Method and apparatus for eliminating salt field bottom plate covering film bulges

A technology of salt field and bottom plate, applied in the direction of alkali metal chloride, etc., can solve the problem of mass production of bulge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

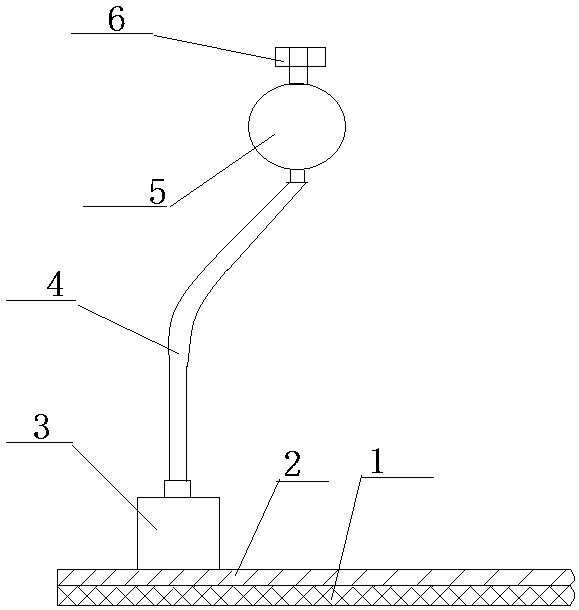

[0024] see figure 1 , a method and device for eliminating film-laying bulges on the floor of a salt field, the specific steps are as follows:

[0025] (1) Pond sun-drying: introduce raw brine on the bottom of the salt pan to sun-dry NaCl pool slabs, and the thickness of the pool slabs is 50cm;

[0026] (2) Leveling and rolling: leveling and rolling the bottom surface and side slope of the salt pan, after the side slope of the salt pan is compacted, spray raw brine until the surface is consolidated, and the spraying amount of raw brine is 1L per square meter of slope;

[0027] (3) Membrane laying: On the bottom surface and side slope of the salt pan, lay the membrane along the slope from the high ground to the low ground, and weld it. After the bottom surface is finished, excavate at the top edge of the salt pan slope Anchor ditch, bury one end of the salt field slope membrane into the anchor ditch to fix;

[0028] (4) Divide the bottom plate of the salt field after film layi...

Embodiment 2

[0032] see figure 1 , a method and device for eliminating film-laying bulges on the floor of a salt field, the specific steps are as follows:

[0033] (1) Pool slab drying: introduce raw brine on the bottom of the salt pan to dry NaCl pool slabs, the thickness of the pool slabs is 40cm;

[0034] (2) Leveling and rolling: leveling and rolling the bottom surface and side slope of the salt pan, after the side slope of the salt pan is compacted, spray raw brine until the surface is consolidated, the spraying amount of raw brine is 3L per square meter of slope;

[0035] (3) Membrane laying: On the bottom surface and side slope of the salt pan, lay the membrane along the slope from the high ground to the low ground, and weld it. After the bottom surface is finished, excavate at the top edge of the salt pan slope Anchor ditch, bury one end of the salt field slope membrane into the anchor ditch to fix;

[0036] (4) Divide the salt field bottom plate after film laying into 1,000 squa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com