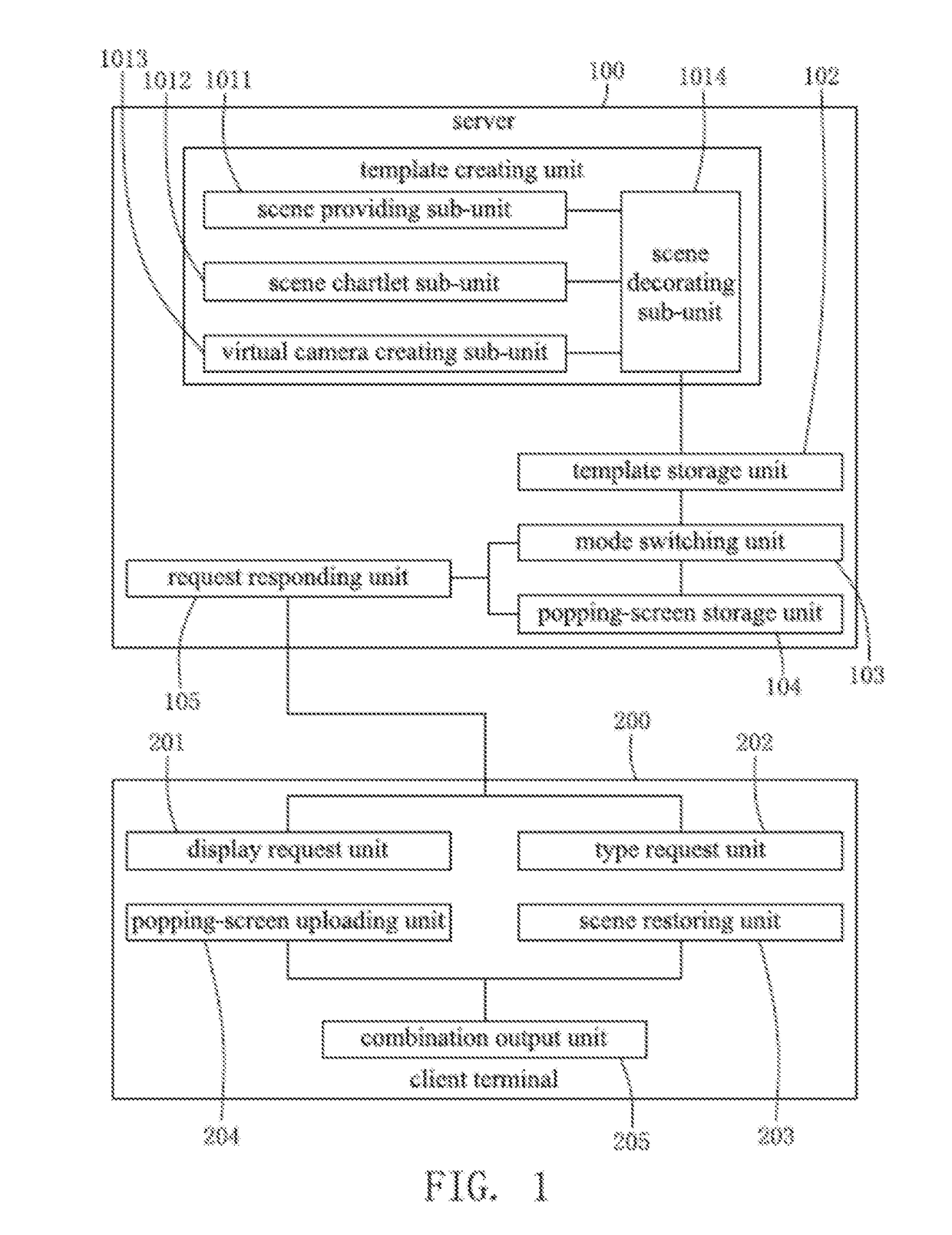

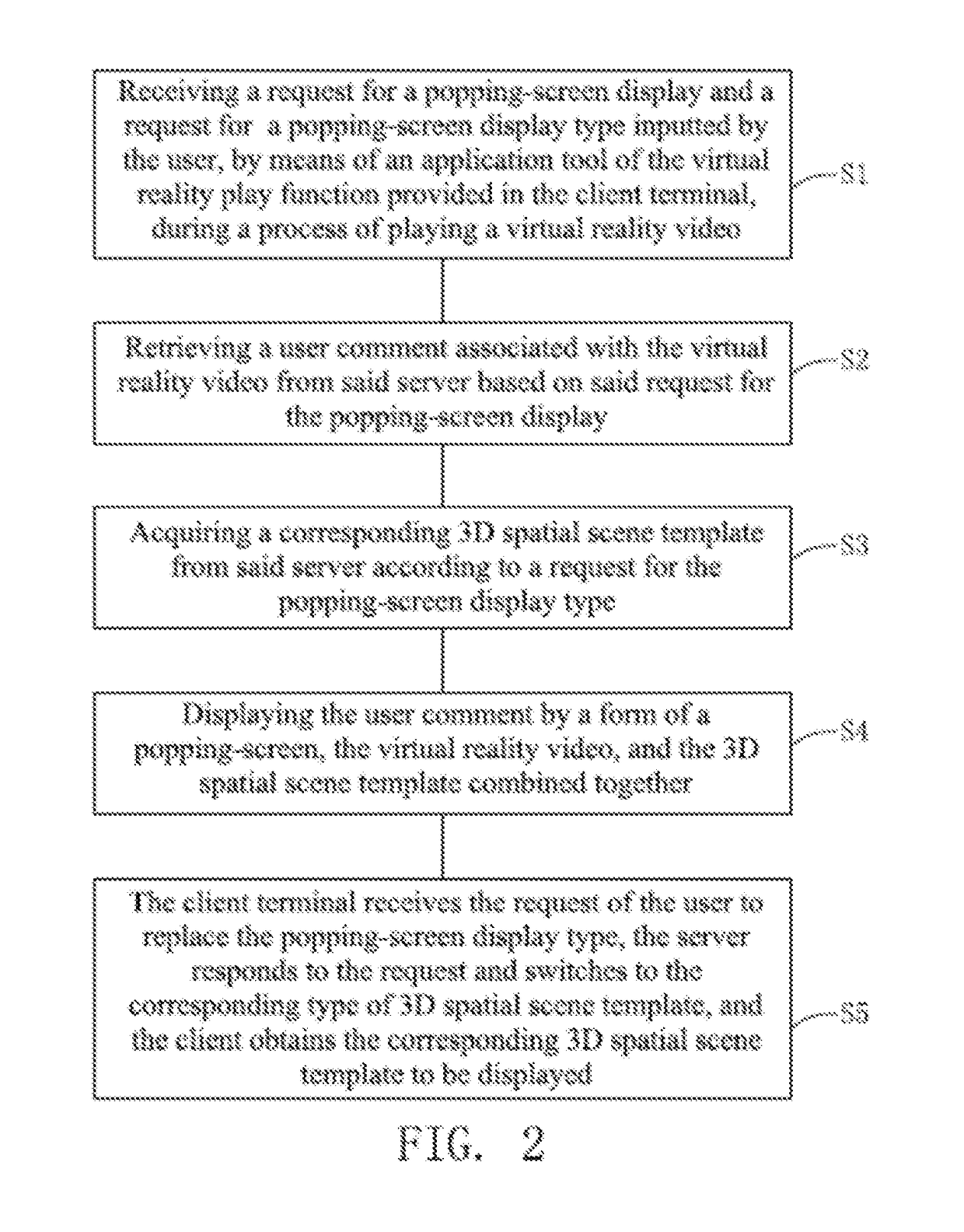

ActiveUS20180063501A1Accurate and fast readingSelective content distributionSteroscopic systemsVirtual cameraVirtual reality

Owner:SHANGHAI HODE INFORMATION TECH CO LTD

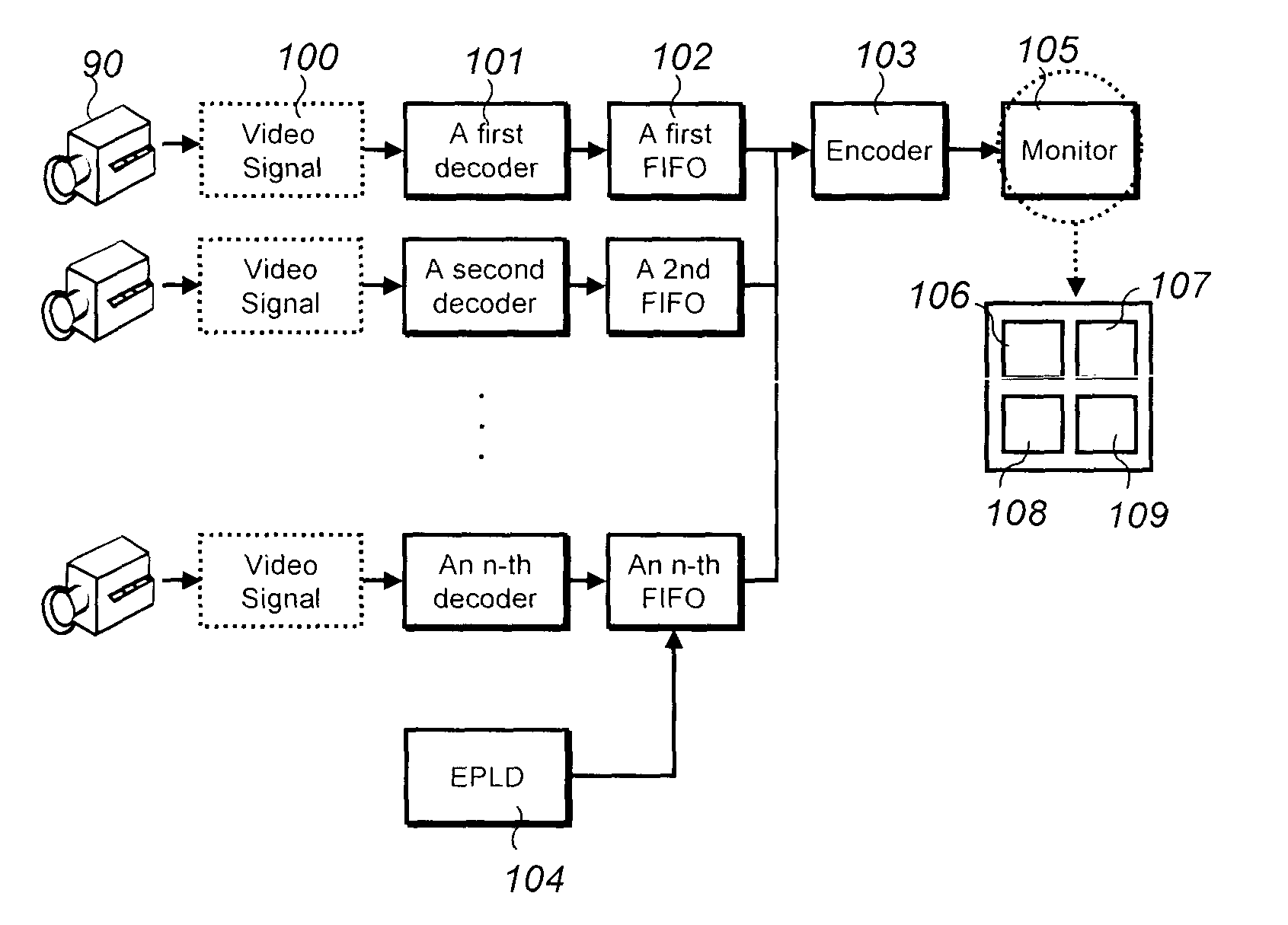

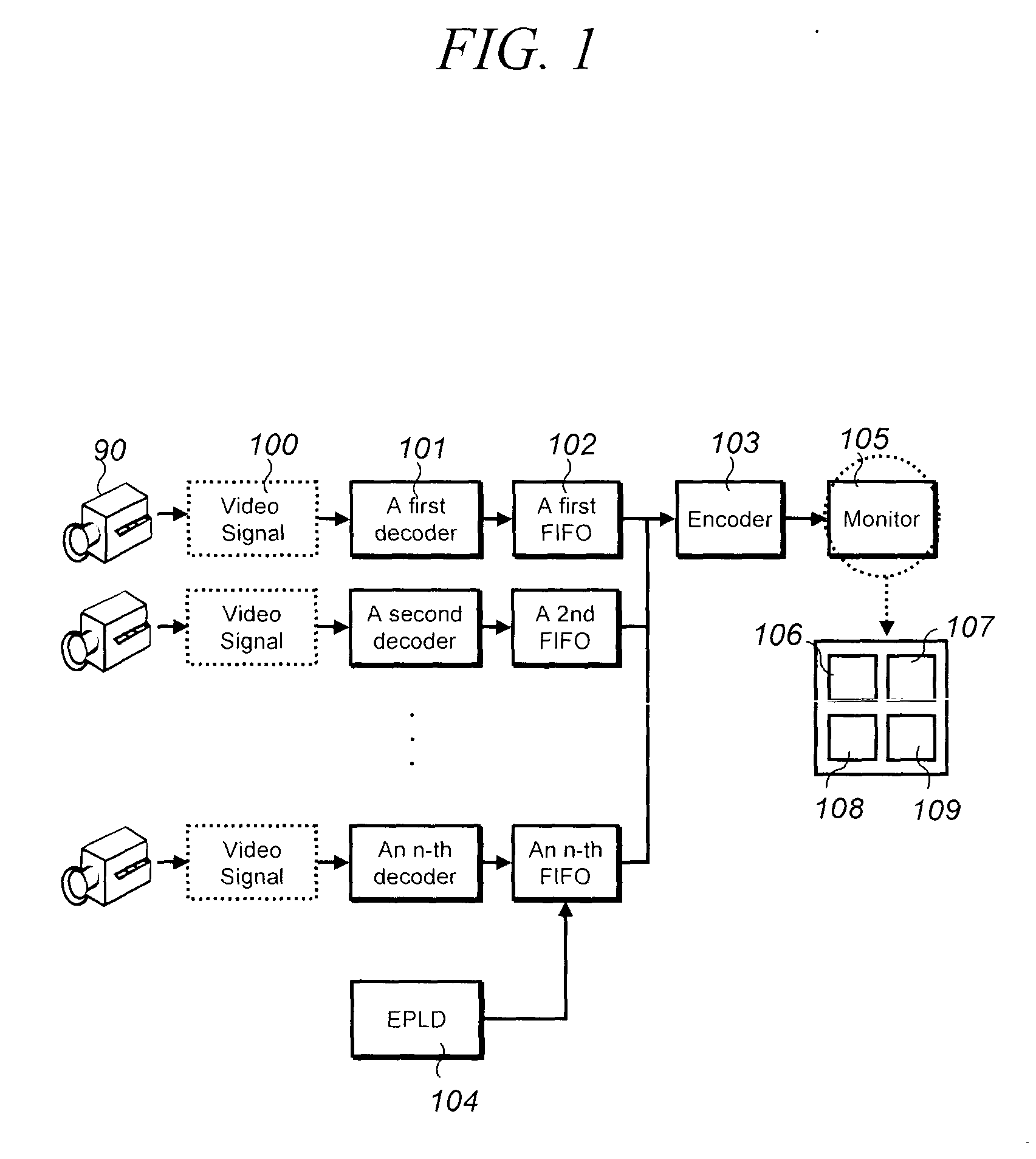

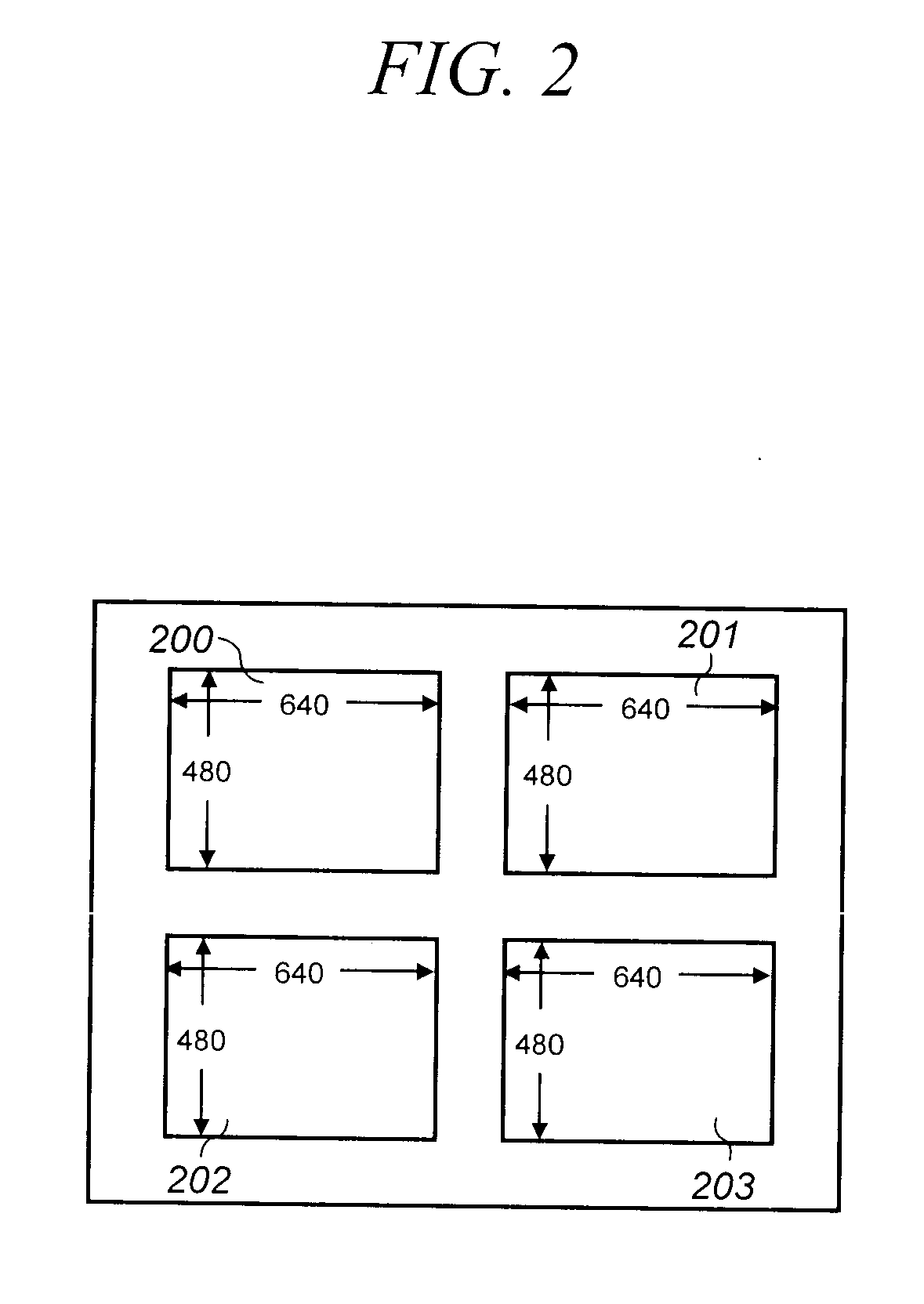

Method and apparatus for high-definition multi-screen display

InactiveUS20040046706A1Television system detailsCathode-ray tube indicatorsComputer graphics (images)Image resolution

