Geometric gradient plate structure

A plate structure and geometry technology, applied in the direction of sheet/plate, building elements, etc., can solve problems such as inability to adapt better, and achieve the effect of meeting actual engineering needs and rich geometric design parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, the present invention will be further described;

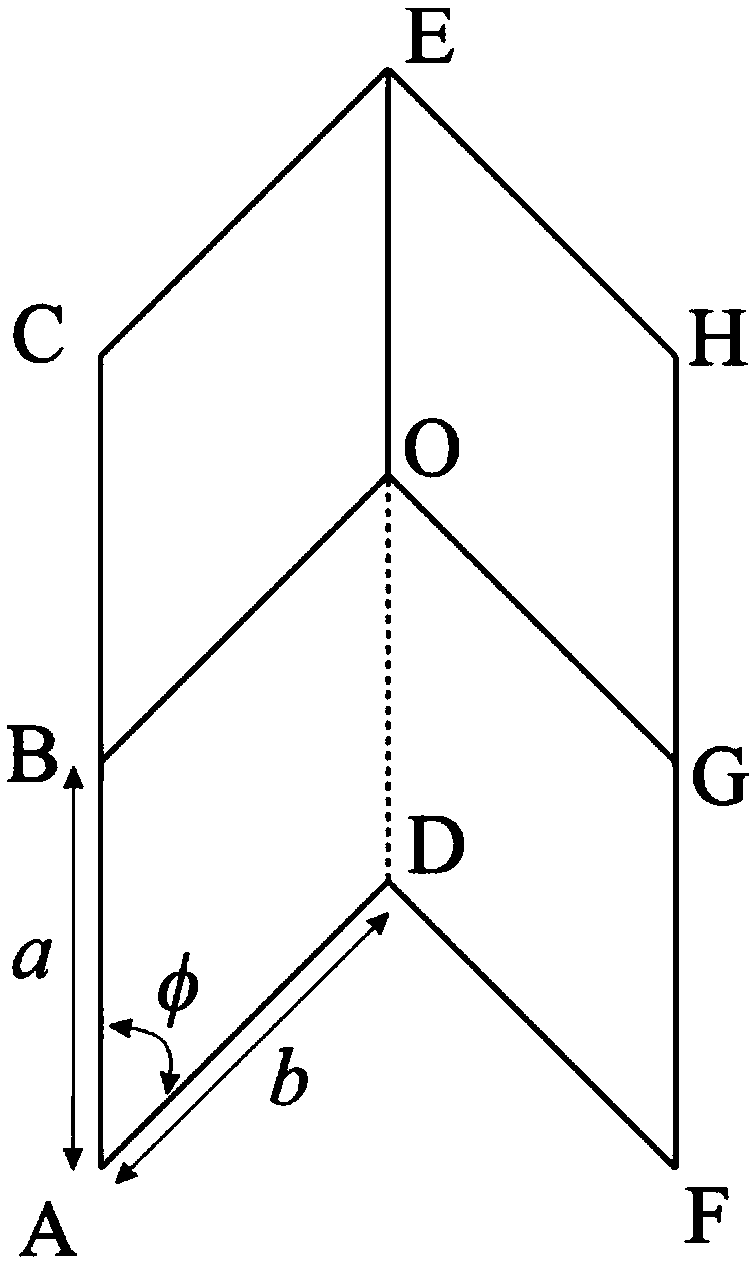

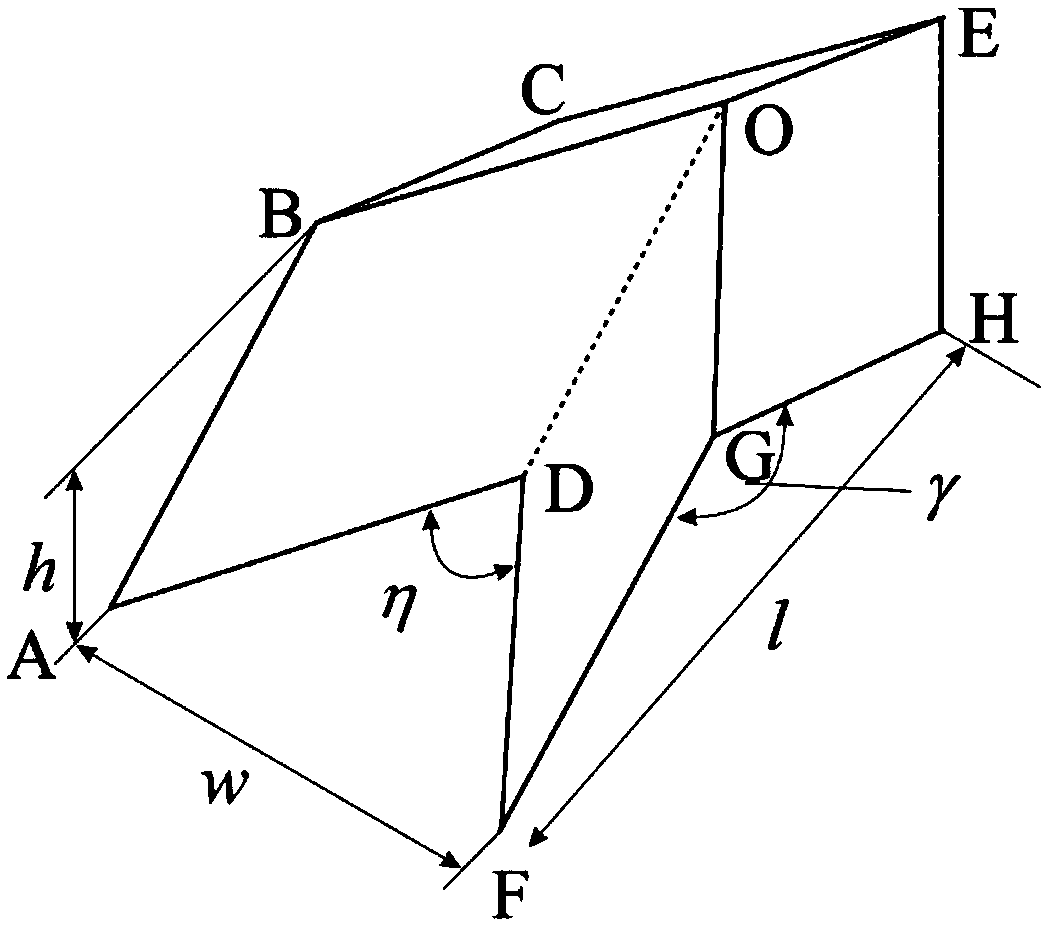

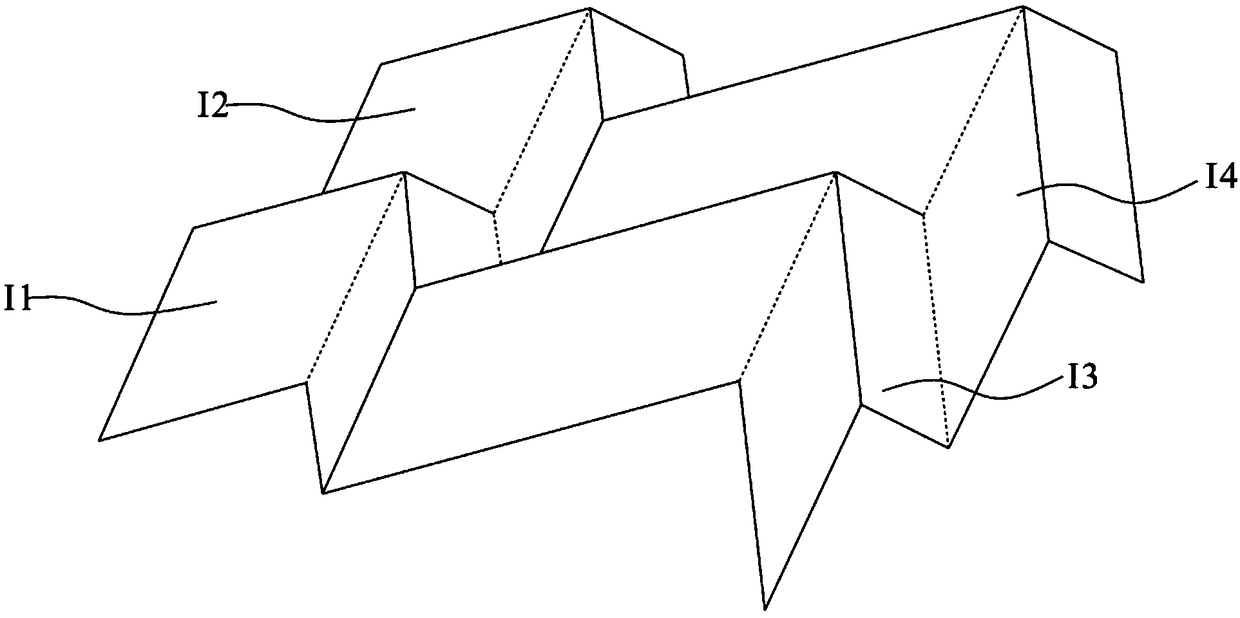

[0037] A geometric gradient plate structure of the present invention has obvious columns and rows, and is a plate structure formed by splicing several modules with pre-folded lines. The modules here are pre-folded by a Miura origami pattern. The three methods of changing the horizontal side length, included angle or vertical side length of the module are used in different columns and different rows to obtain different gradient board structures. For all the figures in this specification, the same or corresponding modules are generally indicated by the same numerals and letters. It should be pointed out that all the figures in the description are only explanatory representations of the invention, and the invention is not limited to these representations. In addition, various parts in the drawings are not necessarily represented in actual scale. Under certain circumstances, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com