Oil return device for slide block of press machine

A technology of presses and sliders, applied in the field of presses, can solve the problems of inability to recycle oil leaks in real time, oil sedimentation, easy to block valves, etc., and achieve the effect of real-time recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

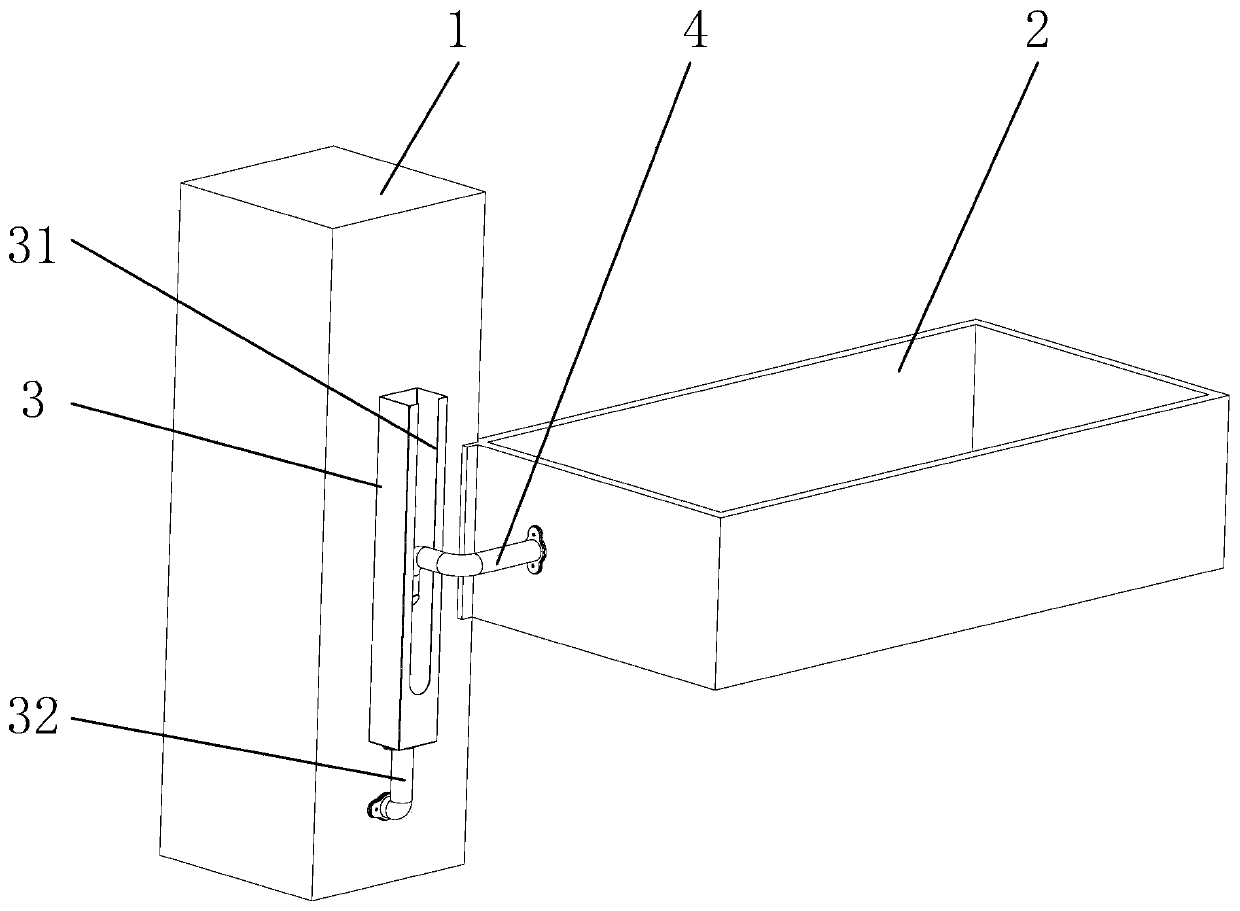

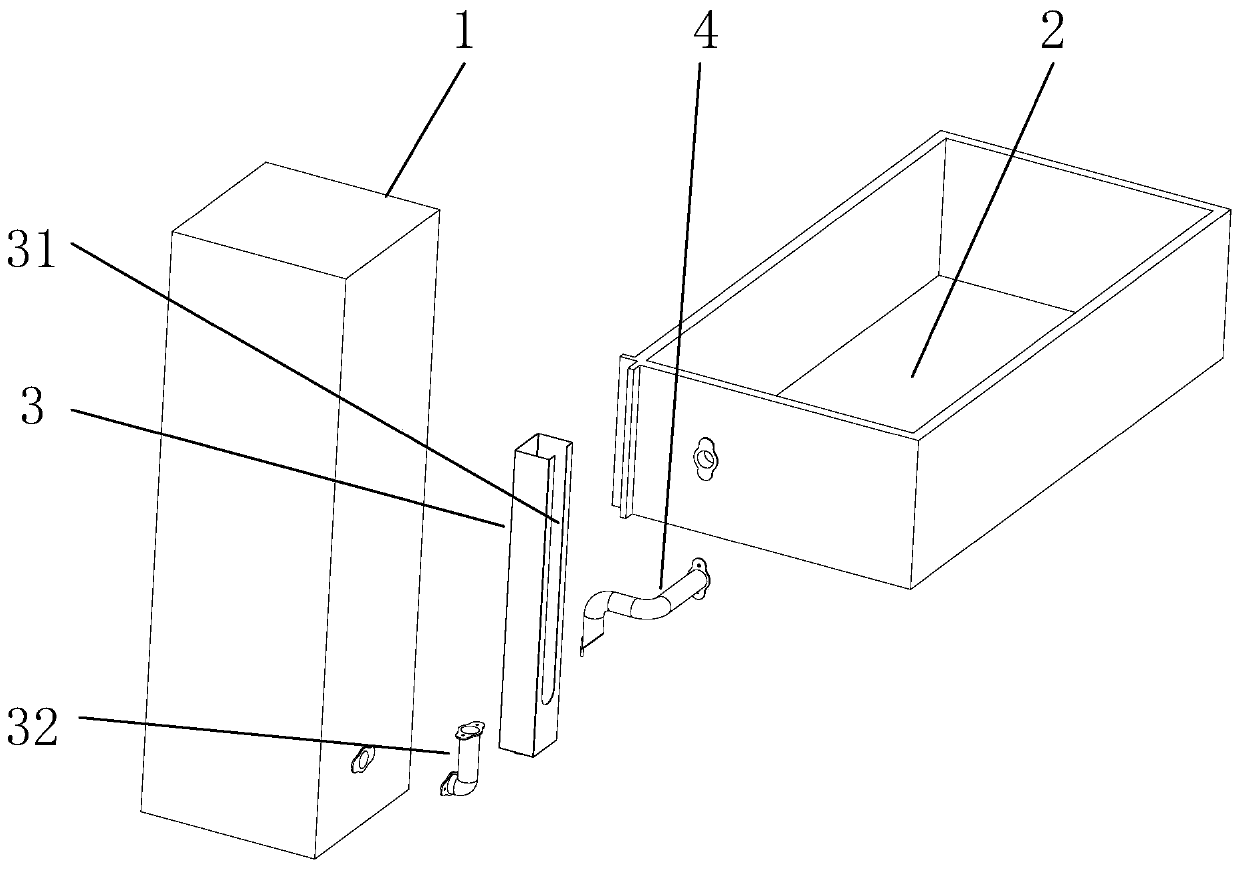

[0032] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0033] An embodiment of the present invention provides an oil return device for a press slide block, which is used for real-time recovery of oil leaked from a press slide block, and avoids the problem of blockage of a blowdown valve caused by the precipitation of oil stains.

[0034] Since the four corners of the slider of the press are provided with upright guide rails for the slider to reciprocate up and down, in order to realize the uniform recovery of oil leakage in the slider, the present invention makes the same improvement on each upright guide rail, as follows The description only takes one column guide as an example.

[0035] see figure 1 and figure 2 As shown, the oil return device for the slide block of the press includes:

[0036] The column guide rail 1 is arranged on one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com