Ring spinning machine with several spinning positions

A ring spinning machine and spinning technology, which is applied in the direction of continuous winding spinning machine, spinning machine, textile and paper making, can solve the problems of increasing the energy consumption of the ring spinning machine, and achieve long-term reliable functionality , optimized energy requirements, and reliable functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

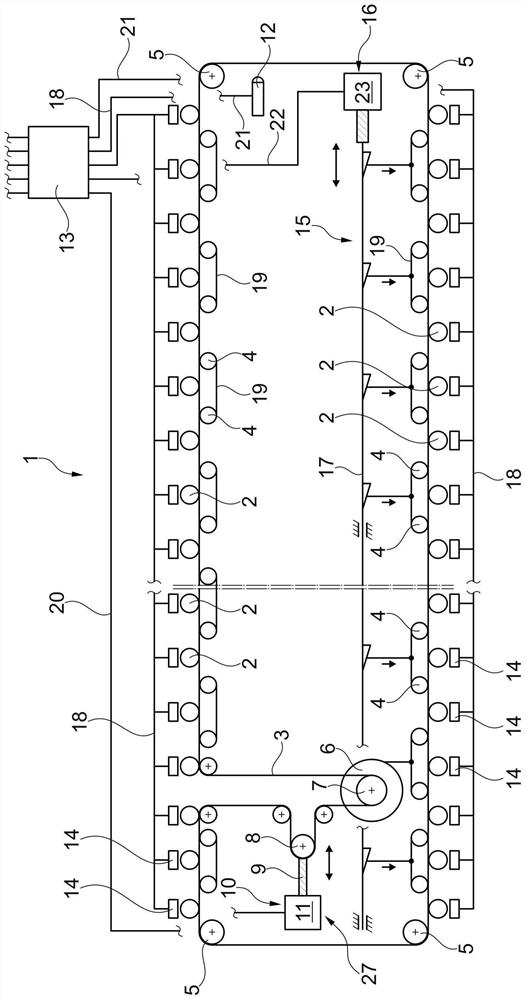

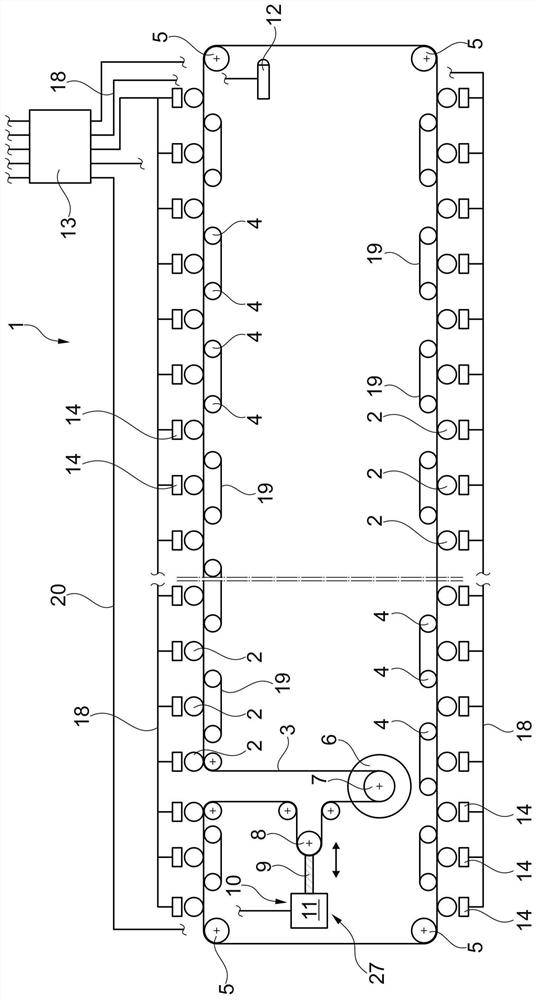

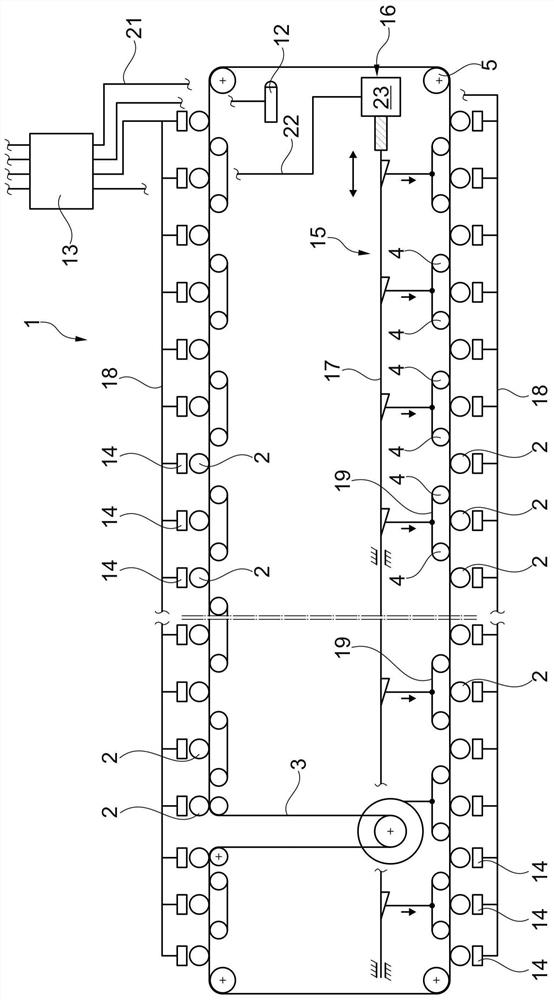

[0035] figure 1 A schematic plan view of a first embodiment of the drive of the spindle 2 of the ring spinning machine 1 is shown.

[0036] As can be seen, the ring spinning machine 1 has a plurality, in some cases more than 1000, of such spindles 2 on both machine longitudinal sides. As known and therefore not explained in more detail, so-called spinning bobbins are produced on said spindle 2, which have relatively little yarn material and are therefore subsequently rewound into a downstream automatic winder. Cross wound bobbins.

[0037] The spindle 2 is mounted freely rotatable and is driven by means of a tangential belt 3 circulating preferably along the length of the machine, which acts on the drive reel of the spindle 2 and frictionally drives the spindle 2 in rotation.

[0038] In order to obtain a certain contact pressure of the tangential belt 3 against the spindle discs of the spindles 2, so-called press rollers 4 are additionally arranged between the spindles 2, pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com