Dual rod directional drilling system

A drilling and inner-rod technology, applied in the field of double-rod horizontal directional drilling systems, can solve problems such as difficult isolation and difficult implementation by operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

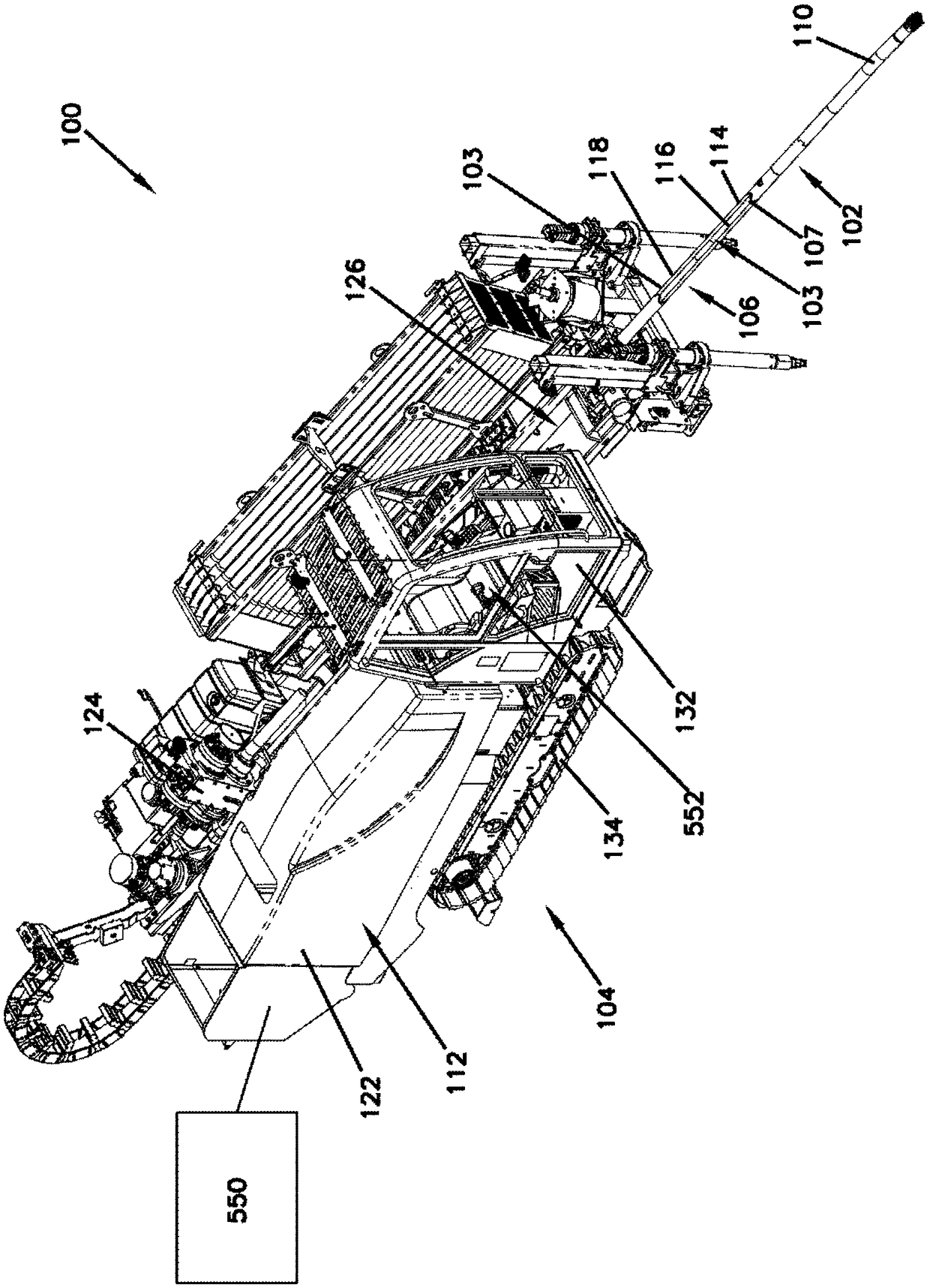

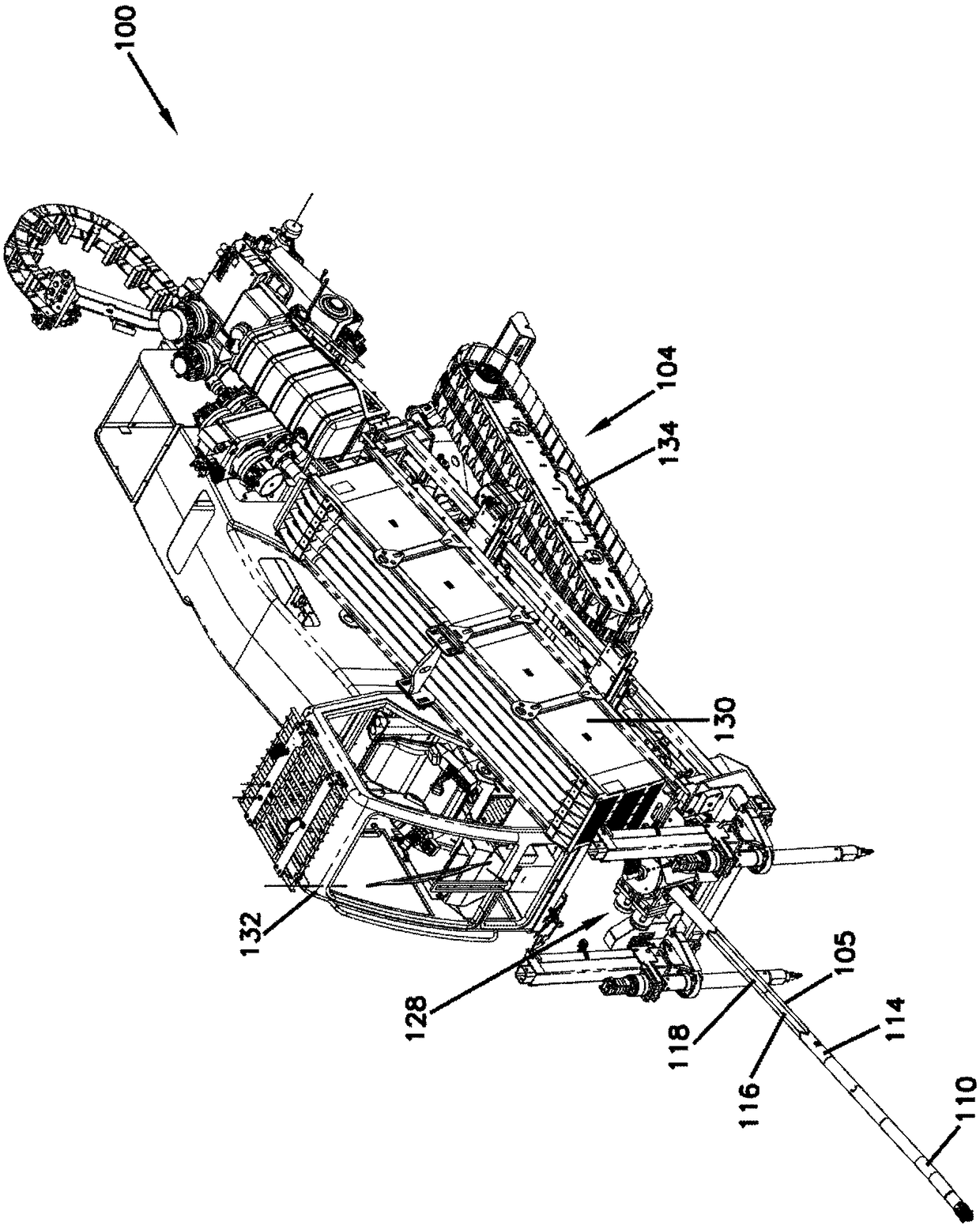

[0103] Various embodiments will be described in detail with reference to the drawings, wherein like reference numerals indicate like parts and assemblies throughout the several views. Reference to various embodiments does not limit the scope of the claims associated therewith. Additionally, any examples set forth herein are not to be considered limiting and merely set forth some of the many possible embodiments for the appended claims.