Owner:SUNGJIN C&C

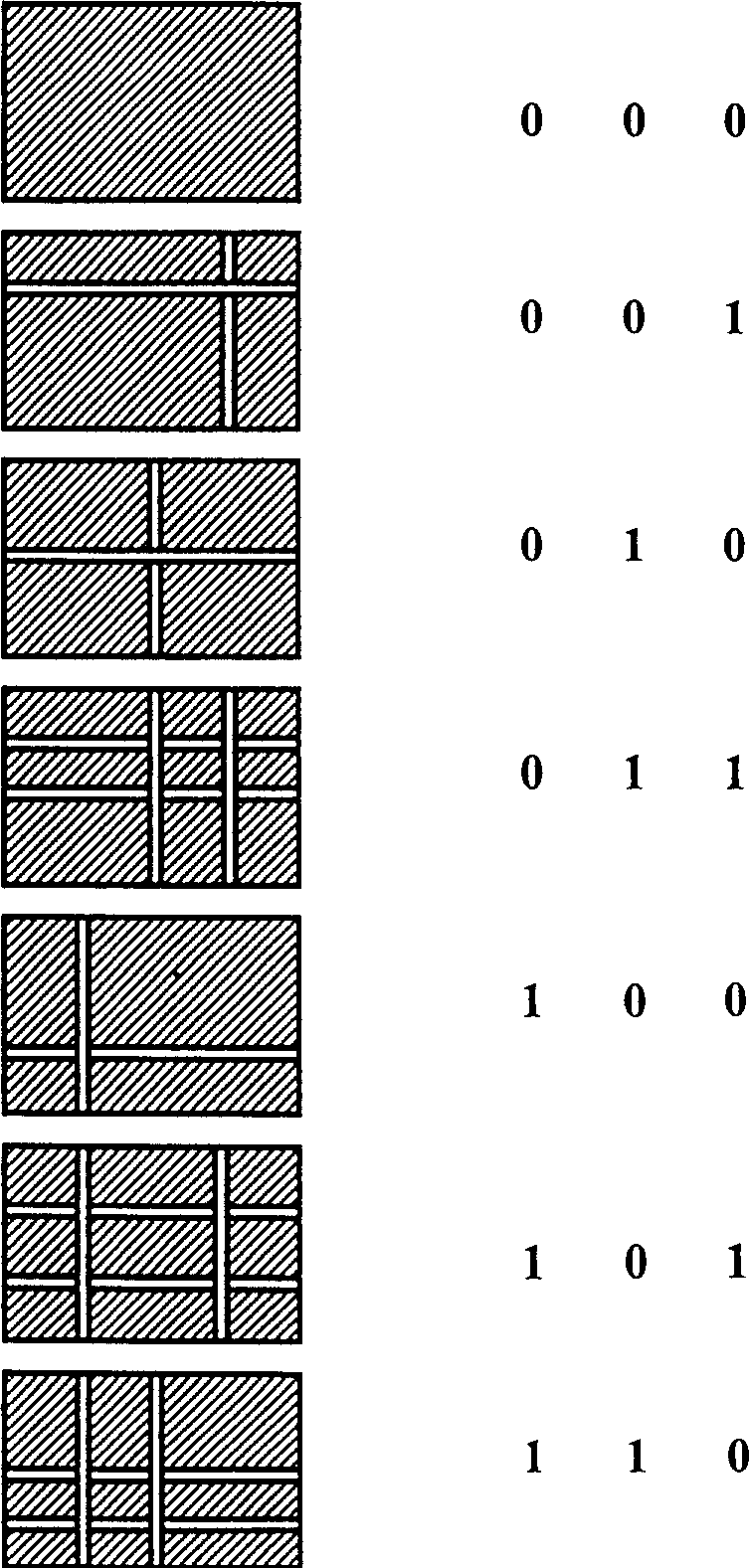

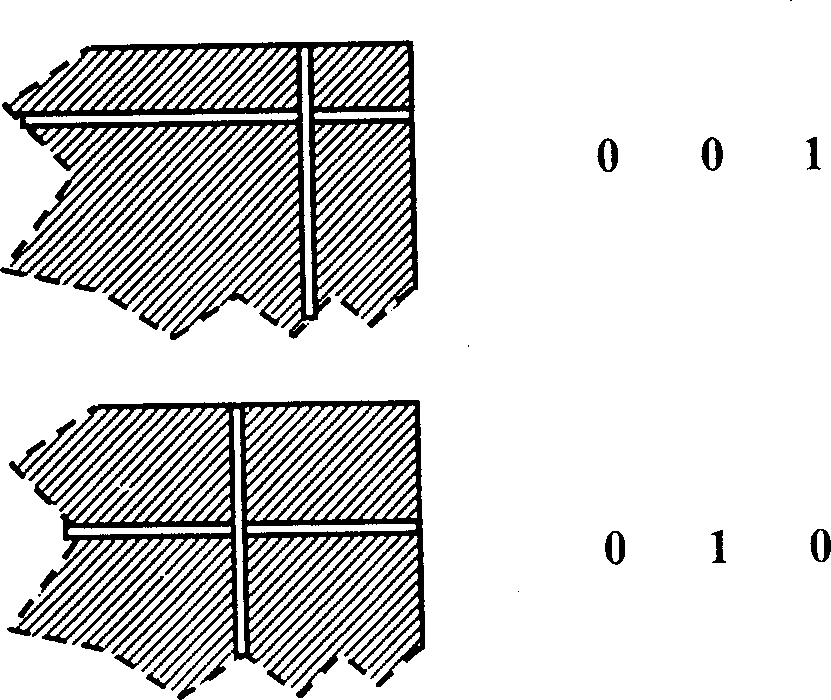

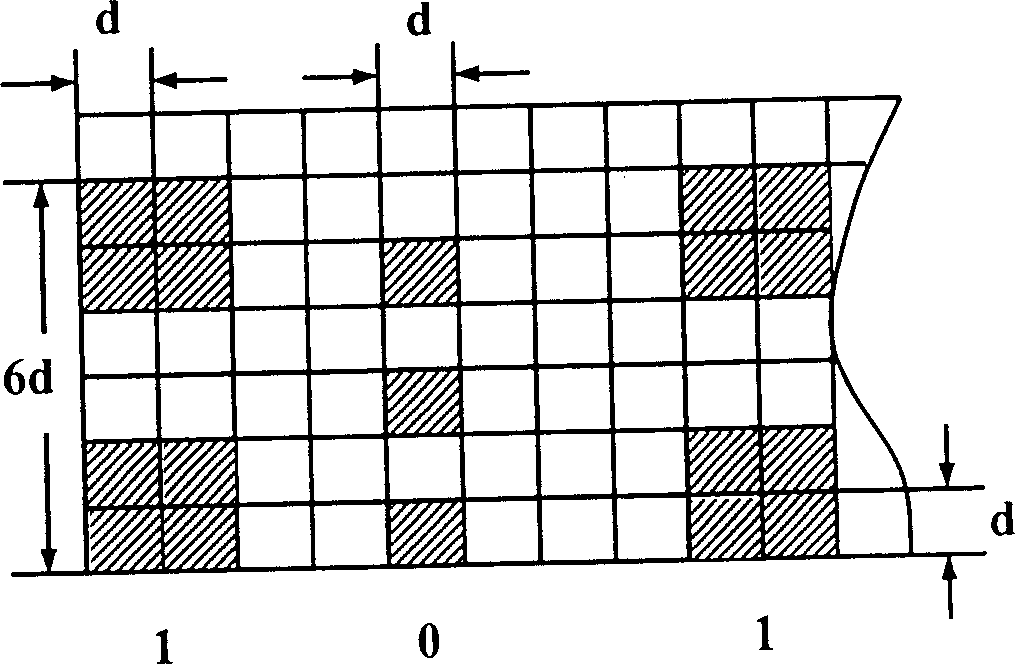

Network screen encoded anti-fakery method

InactiveCN1424690AImprove accuracyPrint quality is not compromisedCharacter and pattern recognitionVerifying markings correctnessElectronic documentGraphics

This invention relates to an anti-falsification method with mesh screen encoding used in electronic documents of government and other smilar cases. The method includes mesh screen technique using large and small mesh points to indicate "0" and "1" and combining the shapes and positions of the mesh points; the ways of character encoding and background encoding, as well as the relevant ways of background encoding and character encoding, with background encoding corresponding to characters in positions; structural way and error-correcting way of the mesh screen encoding. The mesh screen encoding has the properties of compression of information and safety, being difficult to distort and forge; being able to directly view and keep forever, specifically, when being used in bills of banks and tax, the contents of the bills can be stored in the lines of forms, and the printed bills and various files can be again input to computer.

