Kitchen sink

A kitchen sink and tank body technology, applied in water supply devices, indoor sanitary plumbing devices, buildings, etc., can solve the problems of sink clogging and normal use, and achieve the effects of increasing reciprocating frequency, good connection and coordination, and faster drainage speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

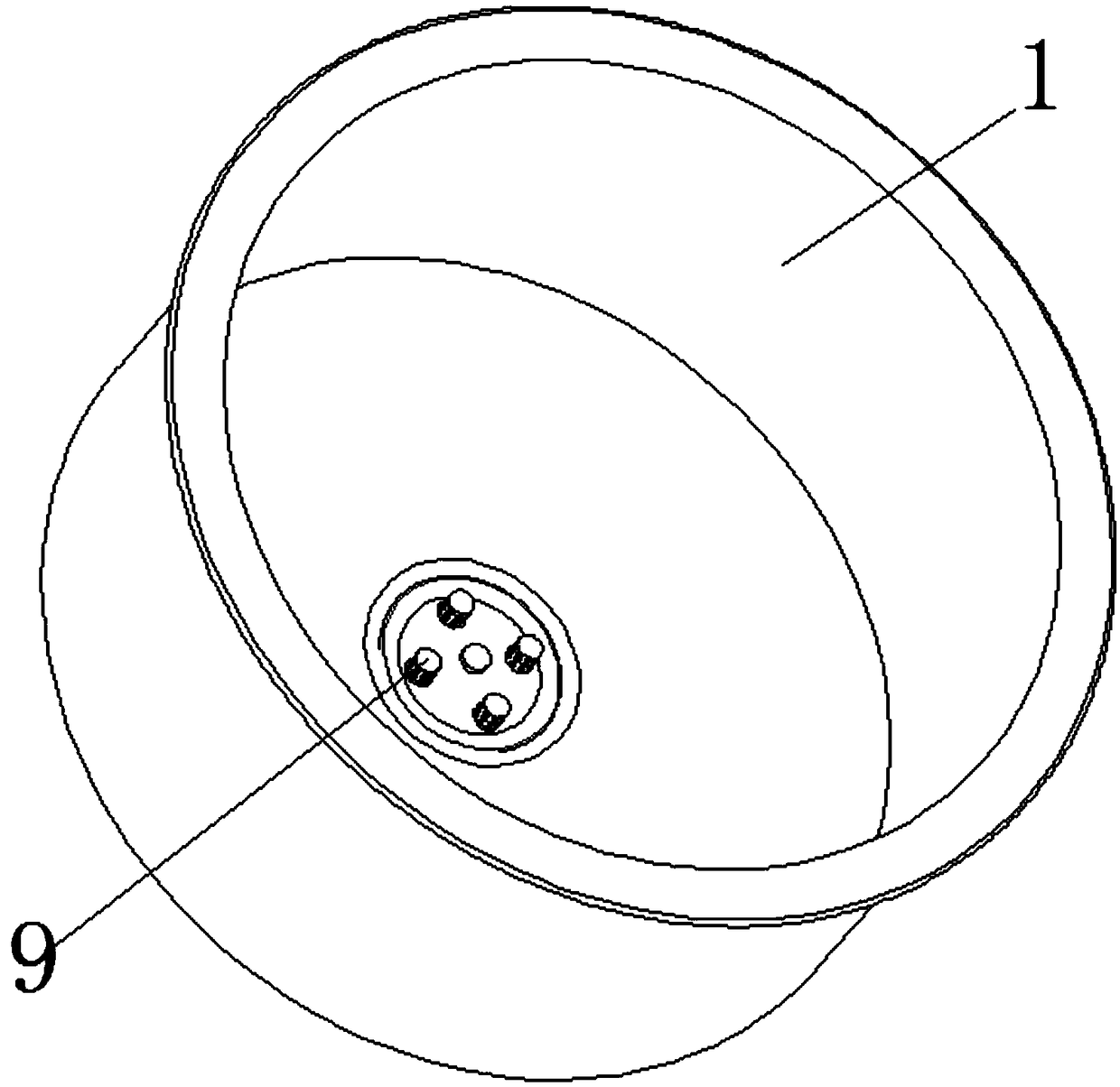

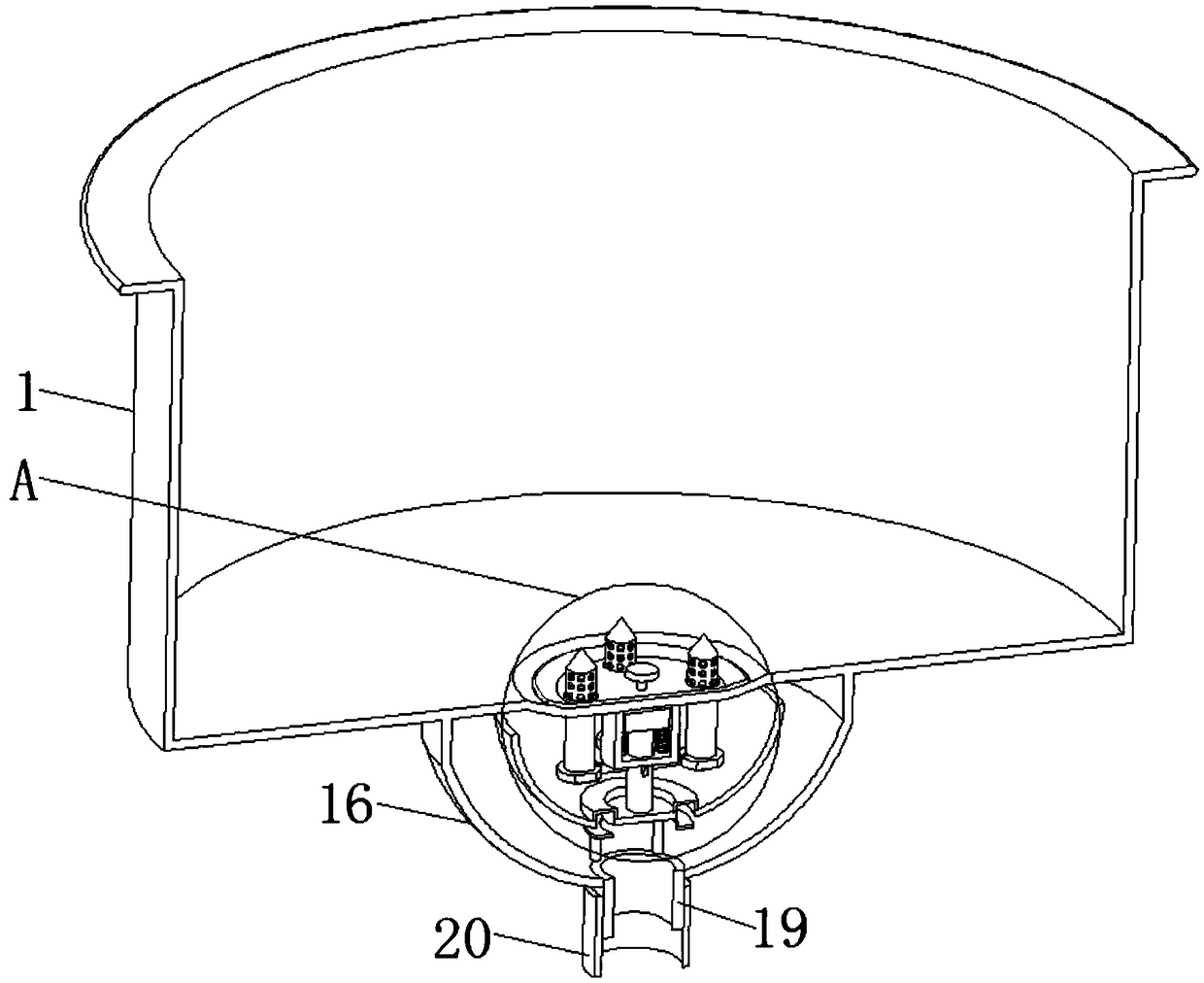

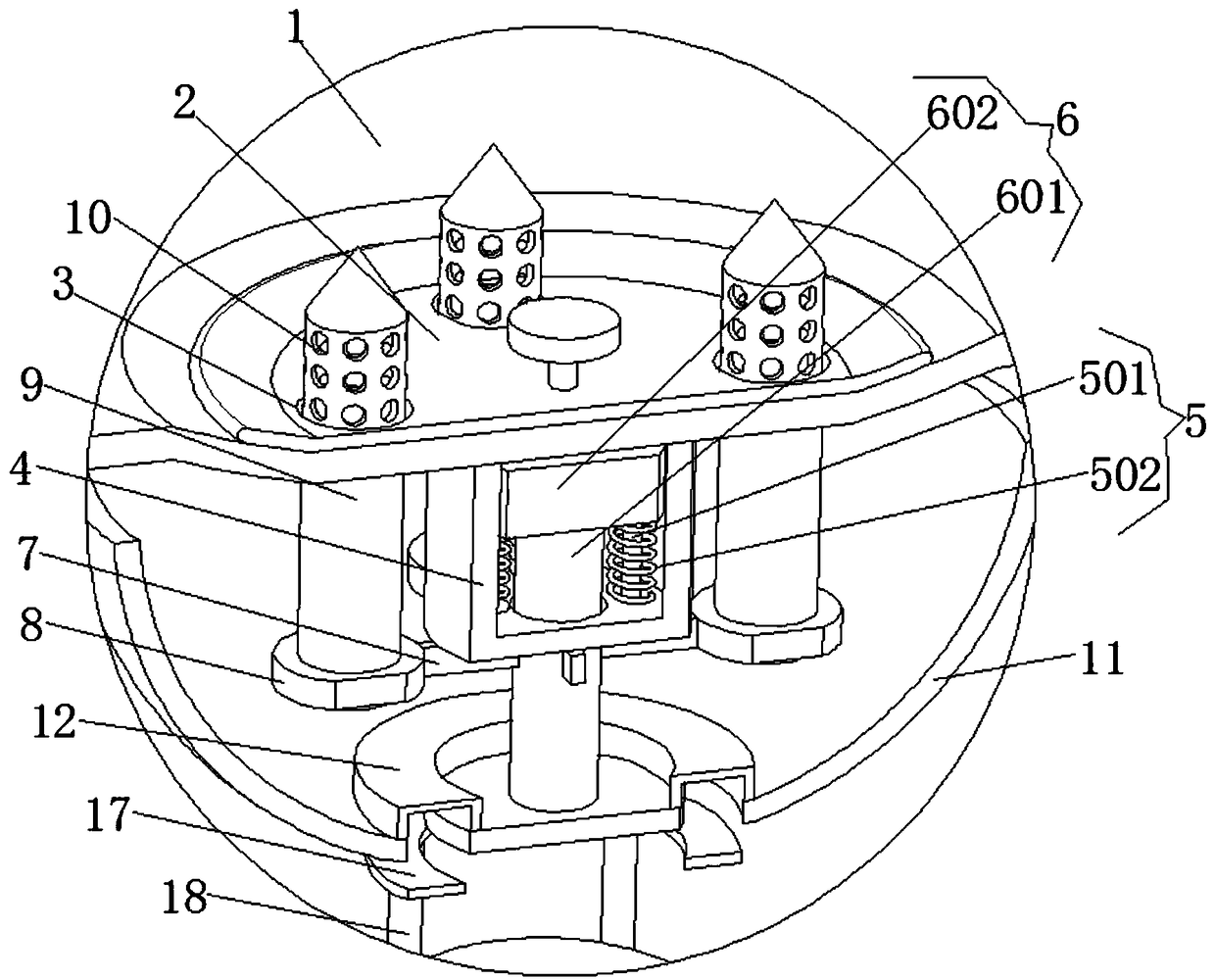

[0030] A Chinese kitchen sink, comprising a tank body 1, a filter plate 2 is placed at the bottom of the tank body 1, and a filter hole 3 is opened on the filter plate 2, and the filter hole 3 is connected to the bottom of the tank body 1, and the bottom of