A connection structure of scaly aluminum curtain wall

A technology for connecting structures and aluminum panels, which is applied to roofs, building structures, and roofs that use flat/curved panels. It can solve the problems of aluminum panels that are difficult to eliminate thermal expansion and contraction, panel gaps that cannot be effectively hidden, and aluminum panels that are easily deformed. , to achieve the effect of solid and reliable connection structure, simple structure, and absorption of installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

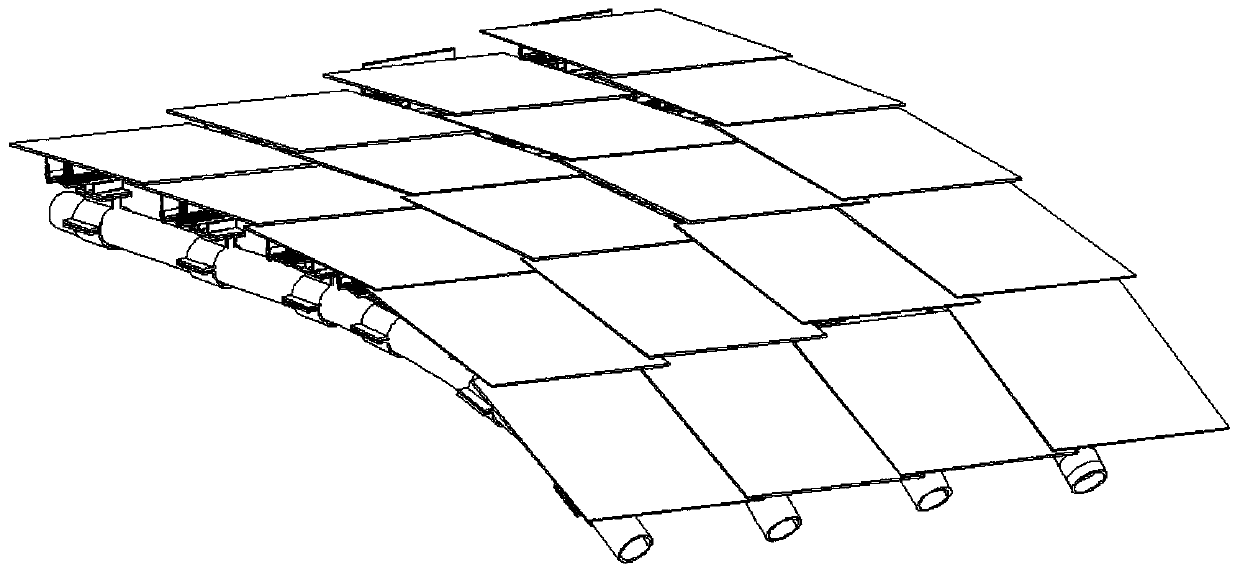

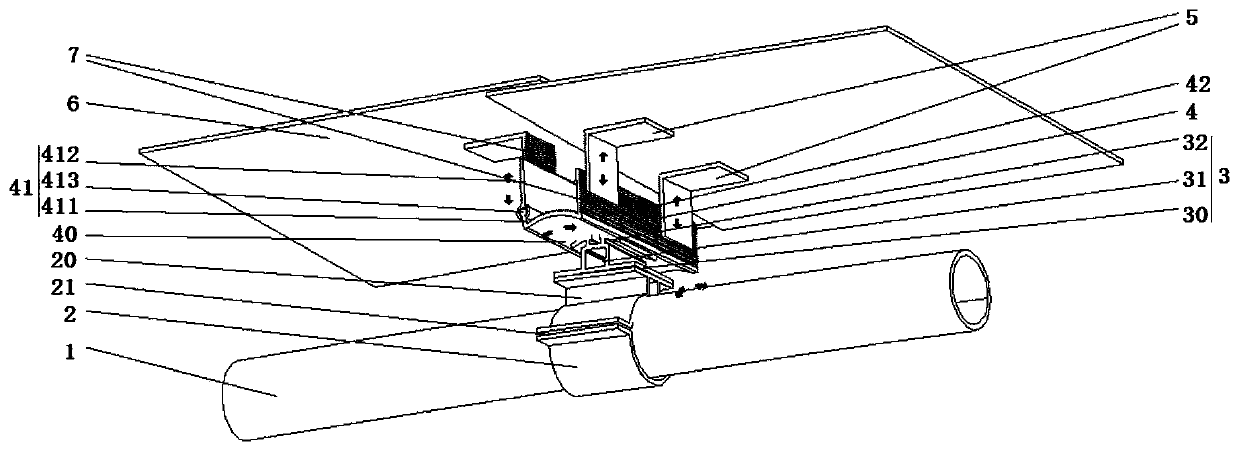

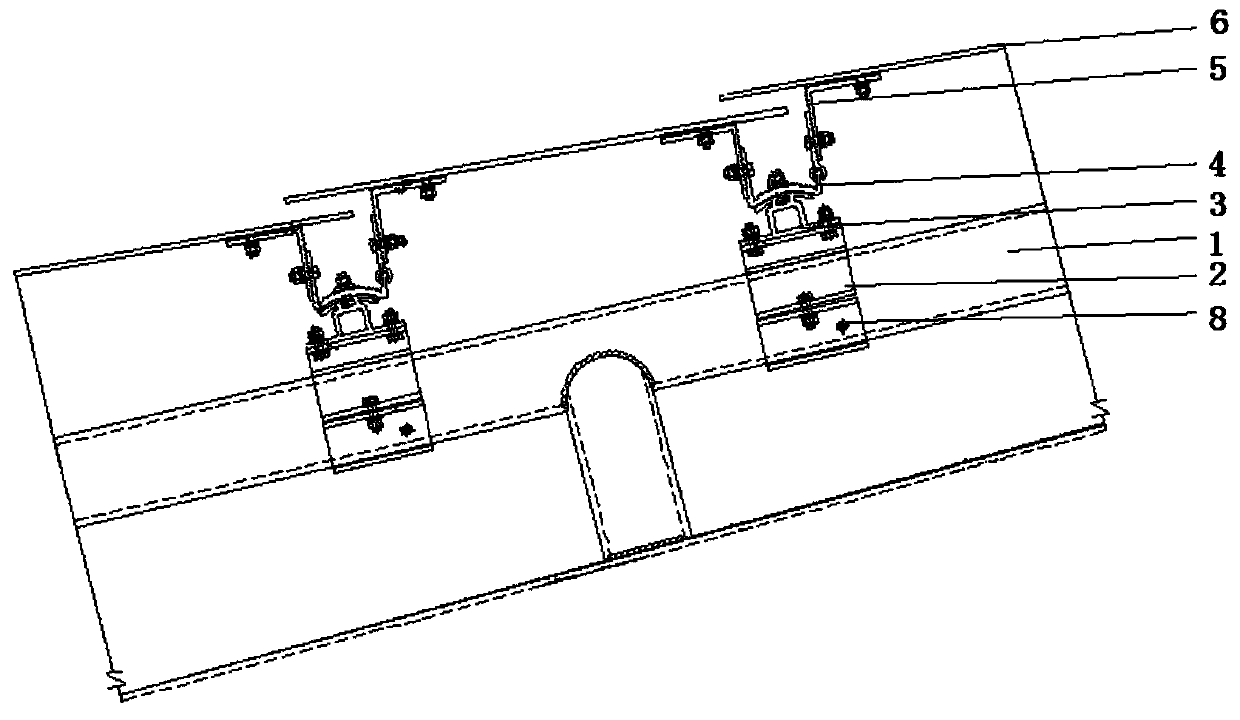

[0027] see Figure 1~Figure 3 , which is a connection structure of a scaly aluminum curtain wall according to the present invention, comprising:

[0028] round tube 1;

[0029] Hoop 2: The hoop 2 is set on the outer circumference of the round pipe 1, the top of the hoop 2 is provided with a top convex groove 20, and the middle part of one side of the hoop 2 is provided with a connecting ear plate 21;

[0030] The base 3: includes a bottom plate 30, the bottom plate 30 is connected with the top convex groove 20, the bottom plate 30 is provided with a square groove 31, and the top of the square groove 31 is provided with two arc-shaped ear plates 32;

[0031] Connecting groove 4: located above the base 3, including a bottom edge 40, a first side edge 41 and a second side edge 42, the bottom edge 40 is in an upwardly convex arc shape, and fits with the arc-shaped ear plate 32, The first side 41 includes a first pivot connection end 411 and a second pivot connection part 412, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com