Annular sliding rail type flexible assembly platform

A flexible assembly, slide rail technology, applied in transportation and packaging, conveyors, metal processing and other directions, can solve the problems of large running friction, large fluctuations in track resistance, low running speed, etc., to achieve strong load bearing capacity, alarm response Sensitive, low coefficient of friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

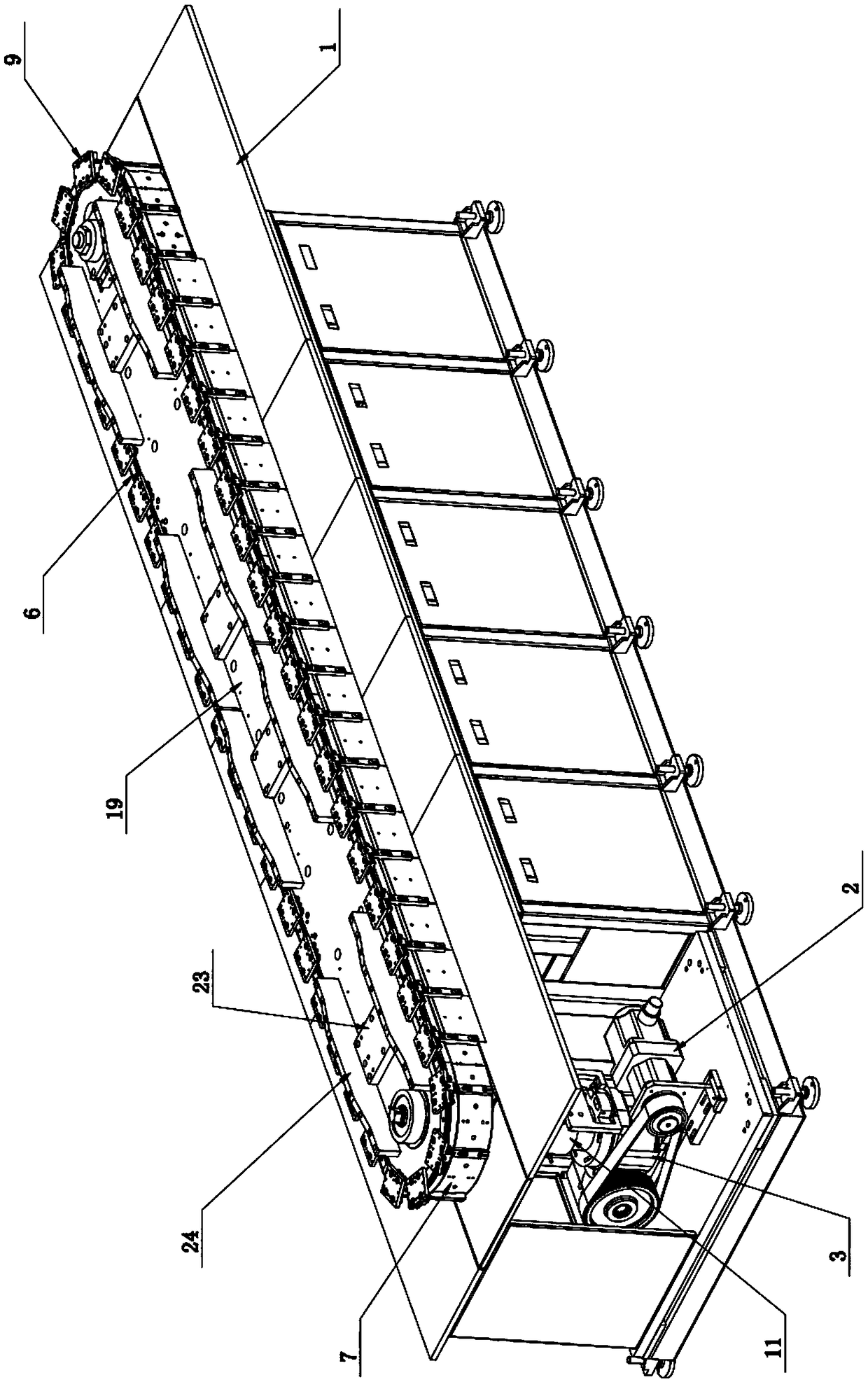

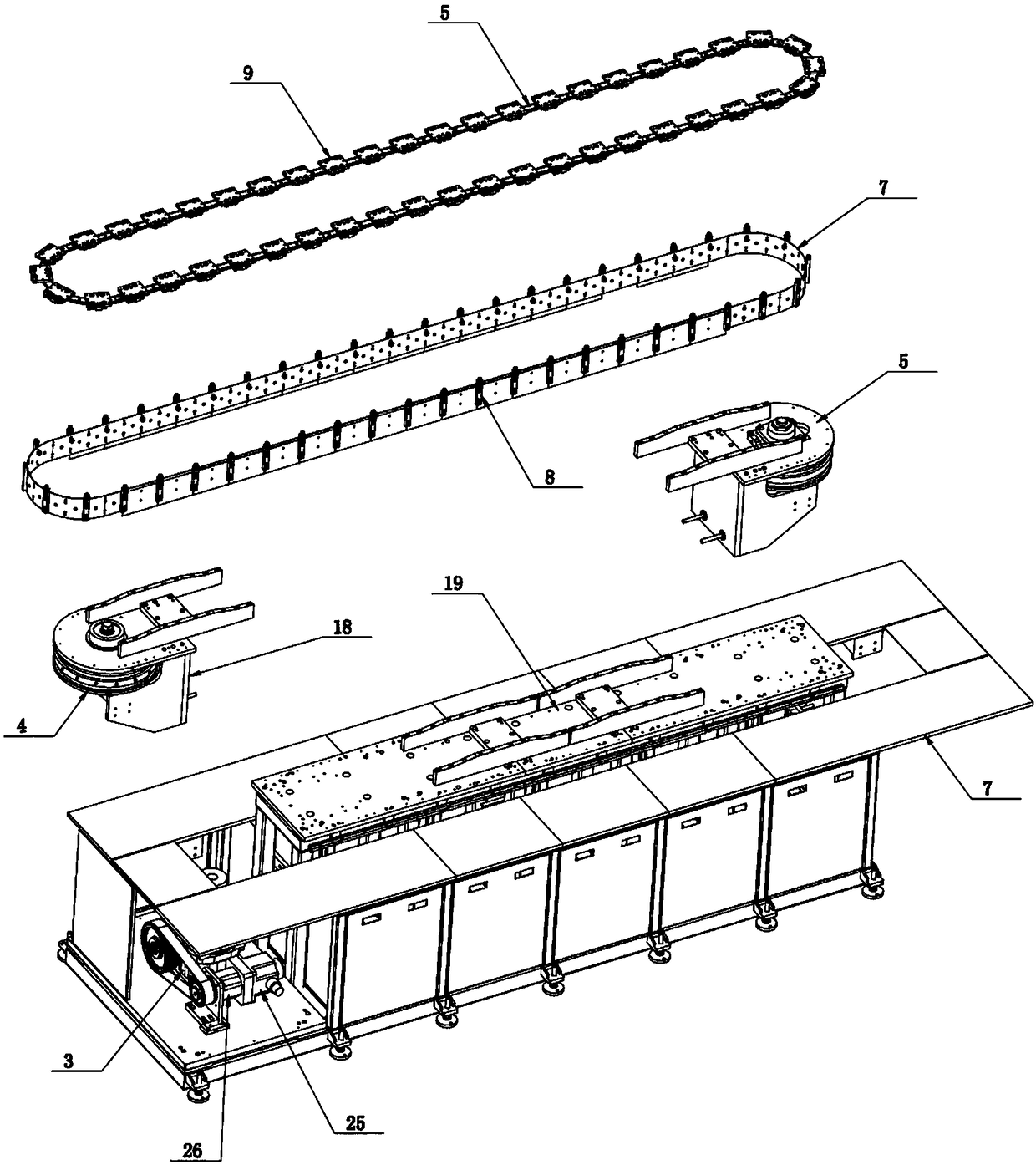

