A multi-core cable splitter

A multi-core cable and splitter technology, which is applied in the direction of electrical components, clamping/spring connections, etc., can solve the problems of bulky junction boxes, wire connection processing, and waste of junction boxes, etc., to achieve flexible settings and cost savings , Simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

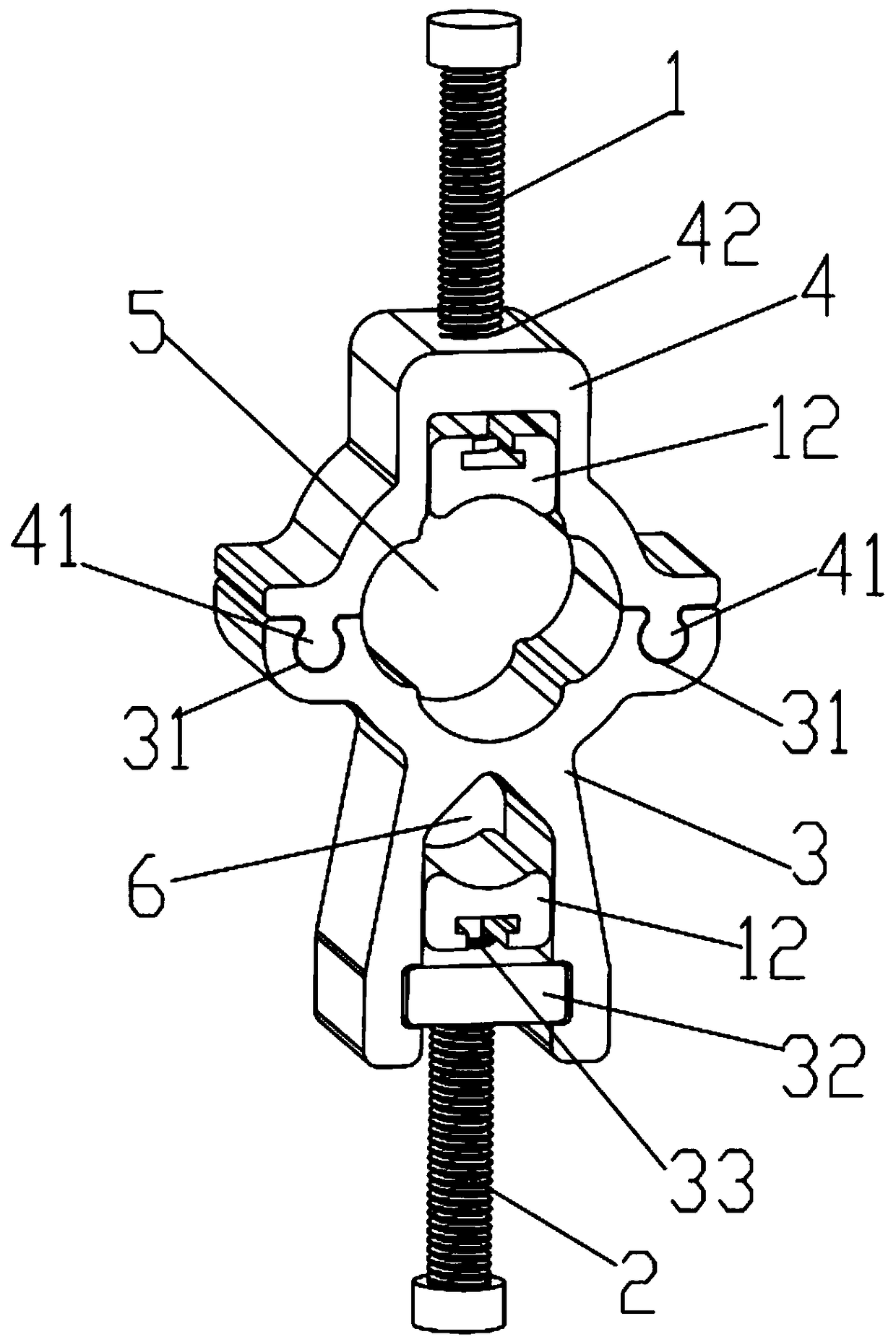

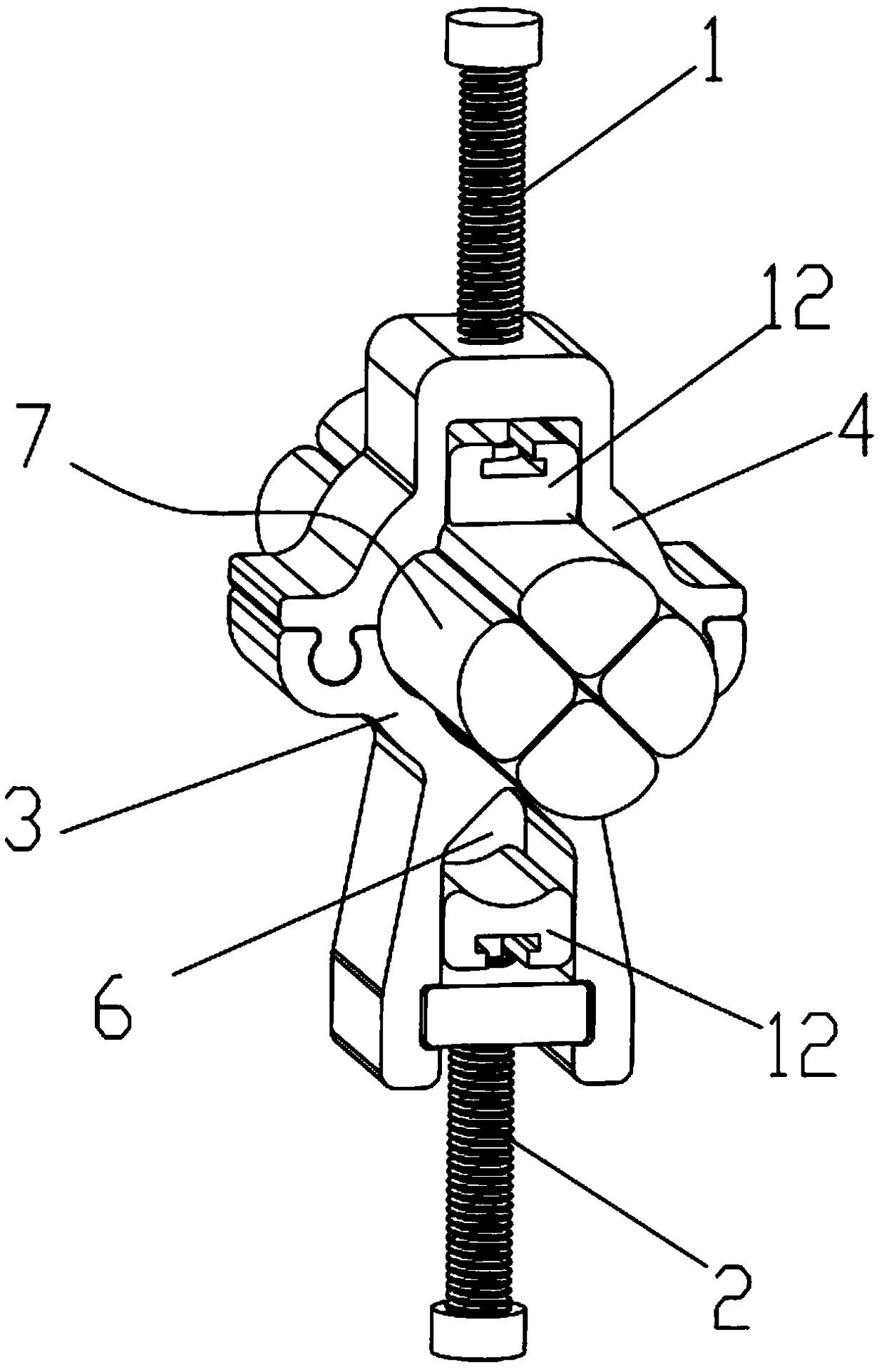

[0023] Such as figure 1 , 2 As shown, a multi-core cable splitter includes a wire core fixing seat 3, a cable fixing frame 4, a first bolt 1 and a second bolt 2, and the two sides of one end of the wire core fixing seat 3 are respectively provided with through-type plugs. Slots 31, the two sides of the cable fixing frame 4 are provided with corresponding convex strips 41, through the embedded fit of the convex strips 41 and the slots 31, the wire core fixing seat 3 and the cable fixing frame 4 are detachably connected, and the wires The core fixing seat 3 cooperates with the cable fixing frame 4 to form a main line cavity 5 for the multi-core cable 7 to pass through. The cable fixing frame 4 is provided with a first screw hole 42, and the first bolt 1 passes through the first screw hole 42 and connects with it. Threaded connection, and the front end of the first bolt 1 faces the wire core fixing seat 3 so as to be able to cooperate to press and fix the multi-core cable 7 in t...

Embodiment 2

[0027] On the basis of the technical solution of embodiment 1, the first bolt 1 and the second bolt 2 are improved as follows:

