Digital positioner for electric controlled valve and method thereof

A valve positioner, electrical technology, applied in valve details, valve device, valve operation/release device, etc., can solve the problems of lack of overall concept of control system, deterioration of control quality, and sudden fluctuation of pneumatic actuator operating conditions, etc. Achieve the effect of improving the quality of the control system, eliminating potential safety hazards and improving the quality of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

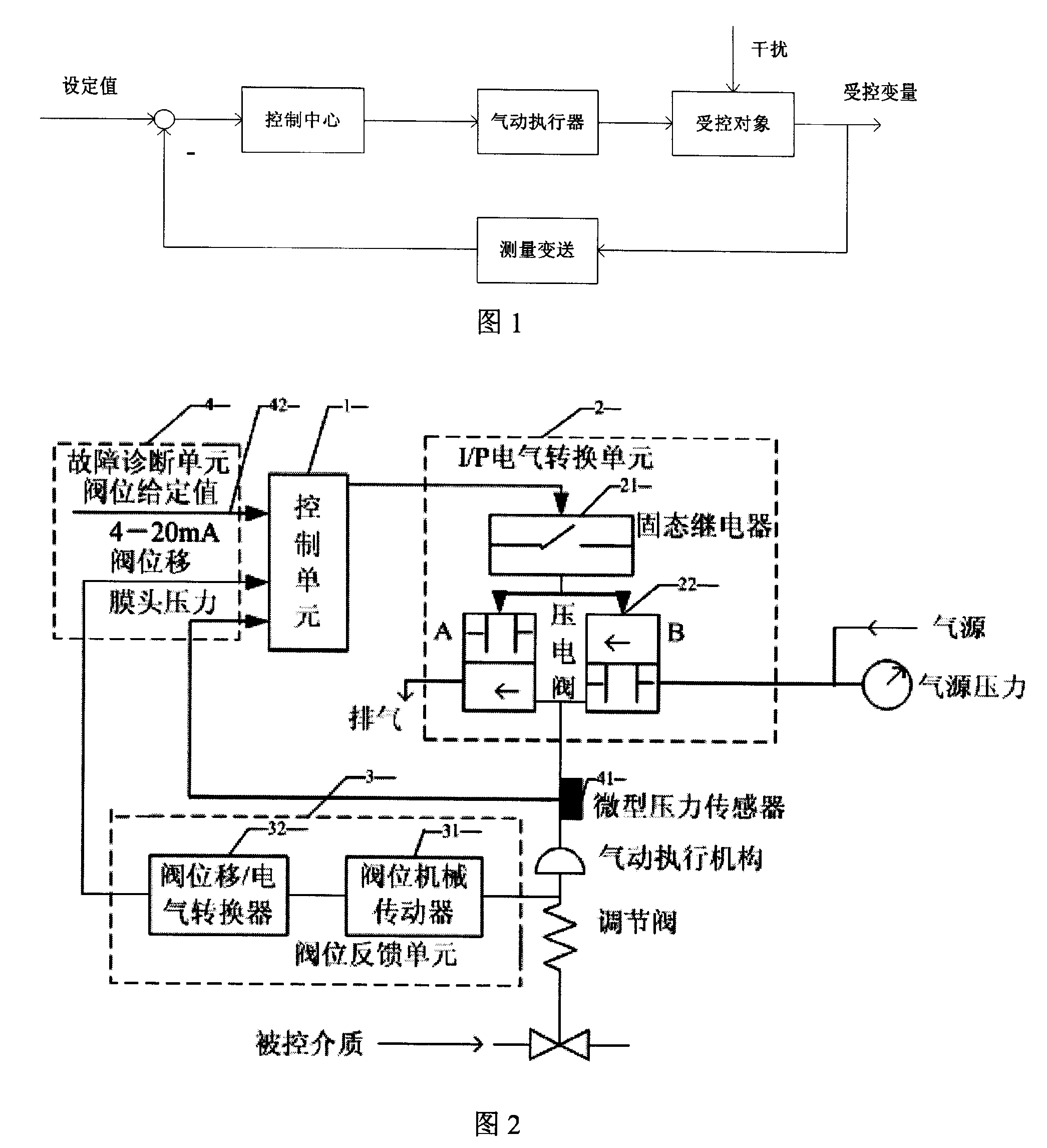

[0024] As shown in Figure 1, the pneumatic actuator is a link in the closed-loop process control system. Its function is to receive the control valve valve position given value signal from the control center, adjust the opening (flow) of the control valve, and make it deviate from the set value due to interference. A fixed value of the controlled variable returns to the set value. Therefore, when designing a pneumatic actuator digital electric valve positioner, in addition to considering the dynamic and static indicators of the pneumatic actuator itself, we must also pay attention to the control quality of the entire control system.

