Perforating machine capable of quickly perforating coconut hole

A technology of hole opener and coconut, which is applied in metal processing, household utensils, applications, etc., can solve the problems of easy cutting, laborious, time-consuming, etc., and achieve the effect of simple structure, low cost, and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

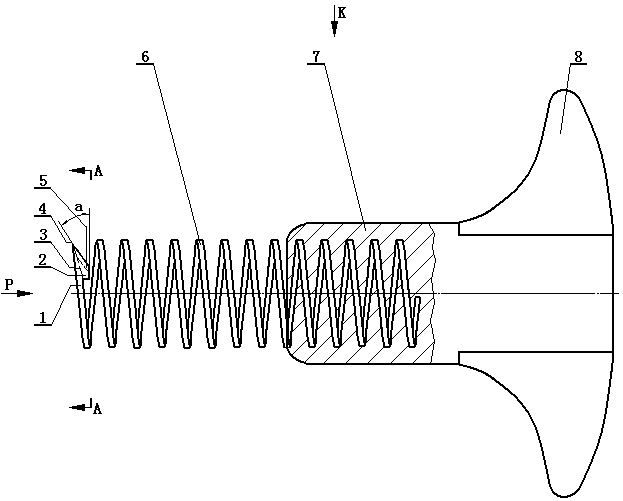

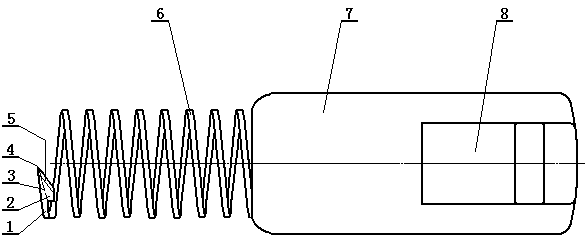

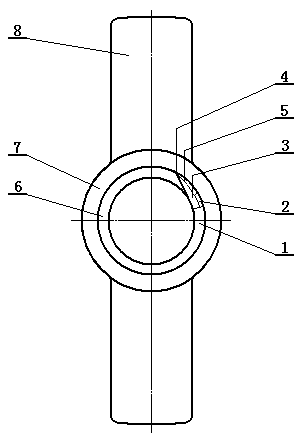

[0027] Embodiment: As shown in the accompanying drawings, a hole opener capable of quickly cutting a coconut hole is composed of an arc blade 2, a spring 6 and a spring seat post 7. The upper end of the spring head 1 is provided with an integral structure for cutting the coconut hole from bottom to top. The upper end is inclined, the sharp first oblique blade 3, and the upper end of arc blade 2 is provided with the second oblique blade 5 that is inclined from the lower right end to the upper left end. The edge 4 of the blade 3 intersects and overlaps together.

[0028] The right end of spring 6 and the left end of cylindrical spring seat post 7 are injection molded together.

[0029] The upper and lower ends of the right end of the spring seat post 7 are respectively provided with a symmetrical, integrally structured, fin-shaped handle 8 .

[0030] The cross section of the material of the spring 6 is set as a rectangle, the width of the cross section of the spring 6 is 2.4mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com