Real-time recycling and reusing device for aggregates at bottom of inner wall of steel wheel of road roller

A technology for road rollers and steel wheels, which is applied to the field of real-time recycling and reuse of granular materials at the bottom of the inner wall of the steel wheel of the road roller. material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

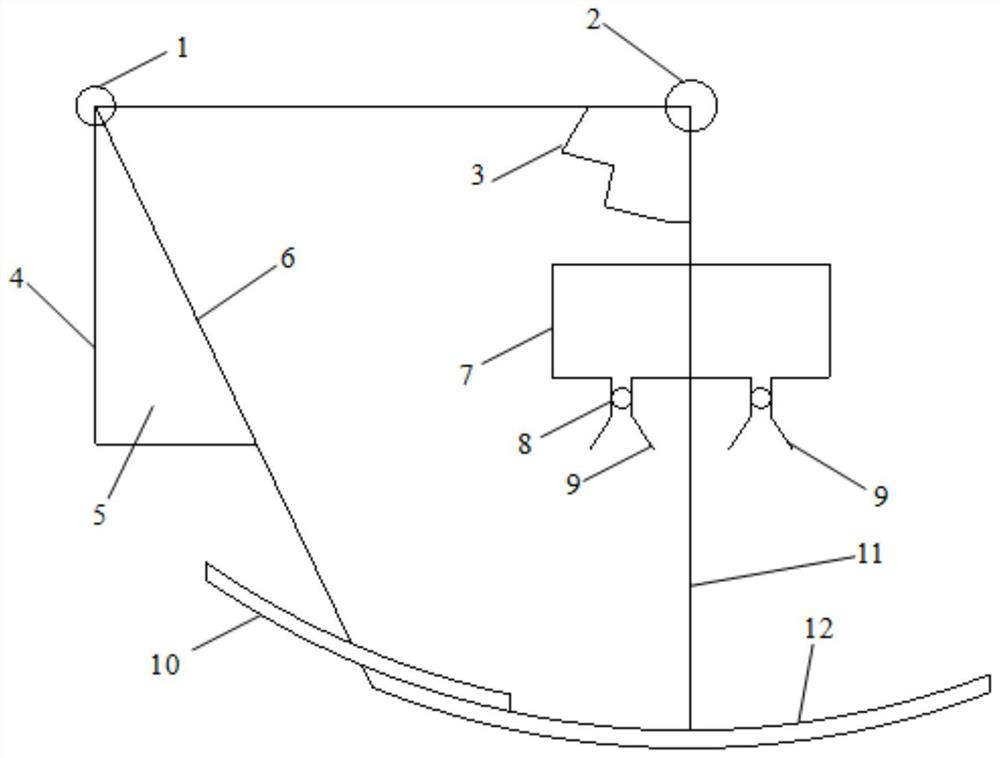

[0022] see figure 1 , a device and method for real-time recovery and reuse of granular material at the bottom of the inner wall of a steel wheel of a road roller, characterized in that it includes a nut 1, a screw 2, a spring 3, an inner wall of the steel wheel 4, a beveled wooden board 5, a diagonal rod 6, a water tank 7, Valve 8, open nozzle 9, arc push plate 10, bracket 11, arc plate 12.

[0023] The bracket is fixed to the center of the inner wall of the steel wheel of the road roller through a nut link. The bracket is made of two steel pipes at right angles and fixed by screw hinges, and is supplemented by spring elastic fixing, so that the lower arc-shaped plate is close to the lower side wall of the steel wheel, and it does not follow the steel wheel. Turn and turn, always maintain an upright position.

[0024] The arc-shaped plate is fixed on the lower end of the support, and its diameter is equal to the inner diameter of the steel wheel. The arc-shaped plate is close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com