Extrusion type 3D printing double- jetting-head device

A 3D printing, dual-nozzle technology, applied in the field of extrusion 3D printing dual-nozzle devices, can solve problems such as restricting the development of extrusion 3D printing technology and being unable to meet gradient materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] as attached Figure 1-3 Shown, device of the present invention comprises:

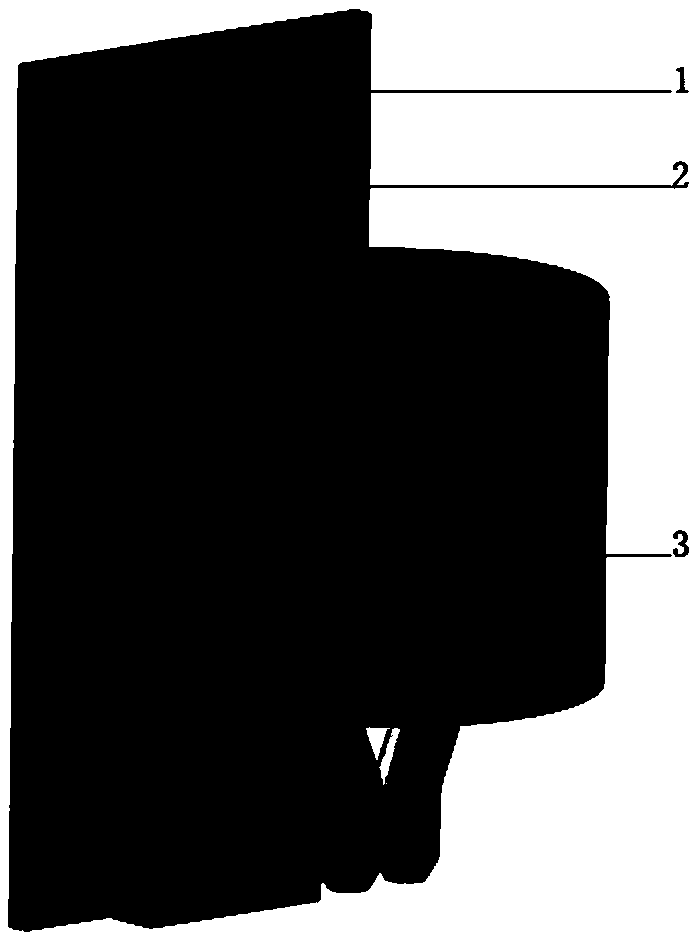

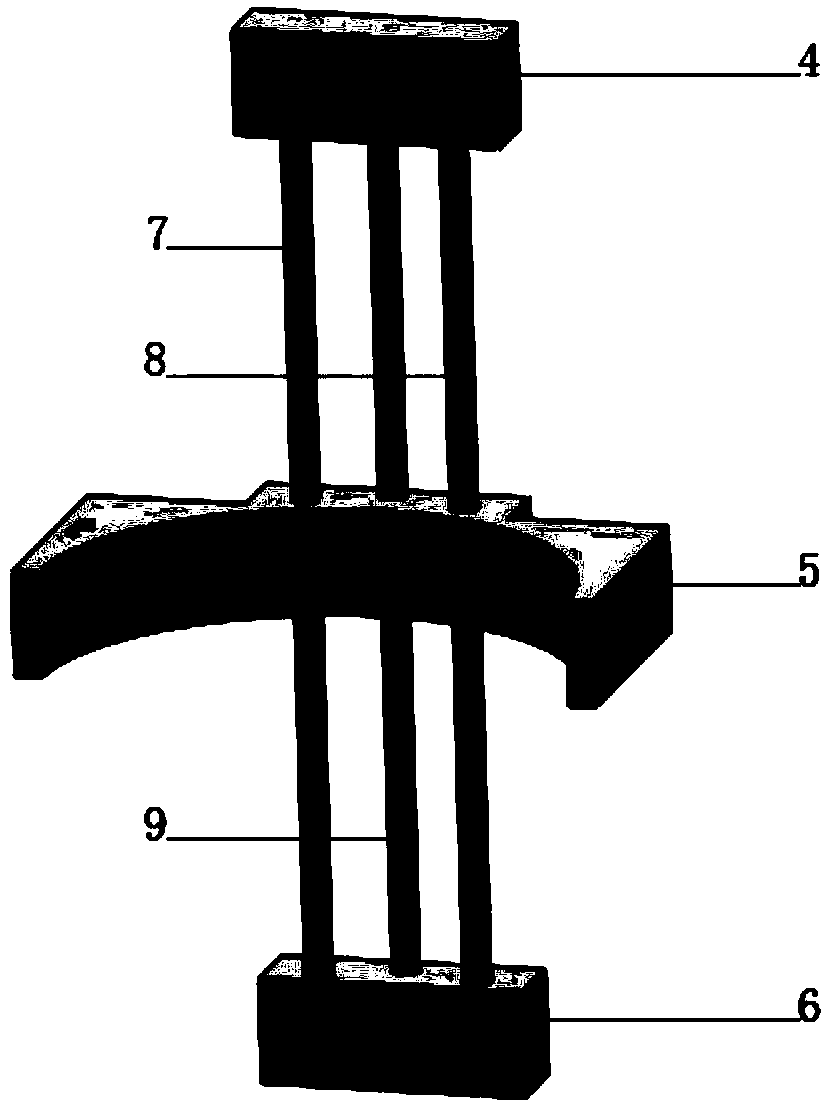

[0016] The printing double nozzle assembly 3 is installed on the nut bracket 5 of the ball screw 1, the ball screw 1 is installed on the steel plate 2, and the printing