Method for preparing rubber pressure-sensitive adhesive

A pressure-sensitive adhesive and rubber technology, applied in the field of pressure-sensitive adhesives, can solve problems such as harsh conditions and insufficient cohesion of pressure-sensitive adhesives, and achieve the effect of improving high-temperature cohesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] Thus, the invention provides a kind of preparation method of rubber pressure-sensitive adhesive, described method comprises the following steps:

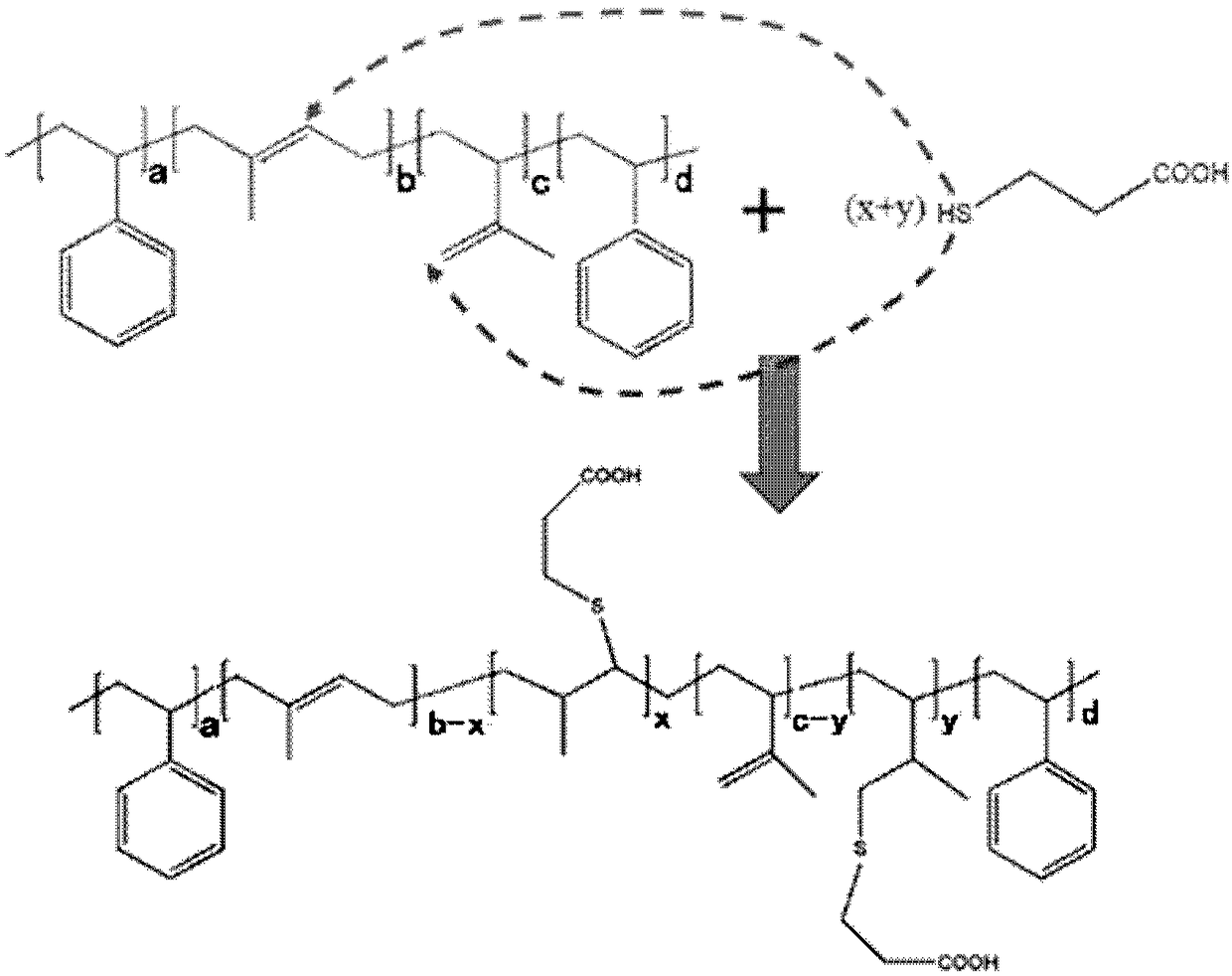

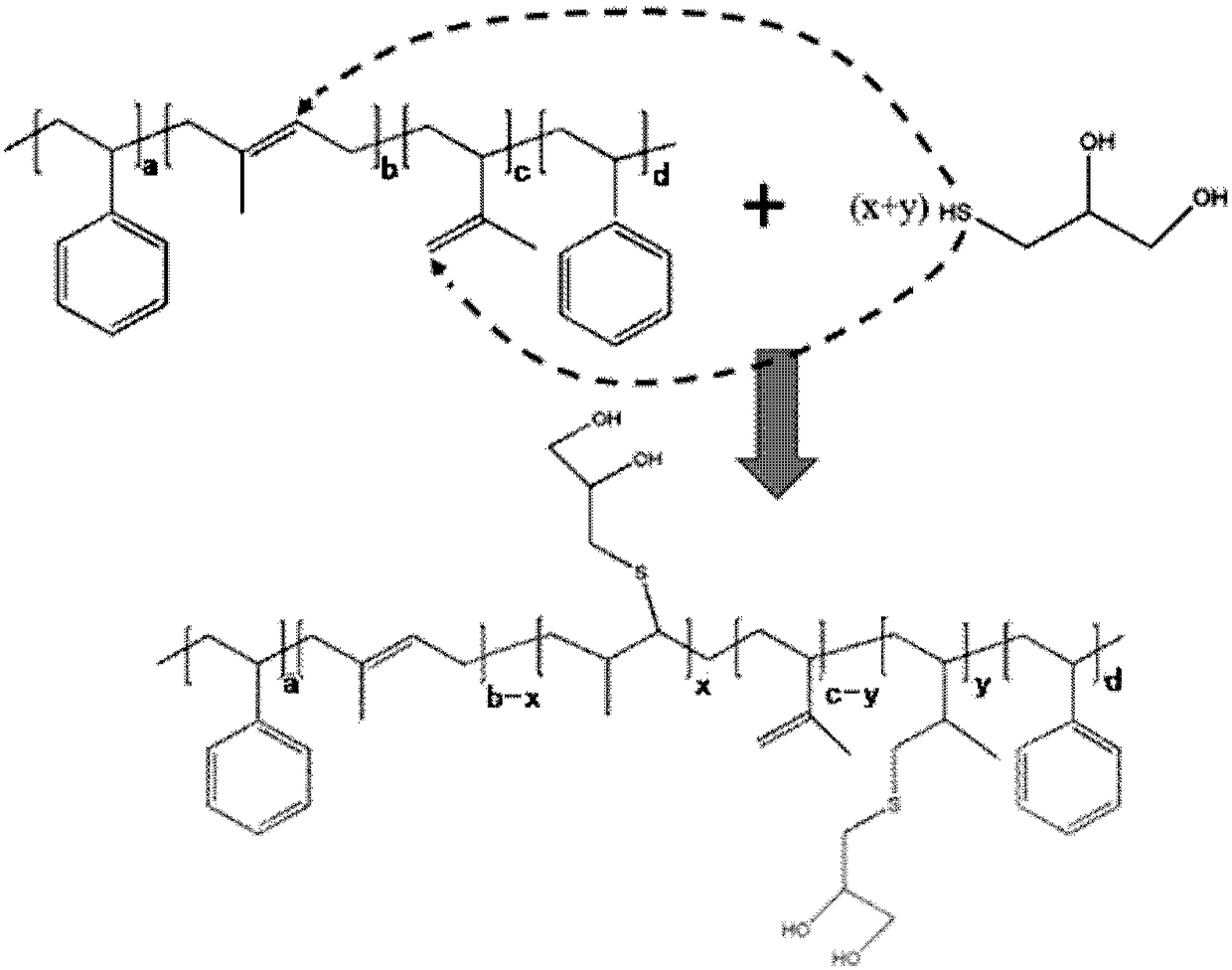

[0017] (a) mixing a styrene-isoprene-styrene block copolymer, a mercapto modifier, an initiator and a solvent to obtain a rubber mixture;

[0018] (b) heating and reacting the rubber mixture obtained in step (a) to obtain a modified rubber solution, which contains mercapto-modified styrene-isoprene-styrene block copolymer things; and

[0019] (c) Adding a tackifying resin to the modified rubber solution obtained in step (b) to obtain a rubber pressure-sensitive adhesive.

