Geometric gradual change folding line pipe

A corrugated pipe and geometry technology, applied in the field of corrugated pipes, can solve the problems that round pipes and square pipes cannot meet the needs of production and life, and achieve the effects of rich geometric design parameters, convenient processing and lower production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

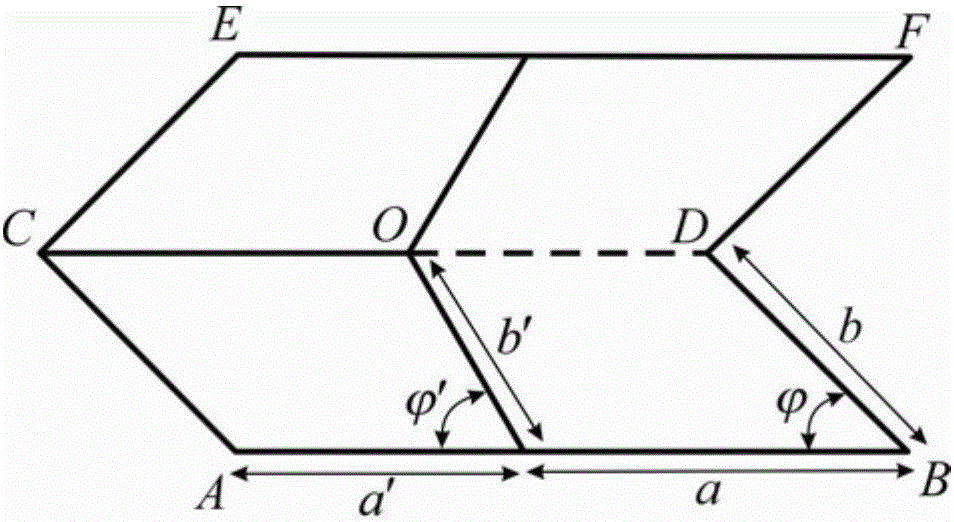

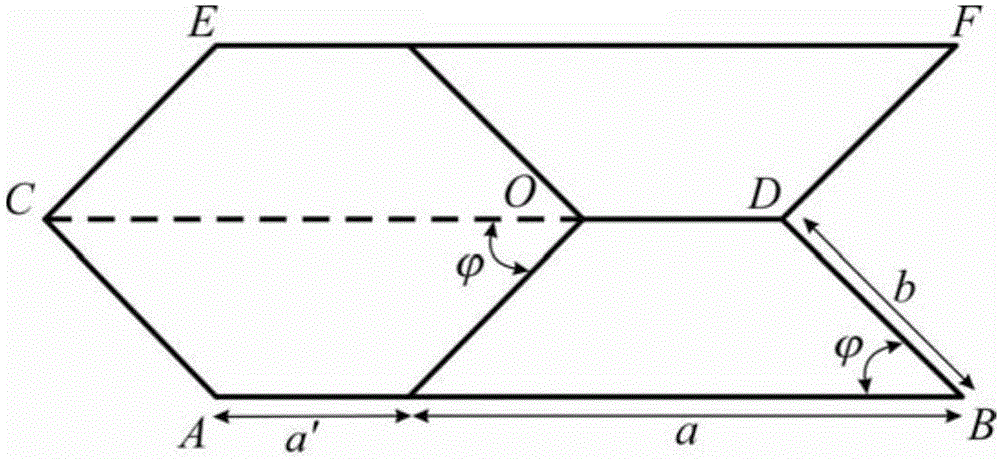

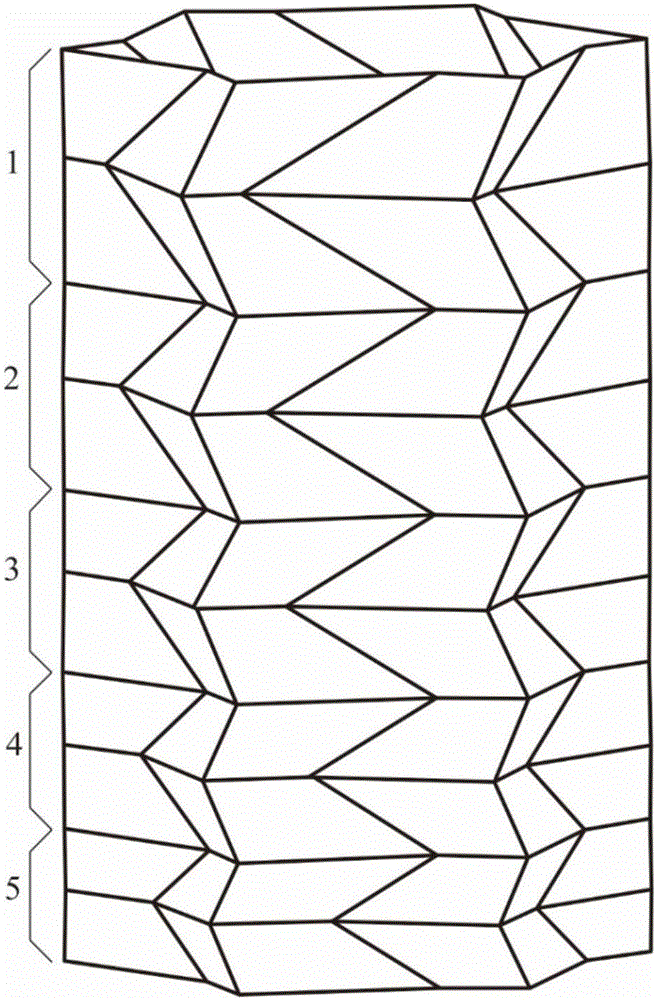

[0067] The geometric gradient pleated pipe of the present invention is a tubular structure formed by connecting several modules with pre-pleated pleats. The module is pre-folded by two different origami patterns, by changing the side length, angle and number of the module, changing the side length and angle of the module at the same time, changing the side length and number of the module, and changing the angle of the module at the same time There are 7 basic ways to change the geometric parameters of the module, such as changing the side length, angle and number of the module at the same time, so as to obtain different bellows structures.

[0068] The geometric change in the axial direction, whether it is origami pattern 1 or origami pattern 2, can change the geometric parameters of the figure in seven ways to achieve the geometric change of the tubular structure, and can be formed by plane folding. The geometric change in the circumferential direction has no The change in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com