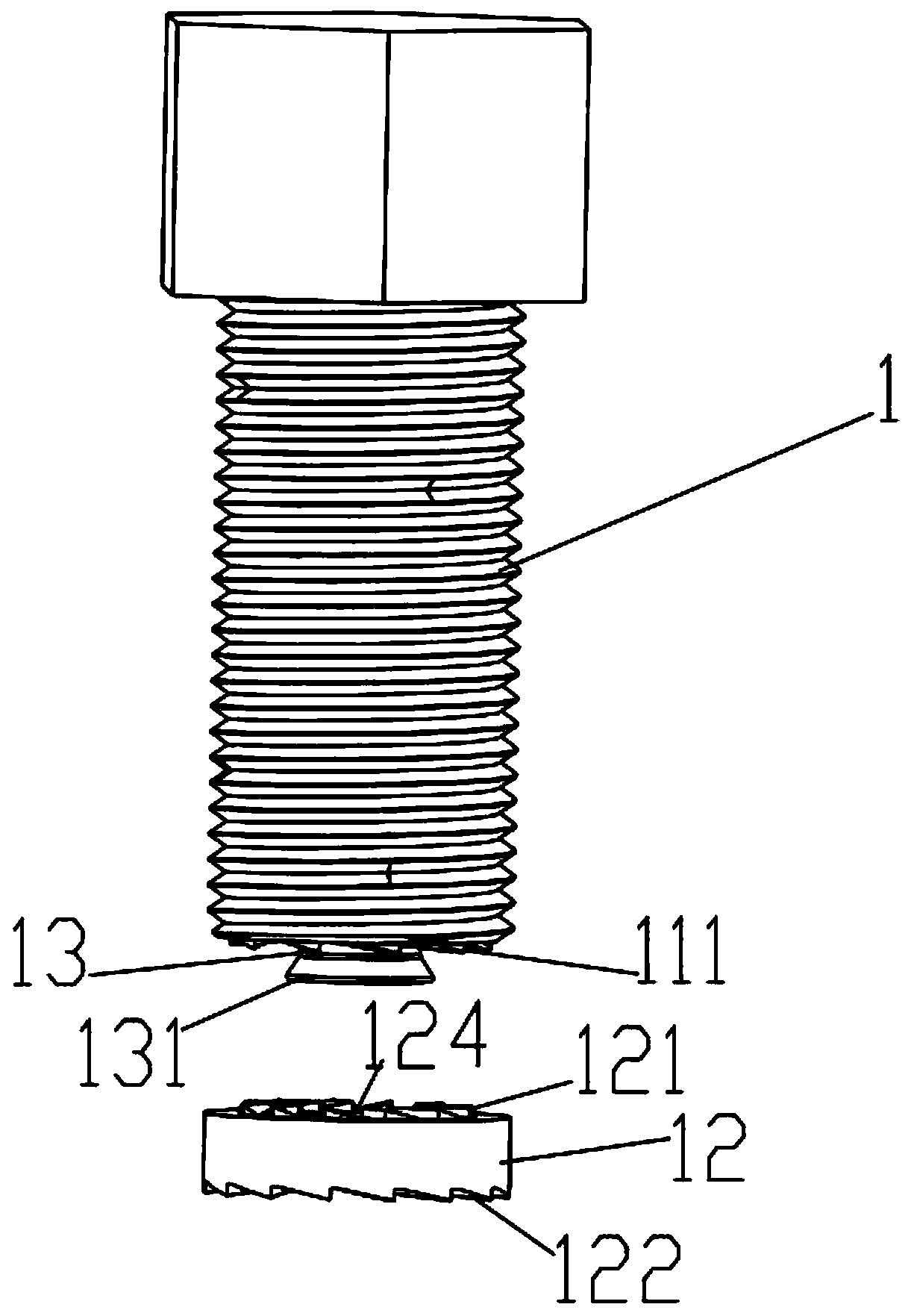

[0028] Such as image 3 As shown, taking the first bolt 1 as an example, the front end surface of the bolt and the back surface of the anti-slip pressure plate 12 are respectively provided with a first anti-reverse helical tooth 111 and a second anti-reverse helical tooth 121 that can engage with each other. , the first anti-reverse helical teeth 111 are circumferentially distributed on the front end face of the bolt to form a first ring gear, and the second anti-reverse helical teeth 121 are circumferentially distributed on the back of the anti-skid pressure plate 12 The second ring gear is formed. The first ring gear and the second ring gear are arranged opposite to each other. The first anti-reverse helical tooth 111 is inclined in the direction opposite to the tightening direction of the corresponding bolt, and the direction of the second anti-re...

Embodiment 3

[0033] On the basis of the technical solution of embodiment 2, the first bolt 1 and the second bolt 2 are further improved:

[0034] Such as Figure 4 As shown, taking the first bolt 1 as an example, the rear end of the bolt is provided with a first screw head 112 and a second screw head 113 in sequence along the axial direction, and a screw head 112 and a second screw head 113 are arranged between The broken part 114, the maximum torque that the broken part 114 can bear is less than the maximum torque that other parts of the bolt can bear, when the torque that the first screw head 112 bears is greater than the maximum torque that the broken part 114 can bear, the broken part 114 will break and thus The first screw head 112 is disengaged from the bolt. The structure of the fracture part 114 is an annular groove 1141 arranged on the outer surface of the bolt and an inner hole 1142 arranged inside the bolt, so that the wall thickness of the fracture part 114 is relatively small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com