Mechanical equipment dustproof device

A dust-proof device, mechanical equipment technology, applied in the direction of dust removal, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems that the dust-proof device affects heat dissipation and reduces heat dissipation performance, so as to avoid excessive temperature and increase heat dissipation function, increase the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

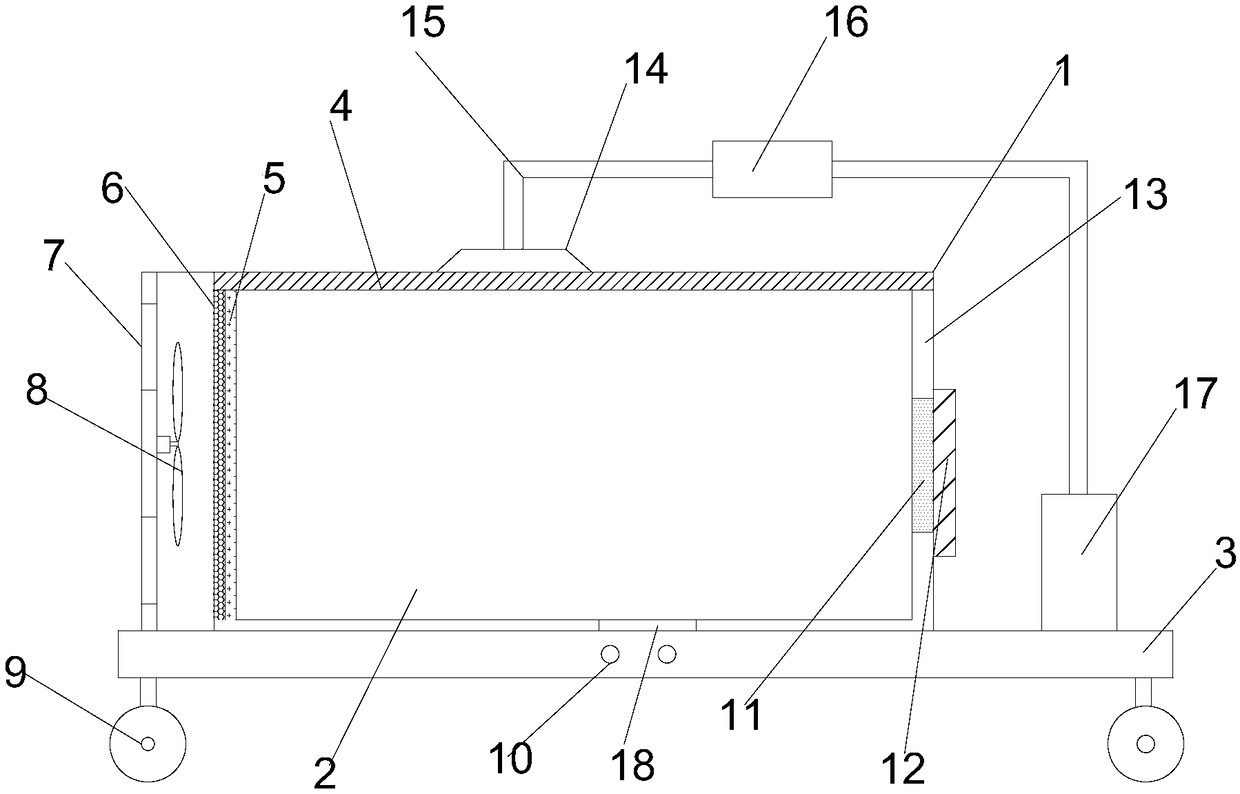

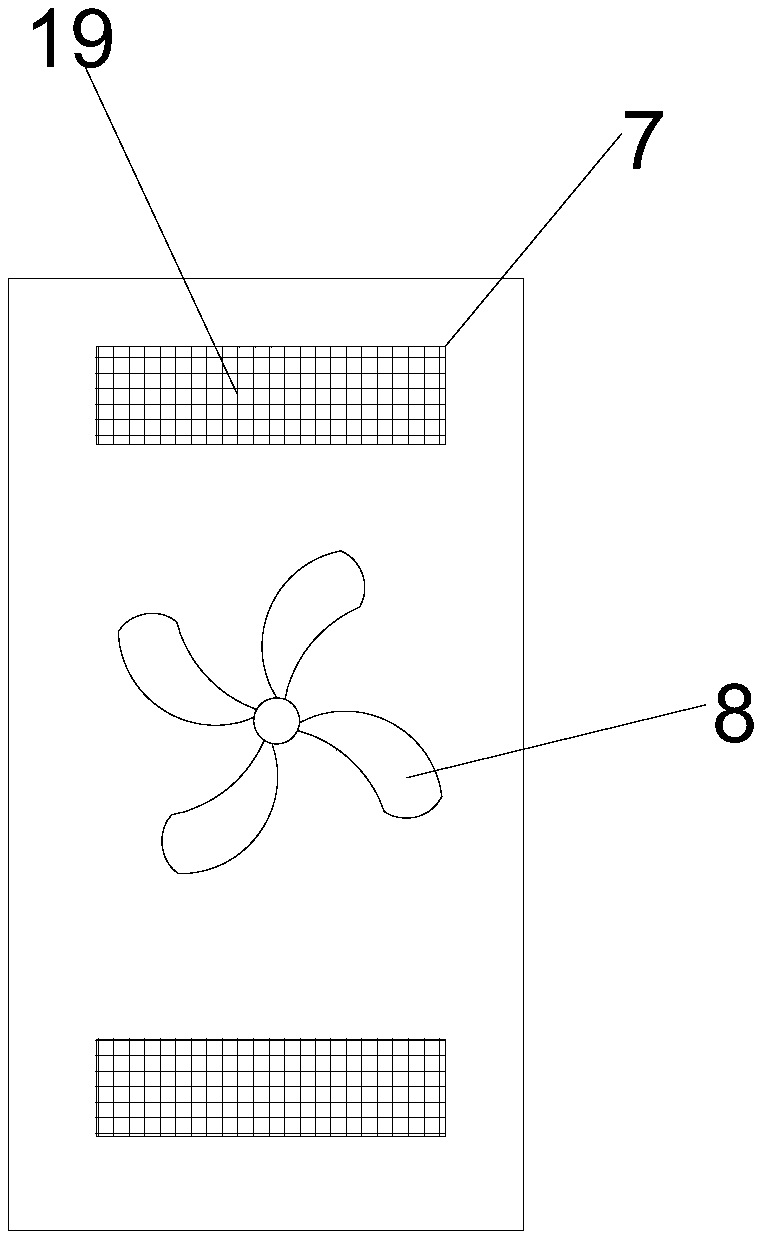

[0026] Such as figure 1 , figure 2 As shown, a dust-proof device for mechanical equipment includes a device body 1, and the device body 1 includes a dust-proof box 2, a dust-removing device arranged on the top of the dust-proof box 2, and a chassis 3 arranged at the bottom of the dust-proof box 2; The front of the dustproof box 2 is provided with an opening, and the opening is hinged with a door; the top of the dustproof box 2 is provided with a dust collection plate 4, and the surface of the dust collection plate 4 is closely attached to the dust removal device; the side of the dustproof box 2 There are two air inlets 7 located at the upper and lower parts respectively and a fan 8 fixed on the inner wall of the middle part of the side, and the two air inlets 7 are covered with a dust-proof net 19; the side facing the fan 8 is provided with a drying layer The opposite side of the dust-proof box 2 is provided with two air outlets 13, and the two air outlets 13 are all covered...

Embodiment 2

