HOUSING ASSEMBLY AND ELECTRONIC device

A technology for housing components and electronic equipment, applied in branch equipment, telephone communication, electrical components, etc., can solve the problems of single function, electronic equipment can not give timely feedback to users, etc., to achieve the effect of multi-machine interaction mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

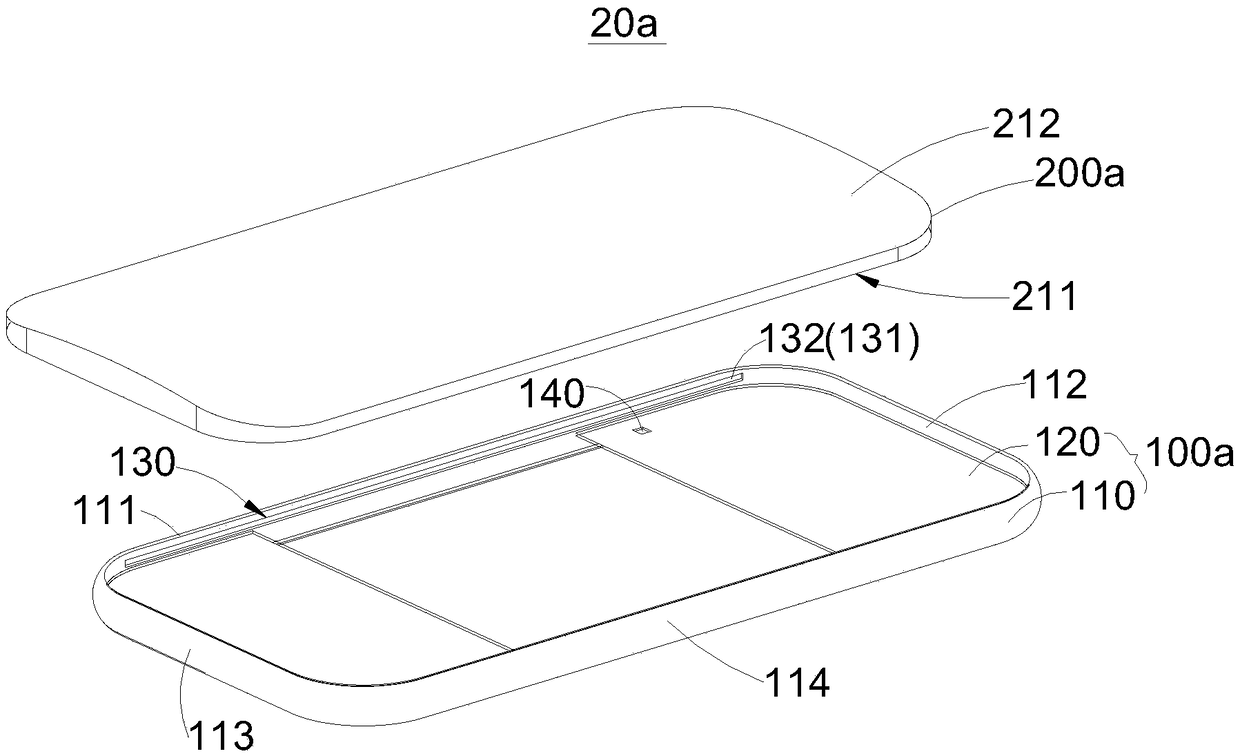

[0020] refer to figure 1 , the present embodiment provides a housing assembly 20a, including a middle frame 100a and a rear cover 200a, and the rear cover 200a can be assembled with the middle frame 100a.

[0021] The middle frame 100 a includes a frame 110 and a mounting part 120 , wherein the frame 110 forms a ring structure, and the frame 110 is provided with a light-emitting assembly installation part 130 , and the light-emitting assembly installation part 130 is used for arranging the light-emitting assembly 30 .

[0022] In this embodiment, the frame 110 includes a first frame 111 , a second frame 112 , a third frame 113 and a fourth frame 114 . Wherein, the first frame 111 and the fourth frame 114 are arranged oppositely, the second frame 112 and the third frame 113 are arranged oppositely, and the first frame 111, the second frame 112, the fourth frame 114 and the third frame 113 are sequentially connected end to end to form a ring. Moreover, in this embodiment, the ...

no. 2 example

[0037] refer to Figure 4 , this embodiment provides a housing assembly 20b, which differs from the housing assembly 20b in the first embodiment in that the structure of the rear cover 200b is different. Refer to the first embodiment for the same parts.