Owner:天津市阿波罗信息技术有限公司

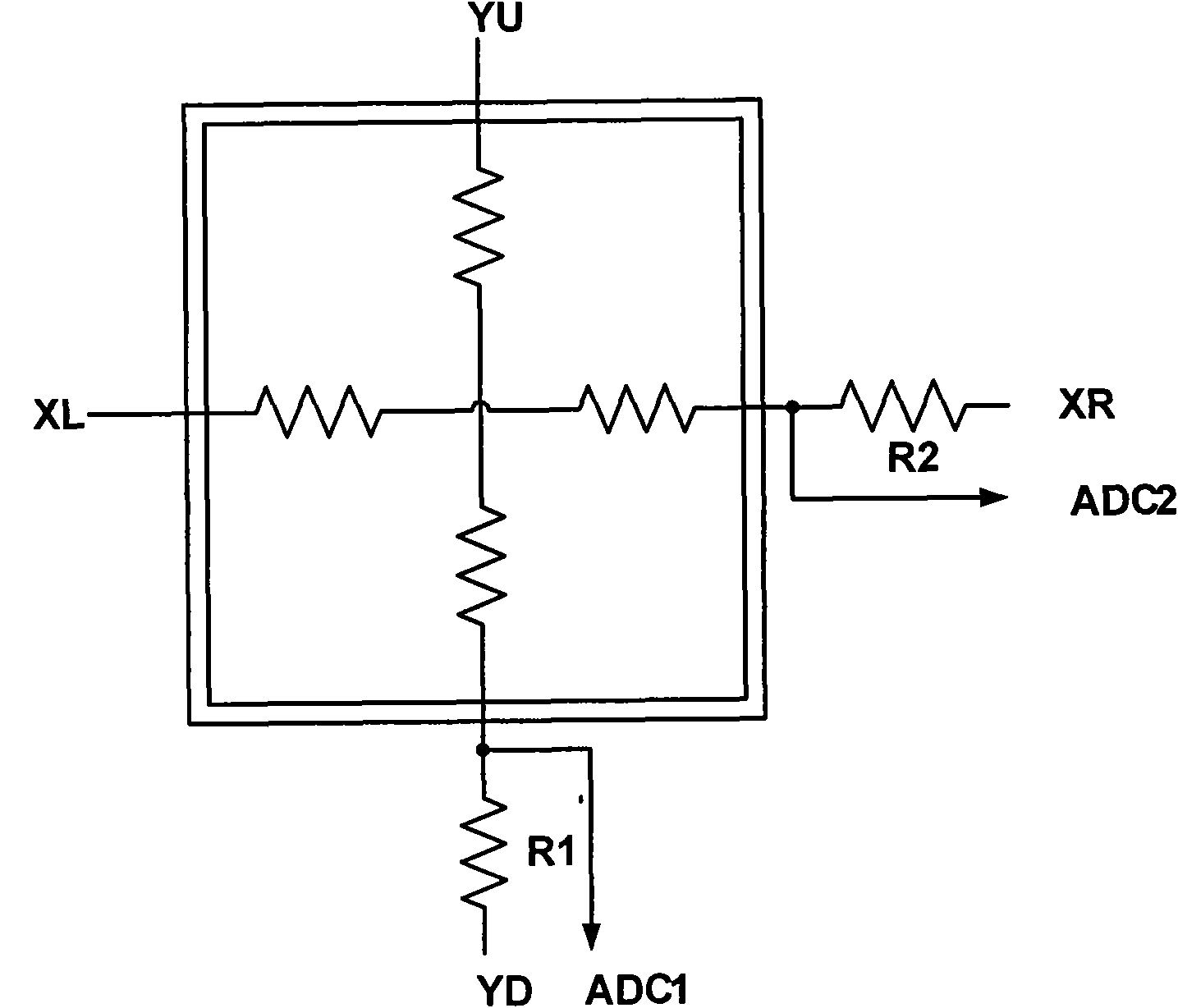

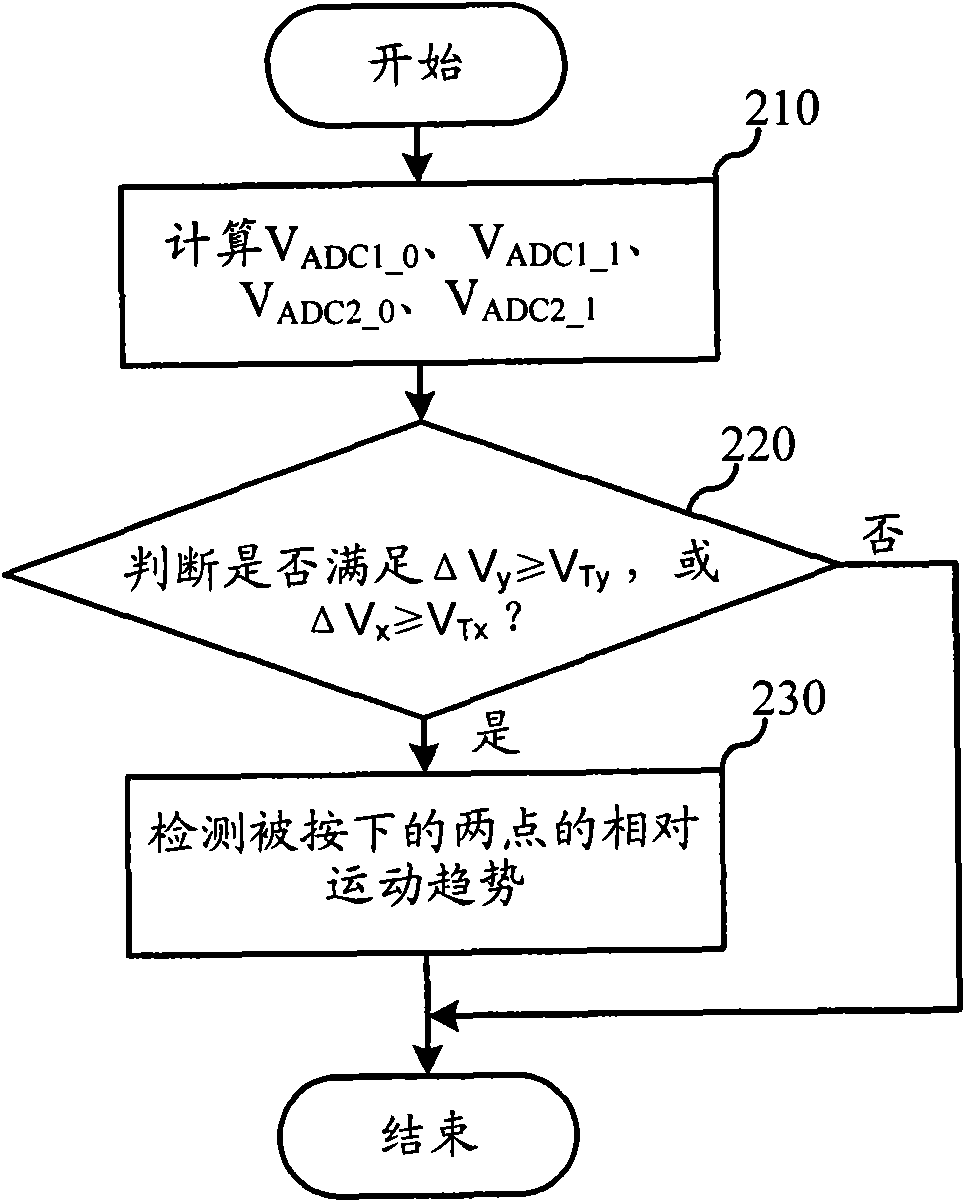

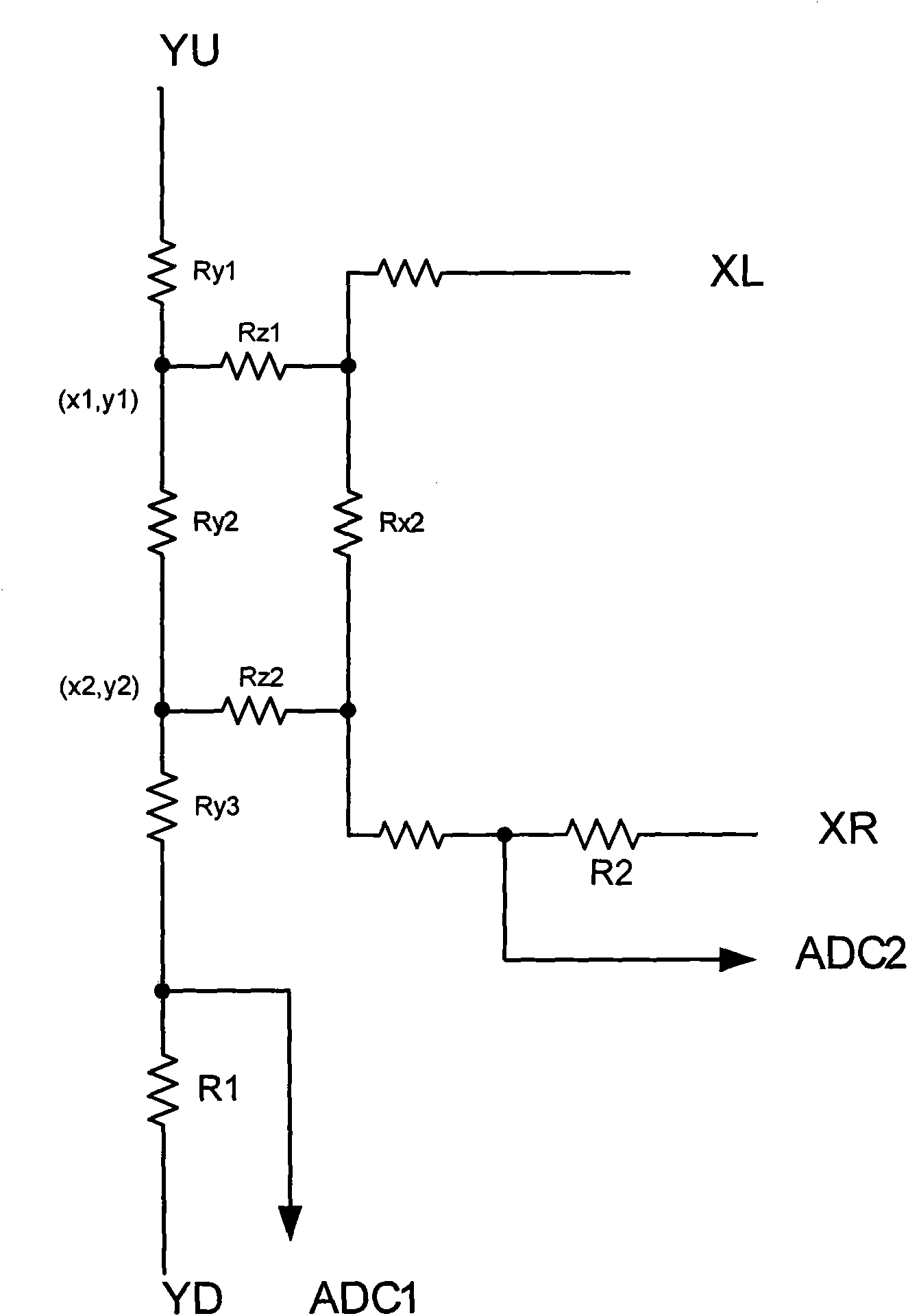

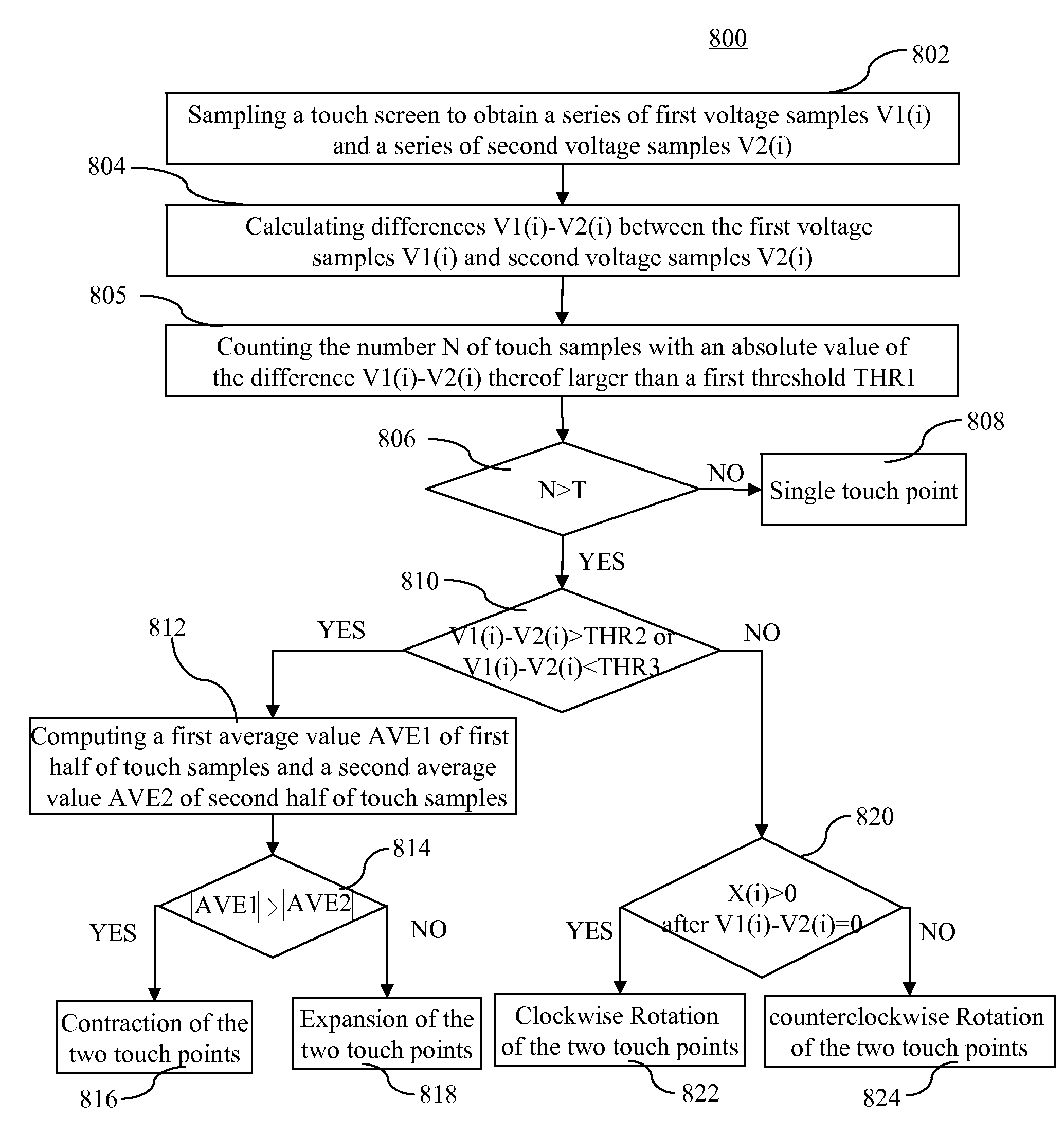

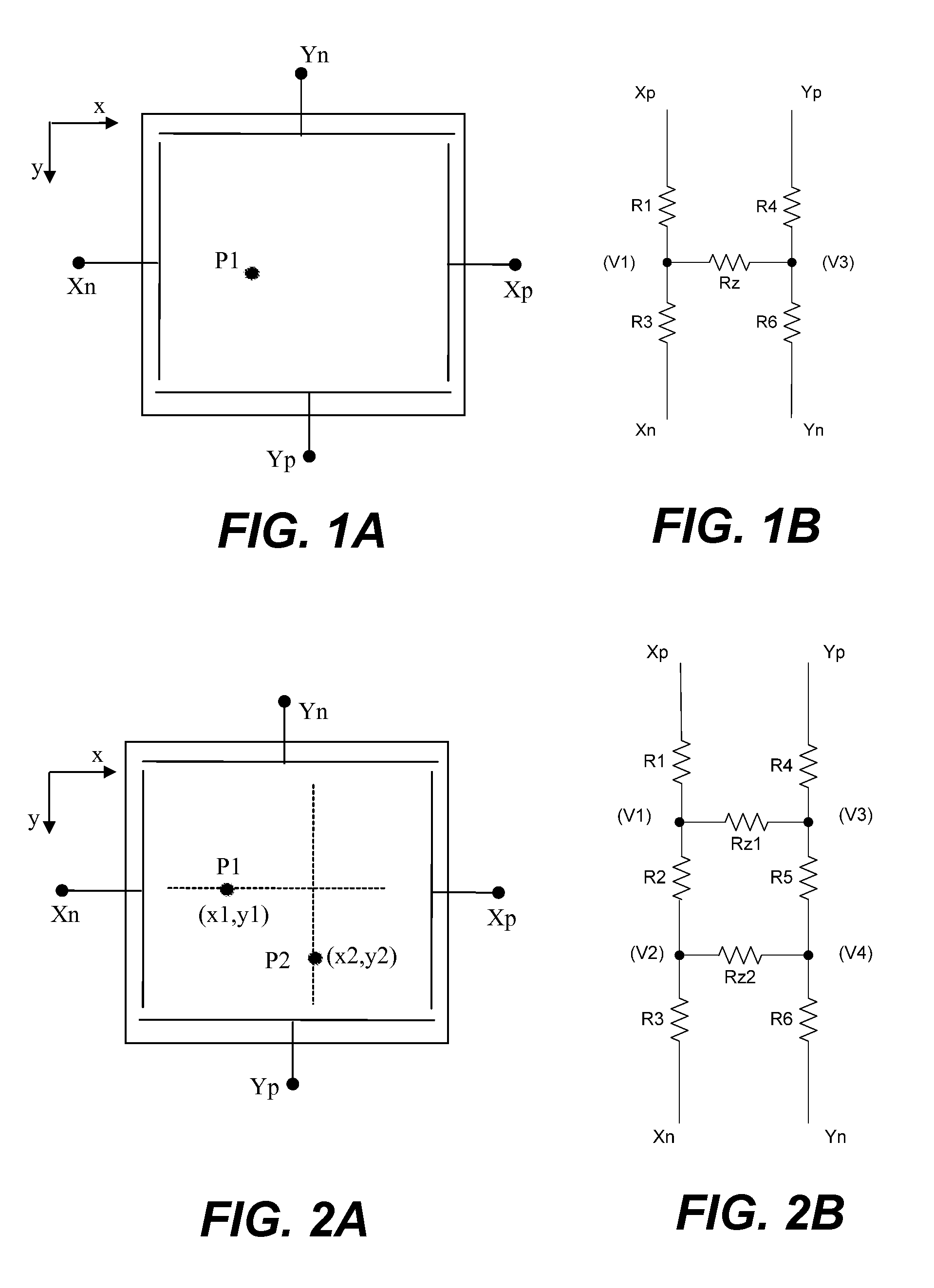

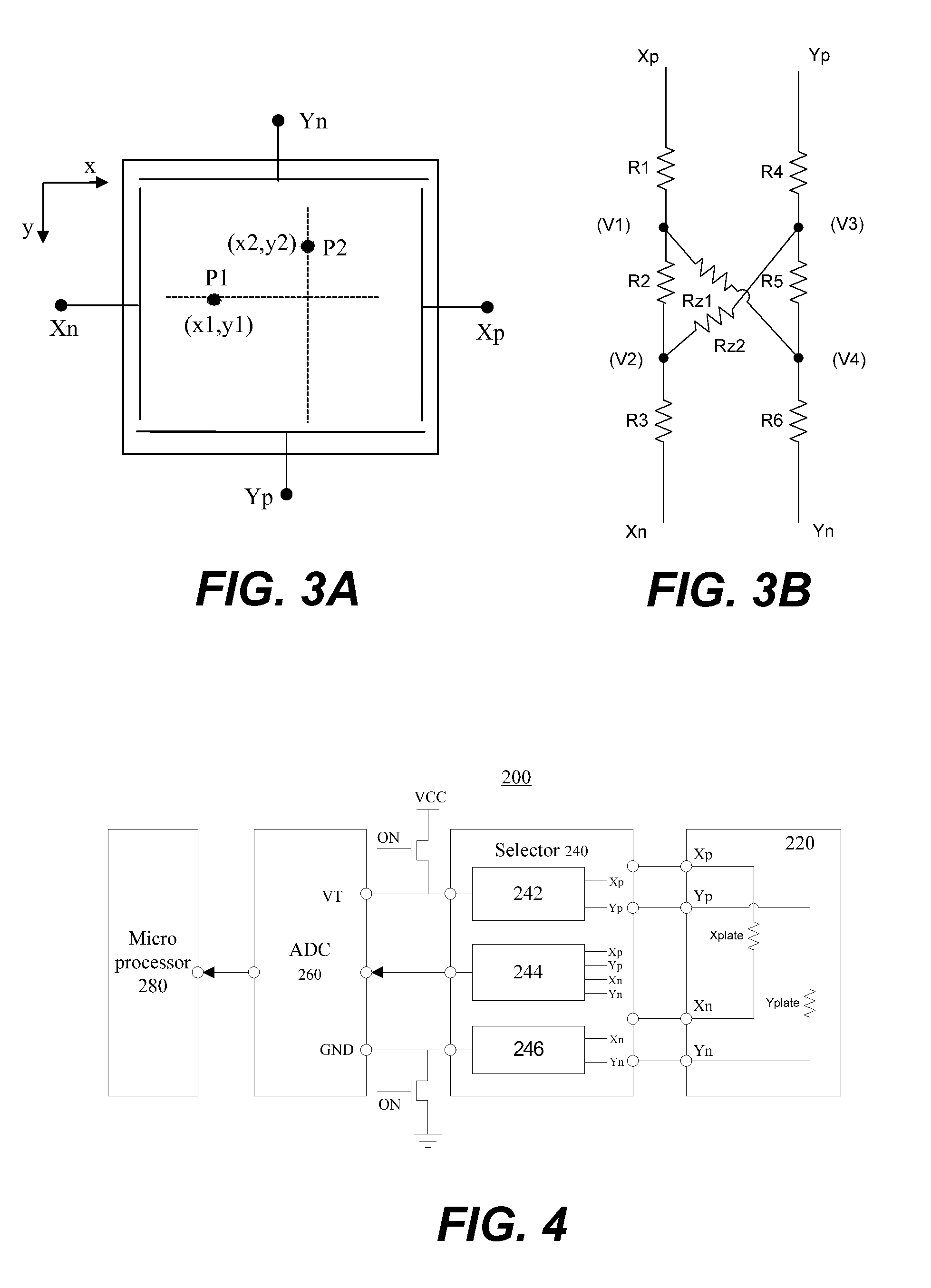

Two-point detection method and equipment for resistive touch screen

ActiveCN102033674ASolve the problem of not being able to detect multiple pointsImprove the sense of touchInput/output processes for data processingElectrical resistance and conductanceResistive touchscreen

The invention relates to a touch screen technique and discloses a two-point detection method and two-point detection equipment for a resistive touch screen. The two-point detection method comprises the following steps of: measuring voltage values VADC1_0, VADC1_1, VADC2_0 and VADC2_1 at the series resistor end by using series resistors; and if a difference value delta Vy of the VADC1_1 and the VADC1_0 is more than or equal to VTy which is a first preset threshold, or if a difference value delta Vx of the VADC2_1 and the VADC2_0 is more than or equal to VTx which is a second preset threshold, detecting that two points are pressed down, so that the problem that the resistive touch screen cannot perform multi-point detection is solved and the application to software operation can be enriched.

Owner:芯鑫融资租赁(厦门)有限责任公司

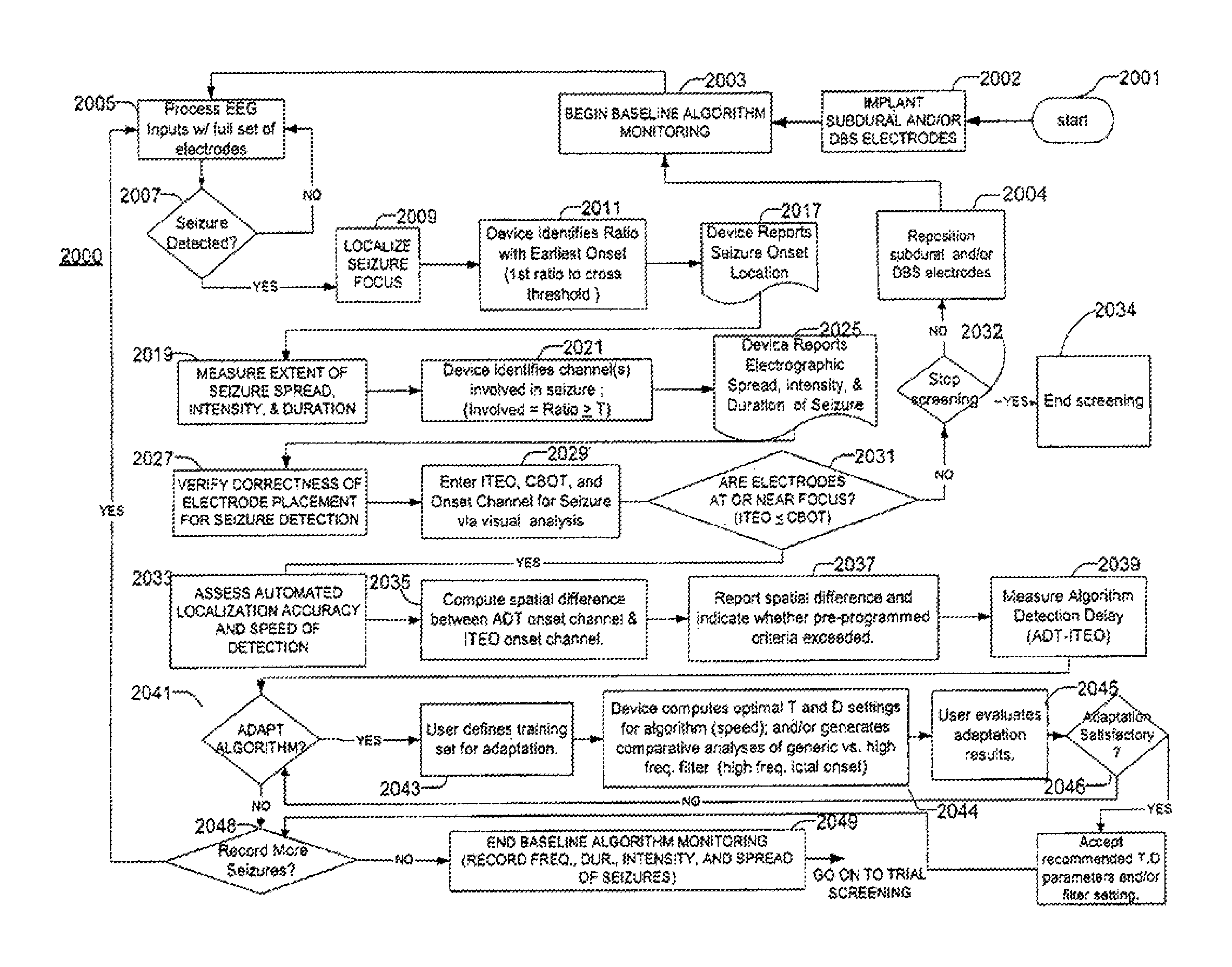

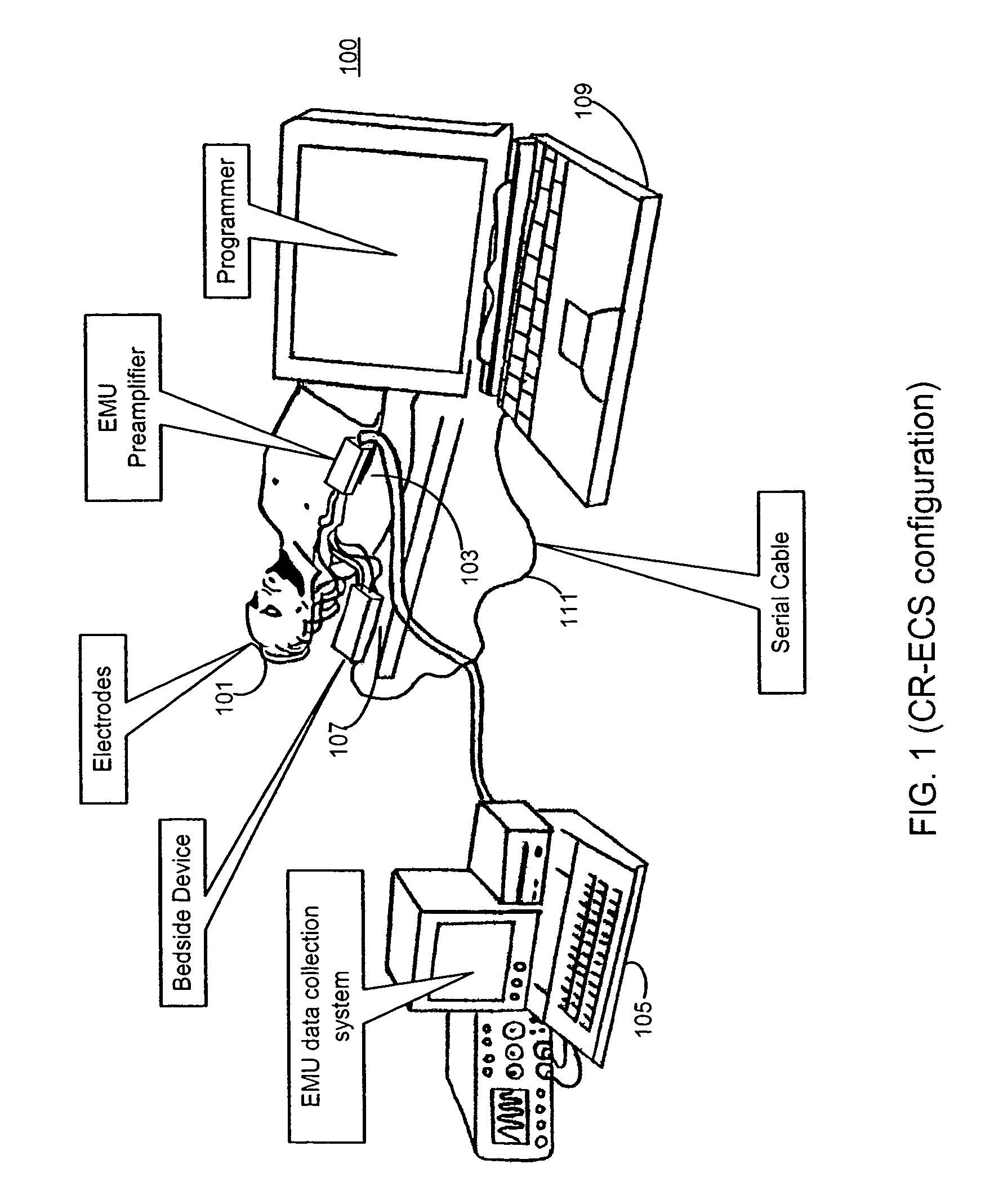

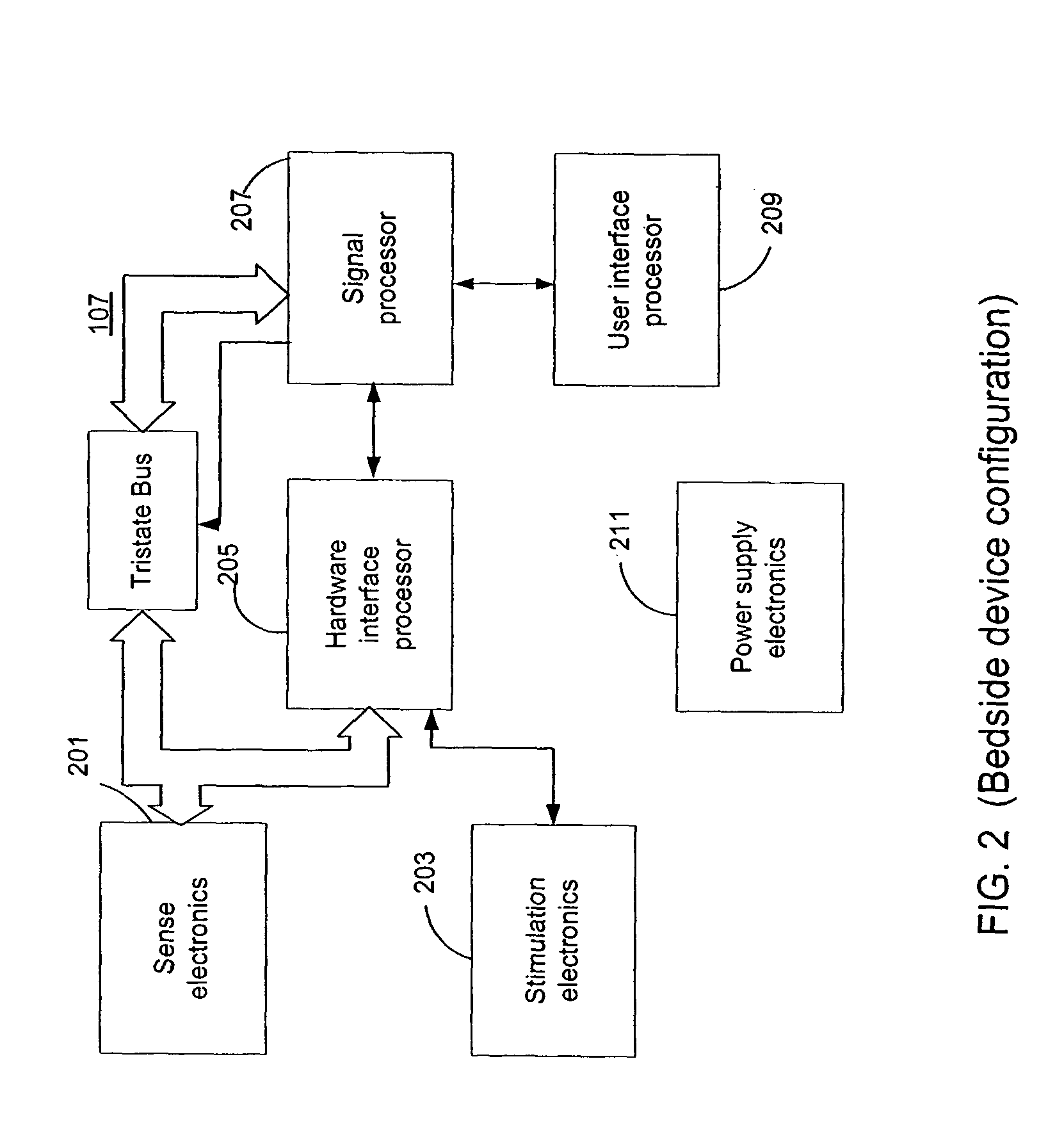

Screening techniques for management of a nervous system disorder

Apparatus and method support a neurological event screening for a medical device. The medical device assists a user in determining a configuration of the medical device for delivering an effective treatment for a nervous system disorder. The medical device detects a neurological event, such as a seizure, and reports a neurological event focus location and a neurological event spread to the user. The user may use the information to provide a configuration of a therapeutic delivery unit and associated therapy parameters. Therapeutic treatment is delivered to the patient, and the medical device is provided an indication of the patient's acceptance to the treatment. The user may modify the configuration and therapy parameters in order to achieve efficacy and acceptance. Depending upon the patient's acceptance, therapy is applied in either an open loop mode or a closed loop mode. The medical device determines whether the treatment is successful in accordance with a criterion.

