A multi-directional core-pulling injection mold for spherical skeleton parts

A technology of injection mold and skeleton, which is applied in the field of injection molding mold structure, and can solve the problems that the core-pulling of extremely large-sized parts cannot be realized, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

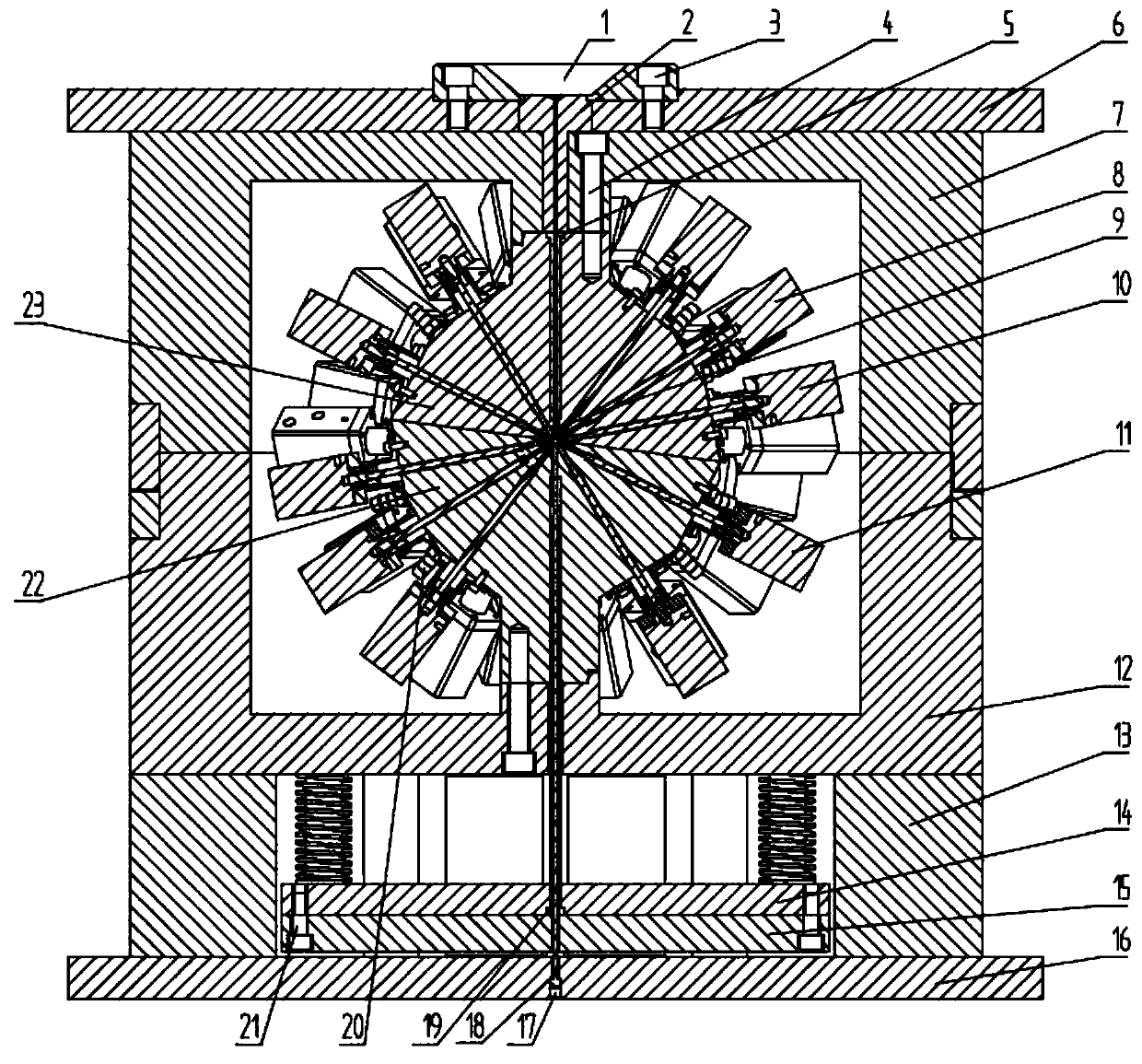

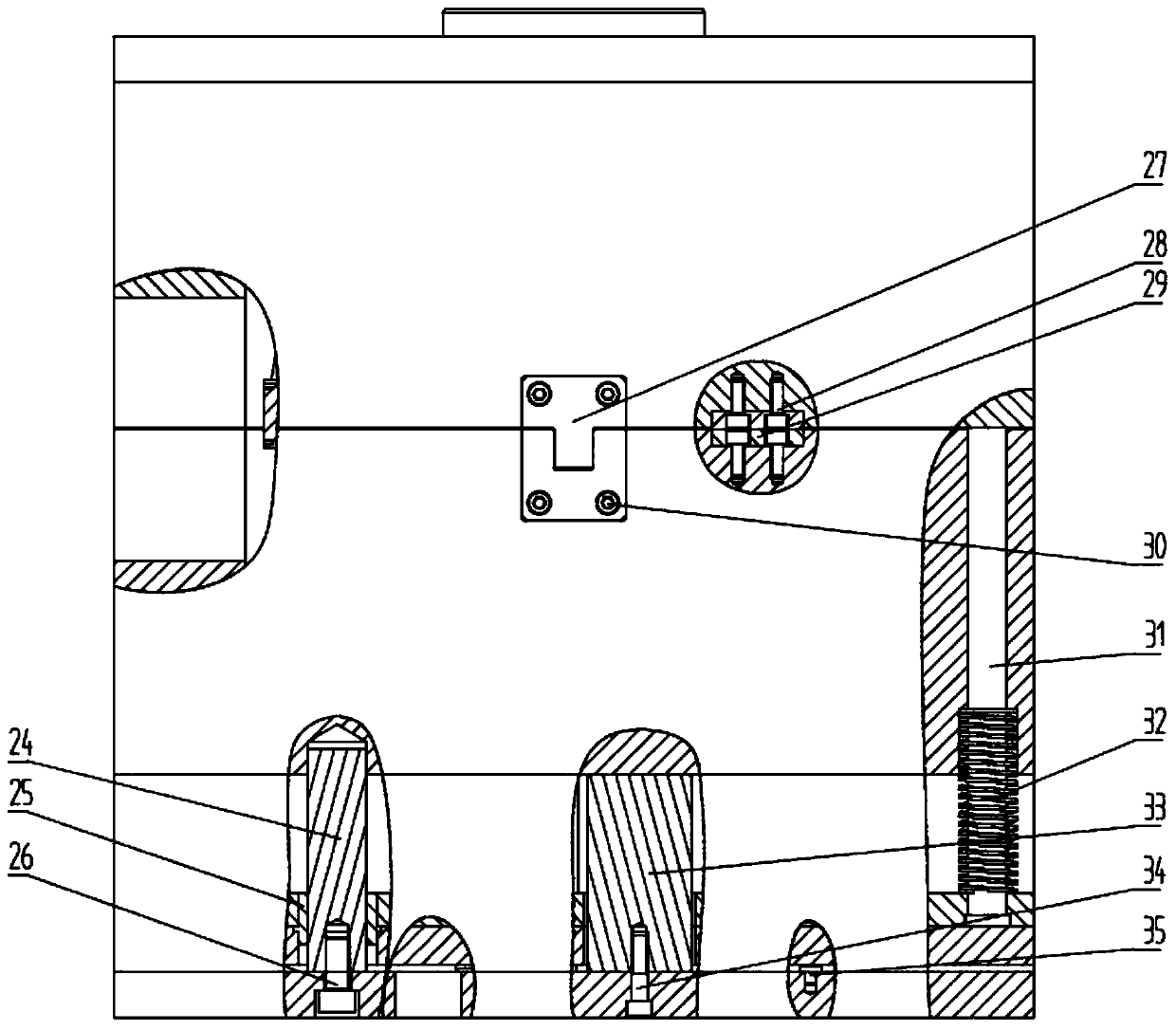

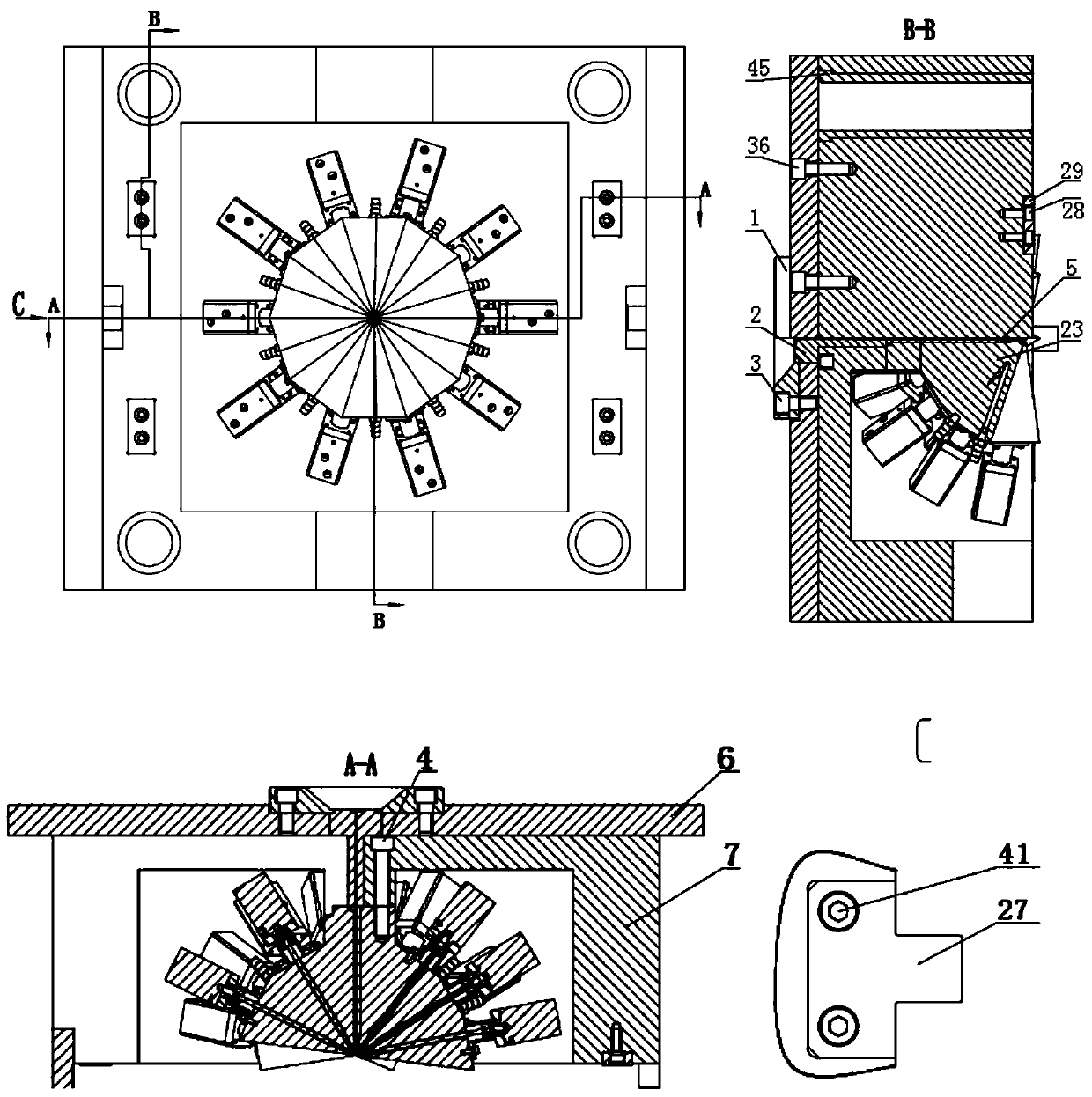

Embodiment 1

[0035] This embodiment provides a multi-directional core-pulling injection mold for spherical skeleton parts, which is mainly designed with a two-plate mold, wherein the mold base adopts the Long Kee Dashuikou mold base standard; the core and the cavity insert adopt a self-designed polyhedron shape; The core-pulling structure adopts the hydraulic cylinder side core-pulling method; the core cavity and the formwork are connected and fixed by bolts, and both of them adopt the positioning form of the boss groove; the pouring system design adopts the latent gate; the ejection scheme adopts the The cylinder is ejected; the cooling method is water cooling, and the drilling and processing of the water channel is used in the movable and fixed mold inserts for mold cooling; the mold exhaust system adopts the form of mold clearance and side core-pulling clearance exhaust.

[0036] The movable and fixed model cavity is divided by the broken line parting surface, and the cavity insert and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com