A kind of manufacturing method of light porcelain structured packing

A technology of structured packing and manufacturing method, applied in chemical instruments and methods, chemical/physical/physical chemical process, chemical/physical process, etc., can solve the problems of low processing and forming efficiency of light porcelain structured packing, cumbersome processing and forming process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

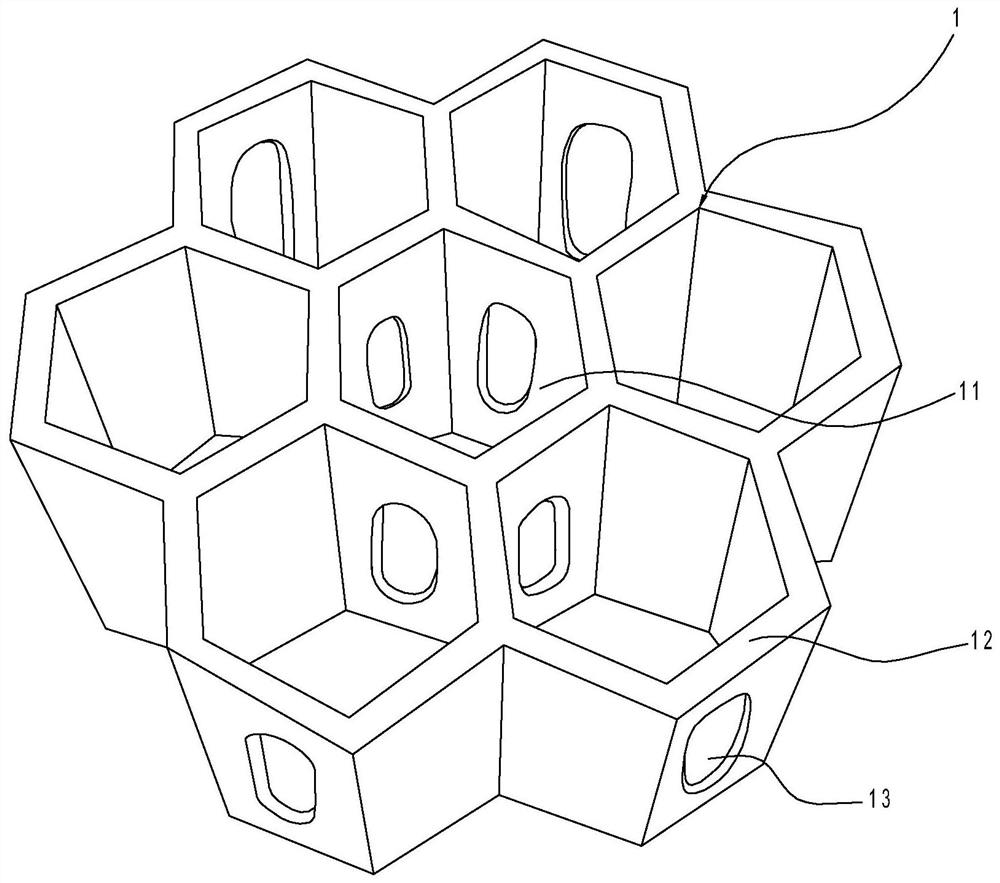

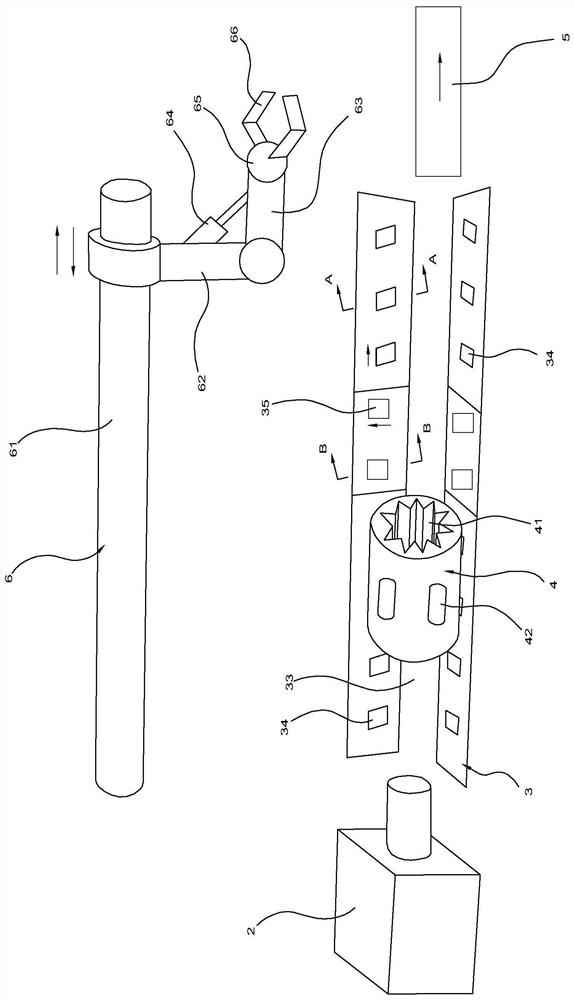

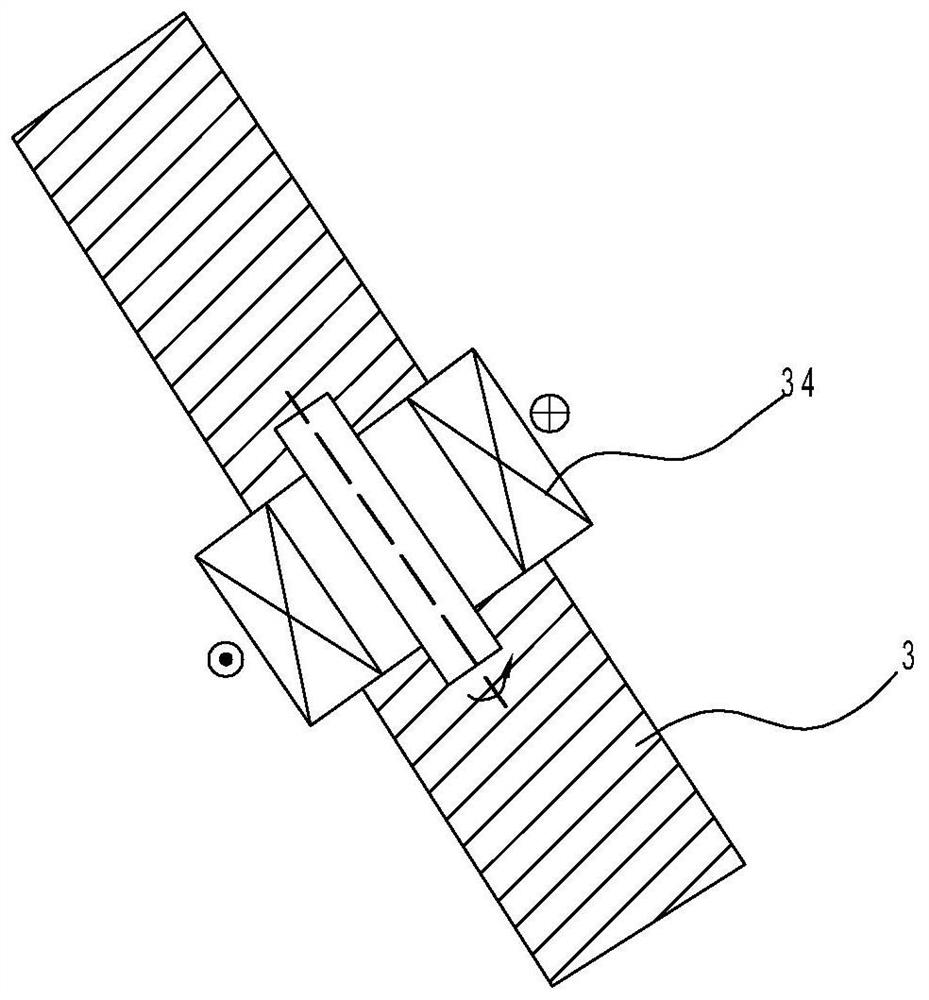

[0025] Firstly, a preliminary description is made on the manufacturing equipment involved in the manufacturing method of the light porcelain structured packing of the present invention. Such as Figures 1 to 5 as shown, The manufacturing device of the light porcelain structured packing in this implementation includes an extruder 2, a cutting knife, a forming sleeve 4, and two conveying guide plates 3. Mobile rotating body 34, circumferential rotating body 35, hole forming assembly 7, moving mechanism 6 and conveyor belt 5 . Wherein the light porcelain structured packing 1 of the present invention comprises a center ring 11 and multiple groups of side rings 12, each group of side rings 12 is relatively arranged in the circumferential direction of the center ring 11, and each side ring 12 is connected with the outer wall of the center ring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com