[0029] Such as figure 1 As shown, based on Embodiment 1, the dust removal device includes a dust suction port 14 close to the surface of the dust suction plate 4, a dust delivery channel 15 communicated with the dust suction port 14, and a dust suction pump provided on the dust delivery channel 15. 16 and the dust collection box 17 connected to the other end of the dust delivery channel 15, the dust collection box 17 is located on the chassis 3, the side of the dust collection box 17 is provided with an opening, the opening is covered with a side cover, and the side cover is fixed to the dust collection box by screws 17 sides.

[0030] In this embodiment, after the dust suction pump 16 is turned on, the dust removal port close to the dust collection plate 4 sucks the dust adsorbed on the surface of the dust collection plate 4 into the dust delivery channel 15, and then is stored in the dust collection box 17 through the dust delivery channel 15. , when there is too much accum...

Embodiment 3

[0032] Such as figure 1 As shown, based on Example 1, the dry layer includes a sponge layer 6 and an activated carbon layer 5 that is close to the sponge layer 6 , and the upper and lower ends of the sponge layer 6 and the activated carbon layer 5 are close to the inner wall of the dustproof box 2 .

[0033] In this embodiment, after the air passes through the sponge layer 6 and the activated carbon layer 5, the water is absorbed to ensure the dryness of the air, avoid the air being too humid, damage the mechanical equipment, and reduce the service life of the mechanical equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com