Owner:MEDTRONIC INC

Device and method for detecting touch screen

Techniques for detecting multiple touch points for touch screen are disclosed. A touch screen includes a first conductive layer and a second conductive layer, each conductive layer having a positive terminal and a negative terminal, an operation of detecting multiple points on a touch screen includes: coupling the positive terminal of the second conductive layer to a positive reference voltage, coupling the negative terminal of the second conductive layer to a negative reference voltage, sampling the positive terminal of the first conductive layer to obtain a series of first voltage samples V1(i), sampling the negative terminal of the first conductive layer to obtain a series of second voltage samples V2(i), wherein i is a sampling number; concluding that a motion tendency of two touch points on the touch screen is contraction when absolute values of the differences V1(i)−V2(i) between the first voltage samples and the second voltage samples tend to increase; and concluding that the motion tendency of two touch points on the touch screen is expansion when the absolute values of the differences V1(i)−V2(i) tend to decrease.

Owner:VIMICRO CORP

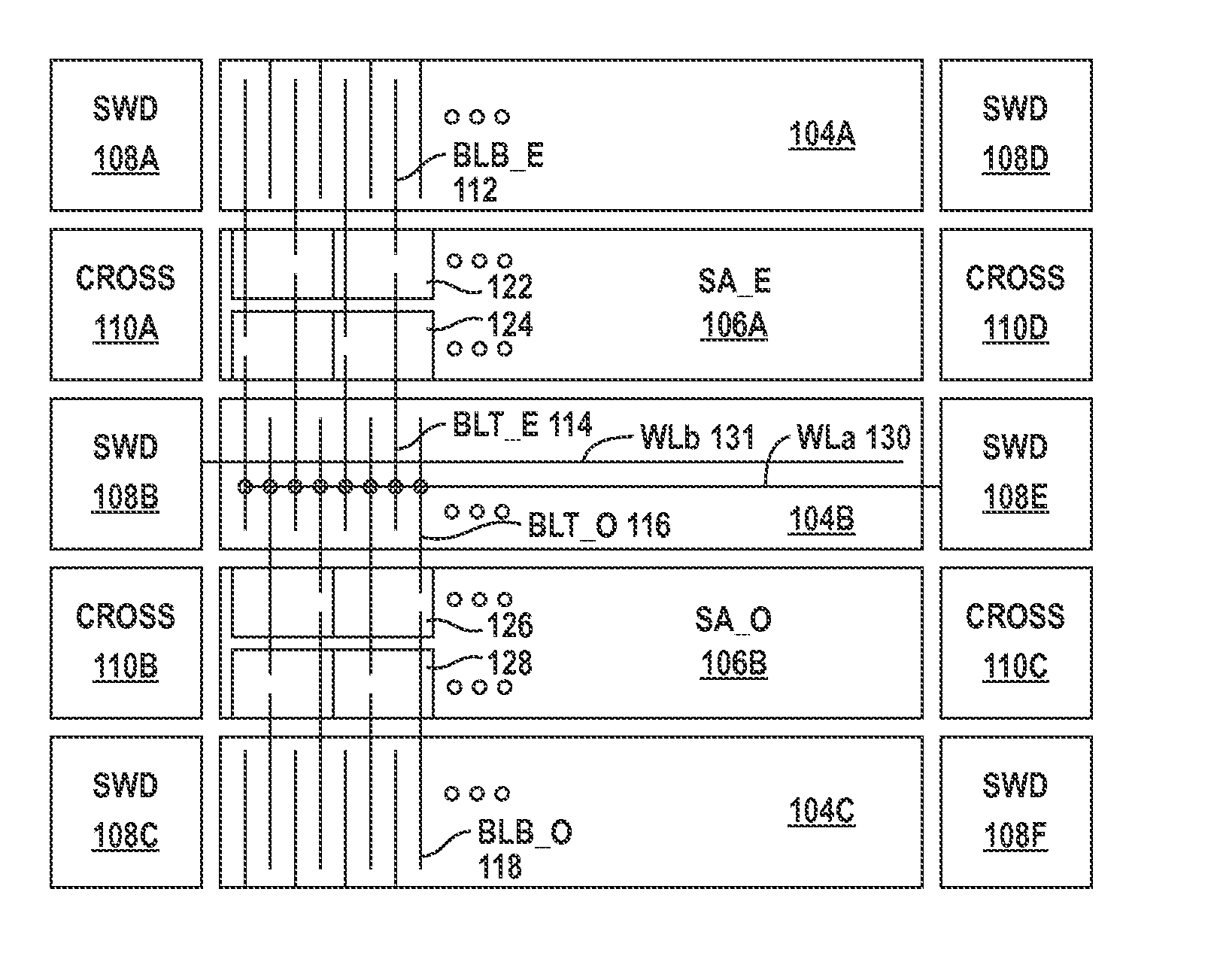

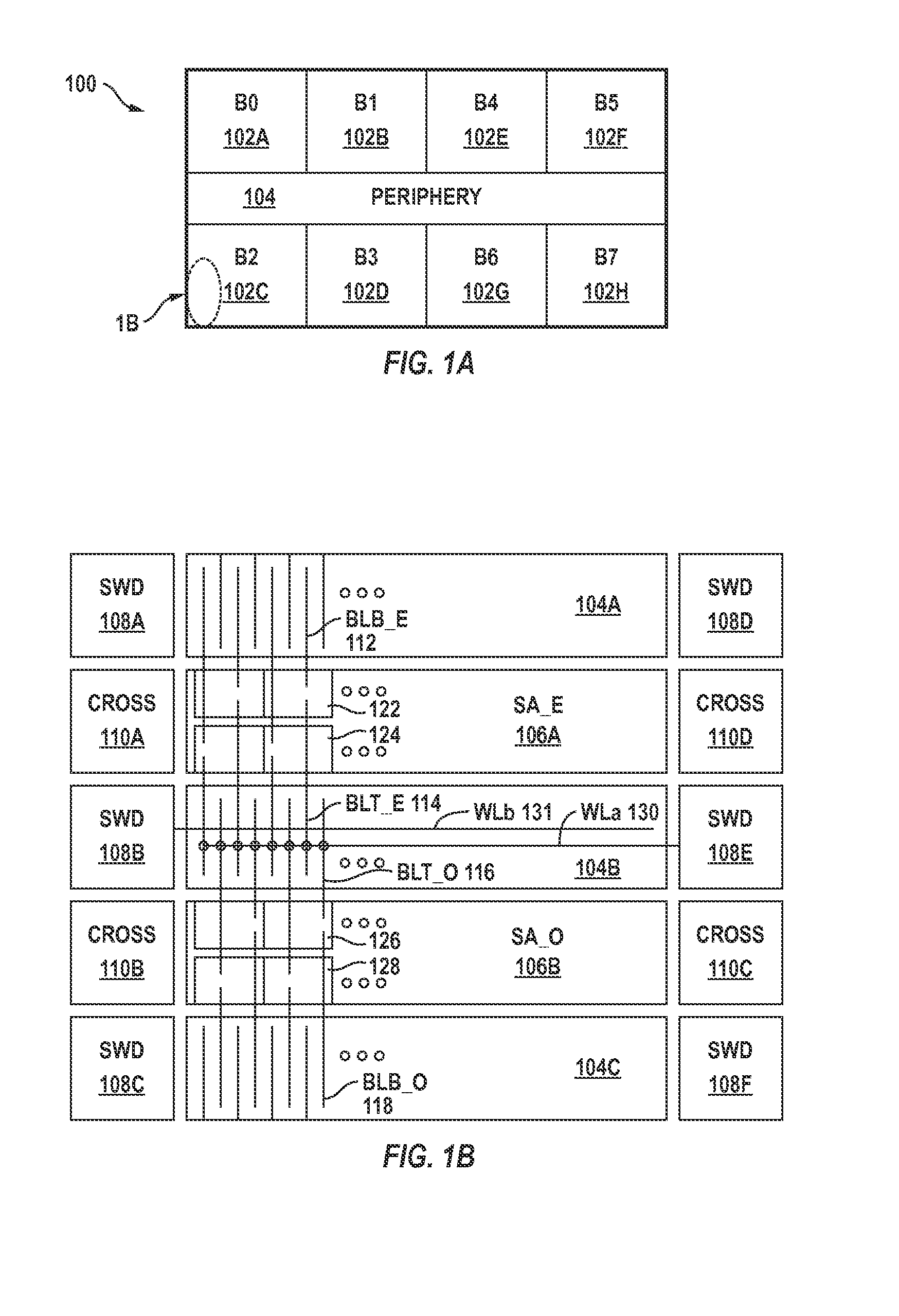

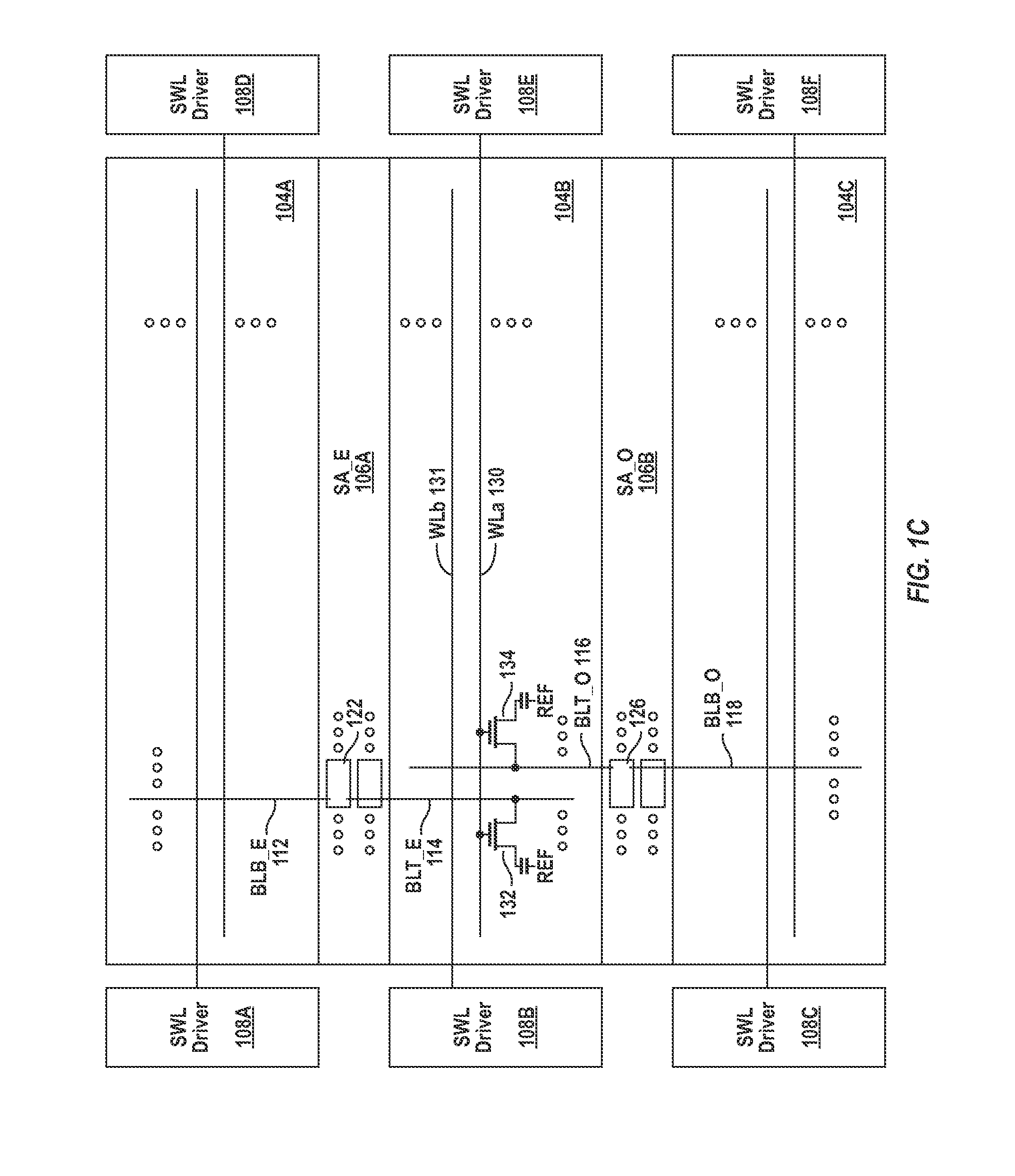

Storage cell bridge screen technique

A semiconductor memory includes a circuit block that is configured to receive a test mode command, a first sense amplifier that is coupled to sense and amplify a state of a first memory cell when enabled, and a second sense amplifier that is coupled to sense and amplify a state of a second memory cell when enabled. In an active cycle, the circuit block generates one or more control signals in response to the test mode command that cause the second sense amplifier to be enabled a predetermined amount of time after the first sense amplifier is enabled.

Owner:SK HYNIX INC

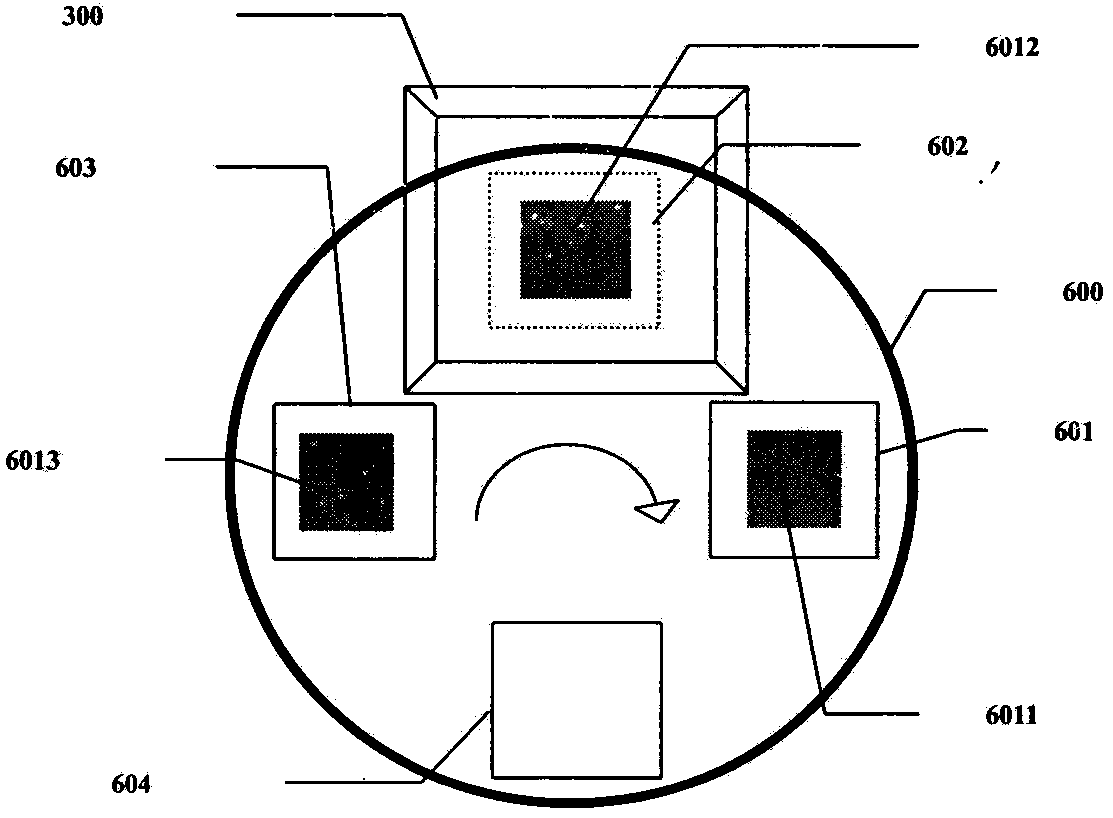

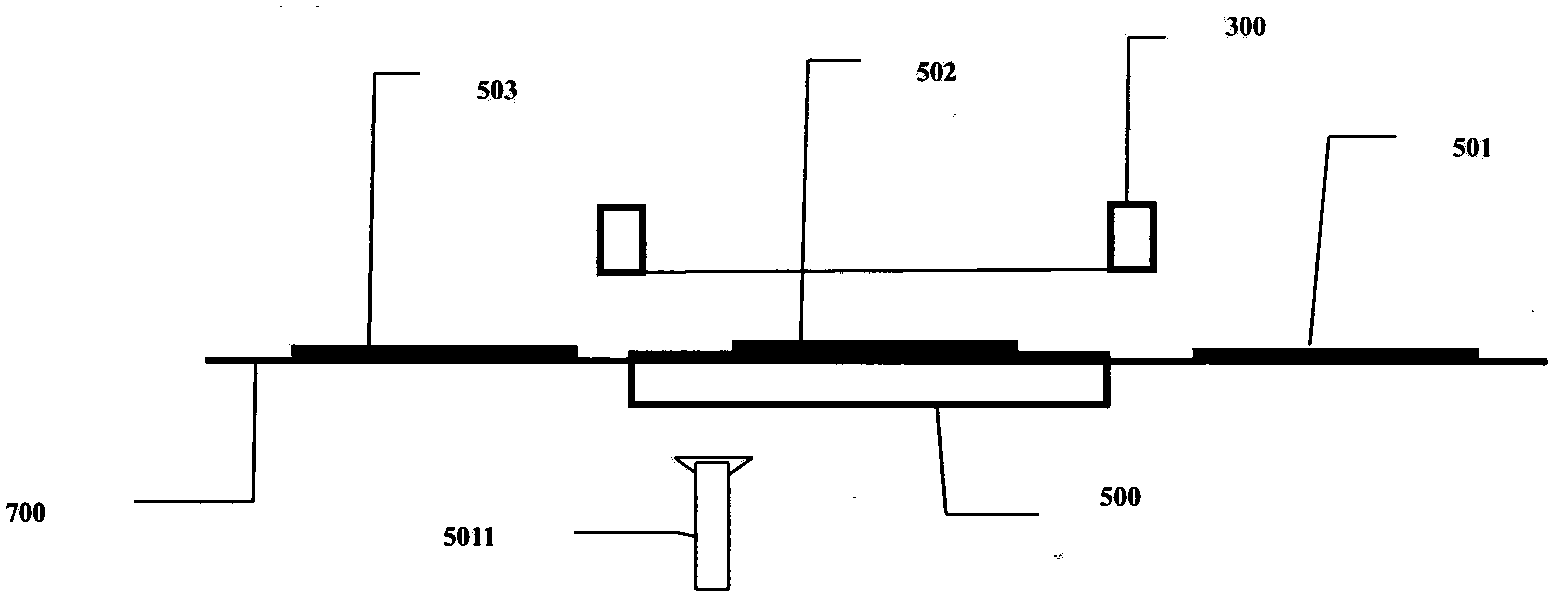

Rectilinear transmission type crystalline silicon solar cell printer with two sets of printing tables

InactiveCN104275916AHigh positioning accuracyFinal product manufactureScreen printersSingle degree of freedomSilicon solar cell

The invention provides a silicon wafer feeding and discharging and printing method adopting two sets of printing tables and applied to crystalline silicon solar cell electrode printing production equipment, and relates to a rectilinear transmission type crystalline silicon solar cell printer with two sets of printing tables. Through the method for alternatively and simultaneously completing silicon wafer feeding and discharging and printing with the two sets of printing tables, printing equipment achieves higher productivity within unit time; rectilinear motion units are adopted to translate the printing tables between a silicon wafer feeding and discharging station and a printing station, and accurate positioned printing of cells is realized by virtue of single-degree-of-freedom high repeatability positioning accuracy; by the same set of camera system, pre-printing and post-printing data analysis is performed on the same silicon wafer on the same feeding and discharging station, and various technological functions including printing accuracy, broken gate detection, screen technique life monitoring, secondary printing screen matching monitoring are realized.

