Point inspection method and device, equipment and medium

A point inspection and equipment technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of large manpower and time consumption, error-prone, and manpower consumption, so as to save manpower and time and reduce errors Efficiency, avoiding time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

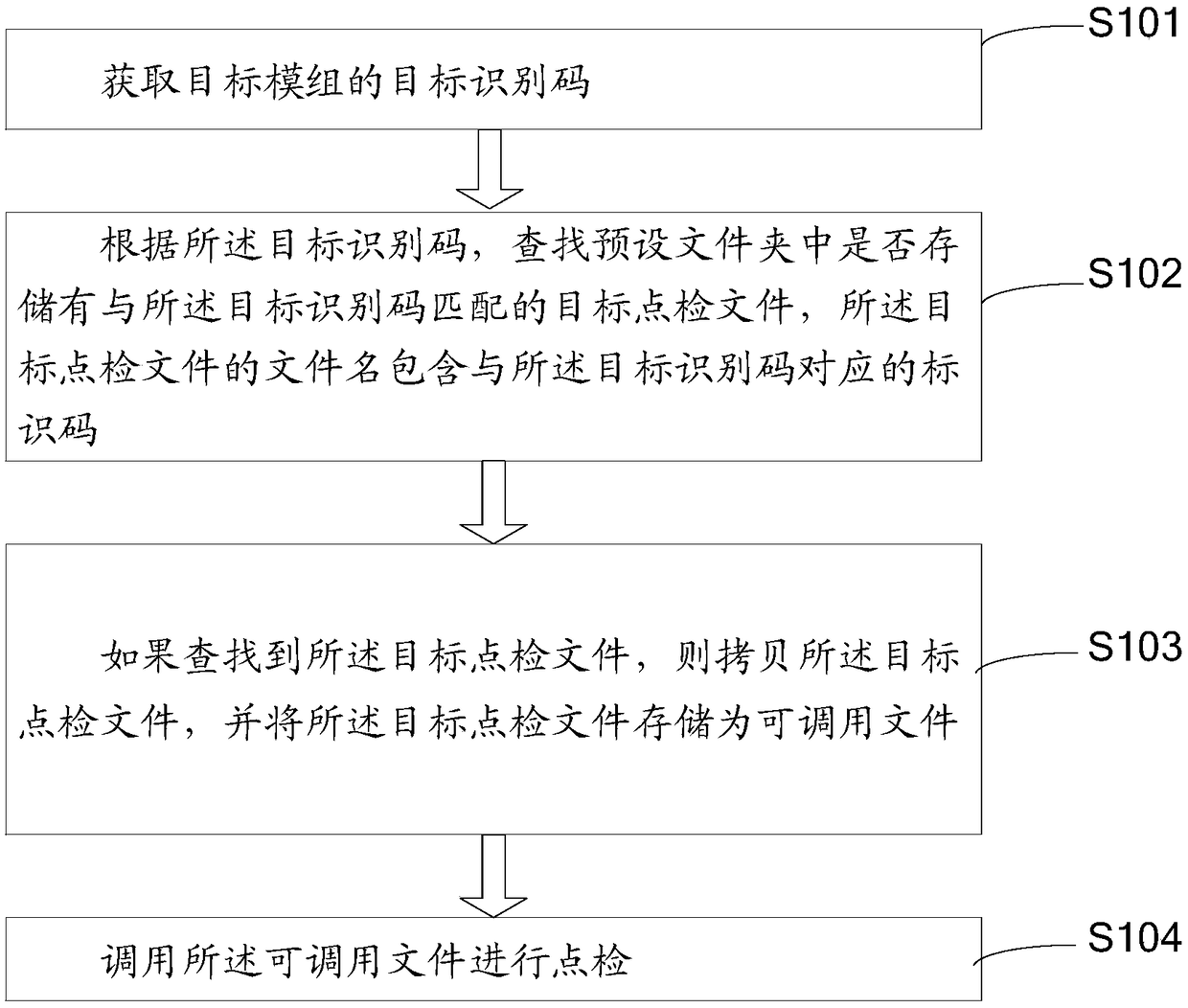

[0034] This embodiment provides a check method, such as figure 1 shown, including:

[0035] Step S101, obtaining the target identification code of the target module;

[0036] Step S102, according to the target identification code, search whether there is a target inspection file matching the target identification code stored in the preset folder, the file name of the target inspection file contains the corresponding to the target identification code identification code;

[0037] Step S103, if the target check file is found, copy the target check file, and store the target check file as a callable file;

[0038] Step S104, calling the callable file for checking.

[0039] It should be noted that the point inspection in this embodiment refers to the inspection of specified parts of the equipment according to a certain period, so as to discover hidden dangers of equipment failures early and correct equipment errors, so that the equipment can maintain its specified functions.

...