the tank body 1 An adjustment ring 4 is fixedly installed, and a telescopic mechanism 5 and an adjustment mechanism 6 are respectively arranged inside the adjustment ring 4. The telescopic mechanism 5 is connected to the adjustment mechanism 6, and the adjustment mechanism 6 extends out of the outer surface of the adjustment ring 4 and is welded with a connecting rod 7 A collar 8 is fixedly welded on the end of the connecting rod 7 away from the adjusting mechanism 6, and the punching hollow column 9 fixedly socketed on the inner wall of the collar 8 passes through the filter hole 3, and the number of the filter hole 3 and the punching hollow column 9 is four. , and four filter holes 3 and four punching hollow columns 9 are ...

Embodiment 2

[0033] like figure 2 As shown, based on Embodiment 1, the telescoping mechanism 5 includes four sliding rods 501, and springs 502 are sleeved on the four sliding rods 501, and the springs 502 adopt a coefficient of resistance to pressure of one kilogram.

Embodiment 3

[0035] like figure 2 As shown, based on Embodiment 1, the adjustment mechanism 6 includes a through pipe 601, and an auxiliary ring 602 is sleeved on the through pipe 601. The auxiliary ring 602 is sleeved on the slide rod 501, and the spring 502 is located below the auxiliary ring 602. , the part of the through pipe 601 located outside the adjustment ring 4 is connected with the connecting rod 7 and the hemispherical carrier 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com