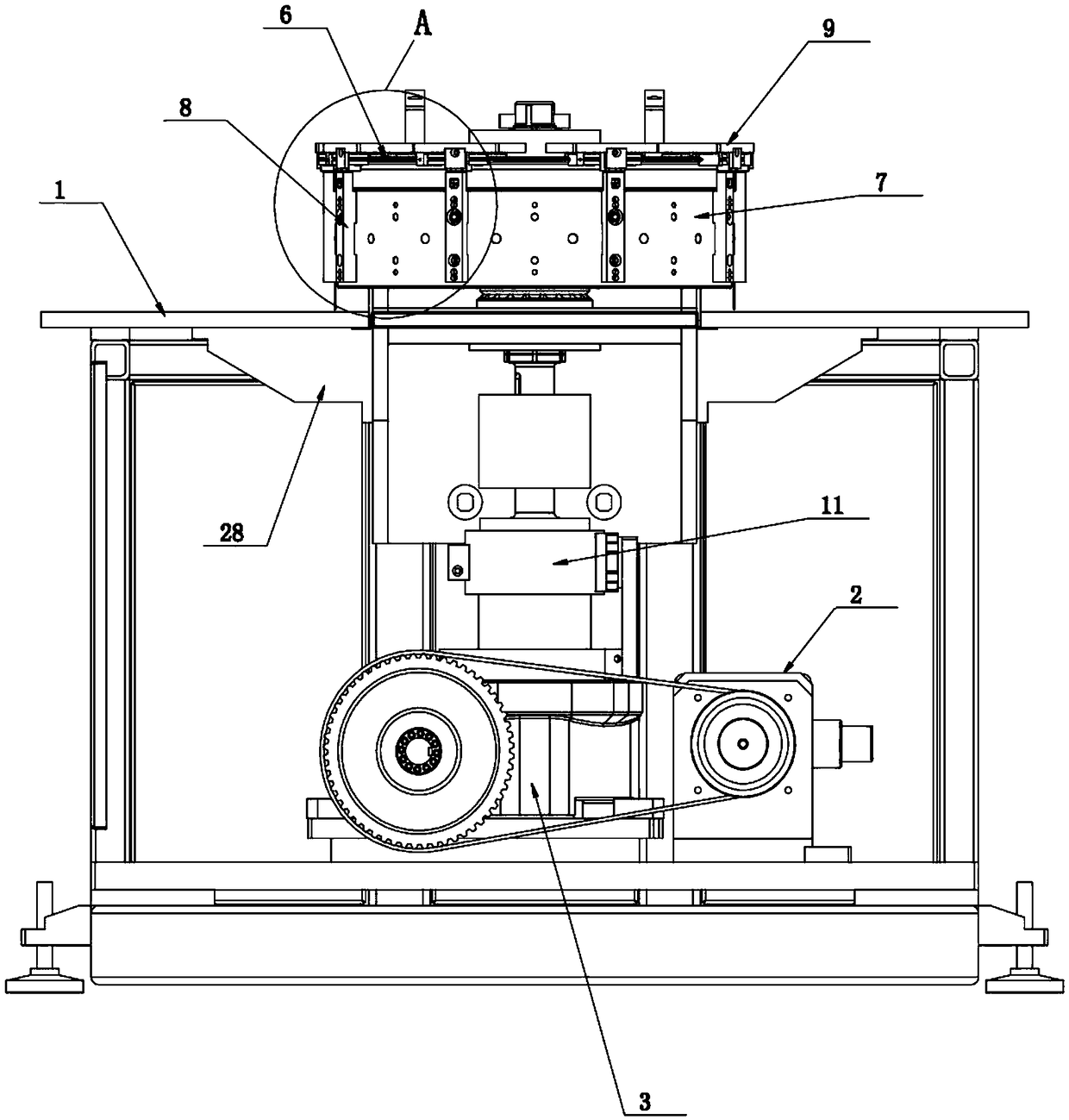

[0029] refer to Figure 1 to Figure 10 , the present invention provides an annular slide rail type flexible assembly platform, comprising: a workbench 1 and a power drive mechanism 2 respectively installed on the workbench 1, an index divider 3, a main drive wheel 4, a slave drive wheel 5, an annular The slide rail 6 and the transmission steel belt 7; the power drive mechanism 2 is sequentially connected with the index divider 3 and the main transmission wheel 4, and the main transmission wheel 4 is used to drive the transmission steel belt 7 to rotate, and the transmission steel belt 7 is equipped with steel belts at equal intervals The station connection block 8 and the station substrate 9 are slidably installed on the annular slide rail 6 , and the steel strip station connection block 8 is connected to the station substrate 9 .

[0030] In this embodiment, the power is output to the transmission steel belt through the power drive mechanism, the indexing divider and the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com