Embodiment 2

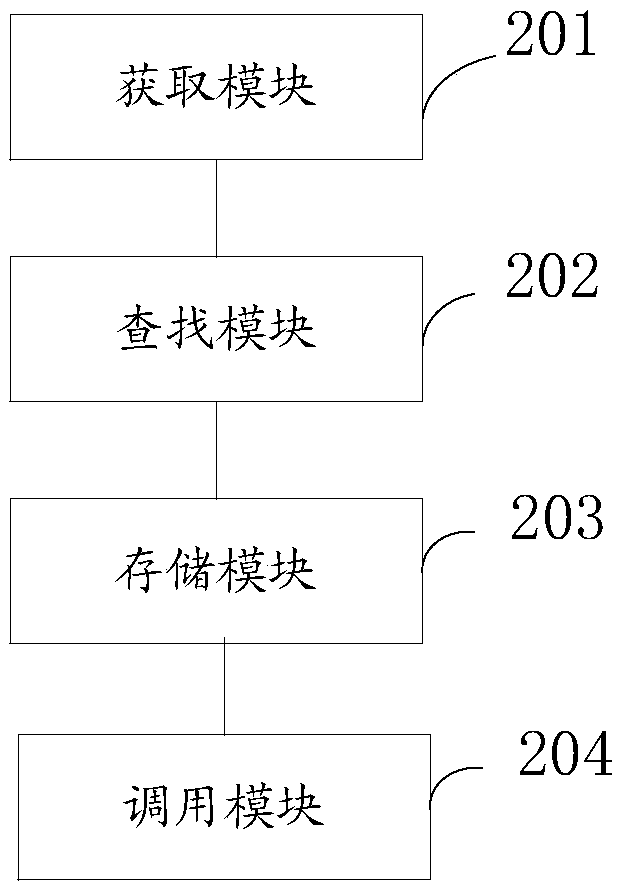

[0087] Such as figure 2 As shown, the present embodiment provides a spot check device, including:

[0088] Obtaining module 201, for obtaining the target identification code of target module;

[0089] The searching module 202 is used to search whether there is a target inspection file matching the target identification code stored in the preset folder according to the target identification code, and the file name of the target inspection file includes the code corresponding to the identification code;

[0090] A storage module 203, configured to copy the target inspection file if the target inspection file is found, and store the target inspection file as a callable file;

[0091] The calling module 204 is used to call the callable file for checking.

[0092] In a specific implementation process, the target module may be a camera module, a fingerprint sensing module, or a speaker module, etc., which is not limited here. The corresponding inspection object may be a test li...

Embodiment 3

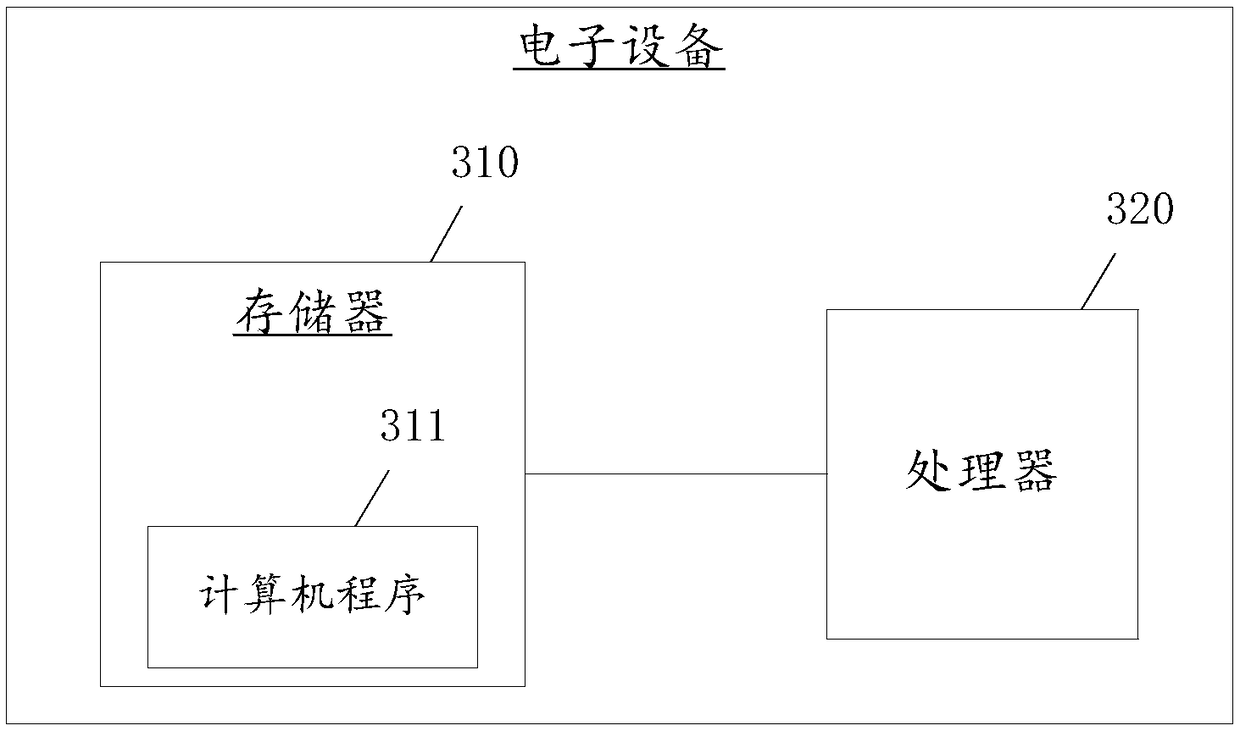

[0101] Such as image 3 As shown, the present embodiment provides an electronic device, including a memory 310, a processor 320, and a computer program 311 stored on the memory 310 and operable on the processor 320. When the processor 320 executes the computer program 311 Implement the following steps:

[0102] Obtain the target identification code of the target module;

[0103] According to the target identification code, it is searched whether a target inspection file matching the target identification code is stored in the preset folder, and the file name of the target inspection file includes an identification code corresponding to the target identification code;

[0104] If the target check file is found, then copy the target check file, and store the target check file as a callable file;

[0105] Invoke the callable for spot check.

[0106] When the processor 320 executes the computer program 311, any implementation manner in Embodiment 1 of the present invention is imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com