Slaughterhouse special slaughter platform with height adjustment function

A technology of height adjustment and height adjustment mechanism, which is applied in the direction of livestock slaughtering platform/slaughtering support, slaughtering tool/knife, blood collection/blood stirring device, etc., which can solve the problem that the use of special slaughtering platform in slaughterhouse is not humanized enough and cannot be adjusted in height , lack of height adjustment mechanism and other issues, to achieve the effect of preventing health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

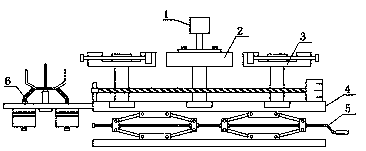

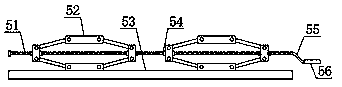

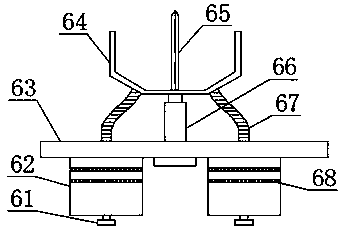

[0021] see figure 1 and figure 2 , the present invention provides a technical solution: a special slaughtering platform with a height adjustment function, including a support base plate 4, a height adjustment mechanism 5 and a slaughter mechanism 6, and a first working plate is arranged in the middle of the upper surface of the support base plate 4 2. A clamping ring 1 is set above the first working plate 2, a second working plate 3 is set on one end of the upper surface of the supporting base plate 4, a height adjustment mechanism 5 is set under the supporting base plate 4, and one side of the supporting base plate 4 is set Slaughtering mechanism 6 is arranged, and height adjusting mechanism 5 comprises first support plate 53, and the junction of first support plate 53 and support base plate 4 is provided with scissor type top 52, and one side of scissor type top 52 is provided with limiting screw rod 51, and scissor type top 52 is provided with limiting screw rod 51, and sc...

Embodiment 2

[0024] see figure 1 and figure 2 , the present invention provides a technical solution: a special slaughtering platform with a height adjustment function, including a support base plate 4, a height adjustment mechanism 5 and a slaughter mechanism 6, and a first working plate is arranged in the middle of the upper surface of the support base plate 4 2. A clamping ring 1 is set above the first working plate 2, a second working plate 3 is set on one end of the upper surface of the supporting base plate 4, a height adjustment mechanism 5 is set under the supporting base plate 4, and one side of the supporting base plate 4 is set Slaughtering mechanism 6 is arranged, and height adjusting mechanism 5 comprises first support plate 53, and the junction of first support plate 53 and support base plate 4 is provided with scissor type top 52, and one side of scissor type top 52 is provided with limiting screw rod 51, and scissor type top 52 is provided with limiting screw rod 51, and sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com