Bottle cell carrier for a bottle cleaning machine

A technology for a carrier and a bottle washer, which is applied in the directions of cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve problems such as disturbing the operation of the bottle washer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

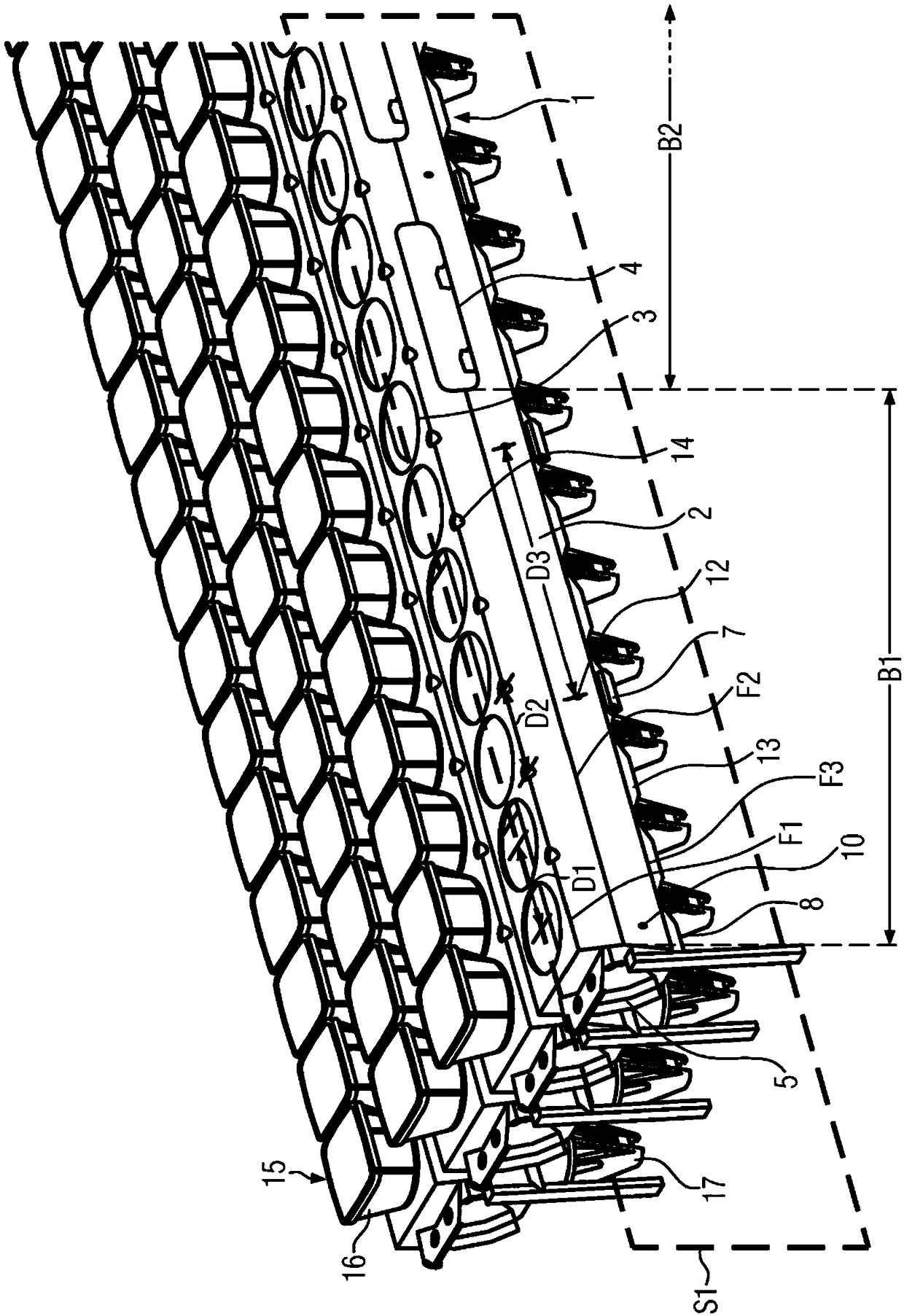

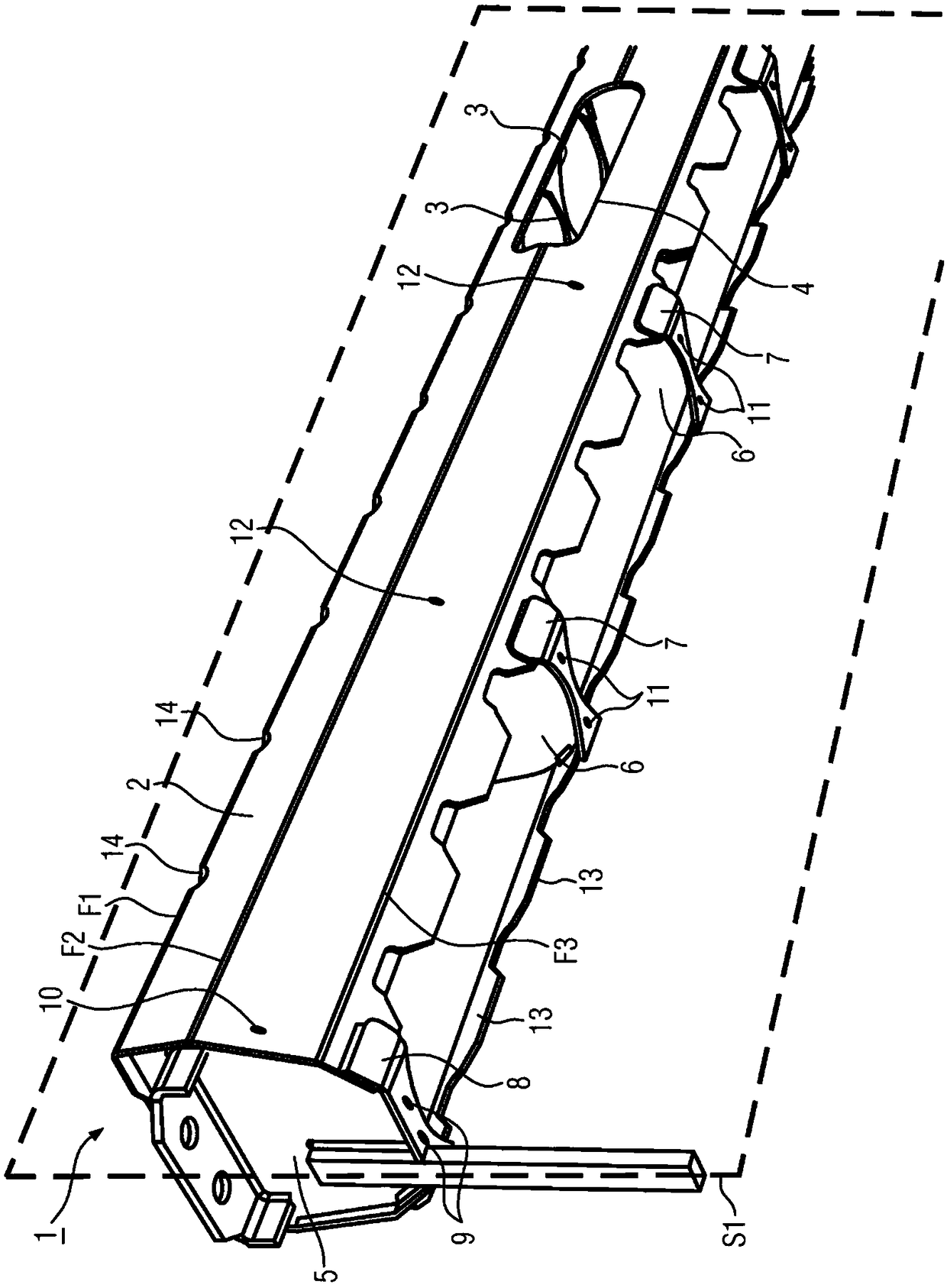

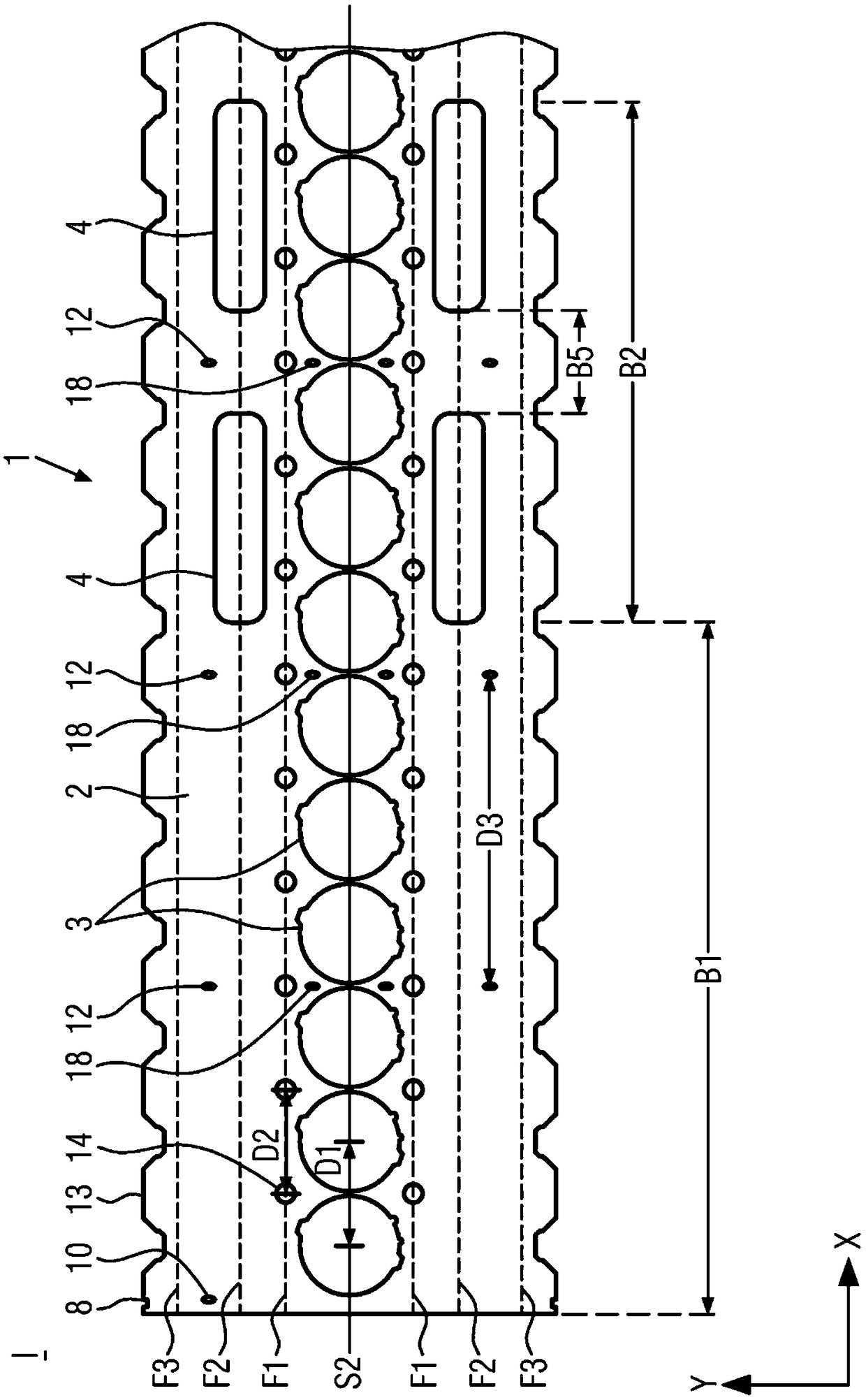

[0026] figure 1 A partial perspective view of four bottle unit carriers 1 is shown obliquely from above, wherein the four bottle unit carriers 1 are positioned side by side and parallel to their own longitudinal axes. A typical bottle unit carrier can have a length of eg 6300 mm. As an example, in three bottle unit carriers 1 , bottle units 15 are inserted into the bottle unit receptacles 3 of the respective bottle unit carriers 1 . The upper part 16 of the bottle unit 15 is located above the bottle unit carrier 1 and the lower part 17 of the bottle unit 15 is at least partially surrounded by the trapezoidal serrated edge 13 of the carrier profile 2 . The bottle to be cleaned can be inserted into the bottle unit 15 from above by means of its downwardly oriented opening. Preferably, the bottle unit 15 is made of plastic.

[0027] The bottle unit receptacles 3 are arranged at a regular center-to-center distance D1 along the horizontal surface of the carrier profile 2 . The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com