Electromagnetic shielding mode of electric apparatus chassis in new type train

An electromagnetic shielding and train technology, applied in the fields of magnetic field/electric field shielding, electrical components, electrical equipment shells/cabinets/drawers, etc., can solve problems such as large deformation, heavy structure, and unsightly appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

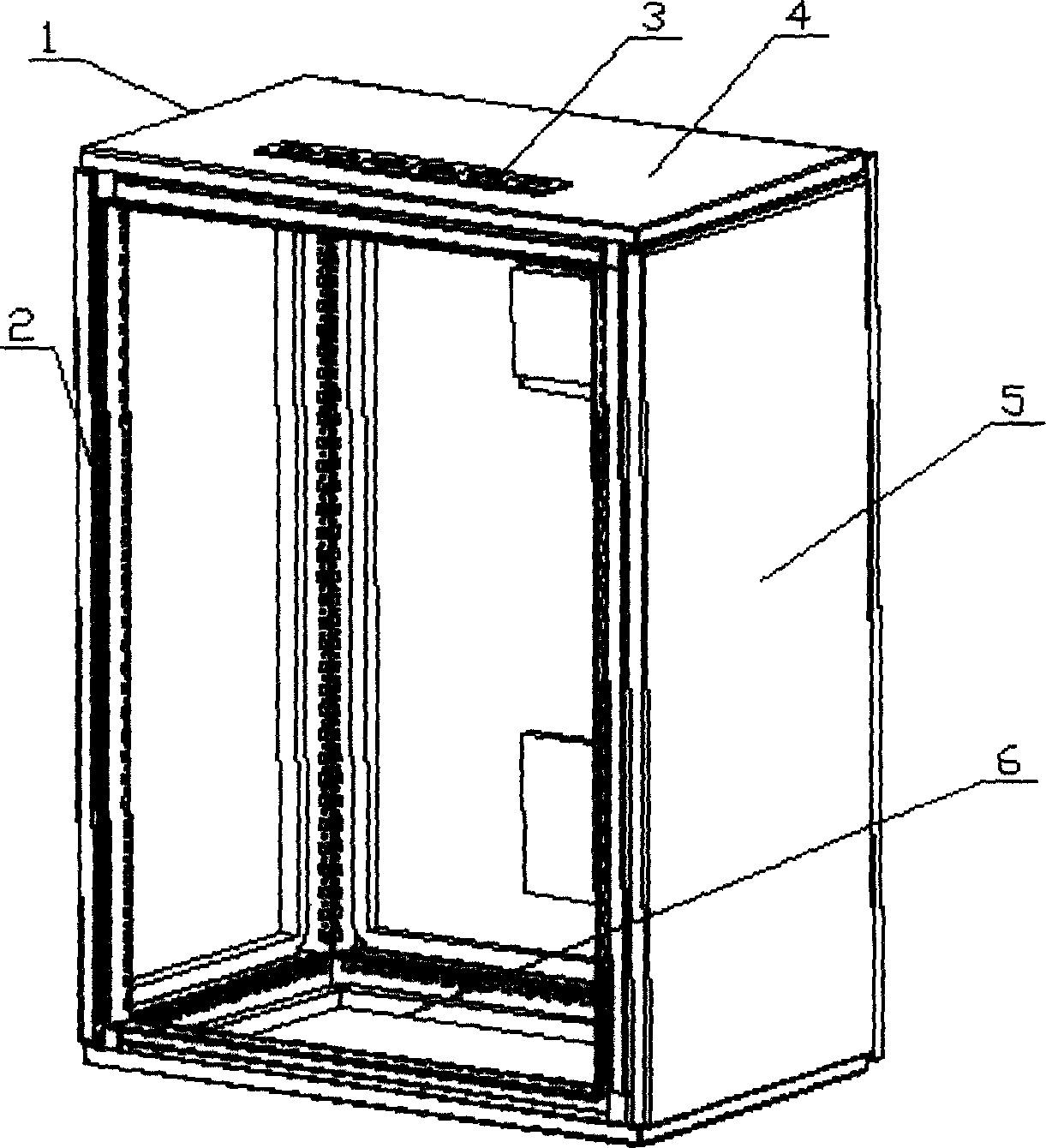

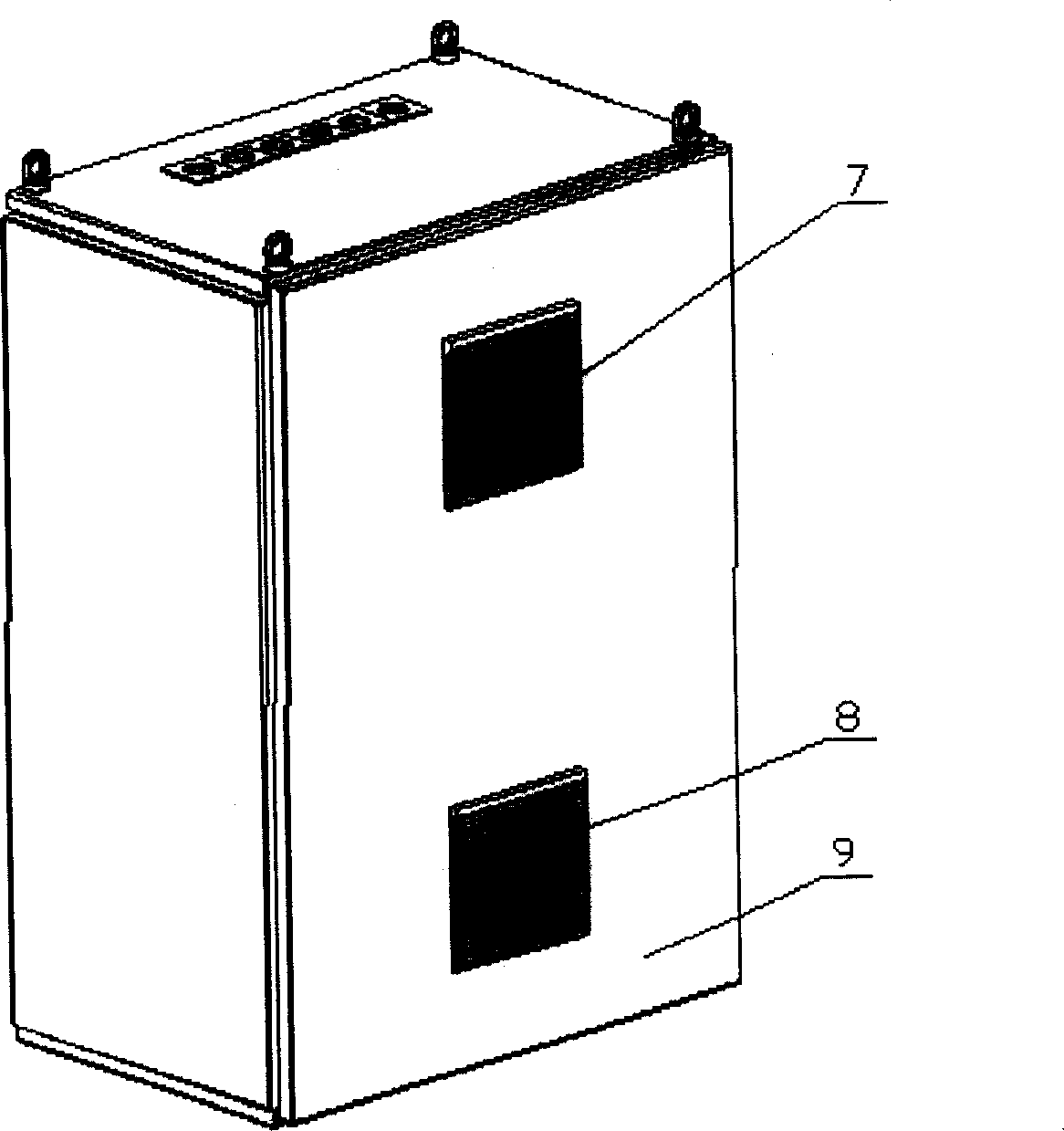

[0013] attached Figures 1 to 4 A specific embodiment of the present invention is given, which is an electromagnetic compatibility embodiment of a locomotive control panel box. It can be seen from the drawings that the control panel box 1 of the present invention is composed of a base frame 2 and a side plate 4, 5, 6, 9 are combined by jigsaw structure. Its characteristic is that all side panels and doors of the cabinet body that need electromagnetic shielding are made of galvanized sheets, and are treated with surface treatment, electrophoresis and plastic spraying, and all outer panels, internal protective panels and profile accessories are all For electrical conduction, to ensure the conductivity of the surface of the box. All the side panels and the parts where the door structure is combined with the base frame 2 use foamed electromagnetic shielding conductive rubber materials and conductive cloth as seals, which are tightly pressed with the frame profiles, which not only...

Embodiment 2

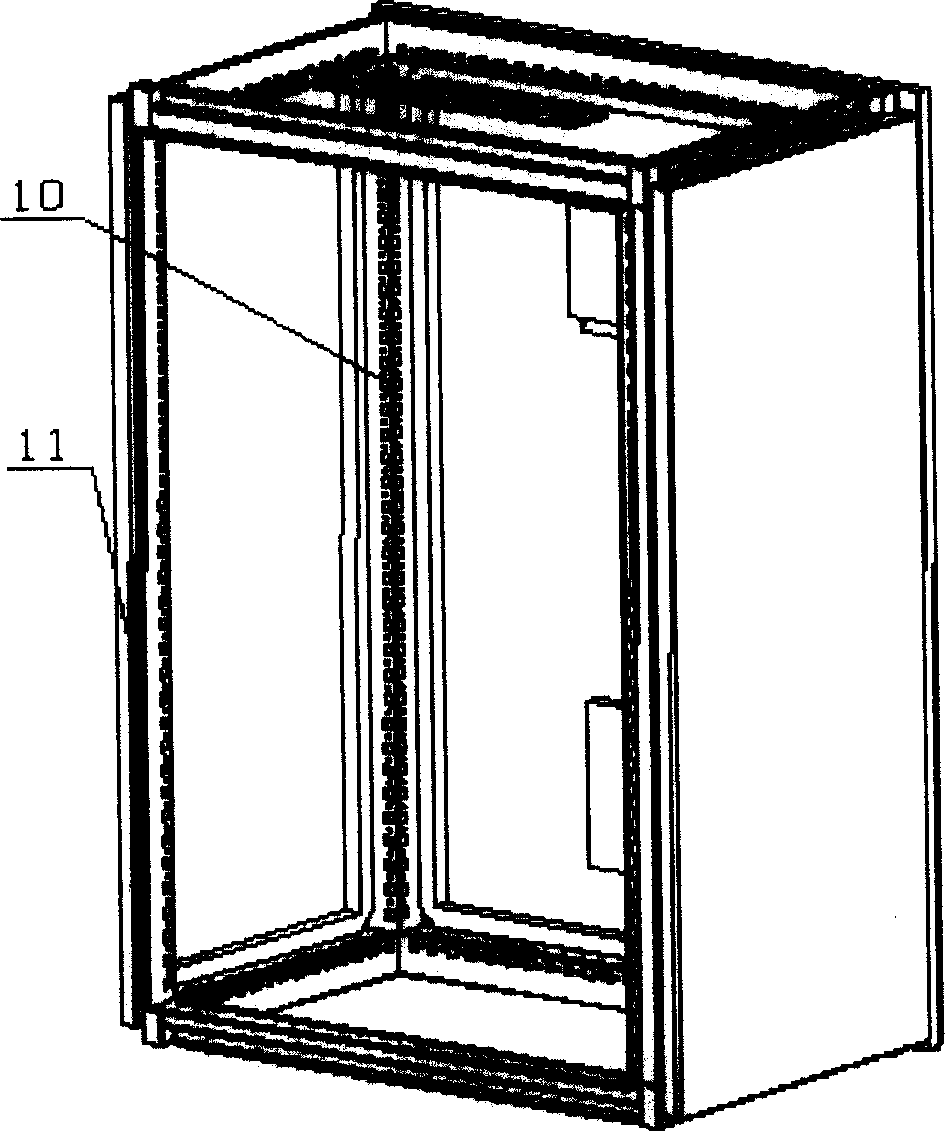

[0015] The structure of embodiment two is the same as that of embodiment one, except that all side plates are made of aluminum alloy plates, and square steel bars 10 for strengthening the side plates are added on the inner surfaces of all side plates.

Embodiment 3

[0017] Embodiment 3 is improved on the basis of Embodiment 1. It mainly welds the side plates of the cabinet body 1 directly with the base frame 2 of the cabinet body 1 using low-temperature welding technology, and the door structure and the further The same electromagnetic shielding structure as in Embodiment 1 is still adopted at the line entrance and the ventilation and heat dissipation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com