Owner:JIERUI LIGHT ENERGY SUZHOU

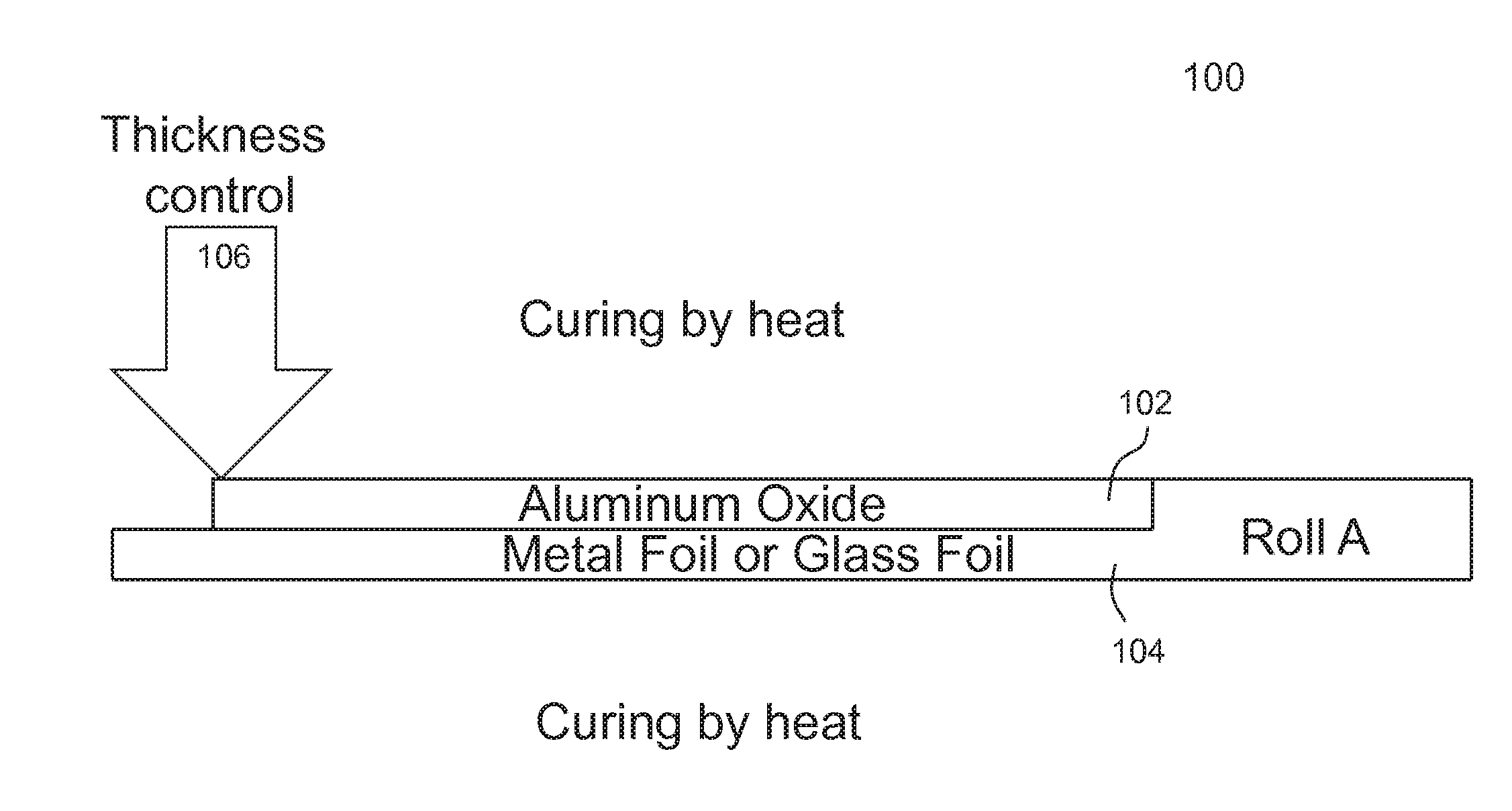

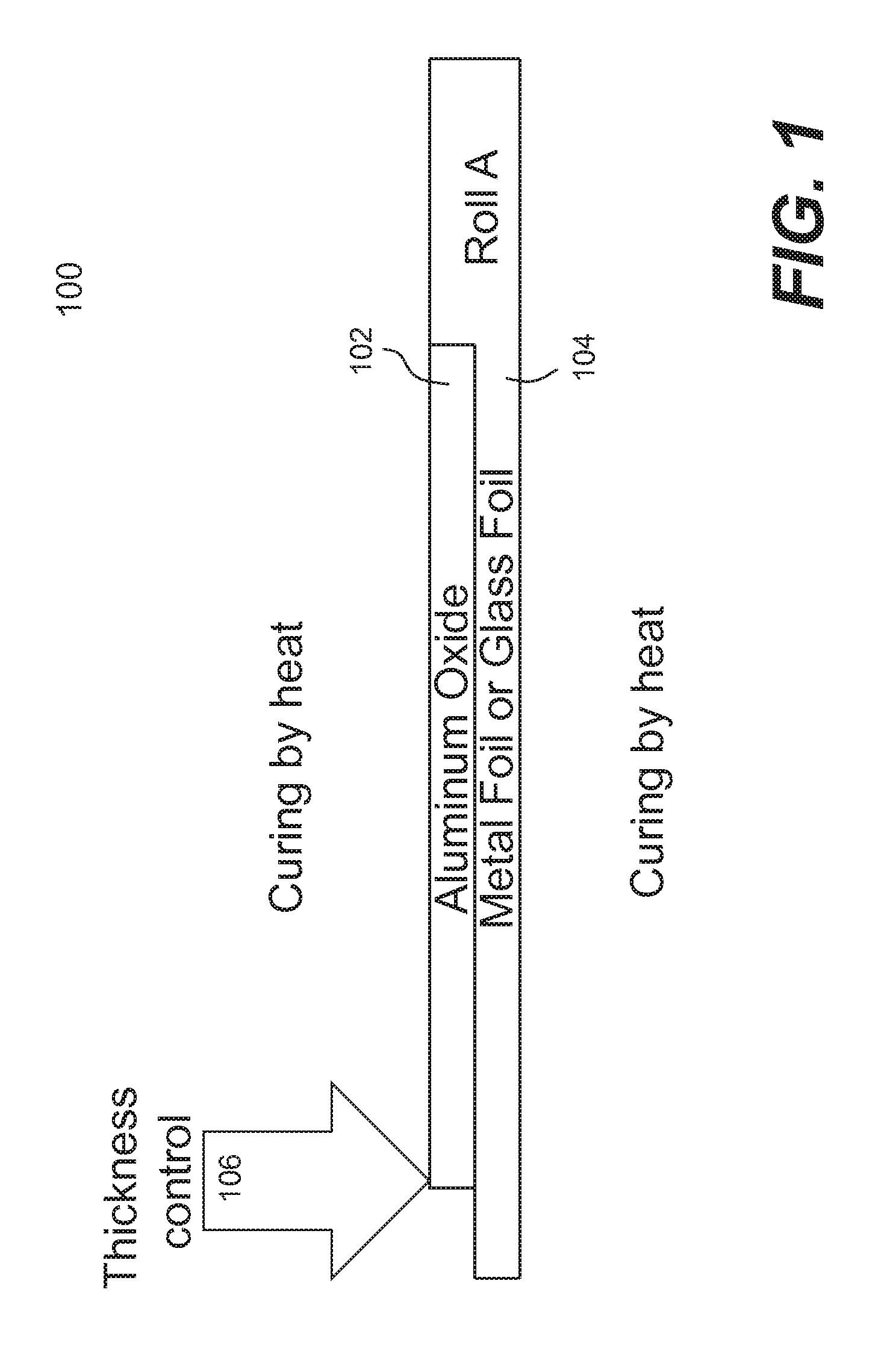

Single flexible cover for touch screen

ActiveUS20150324042A1Easily turn regular displaySynthetic resin layered productsElectrical equipmentPolyethylene terephthalateAdhesive

Techniques for manufacturing a single flexible cover to equip a display with touch screen capabilities are disclosed. The single flexible cover is easy to be applied to nearly all displays and maintains its durability on the displays. According to one aspect of the present invention, the single flexible cover includes at least three layers, a crystalline aluminum oxide layer, a polyethylene terephthalate (PET) film sensor stacking layer and an adhesive layer to bond the PET film sensor stacking layer to the crystalline aluminum oxide layer. The single flexible cover is produced by a manufacturing process including processes comprises: providing a foil as a substrate; coating the substrate with a set of materials including primarily aluminum oxide; curing the set of materials with heat to cause the set of materials to be crystallized to form the crystalline aluminum oxide layer; bonding the PET film sensor stacking layer to the crystalline aluminum oxide layer with optically clear adhesive (OCA); and applying anti-etching ink to top of the PET film sensor stacking layer. Then the foil and anti-etching ink are removed.

Owner:HU DARWIN

Wood floor with decorating patterns and manufacturing method thereof

InactiveCN101545313AStrong adhesionImprove stabilityWood working apparatusFlooringColor printingEngineering

The invention relates to a wood floor and a manufacturing method thereof. The wood floor with decorating patterns comprises a base material layer, a decorating pattern layer and a protective layer, wherein the decorating pattern layer is arranged on the base material layer and printed by a silk-screen technique and a transfer printing technique or a computer color printing technique, and the protective layer is arranged on the decorating pattern layer. The manufacturing method of the wood floor with the decorating patterns comprises the following steps: (a) coating base paint on the right sides of base materials and also drying the base paint; (b) sanding the base paint of the step (a) and coating a second base paint layer; (c) printing patterns on the surface of the second base paint layer of the step (b) by utilizing the silk-screen technique and the transfer printing technique or the computer color printing technique; (d) covering the protective layer on the pattern surface; and (e) cutting blanks to form floor dimensions. The invention prints the patterns on the base materials through the silk-screen technique and the transfer printing technique or the computer color printing technique so that the adhesive force of the patterns is strong, thereby enhancing the stability of the wood floor; and in addition, the invention enhances the availability of regenerated woods, thereby reducing the production cost.

Owner:GUANGDONG YINGRAN WOOD IND

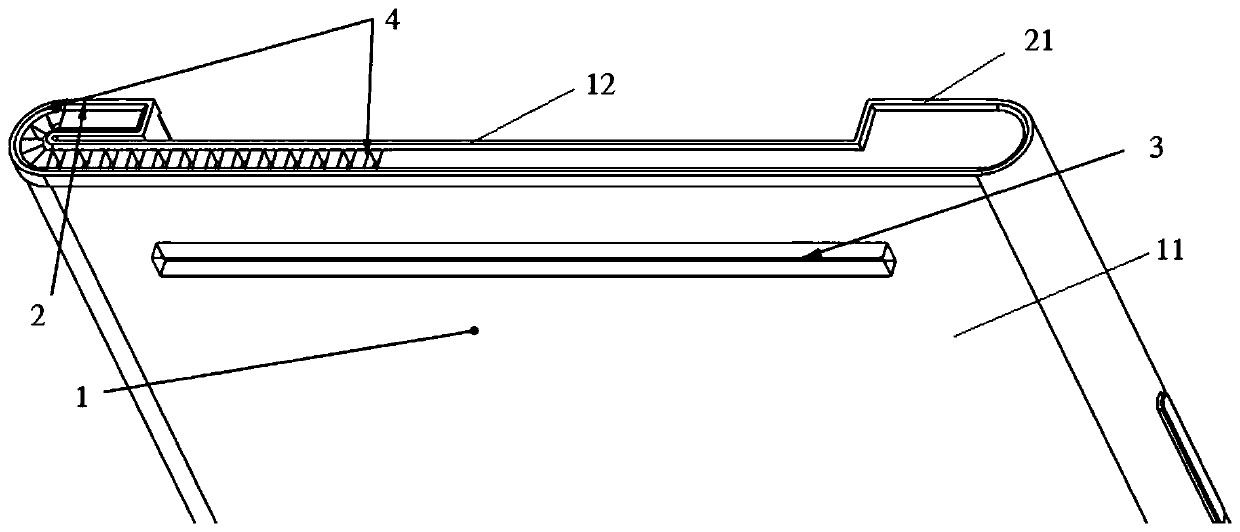

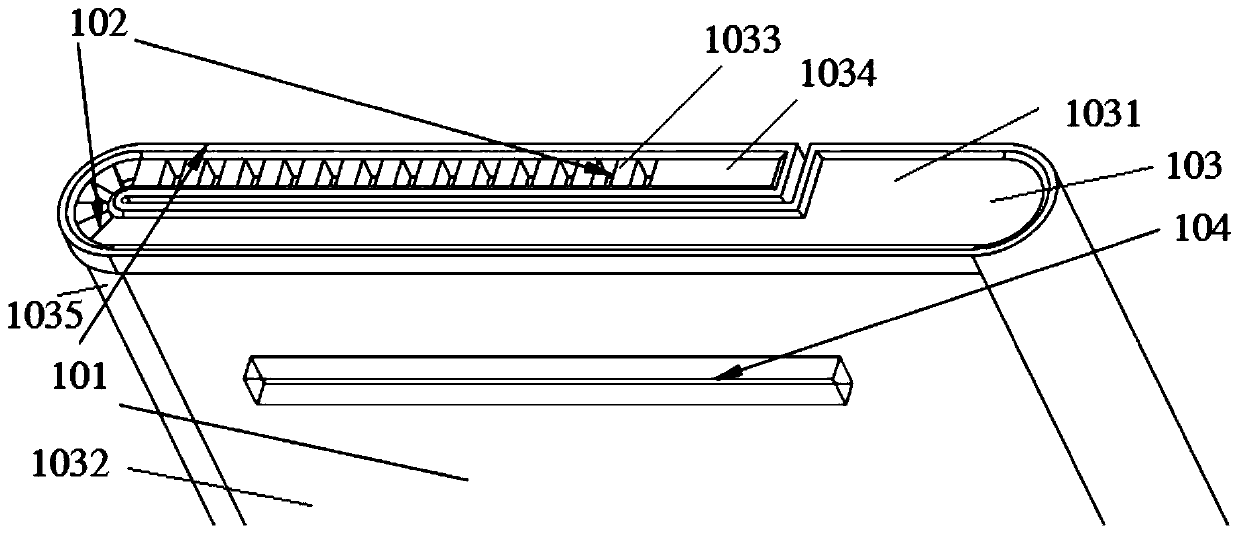

Mobile terminal

PendingCN110545342ATroubleshoot extended technical issuesIncrease diversityTelephone set constructionsScreen techniquesMultimedia

The invention provides a mobile terminal. Flexible screen techniques are used, and the invention provides a mobile terminal with two display areas capable of sliding relatively. When the two display areas are in a common display state or in mutual back-to-back arrangement, the two display areas can display different display contents independently; or one of the display areas is in a storage state,and when one of the display areas slides to the surface where the other display area is located, the display areas are combined into an extended screen, and a unified and complete content is displayed in the screen, so that the effect of extending the display screen is achieved, and excellent terminal practical experience is brought to a user.

Owner:SHENZHEN TRANSSION HLDG CO LTD

GAMMA debugging method capable of improving color temperature non-uniformity of liquid crystal screen

InactiveCN106791761AEnsure consistencyColor signal processing circuitsStatic indicating devicesComputer scienceImage signal

The invention relates to a liquid crystal screen technology, aims to solve the problem that white balance consistence of a whole liquid crystal screen cannot be ensured by an existing color temperature debugging method of the liquid crystal screen, and provides a GAMMA debugging method capable of improving the color temperature non-uniformity of the liquid crystal screen. According to the technical scheme, the GAMMA debugging method comprises the following steps: firstly, observing the color cast condition of the liquid crystal screen; selecting N partitions of image signals according to the cast condition, and transmitting the image signals to the liquid crystal screen; and performing GAMMA debugging by N partitions respectively. The GAMMA debugging method has the beneficial effects of convenience for a user and suitability for intelligent refrigerators.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

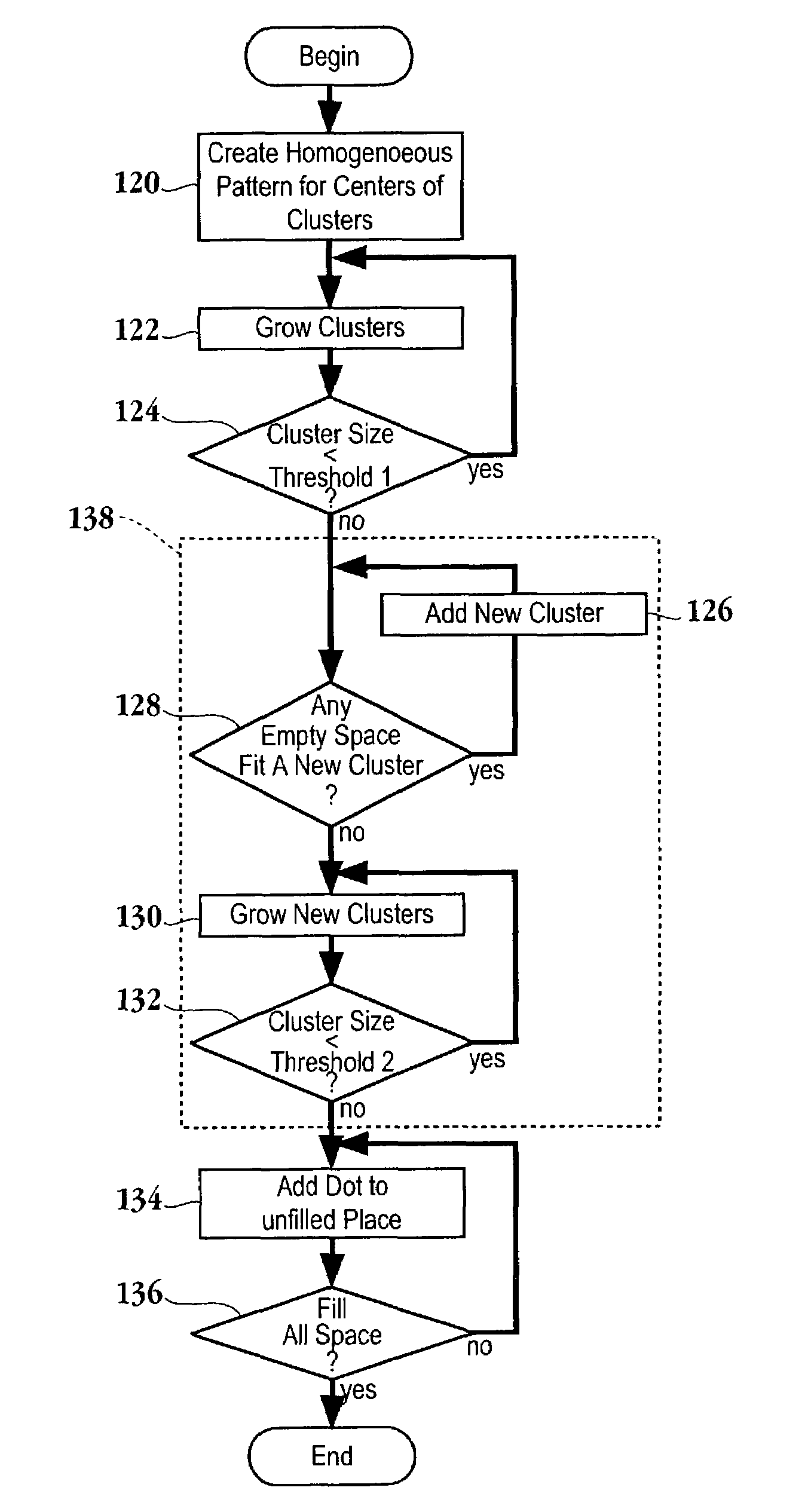

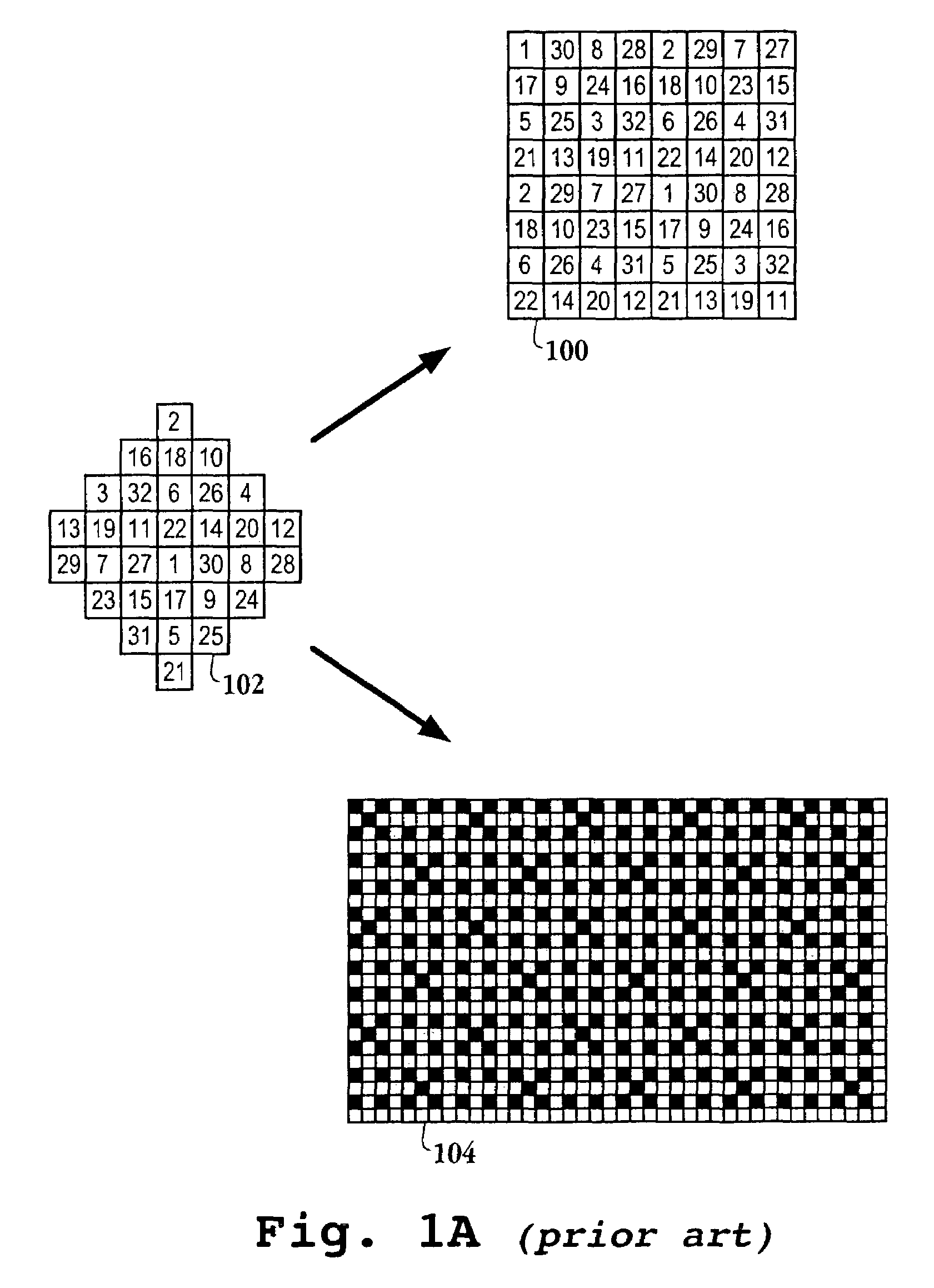

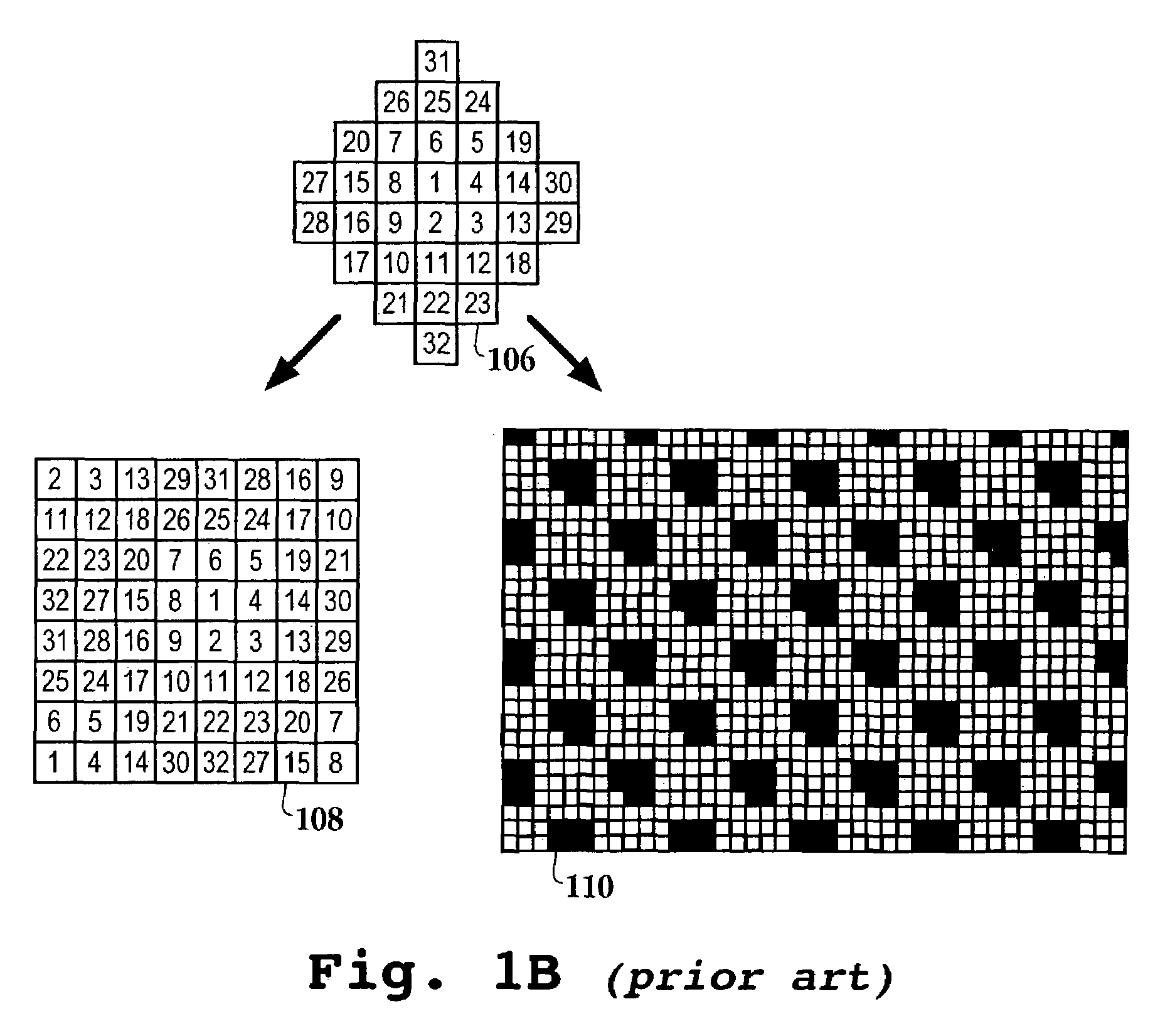

Method and apparatus for generating dispersed cluster screen

InactiveUS7239429B2Small sizeImage enhancementVisual presentationPattern recognitionProgram instruction

A method for generating a dispersed cluster screen defining a stable environment for printing an image is provided. The method initiates with generating a pattern of cluster centroids. Then a cluster growth sequence is defined. Next, a cluster is grown around the cluster centroid according to the cluster growth sequence. A computer readable medium having program instructions for generating a dispersed cluster screen and an image forming device configured to print an image according to a dispersed cluster screen technique are also provided.

Owner:SEIKO EPSON CORP

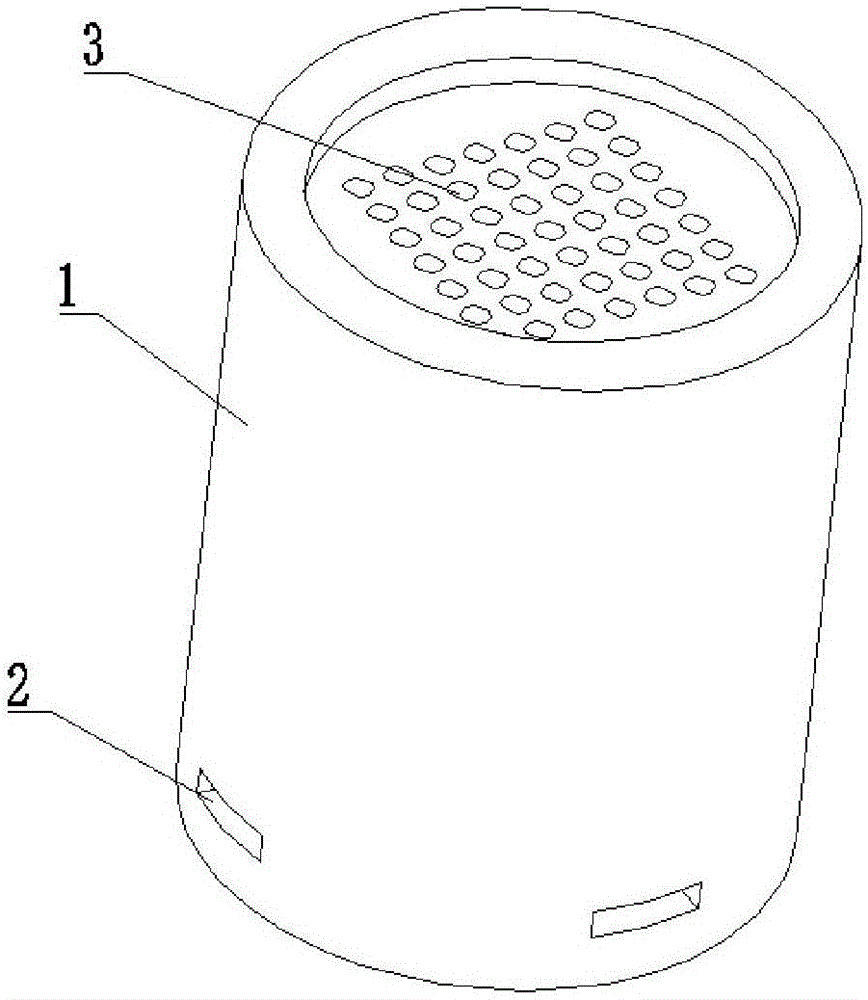

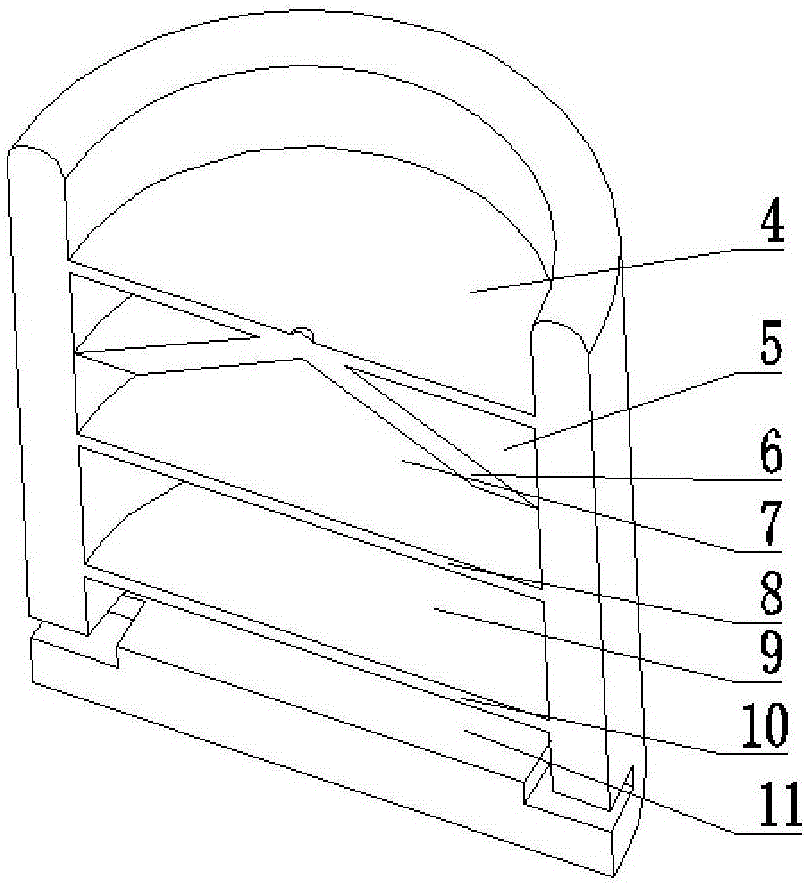

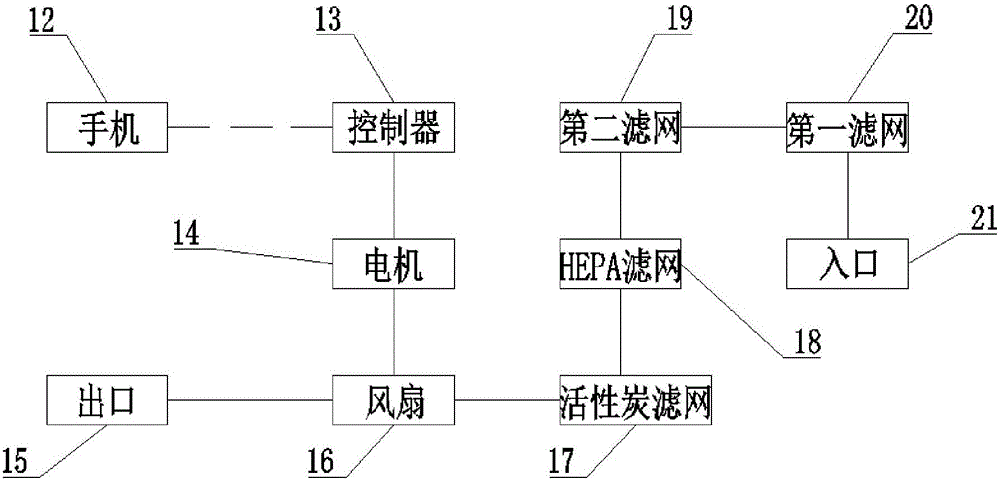

Filtration type air purifier

InactiveCN106390618AEffective filteringGas treatmentDispersed particle filtrationHEPAActivated carbon

The invention discloses a filtration type air purifier. The filtration type air purifier comprises a base, vent holes, air inlet holes, a motor, an outlet, a fan, an activated carbon filter screen and an HEPA (high-efficiency particulate air) filter screen. The base is a hollow cylinder, the bottom of the base is provided with the vent holes, and the fan is mounted beside the vent holes and driven by the motor. A plurality of filter screen layers are arranged in the base and include a first filter screen layer, a second filter screen layer, an HEPA filter screen layer and an activated carbon filter screen layer. The screen layers are provided with fine and dense through holes. Filter screen films are correspondingly mounted on the filter screen layers and cover the through holes. A controller is mounted in the base and electrically connected with the motor, and the controller is connected with a mobile phone through Bluetooth signals. By adoption of various filter screen techniques, effective filtration of solid particles and gaseous pollutants in air is realized, so that indoor air purification can be achieved; an equipment operation process can be controlled by the mobile phone, and real-time purification starting is realized.

