Production device and production method for all-ceramic hexagonal hole composite packing

A technology of combined packing and production equipment, which is applied in chemical instruments and methods, ceramic molding machines, manufacturing tools, etc., can solve the problems of cumbersome processing and molding procedures, low processing and molding efficiency of all-ceramic hexagonal hole composite packing, and achieve automation Molding processing, the effect of improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the embodiments of the drawings.

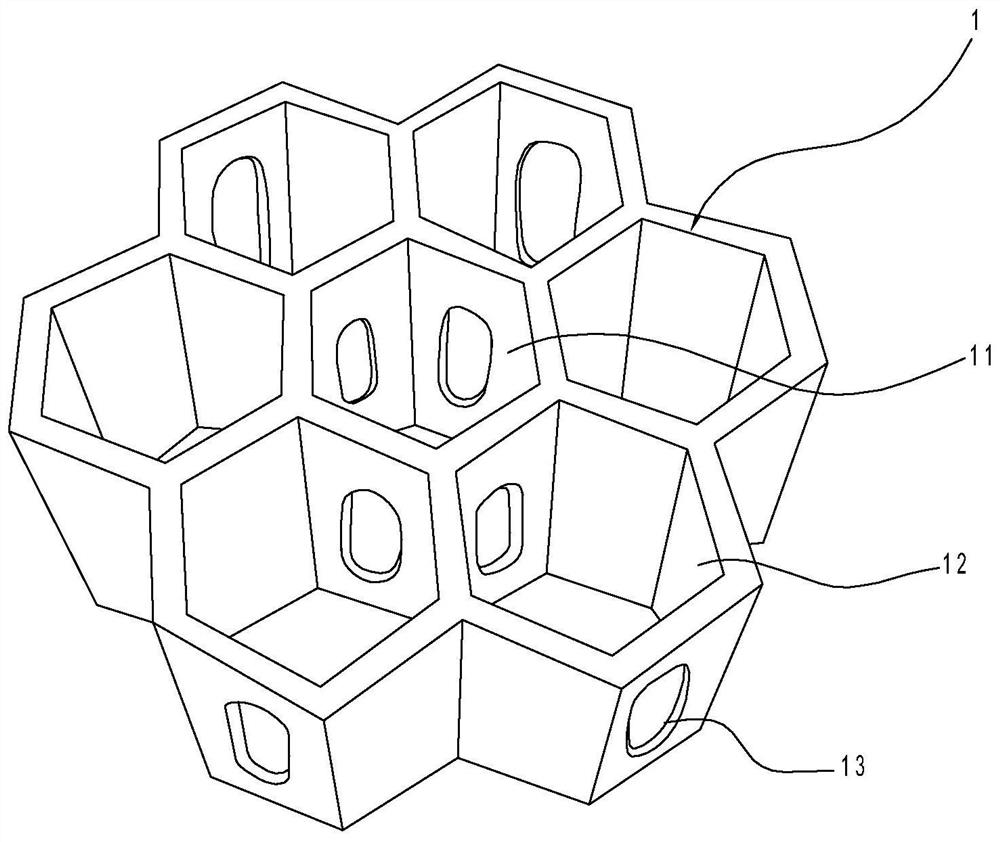

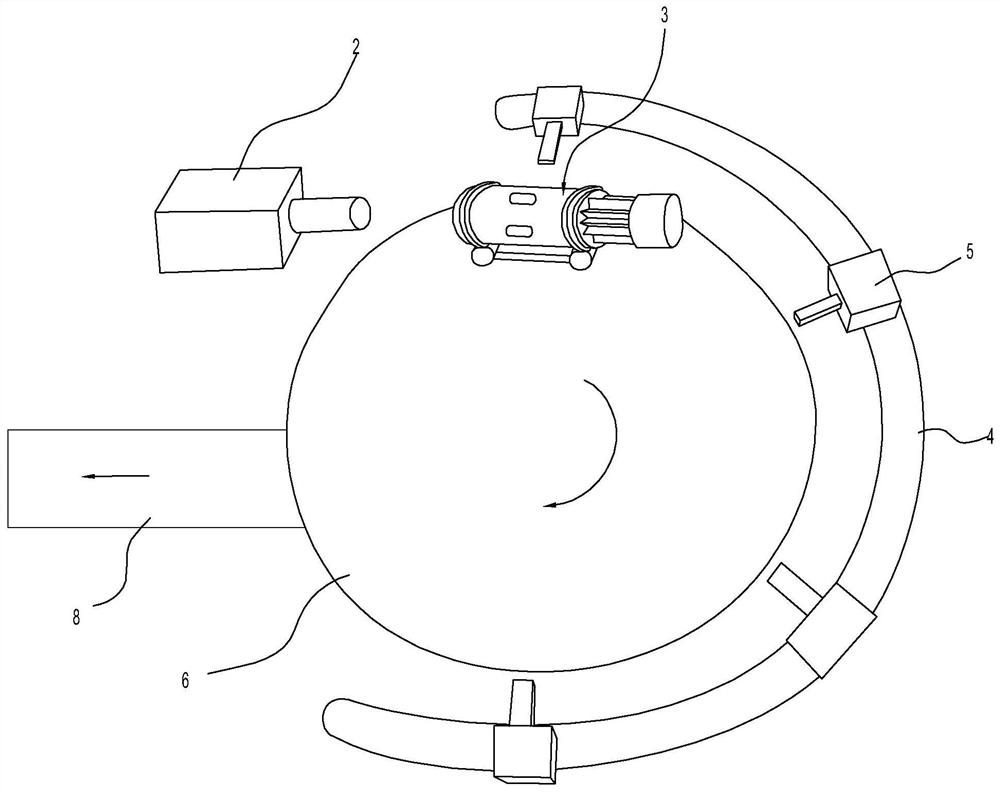

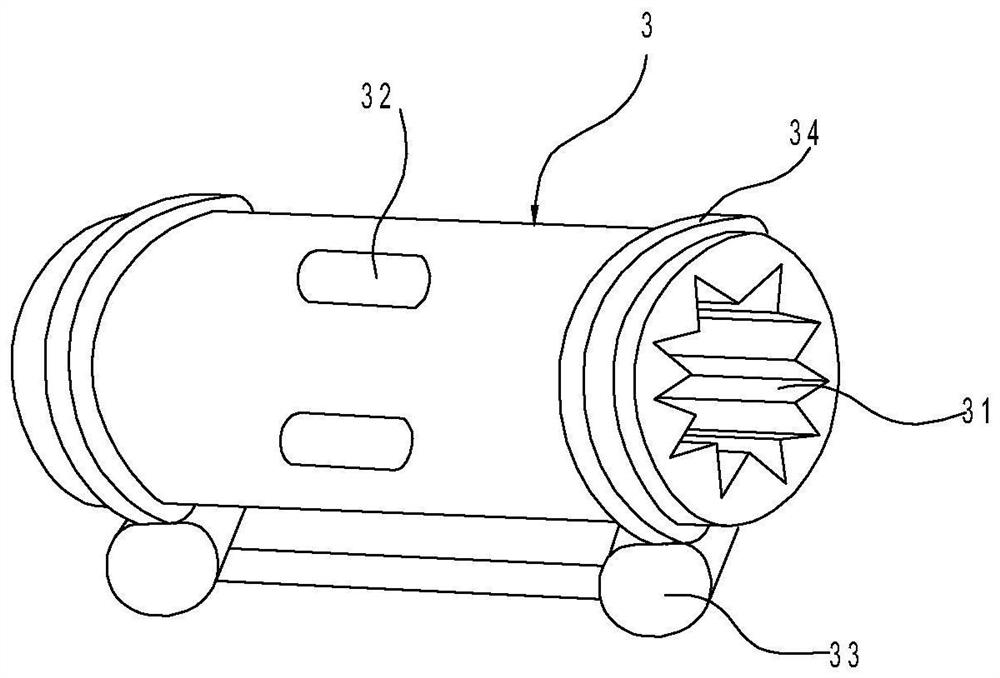

[0024] Such as Figure 1 to 5 As shown, the production device for all-ceramic hexagonal hole composite packing in this implementation includes an extruder 2, a cutting knife, a turntable 6, an intermittent rotating mechanism 7, a material carrying component 3, an arc-shaped table 4, and a hole forming component 5. Conveyor belt 8, wherein the all-ceramic hexagonal hole composite packing 1 of the present invention includes a packing body. The packing body includes a central ring 11 and multiple sets of side rings 12, and each set of side rings 12 is arranged relative to the circumferential direction of the center ring 11. Each side ring 12 is connected to the outer wall of the center ring 11, and a through hole 13 penetrating the center ring 11 is provided on the same group of side rings 12.

[0025] Among them, the extruder 2 is used to extrude a filler bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com