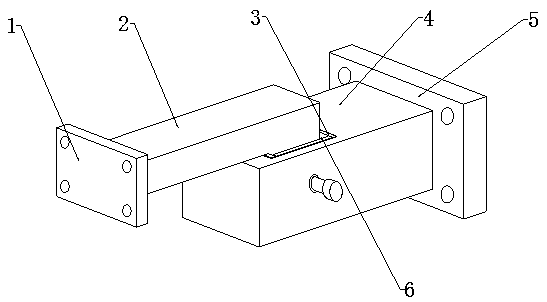

Bracket for trailer based on industrial machinery

A technology for industrial machinery and trailers, applied in the field of brackets for trailers, which can solve the problems of lack of shock absorption and easy falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

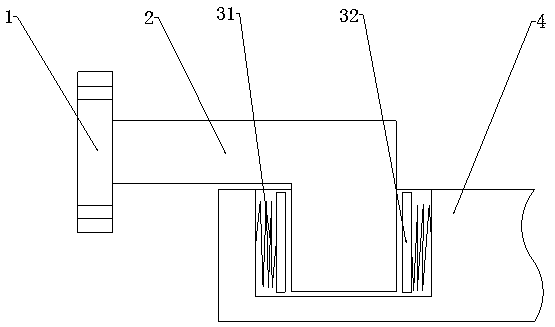

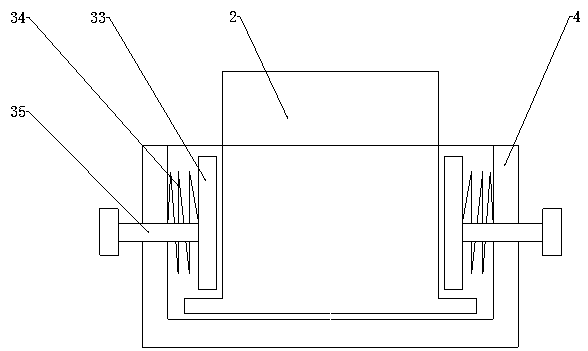

[0020] Specific implementation method: when in use, the user first fixes the fixed block 1 and the fixed block 2 on the tractor and the trailer respectively, and then the user holds the fixed frame 1 and moves it downward, and the fixed frame 1 2 moves downward Drive the rectangular projection to move downward, the rectangular projection moves downward so that the splints 33 on both sides of the front and rear of the fixed mount 2 move outward, the splint 33 moves to the outside and drives the pull bolt 35 to move to the outside, and the splint 33 moves to the outside to make the spring two 34 compresses and generates elastic force. When the rectangular projection moves downward to the lower side of the splint 33, stop moving the fixed frame one 2, and then the splint 33 moves inwardly under the elastic force of the spring two 34, and the splint 33 moves inwardly to drive the pull bolt 35 moves to the inside, and when the splint 33 moves to the inside until its inner end faces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com