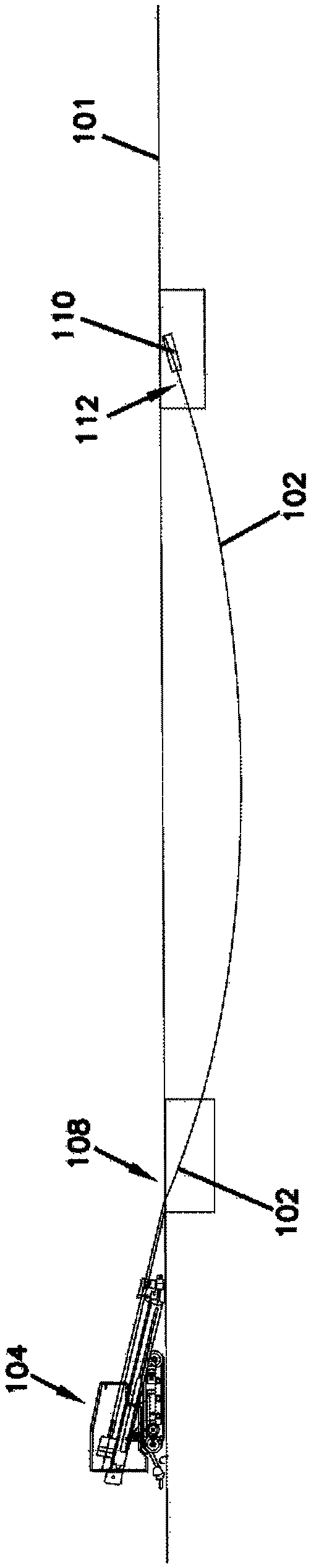

[0104] Figure 1-3 A twin rod drilling system 100 is shown. The twin rod drilling system 100 includes a drill string 102 that is guided into the surface 101 by a drilling machine 104 . Example drill string 102 at figure 1 shown in .

[0105] The drilling machine 104 includes a prime mover 122 (eg, a diesel engine), a gearbox 124, a rack 126, and a disconnect mechanism 128 (eg, a vise system). Optionally, drilling machine 104 may include a drill rod storage bin 130 , an operator station 132 and a set of tracks or wheels 134 .

[0106] Dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com