Joint Scheduling Method for Production and Transportation Oriented to Continuous Production

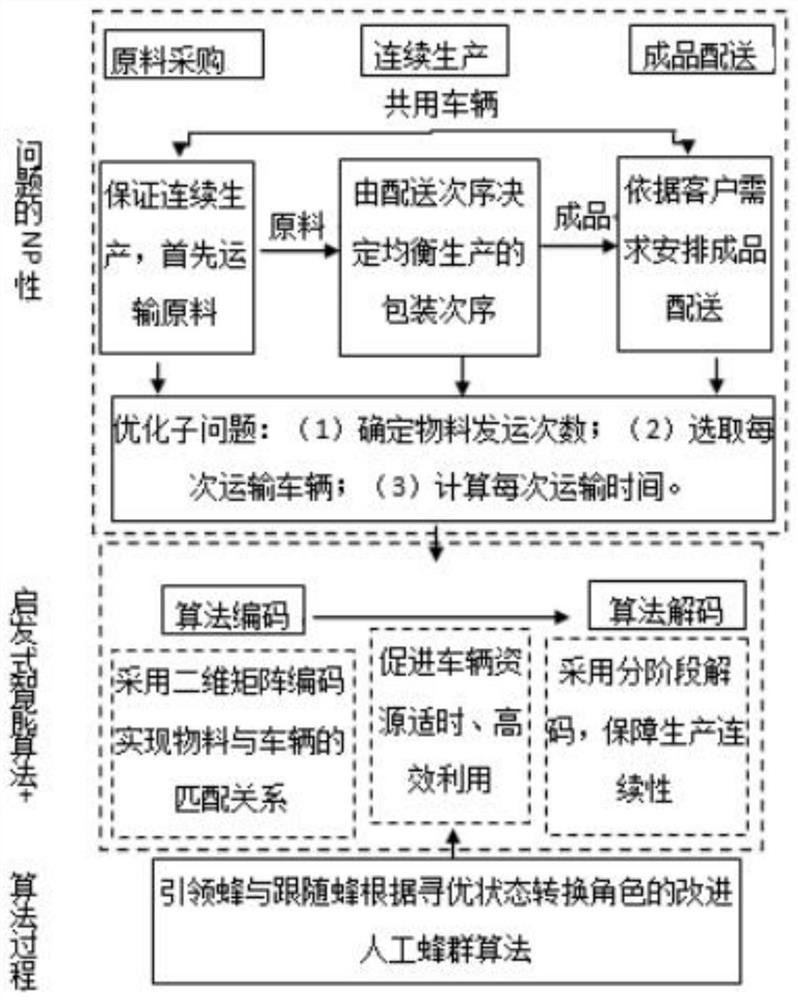

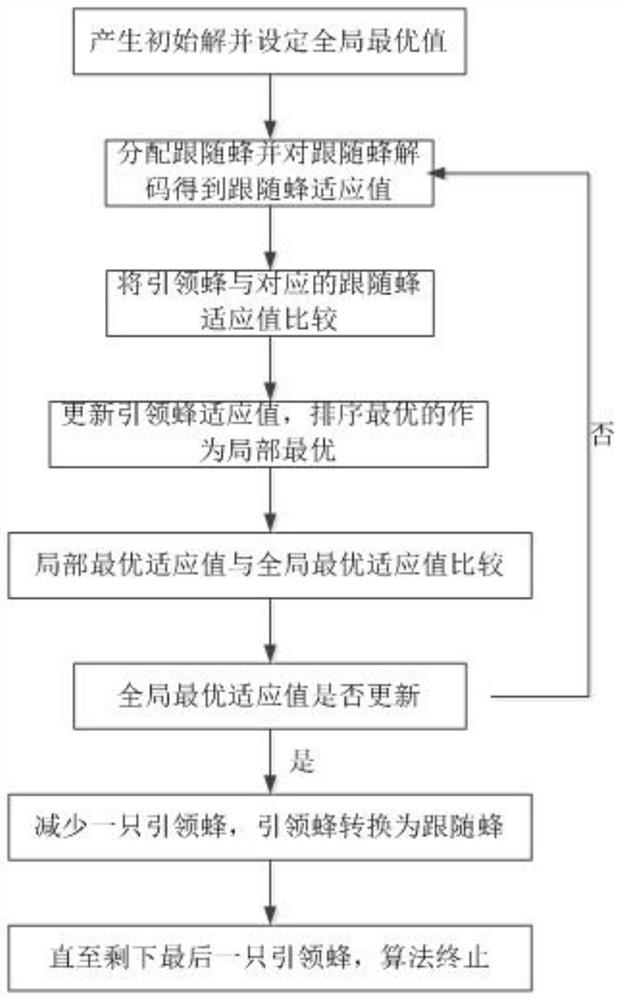

A joint scheduling and manufacturer's technology, applied in artificial life, biological models, data processing applications, etc., can solve the problems that continuous production cannot be used, and there is no simultaneous scheduling of raw materials and finished products to shorten the total scheduling time, so as to shorten the total scheduling time , strong search and development capabilities, and excellent solution results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] This embodiment is oriented to the joint production and transportation scheduling method for continuous production,

[0108] (1) Description of the problem:

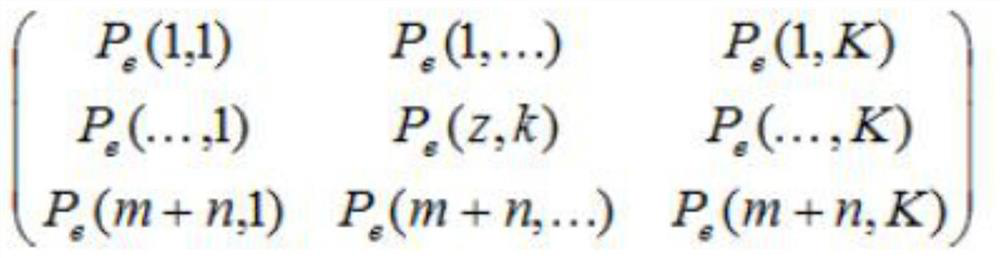

[0109] The manufacturer received orders from n customers at the beginning of the period, and each order requires different types of finished products, O={W 1 ,W 2 ,...,W n} represents the set of orders, order W i Finished product i is needed, and the quantity demanded is q i , production requires m kinds of raw materials; starting from the manufacturer, the vehicle first transports raw material j, and puts the raw material into the raw material warehouse after arriving at the manufacturer. After all the raw materials are ready to ensure continuous production, it will be produced again; in production, it is necessary to input raw material j in a certain proportion, and use Constant production rate P produces and packs finished products of n specifications for sale; finished products can be delivered directly to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com