Rectilinear transmission type crystalline silicon solar cell printer with two sets of printing tables

A printing table and linear motion technology, which is applied to printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of low production capacity, poor printing quality consistency, and low mechanical positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

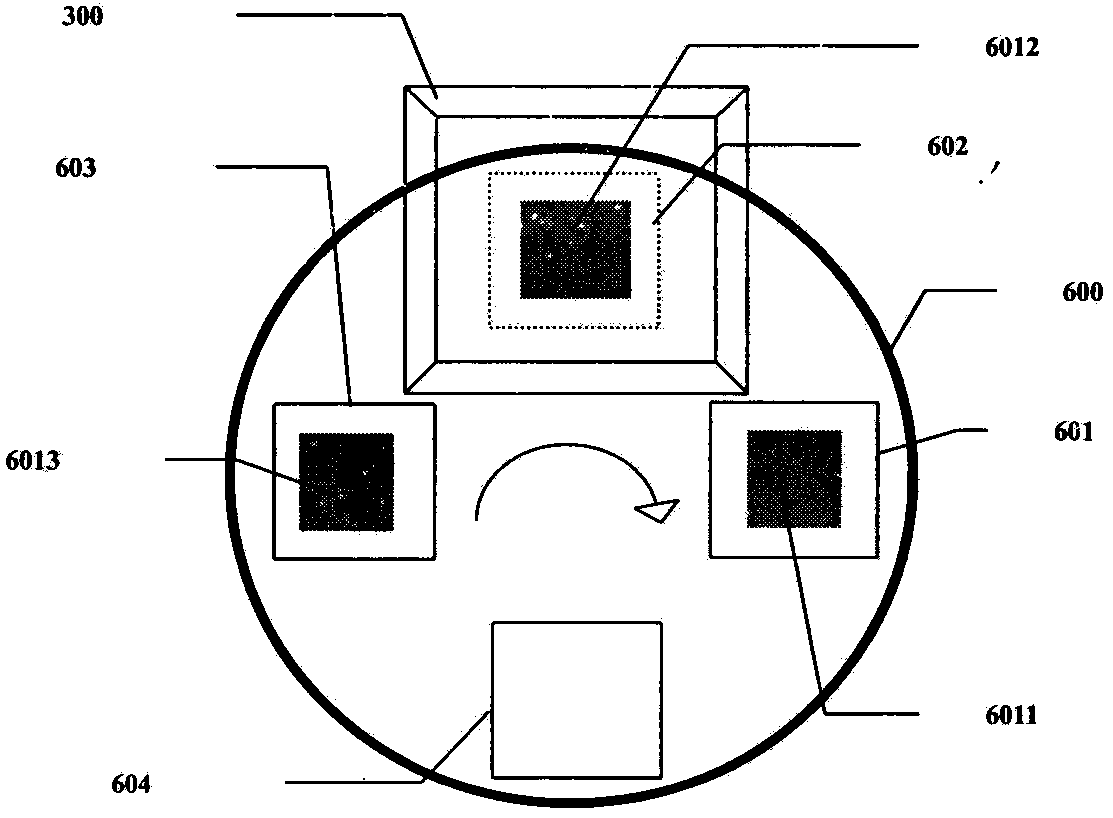

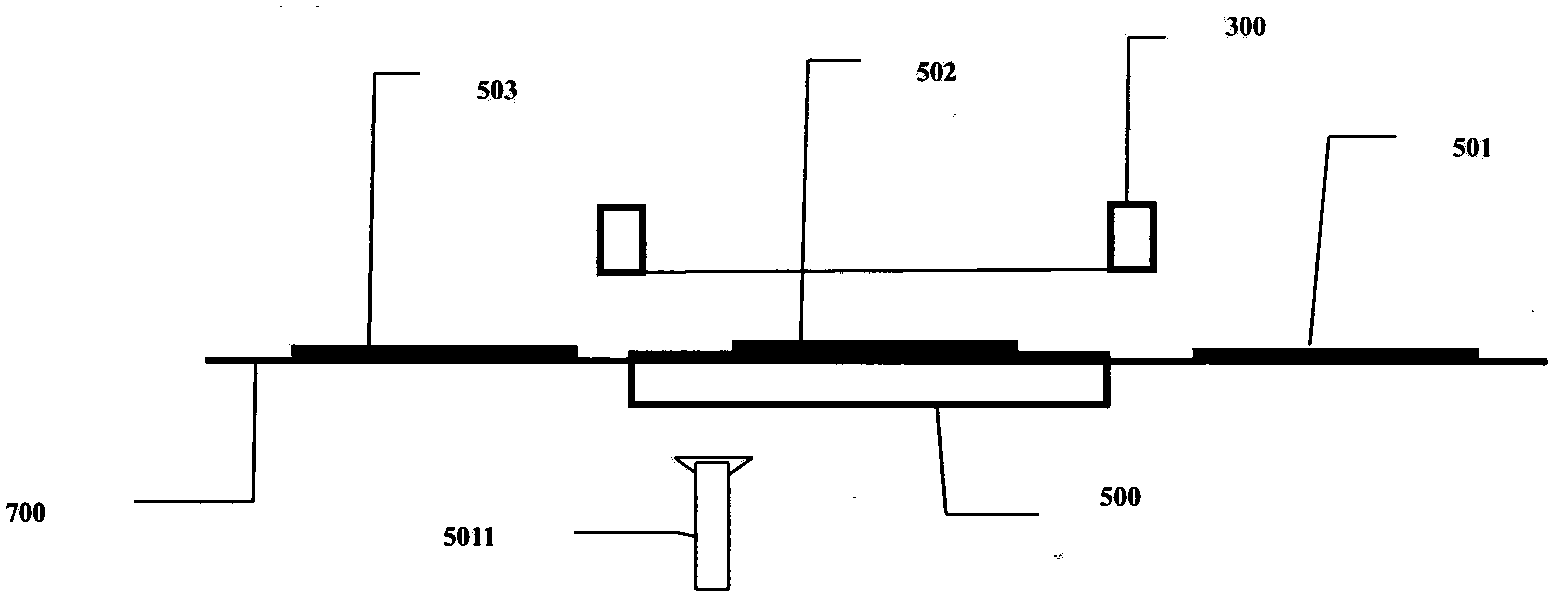

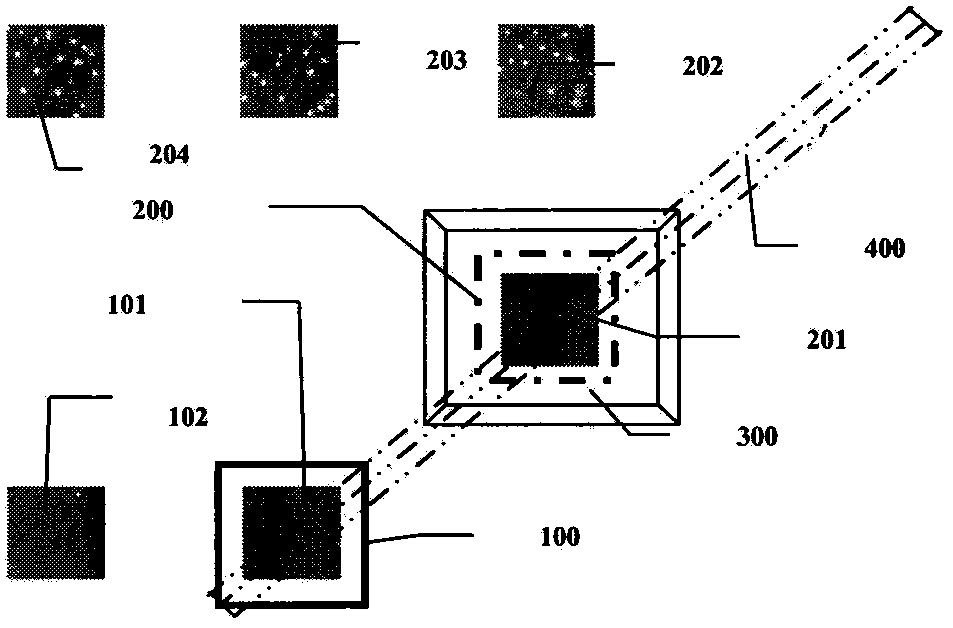

[0012] The silicon wafer loading and unloading and printing methods proposed by the present invention are as follows: image 3 As shown, after the silicon wafer 101 is transferred to the printing table 100, the vacuum system on the printing table 100 adsorbs and fixes the silicon wafer 101, and the camera system located above the printing table 100 detects the shape of the silicon wafer 101, and according to the cell technology The position information of the silicon wafer 101 or the position information of the existing process patterns on the silicon wafer 101 (such as the front silver gate line printed for the first time, or the selective re-expansion area, etc.) is collected. At the same time, the printing table 200 is in the printing station directly below the printing screen 300 , and the printing equipment completes the printing of the silicon wafer 201 on the printing table 200 . After the printing is completed, the printing table 200 will leave the printing station wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com