A construction method for a multi-directional adjustable cast-in-place box girder support system for oblique-span low-clearance active highways

A low-headroom, multi-directional technology, used in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of dead fixed trusses, inability to adjust the vertical and horizontal positions of the trusses, and inability to meet the strain. requirements and other issues, to achieve the effect of ensuring synergistic force deformation, ensuring motion consistency, and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

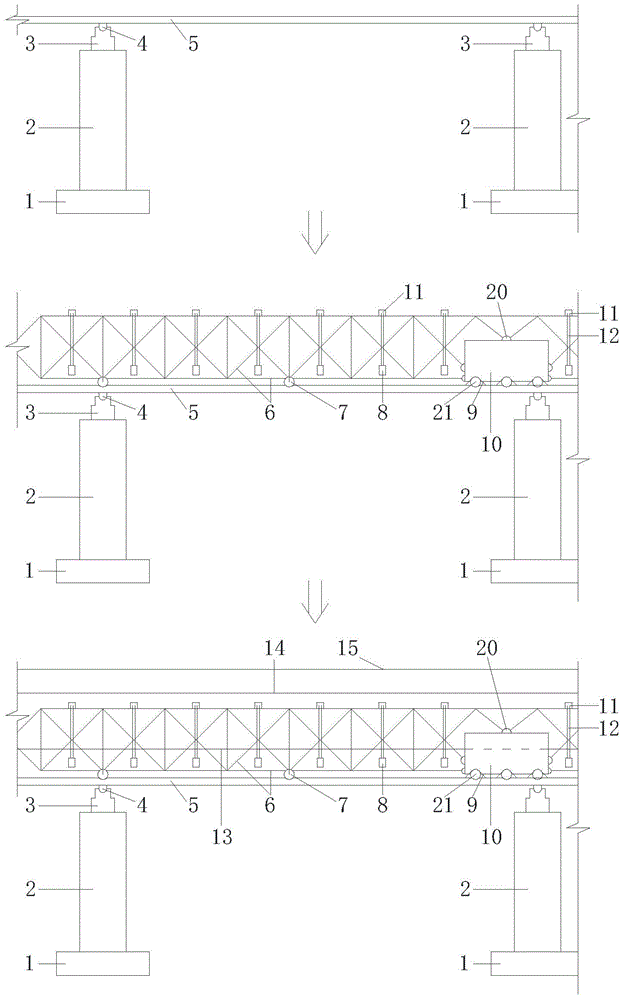

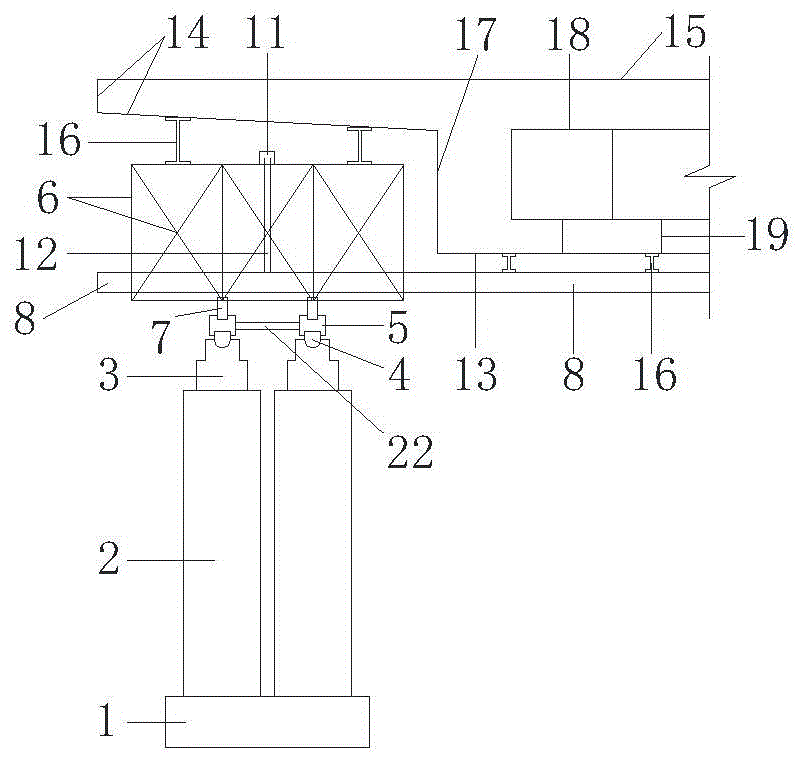

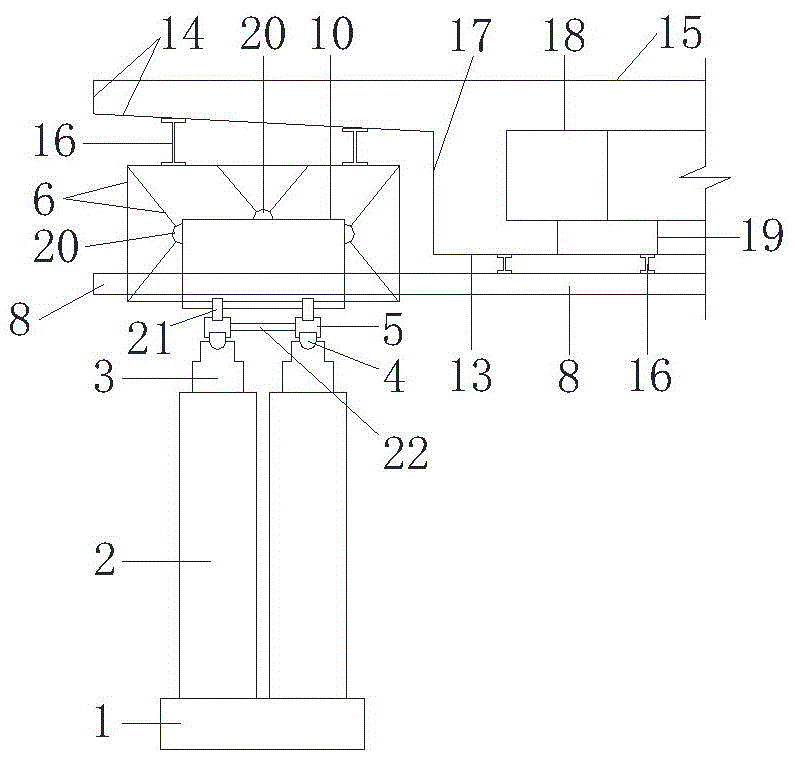

[0023] The technical scheme of the present application will be specifically described below in conjunction with the accompanying drawings and embodiments:

[0024] A bridge under construction is inclined at 30° to the active road, and the design clearance is 5.8m. The bridge is constructed with prestressed concrete continuous box girder. The clear road width cannot be less than 10m, and the driving clearance cannot be less than 5.0m. In order to meet the above requirements, the mobile adjustable cast-in-place box girder support system of the oblique-span low-clearance active road used in the present invention, its specific construction and implementation process are as follows:

[0025] refer to figure 1 , set the foundation 1 with length×width×height=2.2m×1.1m×0.8m in the parking lane and the middle zone on both sides of the active road, the span of foundation 1 along the box girder direction is 11.5m, With a span of 6.75m along the highway, double steel pipes with a length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com