Systems for detecting overloads and electrical differential protection equipment for electric lines

A technology for electrical equipment and wires, applied in the field of systems for detecting overload, which can solve the problems of metal straps that cannot ensure lock release, jamming, and sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

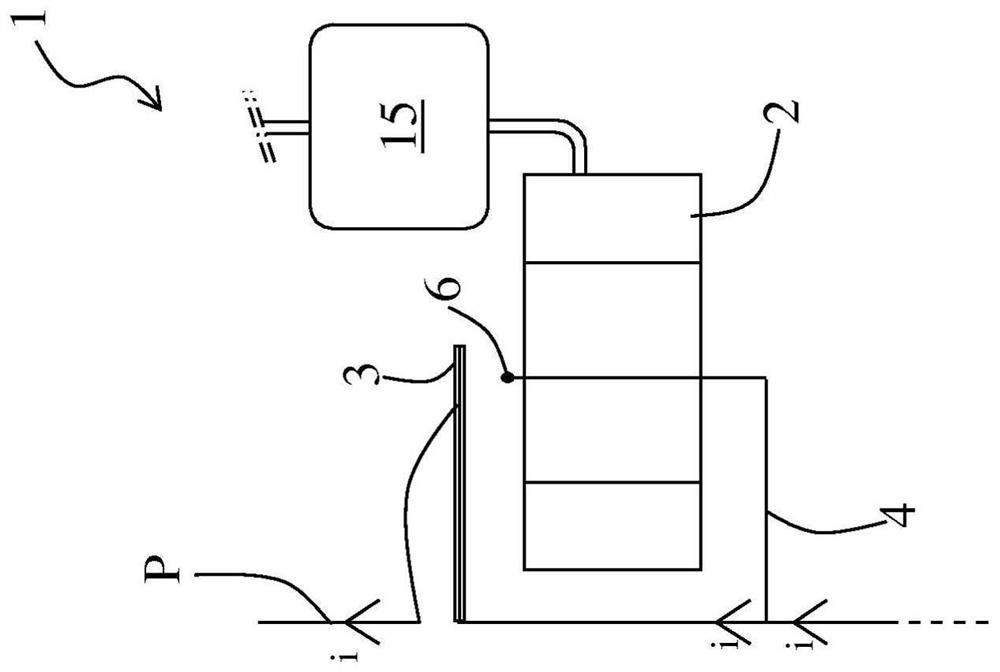

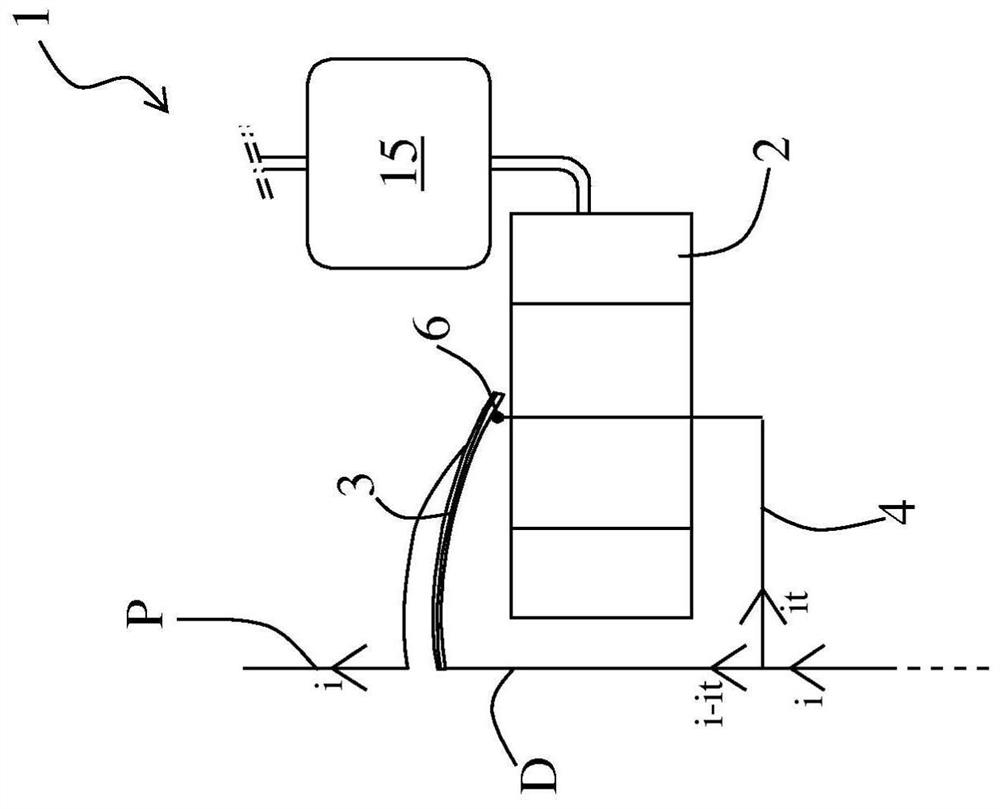

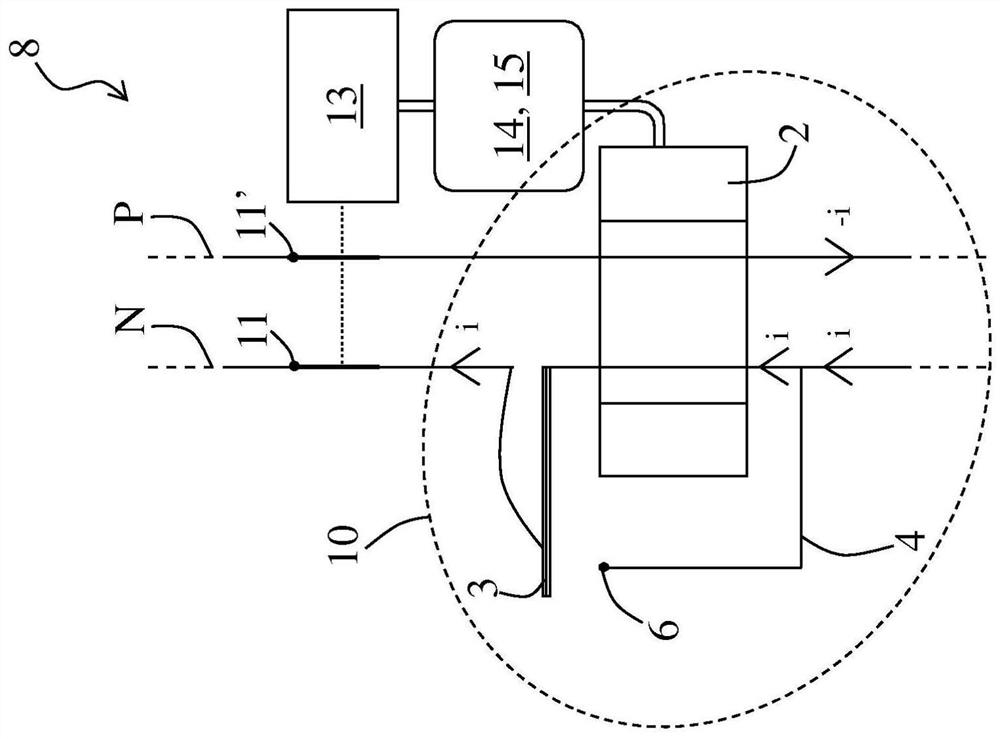

[0032] A system 1 , 10 , 100 for detecting overloads according to the invention comprises a measuring toroid 2 , a bypass branch 4 and an actuator 3 . Said detection system 1 , 10 , 100 makes it possible to detect an overload via an actuator 3 in response to an increase in current, the function of which is to transmit information of the overload to the measuring toroid 2 . This information is advantageously identified due to the presence of a bypass branch 4 which is connected in parallel to the wires N and / or P in question to form a bypass loop D during an overload. The bypass loop D and the measuring toroid 2 engage in each other, in other words the bypass loop D is surrounded by the measuring toroid 2 and vice versa.

[0033] In response to an increase in the current flowing through said wires N and / or P, the bypass branch 4 can be closed or connected to the monitored wires N and / or P by means of the actuator 3 . Said actuator 3 is in thermal contact with the wires N and / o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap