Cement slurry testing equipment and cement slurry testing method

A technology for cement slurry and testing equipment, applied in the direction of measuring devices, analytical materials, instruments, etc., can solve the problems of invisibility and accuracy of permeability, and inability to quantitatively characterize the permeability of slurry, and achieve the effect of improving testing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

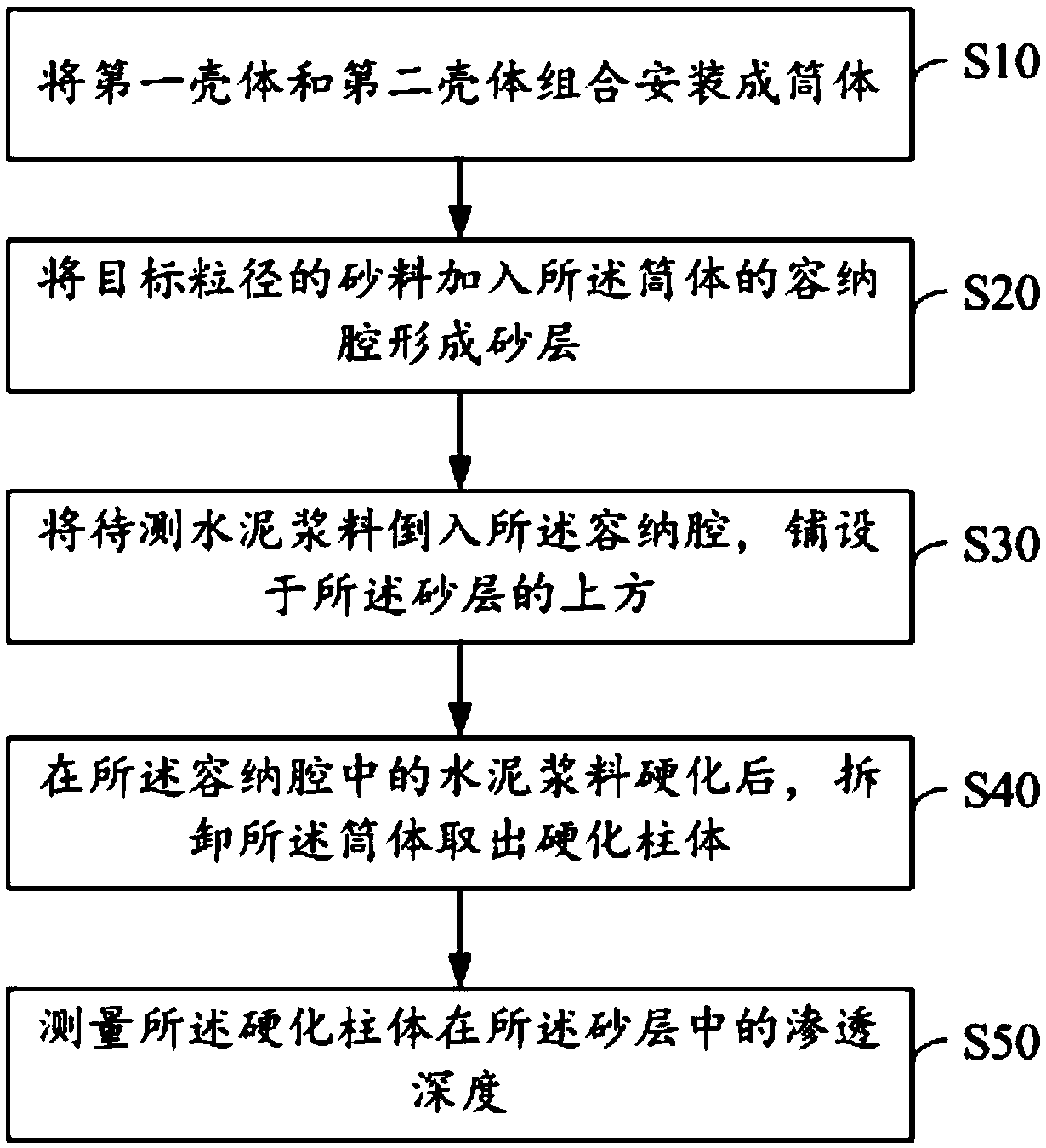

