Multi-core connector connecting piece for optoelectronic equipment

A technology of joint connection and photoelectric equipment, which is applied to the device for joining/disconnecting connecting parts, parts and connections of connecting devices, and can solve problems such as poor contact, loose connection at the beginning and end of the connection, disconnection of the circuit, etc. , to achieve the effect of convenient connection and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

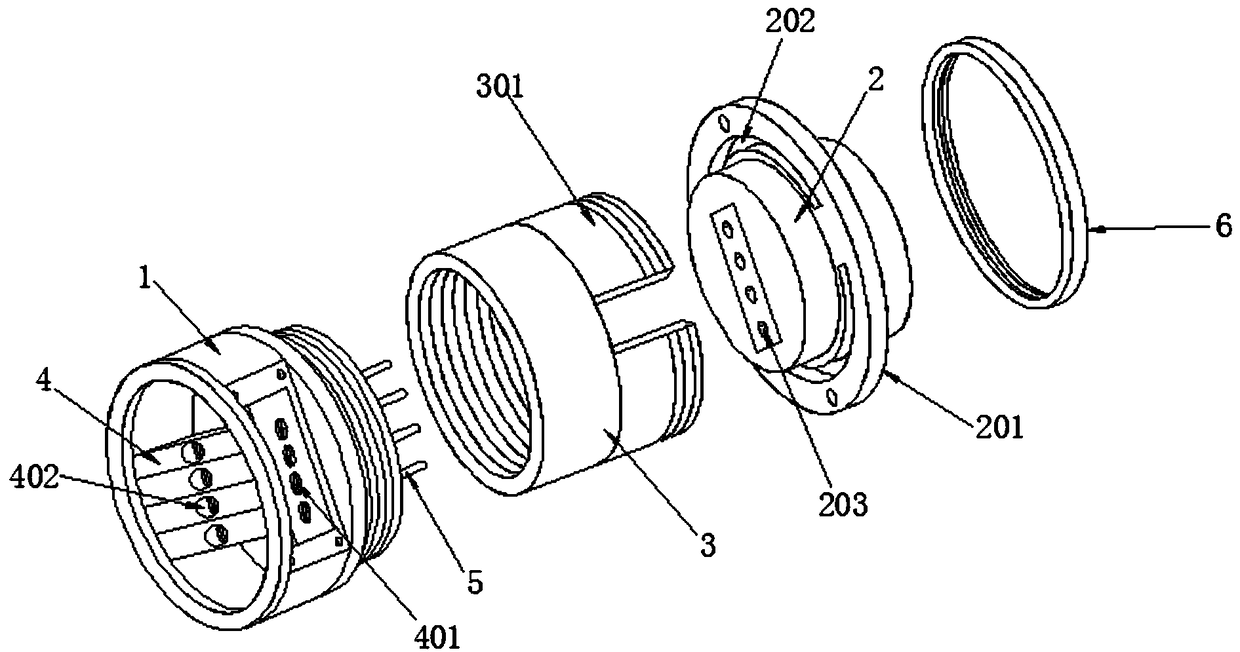

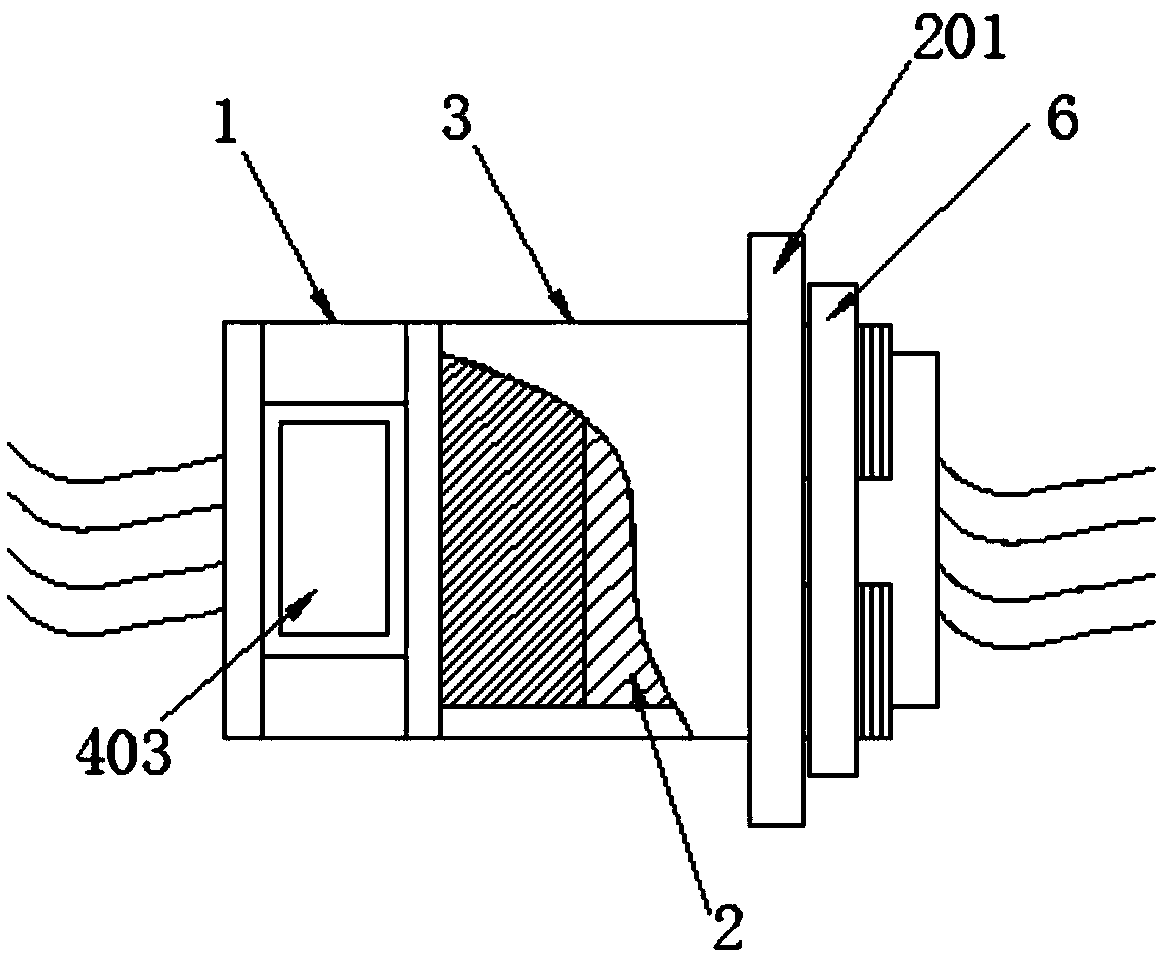

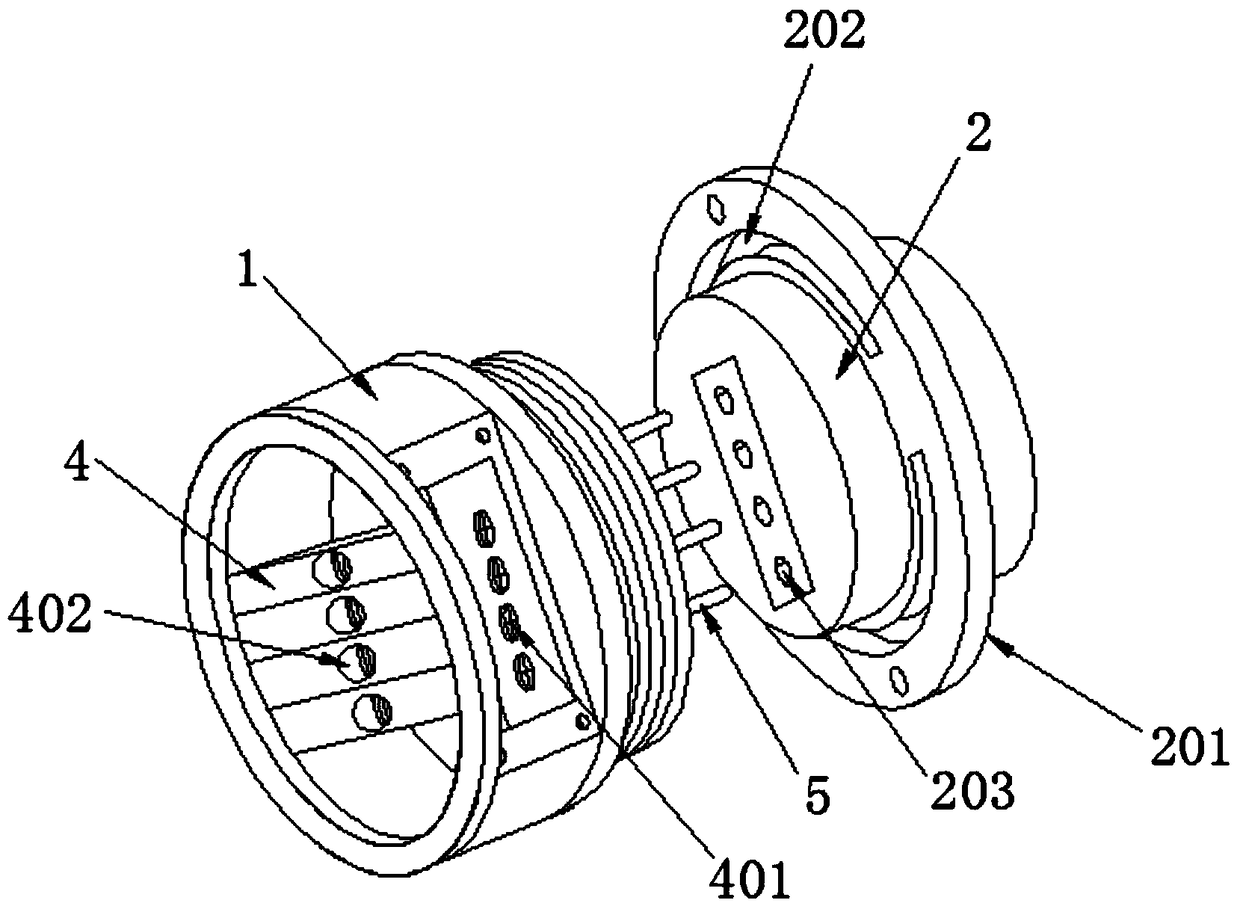

[0025] see Figure 1-5 , the present invention provides a technical solution:

[0026] A multi-core joint connector for optoelectronic equipment, comprising a wiring head 1, a wiring tail 2 matched with the wiring head 1, one side of the wiring head 1 is embedded with a wiring terminal 4, and the other Pin 5 is fixedly installed on the side, and one end of the pin 5 is connected to the wiring hole 402 through a metal connecting piece, and the pin 5 is made of metal conductive material, so that the connection hole 402 and the pin 5 can be conducted current.

[0027] More specifically, the connection terminal 4 includes a terminal housing, a connection hole 402 opened on the casing and a fastening screw 401 used in conjunction with the connection hole 402, and the screw post of the fastening screw 401 passes through Embedding through the housing into the wiring hole 402, as an example: insert one end of the wire into the wiring hole 402, tighten the fastening screw 401, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com