Owner:WEIHAI YUNRUI INFORMATION TECH CO LTD

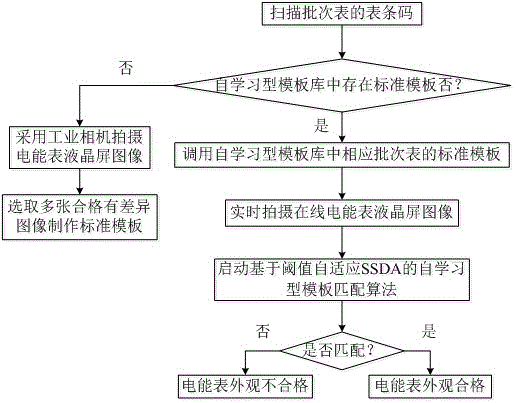

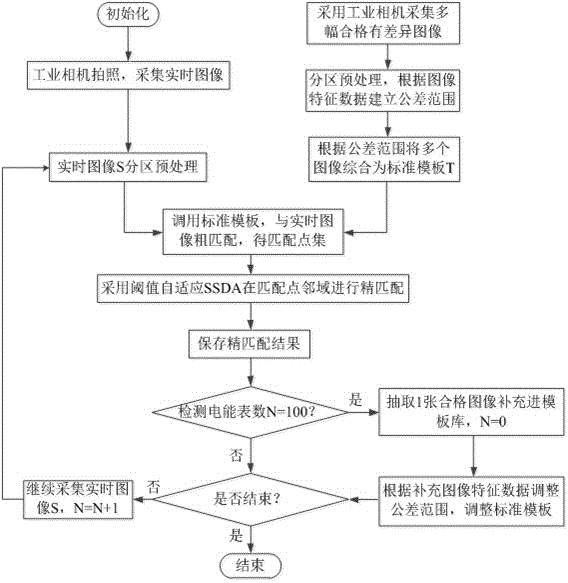

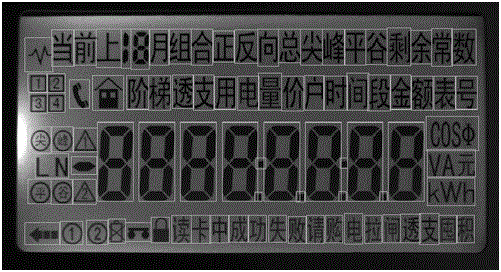

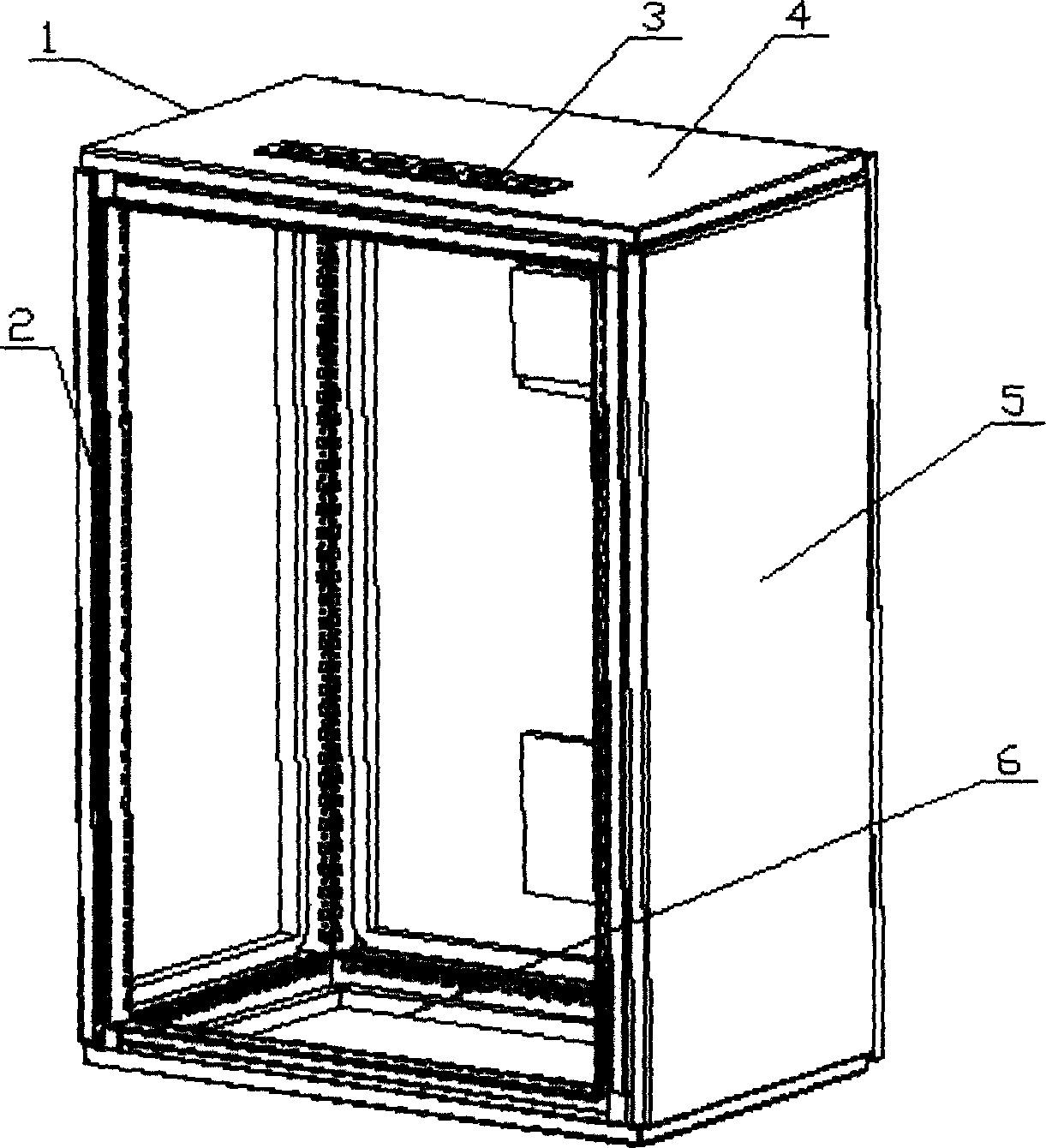

Online appearance detection method for power meter

ActiveCN104899879AIncrease productivityOvercome the influence of detection errorImage enhancementImage analysisTemplate matchingLight irradiation

The present invention discloses an online appearance detection method for a power meter. The method is applicable to a large-scale smart power meter automatic detection system. During the appearance detection, a self-learning profile library is established, thereby eliminating the impact on the detection error due to the image grey value difference caused by the differences of external conditions (light irradiation, air and dust) and the liquid crystal screen technique, and effectively reducing the misjudgment rate. By employing the self-learning profile matching algorithm based on adaptive threshold SSDA, calculation for the non-matched point is quickly terminated, thereby saving the matching time, improving the matching efficiency, improving the yield of the appearance detection, saving manpower and material resources, and further effectively solving the problem of high misjudgment rate.

Owner:STATE GRID CORP OF CHINA +2

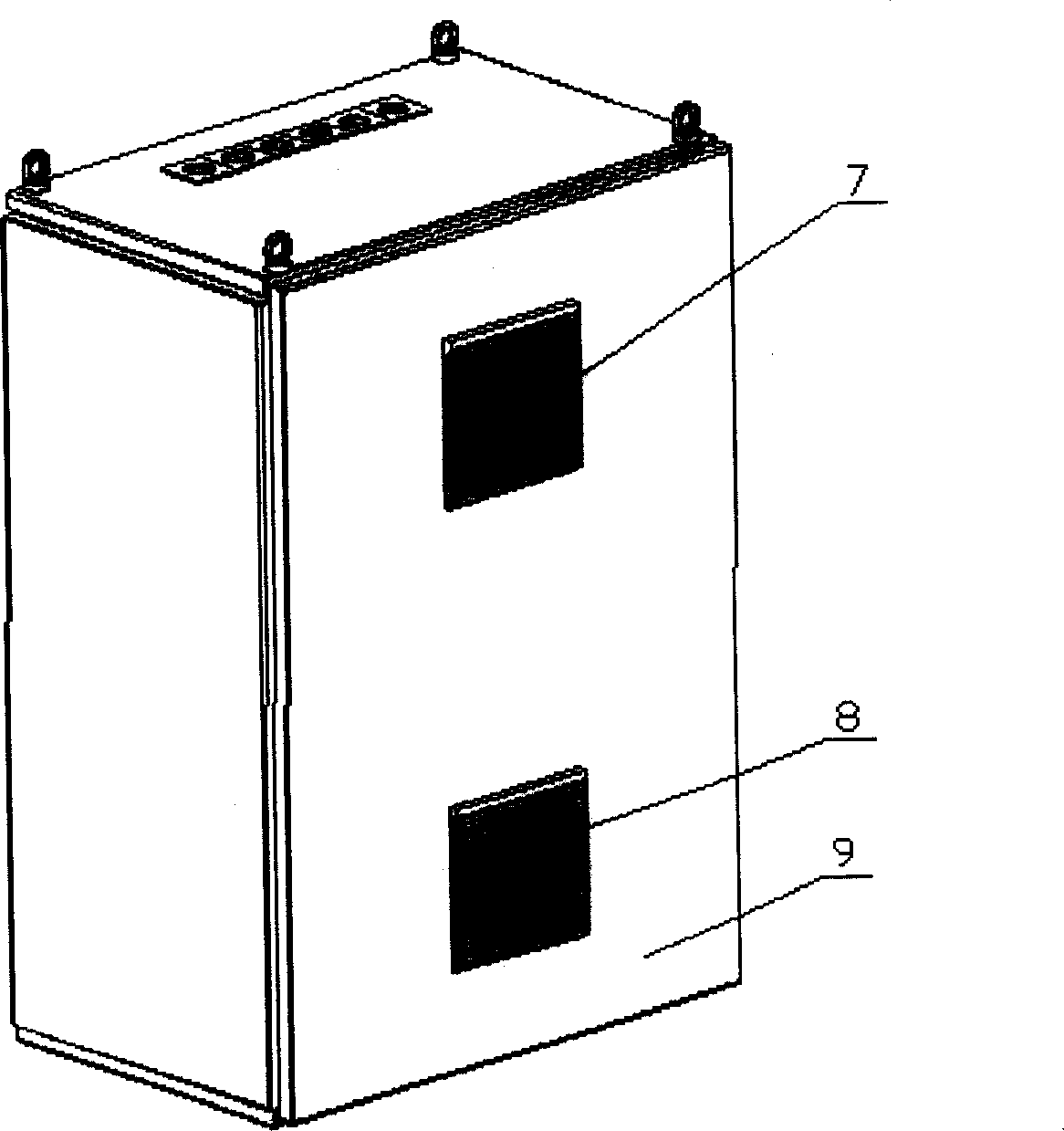

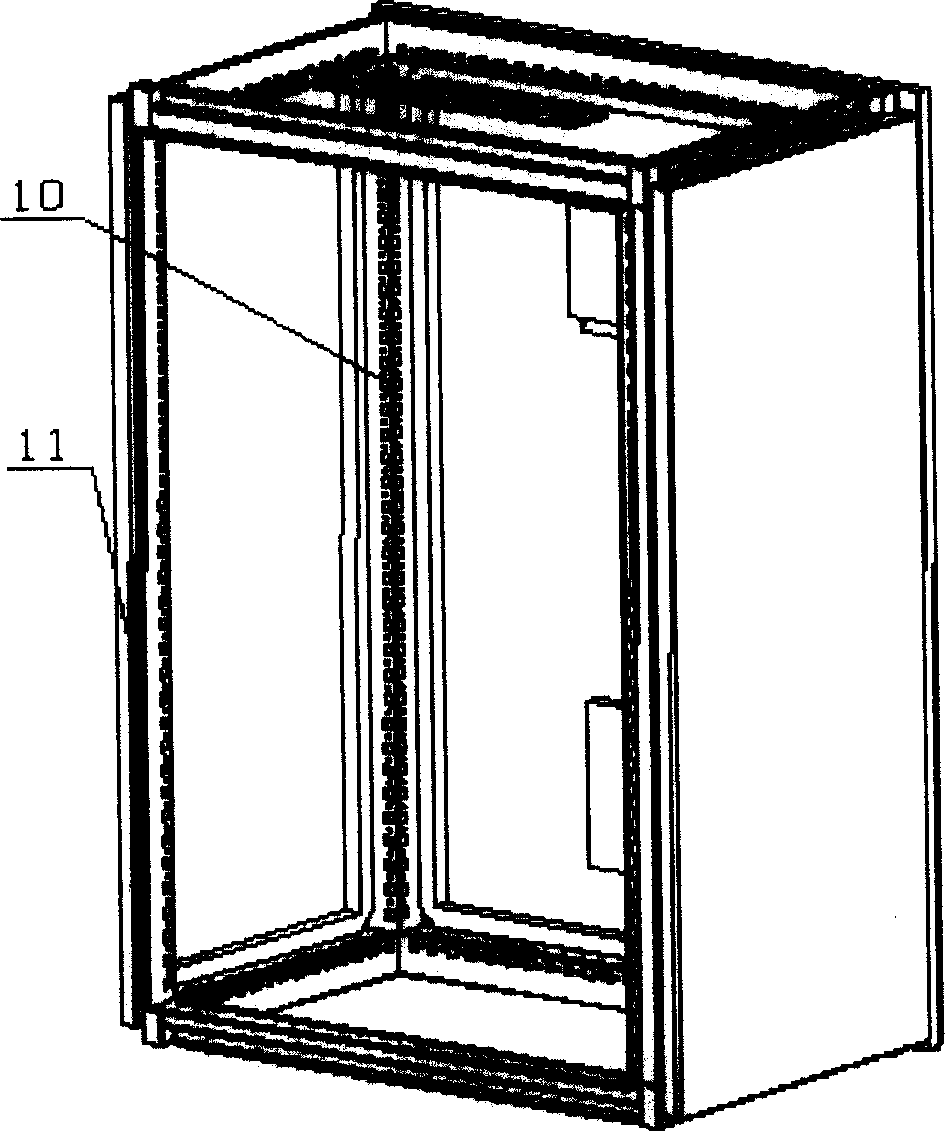

Electromagnetic shielding mode of electric apparatus chassis in new type train

InactiveCN1627895AMagnetic/electric field screeningElectrical apparatus casings/cabinets/drawersElectrophoresisLacquer

In the method, part of electric apparatus chassis needed to be electromagnetic shielded, and all side plates and doors are made from conducting material (can be galvanizing plate or aluminum alloy plate) and carried out surface treatment, electrophoresis and plastic jetting treatment; inside of all external side plates and internal protective plate and shaped section accessories is conducted electrically in order to guarantee conductivity of surface of chassis. 'weitu' ROXTEC electromagnetic screen technique and flexible type conducting rubber are adapted for top part of chassis or incoming line portion of other parts. Electromagnetic screen foaming conducting rubber is adopted for sealing contact place between side plates, door edges and framework of basal body. Technique of electromagnetic screen foaming conducting rubber and conductive paint spray coating are adopted for door structure. In the invention, fan and intake also possess electromagnetic screen effect.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Multicolor printing method on natural stone

InactiveCN1631679AAccurately reflectDelicate reflectionOther printing apparatusColor printingNatural stone

The invention is a color printing technique on the natural stone materials, which is based on silk-screen technique. The printing steps are that firstly, cast surface polishing process on the plank stone material; secondly, bed paints on the polished stone; thirdly transfer printing the figures to the surface of the plank stone with silk-screen technique. The technique is based on surface silk-screen technique and applies it to plank stone material printing. It is simple and easy, of low cost and low technics requirements which precisely and smoothly reflect the style and intension of the original figure and acquires mass industrial production with the product figures resistant to dampness, washing, high temperature and sun burning with constant color.

Owner:陈嘉星

Saccharomycetes used for making wine, screening technique of the saccharomycetes and application of the saccharomycetes in blueberry red wine fermentation

ActiveCN108865910AStrong fermentation abilityImprove fermentation performanceFungiMicroorganism based processesScreening techniquesAdditive ingredient

The invention relates to a saccharomycetes used for making wine, with the preservation number of CGMCC NO.15931, which relates to the screening technique of the saccharomycetes and the application ofthe saccharomycetes in blueberry red wine fermentation. The blueberry red wine made by fermentation of the saccharomycetes has high quality, clearness and transparency orange red color and classic redwine flavor. The production of blueberry fruit creates a good development opportunity for the red wine industry, fermented wine contains a large amount of nutritional ingredients such as amino acids,vitamins and minerals and the like, and a certain physiological activator, which mainly plays a role of relaxing muscles, stimulating blood circulation and boosting metabolism, and is suitable for drinking.

