Coil-in-coil springs with non-linear loading responses and mattresses including the same

A coil spring and coil sleeve technology, which is applied in the field of coil sleeve coil springs, can solve the problems of high production cost of foam cushions, affecting the overall comfort of foam cushions, and reducing mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

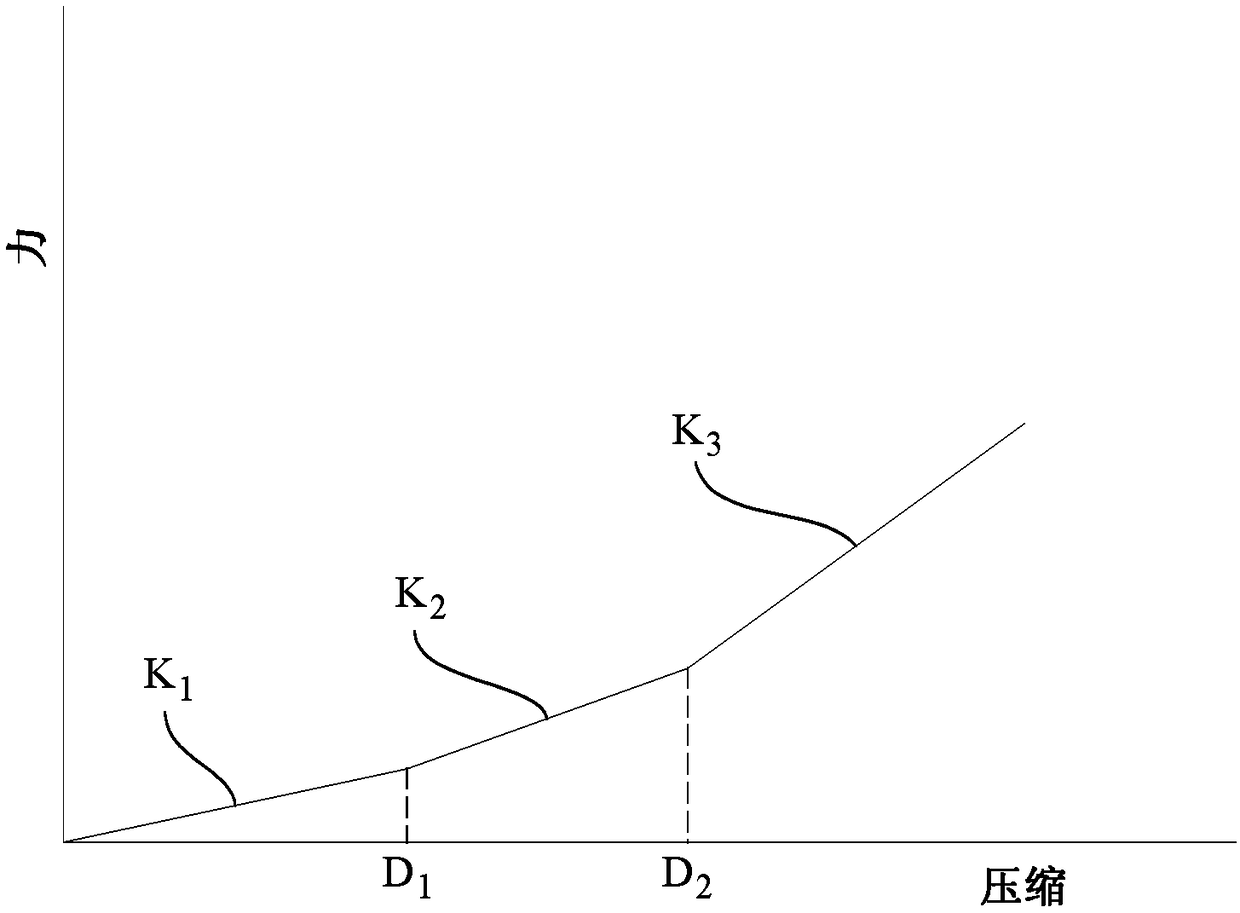

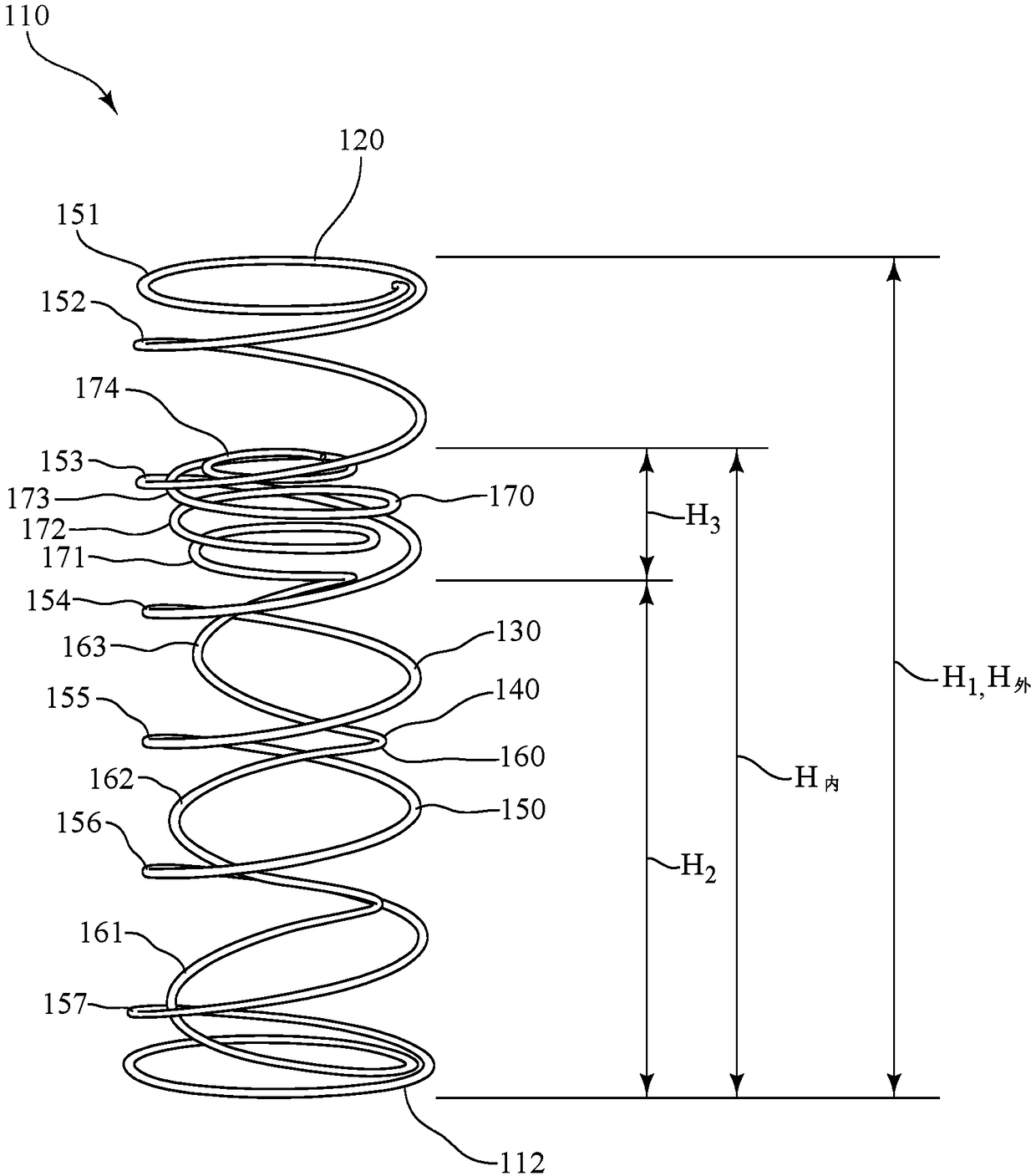

[0018] The invention includes a coil sleeve coil spring and a cushion including the coil sleeve coil spring. In particular, the present invention includes a coil-in-coil spring that is composed of a continuous wire and exhibits a variable non-linear load response when compressed. Therefore, the coil-in-coil spring of the present invention provides a non-linear support for the user. This non-linear support usually exists in a foam cushion, but is achieved by using the coil-in-coil spring.

