Telescopic rotary joint

A technology of rotary joints and rotors, applied in mining equipment, earthwork drilling, tunnels, etc., to reduce the risk of wear and improve geological adaptability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

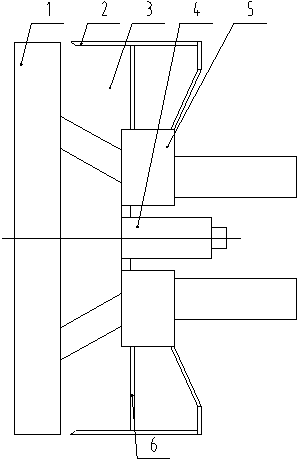

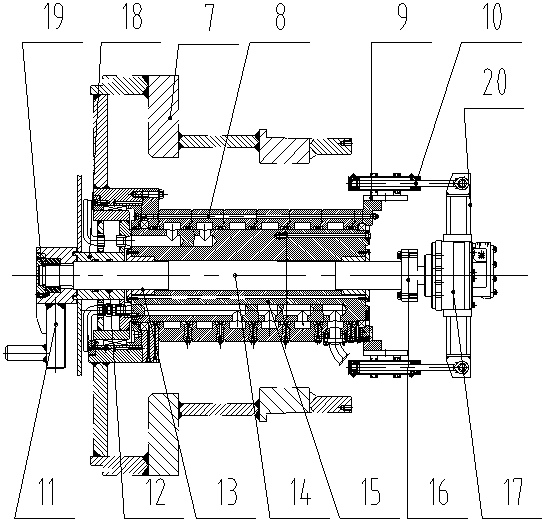

[0020] Embodiment 1: as Figure 1-2 As shown, a telescopic rotary joint includes a cutter head 1, a shield shell 2, an excavation chamber 3, a rotary joint 4, a driving device 5 and a front shield partition 6, and the shield shell 2 is fixed with a front shield partition 6. The drive device 5 is fixed on the front shield partition 6, the middle part of the shield shell 2 is provided with a rotary joint 4, the front end of the shield shell 2 is provided with a cutter head 1, the cutter head 1 is connected with the drive device 5, and the front shield partition 6 is connected with the drive device 5. An excavation chamber 3 is arranged between the cutterheads 1, and the driving device 5 drives the cutterhead 1 to rotate to excavate and cut the stratum, and the muck flows inside the excavation chamber 3.

[0021] The rotary joint 4 includes a rotary joint rotor 15 and a rotary joint stator 8, the rotary joint rotor 15 is movably connected with the rotary joint stator 8, a copper ...

Embodiment 2

[0024] Embodiment 2: A telescopic rotary joint, the front end of the stirring shaft 14 is horizontally fixedly connected with the stirring rod 11 through a spline, and the front end of the stirring shaft 14 is clamped and fixed by a semicircular key to prevent the axial movement of the stirring shaft 14, and then use End cover 19 fixedly covers stirring shaft 14, prevents stirring shaft 14 from wearing and tearing in excavation bin 3. All the other are identical with embodiment 1.

Embodiment 3

[0025] Embodiment 3: A telescopic rotary joint, the working method is:

[0026] 1) Telescopic: the hydraulic cylinder 10 stretches back and forth, drives the motor 17 to move back and forth relative to the rotary joint 4, the motor 17 drives the stirring shaft 14 to move back and forth through the coupling 16, and the stirring shaft 14 further drives the stirring rod 11 to stretch;

[0027] 2) Sealing: During the forward and backward movement of the stirring rod 11, the inner seal 12 of the cutter head drive shaft sleeve 18 separates the excavation chamber 3 from the copper sleeve 13, preventing the rotation of the stirring shaft 14 from being obstructed by dregs;

[0028] 3) Adding the improvement liquid: the cutter head drive bushing 18 is fixed to the rotary joint rotor 15, the driving device 5 drives the cutter head 1 to rotate, the rotation of the cutter head 1 drives the rotary joint rotor 15 to rotate, and then introduces the improvement liquid into the cutter head 1. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com