Owner:贵州凯缘春酒业有限公司

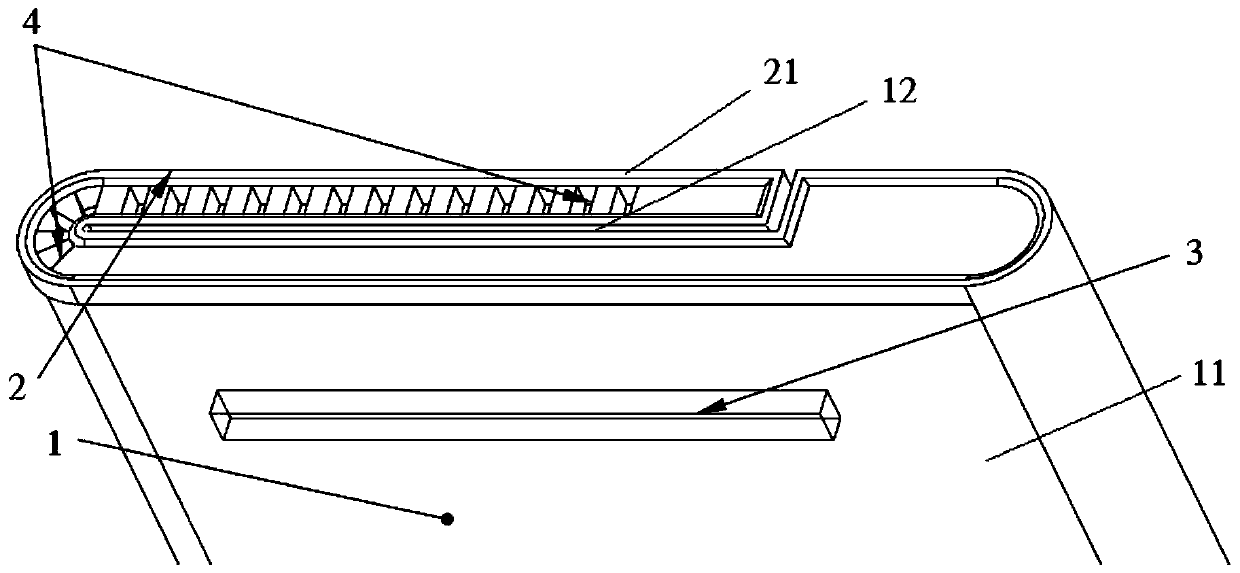

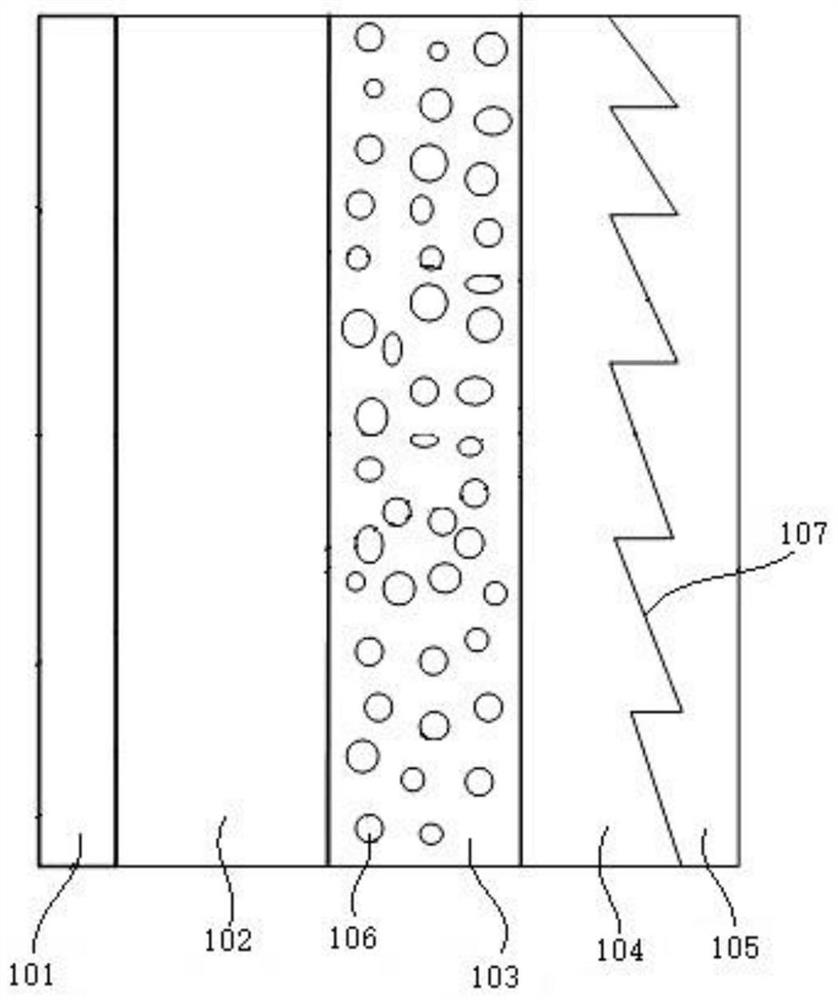

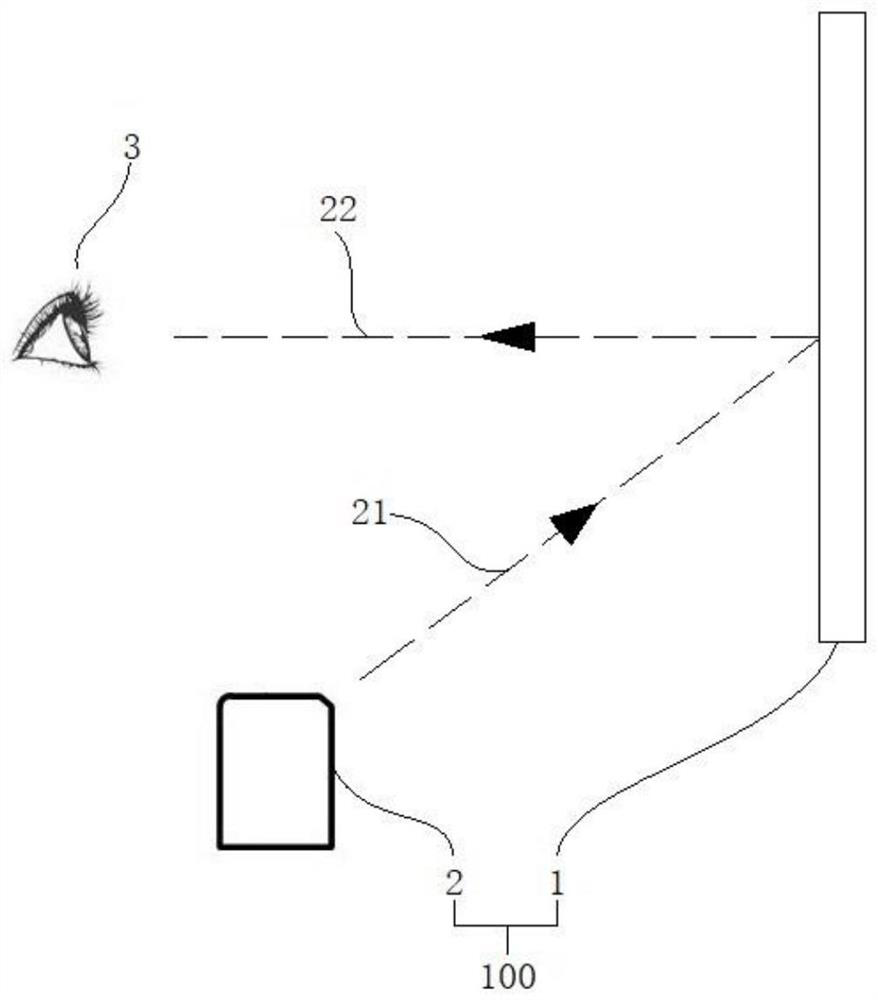

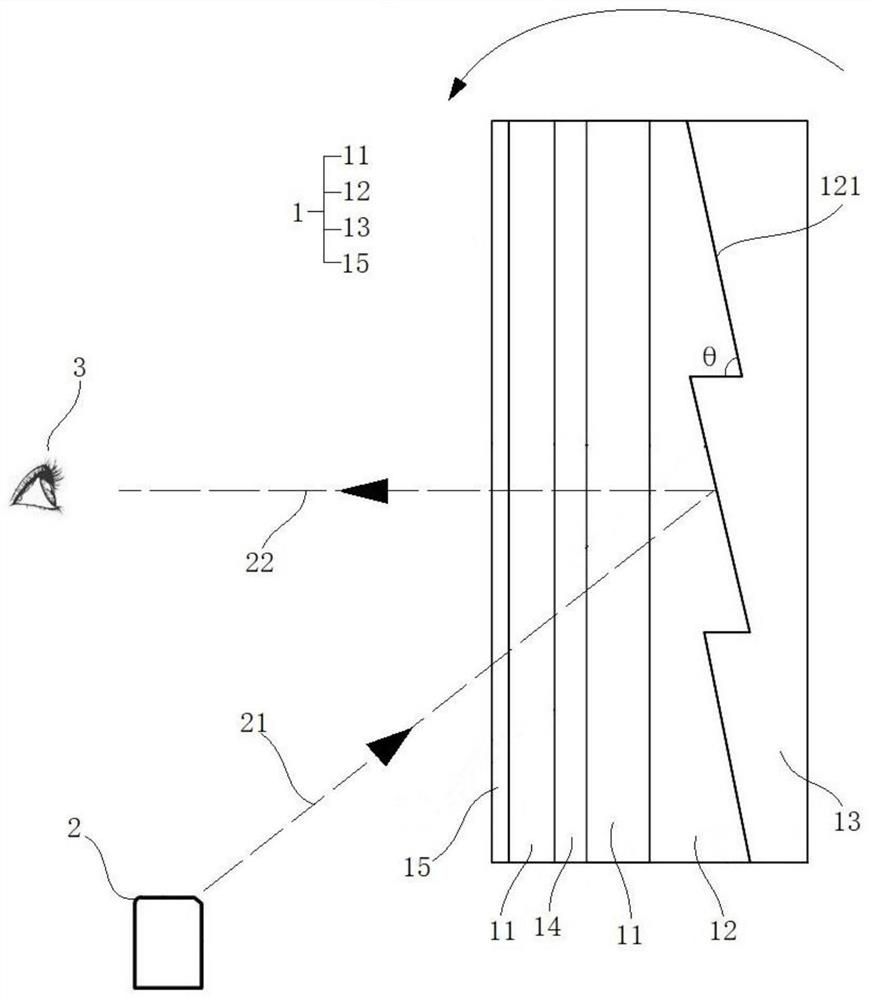

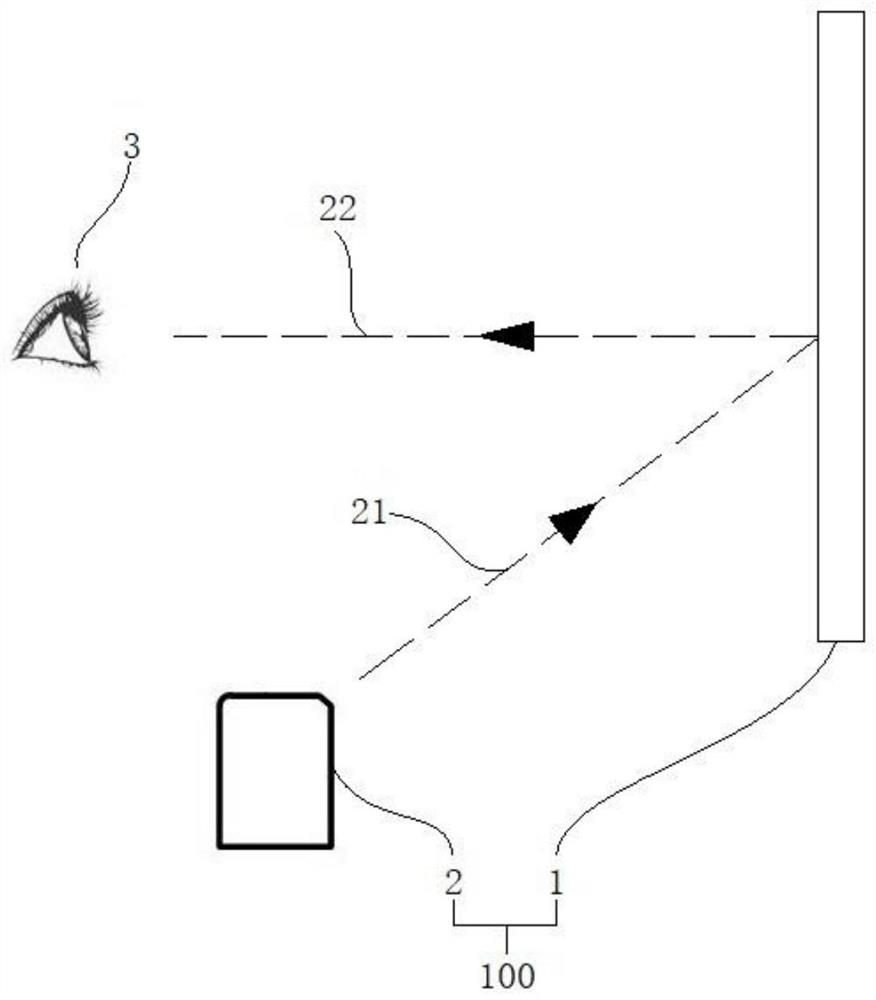

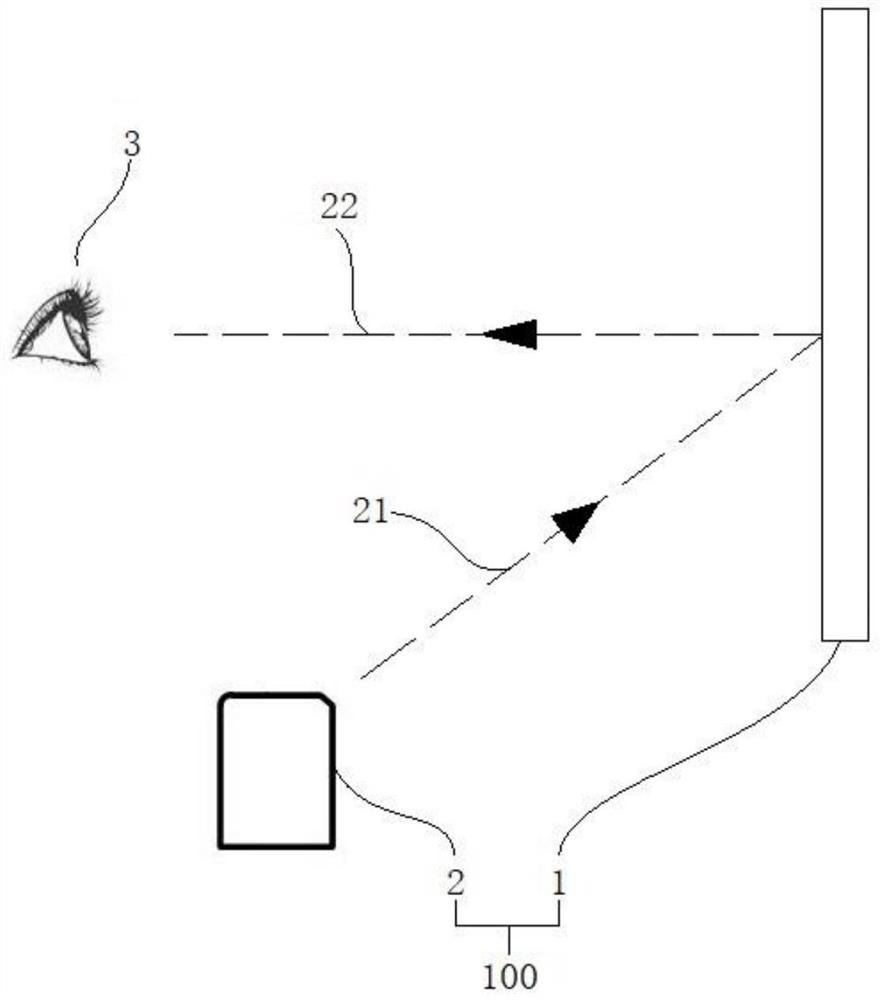

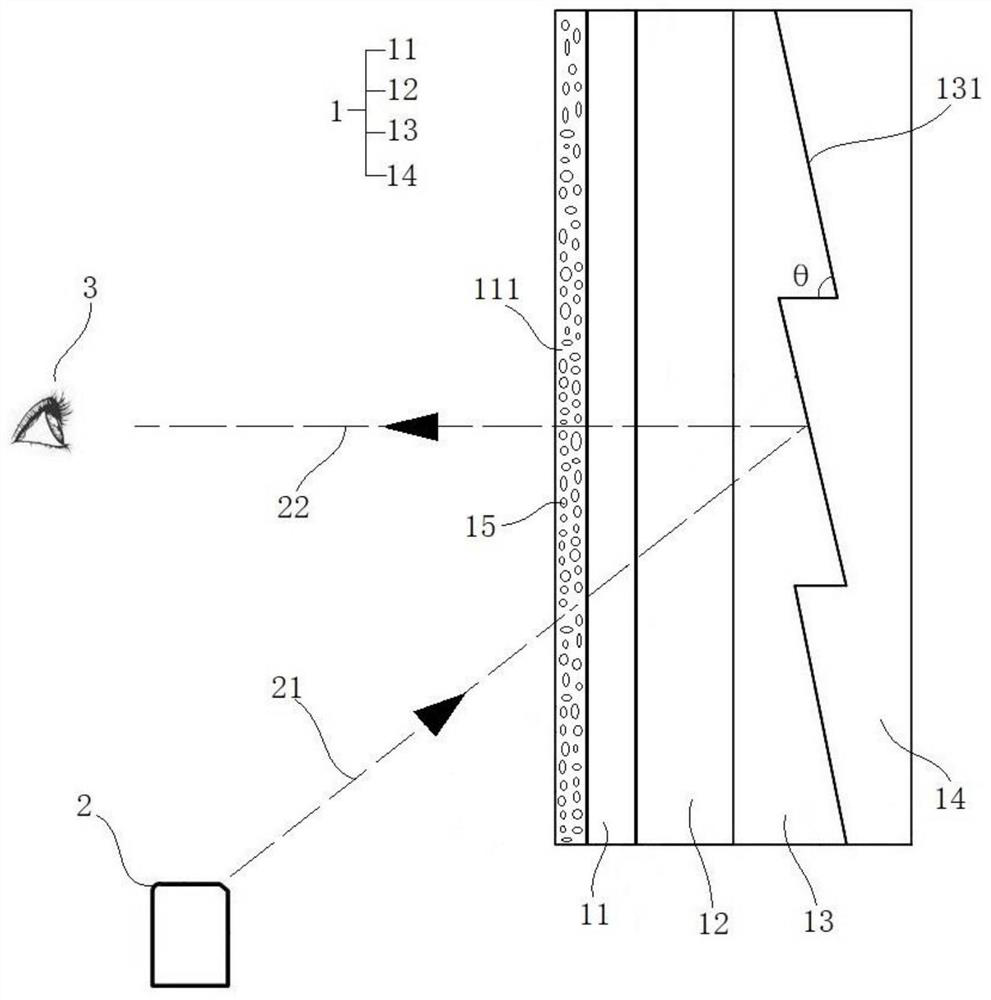

Rollable projection screen and projection system

The invention discloses a rollable projection screen and a projection system, relates to the technical field of projection screens, and is used for solving the problem that a projection screen in the prior art cannot be rollable. The rollable projection screen comprises a flexible surface layer, flexible base material layers, a Fresnel lens layer and a reflecting layer which are sequentially stacked and arranged. The number of the flexible base material layers is multiple, and in the curling direction of the rollable projection screen, the thickness of the front flexible base material layer is smaller than that of the rear flexible base material layer. The rollable projection screen can be rollable and is very convenient to transport, install and use.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

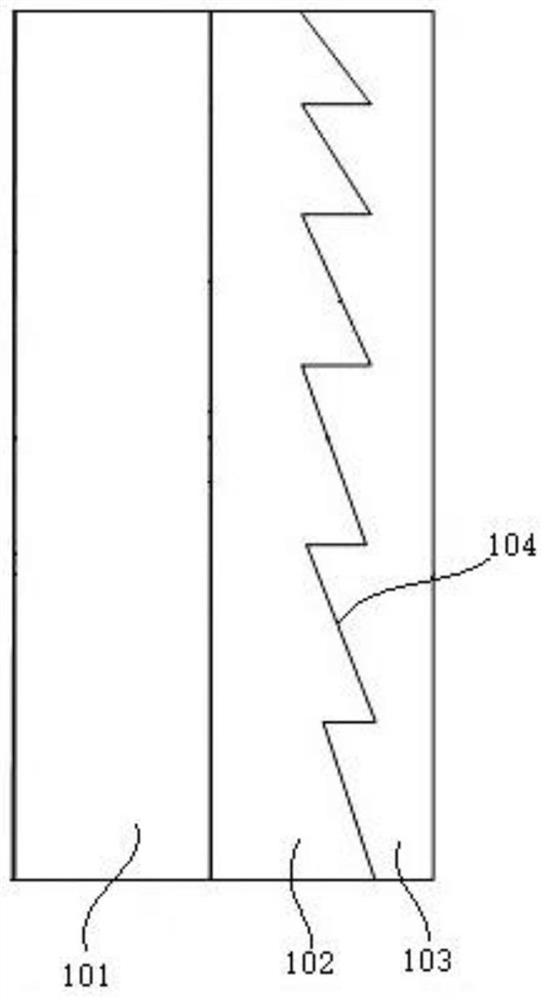

Projection screen and projection system

The invention discloses a projection screen and a projection system, relates to the technical field of projection screens, and is used for solving the problem that aluminum powder in a reflecting layer in a projection screen in the prior art is easy to fall off. The projection screen comprises a surface layer, a base material layer, a Fresnel lens layer and an aluminum reflecting layer which are sequentially stacked and arranged, and aluminum particles in the aluminum reflecting layer are scaly aluminum powder. The aluminum particles in the aluminum reflecting layer in the projection screen are high in adhesion fastness and not prone to falling off.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

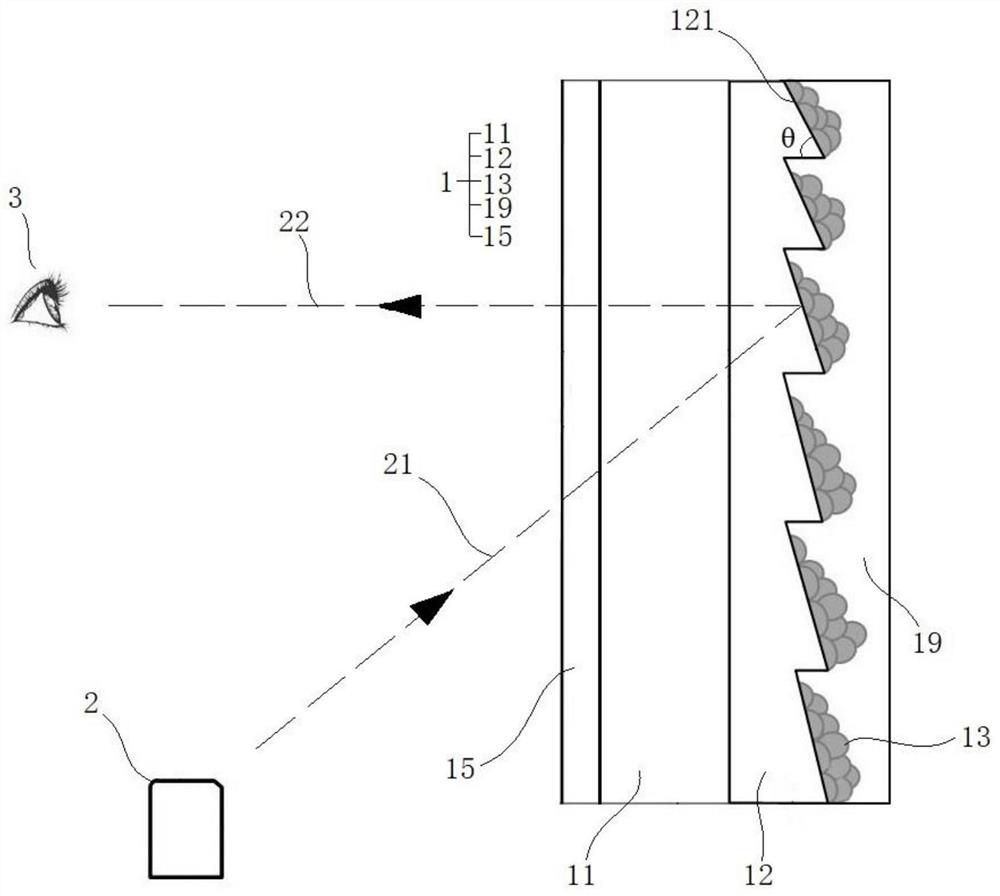

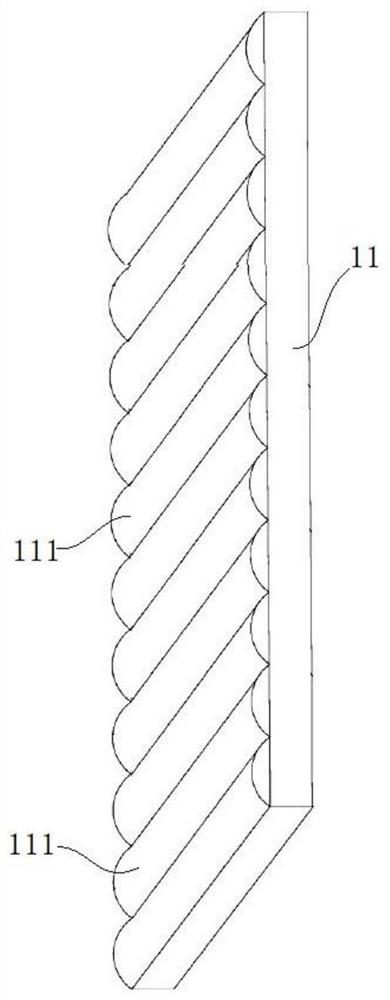

Ceiling reflection resistant projection screen and projection system

The invention discloses a ceiling reflection resistant projection screen and a projection system, relates to the technical field of projection screens, and aims at solving the problem that a projection screen in the prior art can generate ceiling reflection in the use process. The ceiling reflection-resistant projection screen comprises a surface layer, a base material layer, a Fresnel lens layer and a reflecting layer which are sequentially stacked and arranged, a plurality of light-transmitting protrusions are arranged on the surface, away from the Fresnel lens layer, of the surface layer, and the surfaces of the light-transmitting protrusions are provided with gradually-shrinking parts and / or gradually-expanding parts in the direction away from the Fresnel lens layer; diffusion particles are arranged in the light-transmitting bulges; and the value range of the haze value of the surface of the light-transmitting bulge is 12%-20%. By using the ceiling reflection resistant projection screen, ceiling reflection resistance can be realized.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com