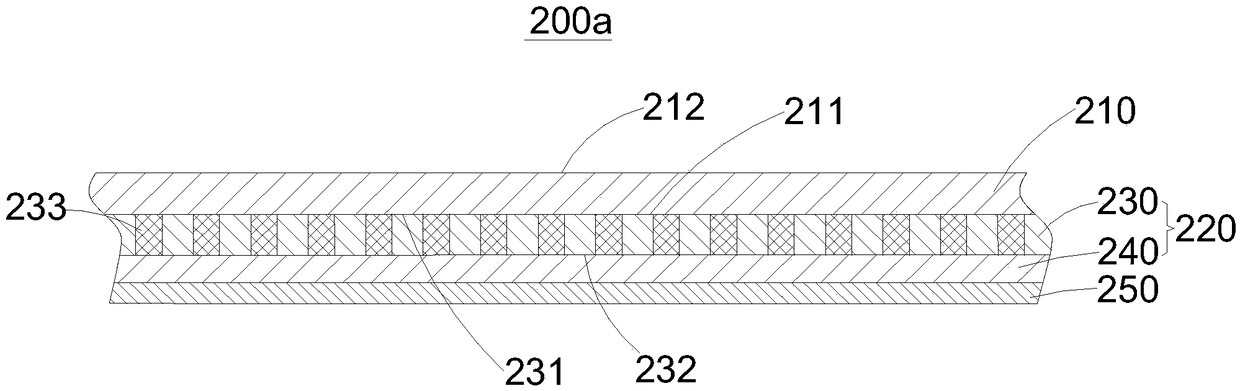

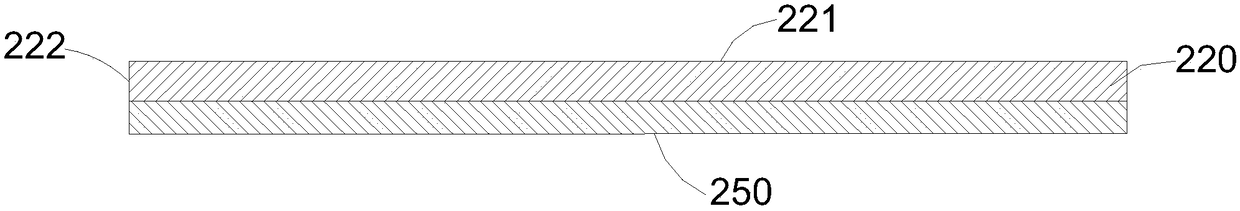

[0038] Please also refer to Figure 4 and Figure 5 , in this embodiment, the rear cover 200b includes a transparent cover 210 , a light guide film 220 and a light-shielding layer 250 , wherein the transparent cover 210 is provided with a mounting hole 213 , and the mounting hole 213 penetrates the inner surface 211 and the outer surface 212 . The mounting hole 213 is used for the camera assembly of the electronic device 10 to protrude. The light guide film 220 is provided with a first through hole 223 , and the first through hole 223 passes through the first surface 231 and the second surface 232 . In some embodiments, the axis of the first through hole 223 and the axis of the installation hole 213 may coincide with each...

no. 3 example

[0044] refer to Figure 7 , this embodiment provides a back cover 200c, which can be used to replace the back cover 200b in the second embodiment. In the embodiment, the back cover 200c includes a transparent cover plate 210, a color film 260, a light guide film 220 and The light-shielding layer 250, wherein the transparent cover plate 210 has an inner surface 211, the color film 260 covers the inner surface 211, the light guide film 220 has a first surface 231 and a second surface 232, and the first surface 231 covers the color film 260 , that is, the color film 260 is disposed between the inner surface 211 and the light guide film 220 . The light shielding layer 250 is formed on the second surface 232 .

[0045] Wherein, the color film 260 refers to a color film, which has light transmission. The color is non-white, for example, it can be various single colors such as blue, red, green, etc., or it can be a color diaphragm 260 formed by mixing multiple colors. The purpose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com