[0020] In the above step (a), the selection of the specific content of styrene-isoprene-styrene block copolymer, mercapto modifier, initiator and solvent is for better realization of styrene-isoprene- Modification of styrene block copolymers plays an important role. According to some specific embodiments of the present invention, based on the total weigh...

Embodiment 1

[0040] first step:

[0041] 74 g of Baling 1105, 1.48 g of mercaptopropionic acid, and 0.37 g of Vazo-67 were added to 126 g of xylene, and mixed well and uniformly to obtain a rubber compound.

[0042] The second step:

[0043] The obtained rubber mixture was heated at 65° C. for 12 hours to obtain a modified rubber solution B2 containing a mercapto-modified styrene-isoprene-styrene block copolymer.

[0044] The third step:

[0045] Based on 100 parts by weight of the solid content of the obtained modified rubber solution B2, 100 parts by weight of Escorez 2203 was added to the modified rubber solution B2 and mixed thoroughly to obtain a rubber pressure-sensitive adhesive.

Embodiment 2

[0047] Prepare a rubber pressure-sensitive adhesive in the same manner as in Example 1, except that: in the third step, based on 100 parts by weight of the obtained modified rubber solution B2, the modified rubber solution B2 is also added Add 0.1 parts by weight of diamine cross-linking agent RD1054 to B2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com