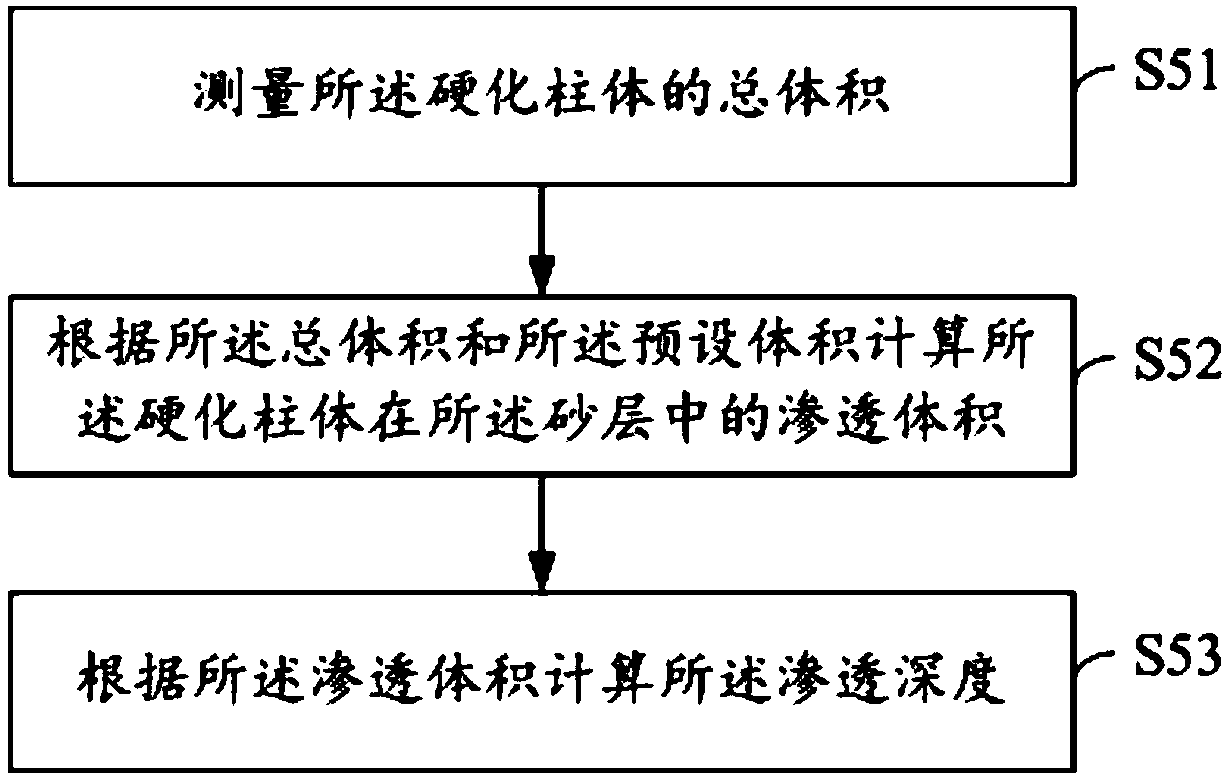

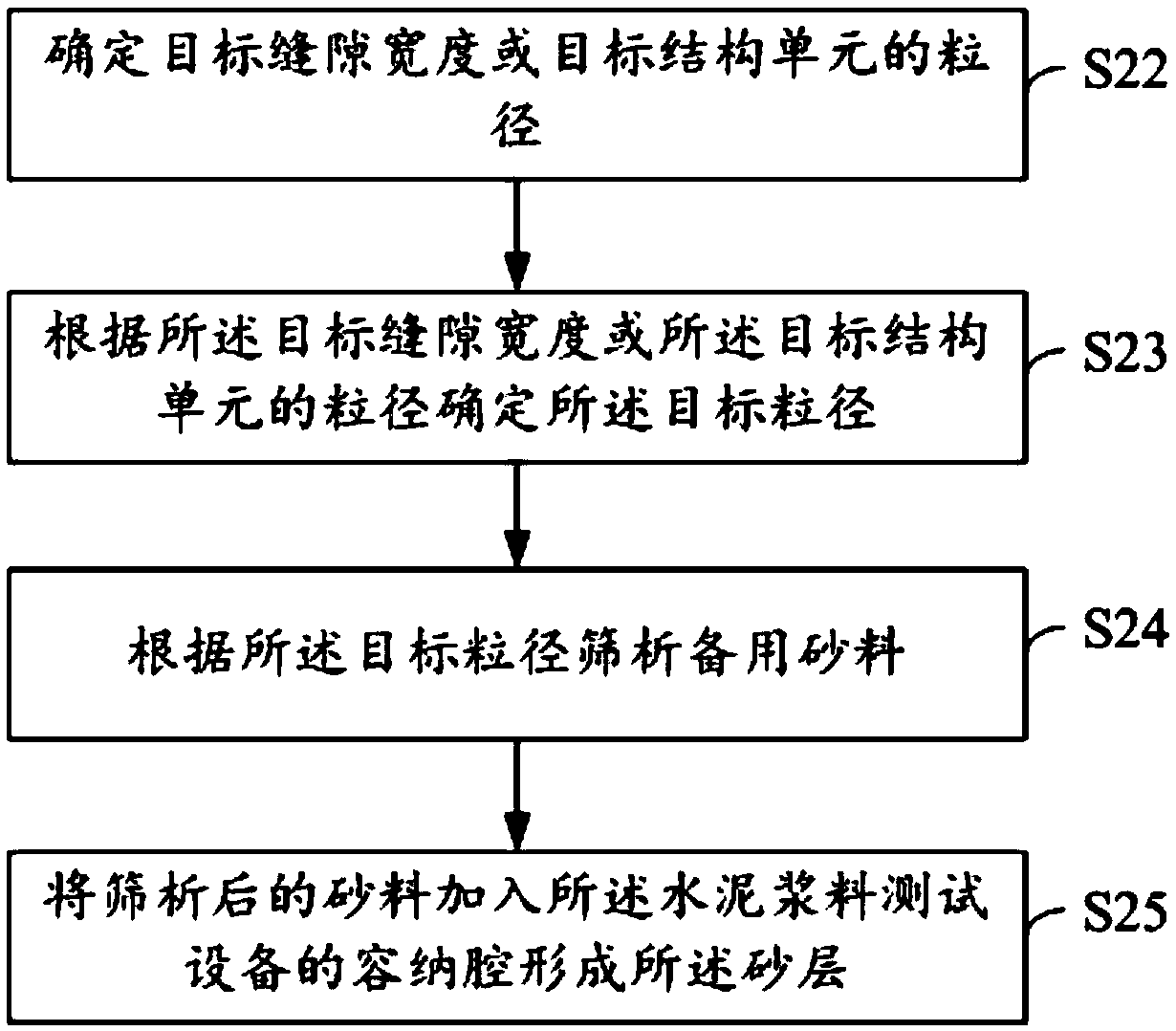

[0046] The main solution of the embodiment of the present invention is to provide a cement slurry testing equipment, the equipment includes a first shell and a second shell, the second shell is detachably fixedly connected with the first shell to form a cylinder body, the second shell The inner wall of the first housing and the inner wall of the second housing are enclosed to form an accommodating cavity inside the cylinder, and the accommodating cavity has an opening for injecting the test material. By combining the first shell and the second shell and installing it into a cylinder; adding sand material with a target particle size into the chamber 300 of the cylinder to form a sand layer 02; pouring the cement slurry to be tested into the chamber 300, laying above the sand layer 02; after the cement slurry in the acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com