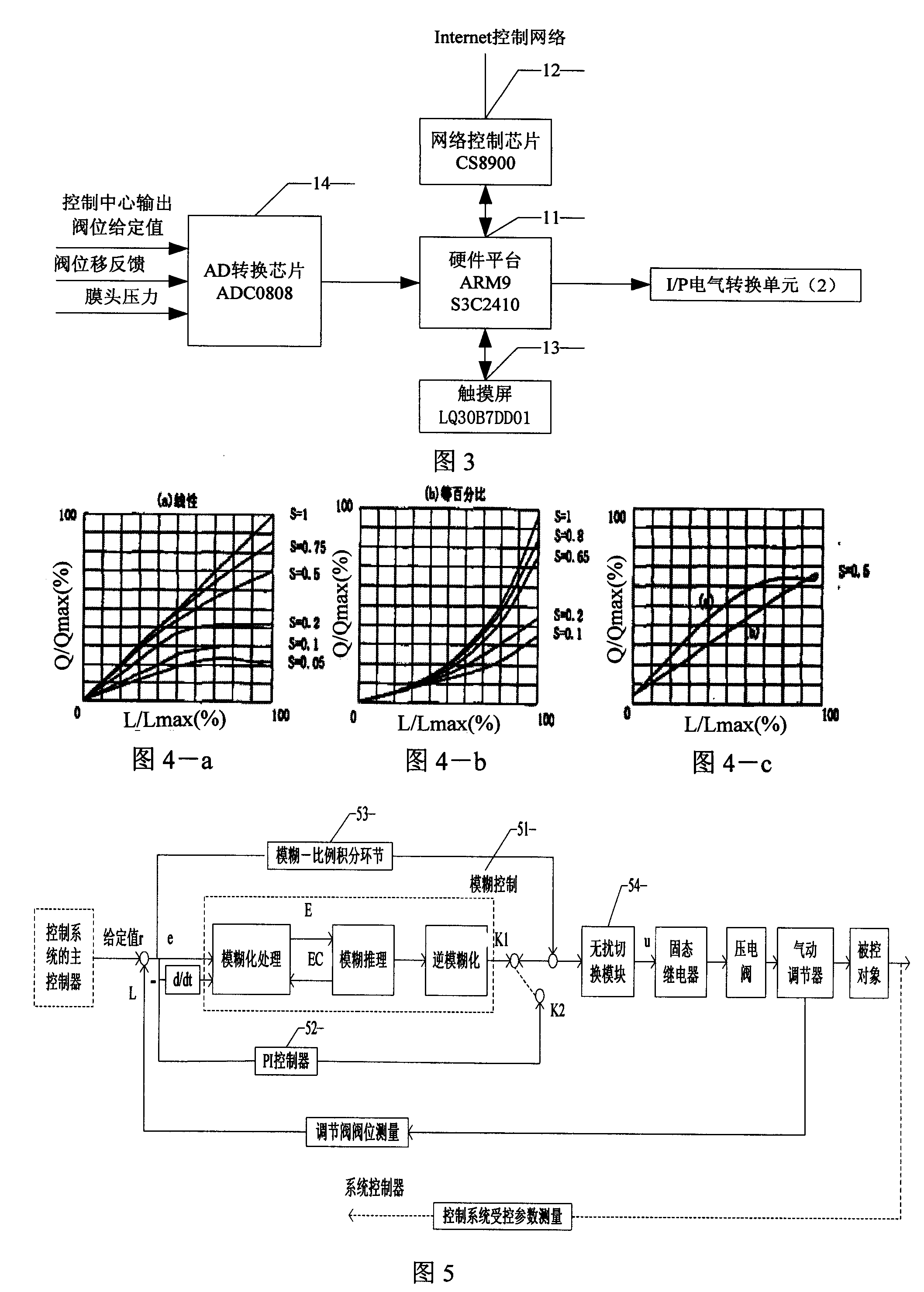

[0025] As shown in Figure 2, the control unit 1 in the digital electric valve positioner is connected with the I / P electrical conversion unit 2, the miniature pressure sensor, and the fault diagnosis unit 4, and the miniature pressure sensor is connected with the valve position feedback unit 3, The fault diagnosis unit 4 is connected with the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com