double nozzle assembly 3 can realize vertical movement up and down under the transmission of the ball screw 1;

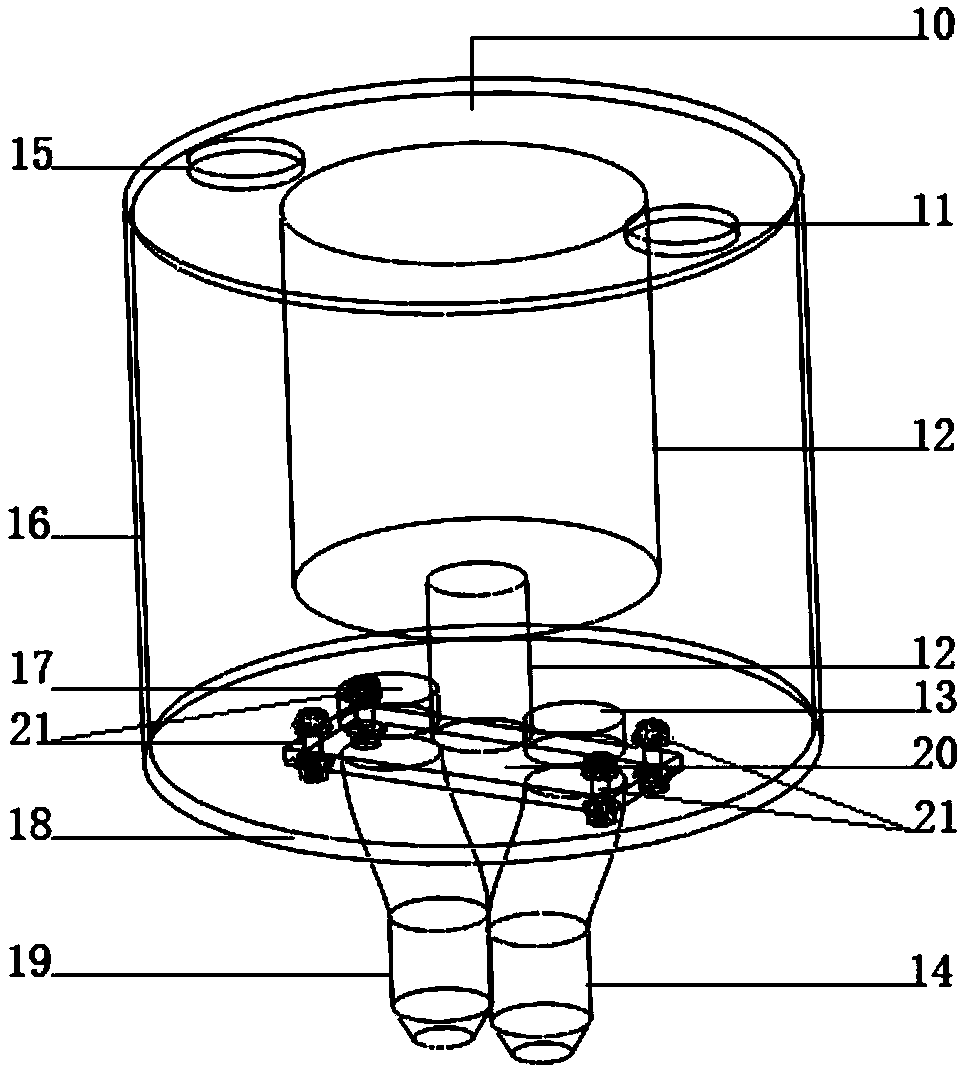

[0017] Among them, the printing double nozzle assembly 3 includes a cover plate 10, an opening A15, an opening B11, a sleeve 16, a bidirectional alternating rotation motor 12, a feed port A17, a feed port B13, a rotatable chassis 18, a nozzle A19, and a nozzle B14;

[0018] The nozzle A19 and the nozzle B14 are respectively connected to the feed port A17 and the feed port B13 with threaded ports, the feed port A17 and the feed port B13 are fixed on the steel plate 20, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com