PE plastic bottle

A technology for plastic bottles and caps, applied in the field of PE plastic bottles, can solve the problems of over-tightening, easily damaged threads, lack of reference for judgment of PE plastic bottles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

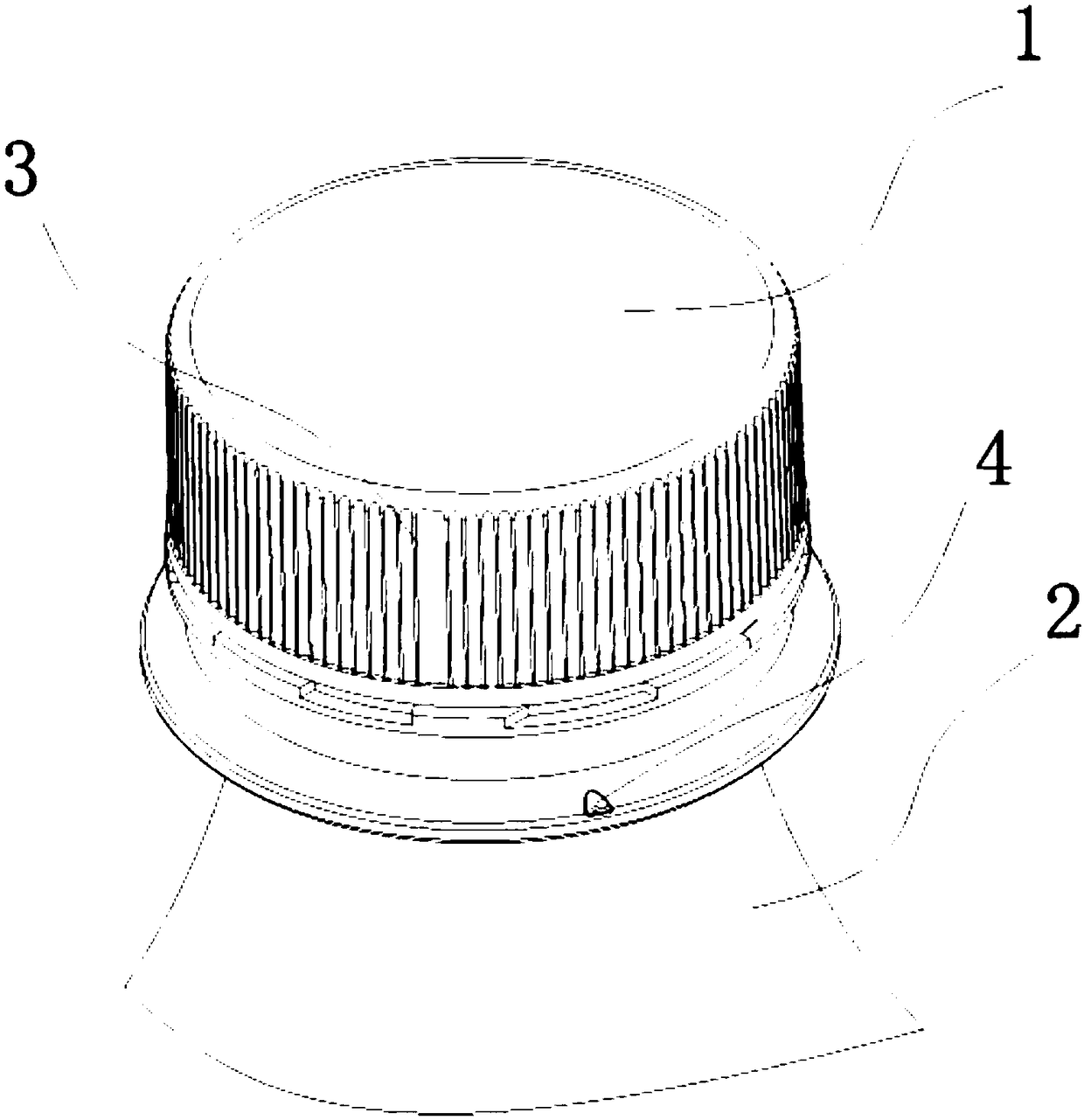

[0011] Such as figure 1 As shown, the present invention includes a bottle cap 1 and a bottle body 2, the bottle cap 1 is provided with a bottle cap mark 3, the bottle body 2 is provided with a bottle body mark 4, and the bottle cap 1 is screwed tightly on the When the bottle body 2 is on, the bottle cap mark 3 corresponds to the bottle body mark 4 . Usually, only one bottle mark 4 and one bottle cap mark 3 are required to be provided. When in use, tighten the bottle cap 1 until you feel the resistance, then screw the bottle cap mark 3 on the bottle cap 1 to correspond to the bottle body mark 4. The bottle body mark 4 and the bottle cap mark 3 do not have to be completely aligned. Yes, as long as the corresponding error is satisfied; when using machine packaging, rotate to the corresponding number of turns, and then match the mark 4 on the bottle body with the mark on the bottle cap 3 to ensure that the seal is in place. The angle formed by the bottle body mark 4 and the star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com