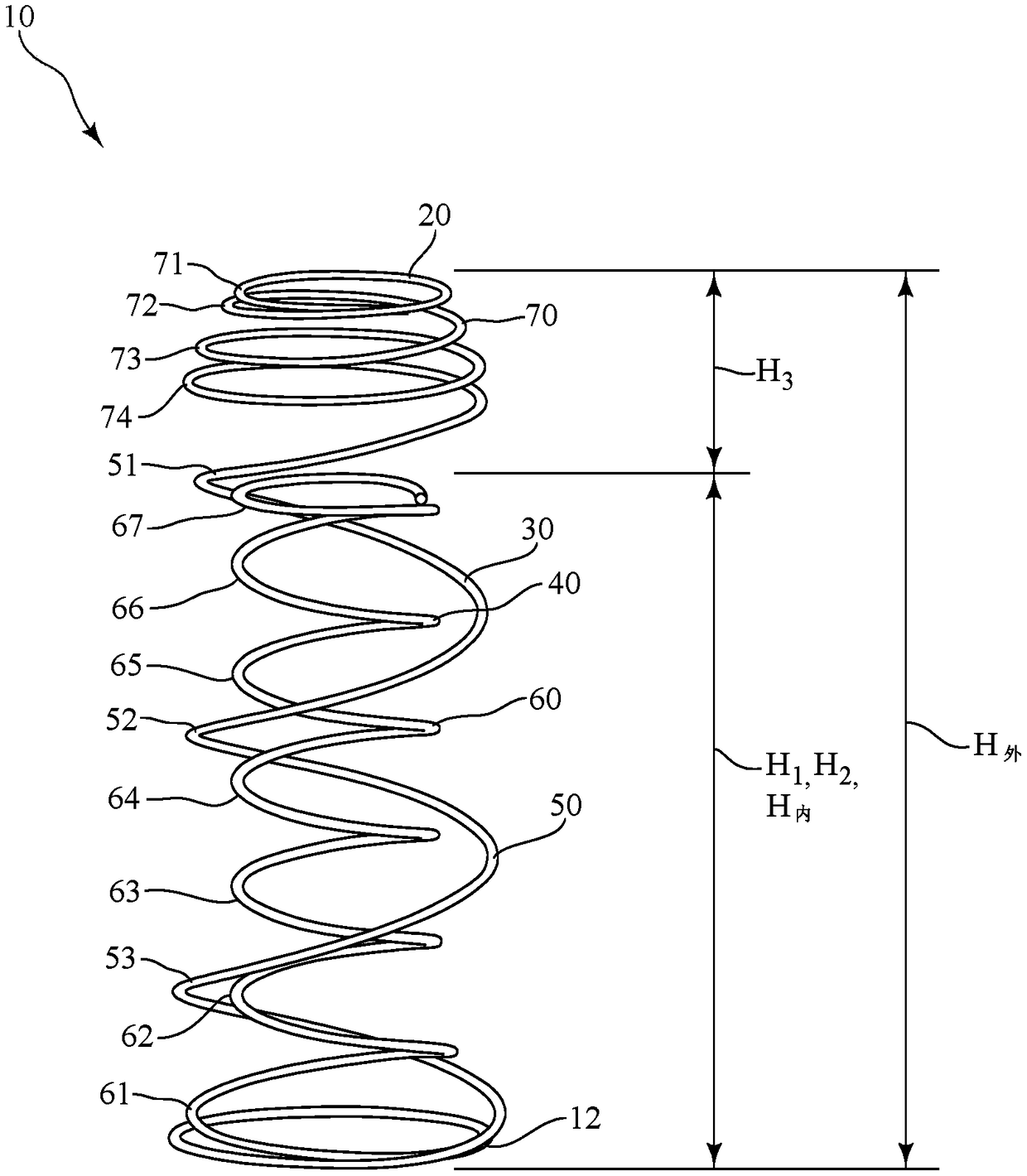

[0019] First reference figure 1 In an exemplary embodiment of the present invention, a coil-in-coil spring 10 composed of a continuous wire 20 forming an outer coil 30 and an inner coil 40 disposed within the outer coil 30 is provided. In addition, the continuous wire 20 forms a first spring portion 50, a second spring portion 60, and a third spring portion 70, which together form the outer coil 30 and the inner coil 40. Specifically, in figure 1 In the illustrated coil-in-coil spring 10, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com