Automatic storing and taking system for moving robot

A mobile robot, automatic access technology, applied in the field of intelligent logistics system, can solve the problem of unable to realize automatic door opening and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

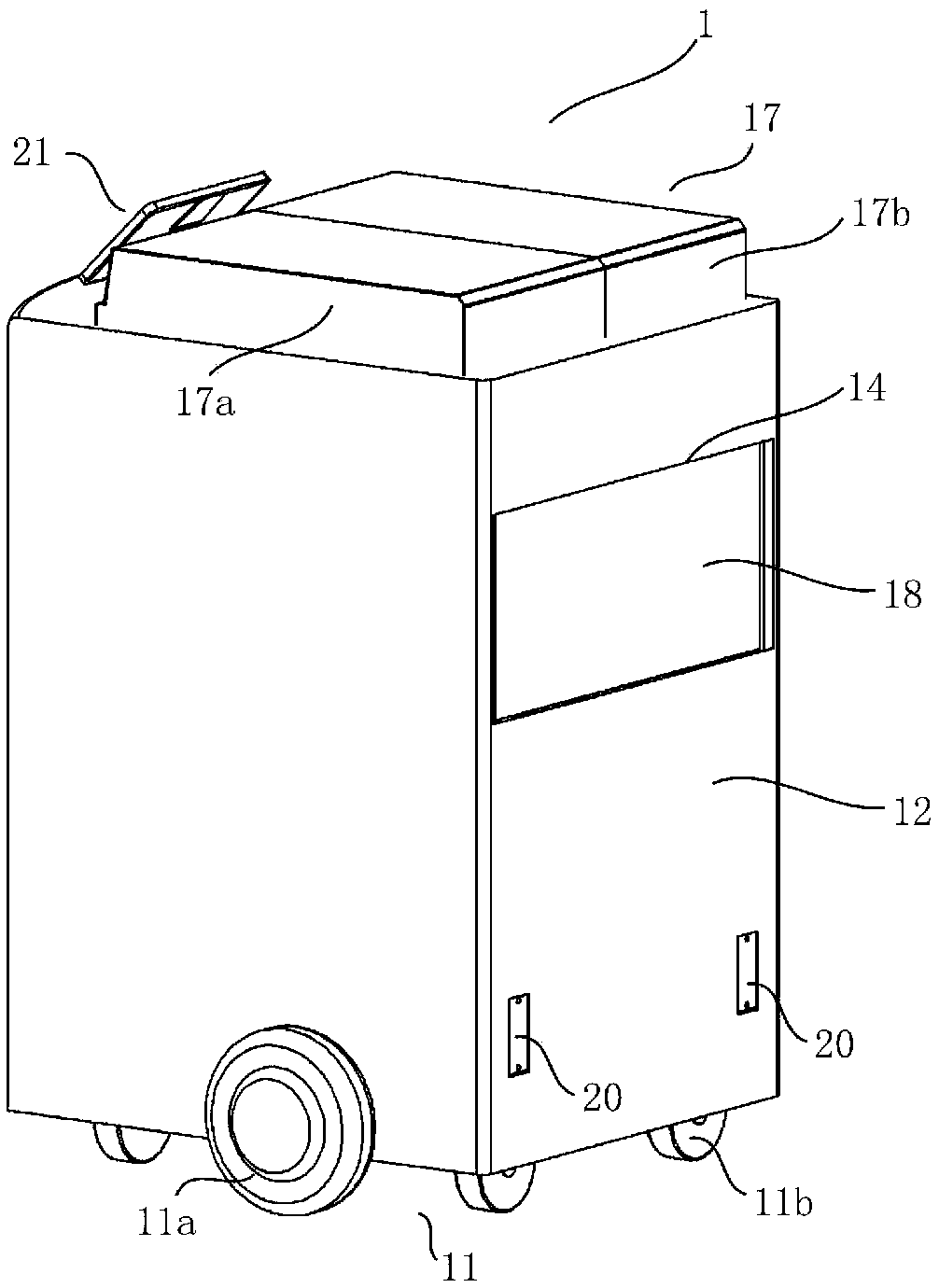

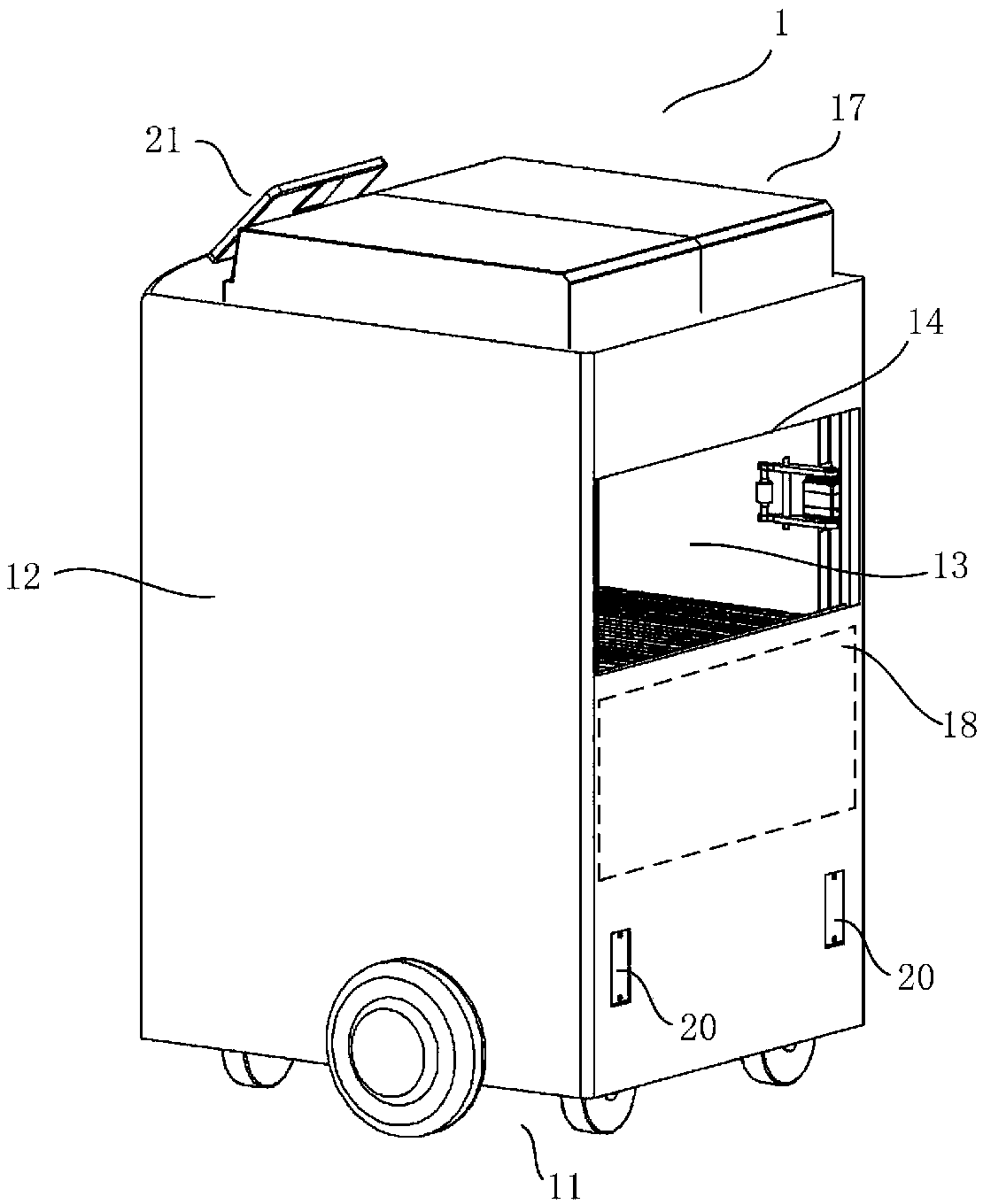

[0047] As shown in Figure 1(a) and Figure 1(b), this embodiment provides an automatic access system for a mobile robot, which includes a storage device 2 and a mobile robot 1;

[0048] This storage device is shown in conjunction with Fig. 5 (a) - Fig. 5 (c), and it comprises a box body frame, and this box body frame is provided with a plurality of storage compartments 4, and it is respectively bottom compartment 4a and upper Box grid 4b, the storage box grid 4 has an opening opened on a side; a box door 6 is pivotally installed on the opening portion through a pivot shaft, and one end away from the pivot shaft, the storage box grid 4 Corresponding to the position of the compartment door 6, there is also a lock for locking the compartment door 6, wherein, preferably, in this embodiment, the lock is an electronic lock, and the compartment door 6 has a The catch in the lockset 6b.

[0049] Simultaneously, a comb-shaped support 5 is arranged inside the storage compartment 4 , and...

Embodiment 2

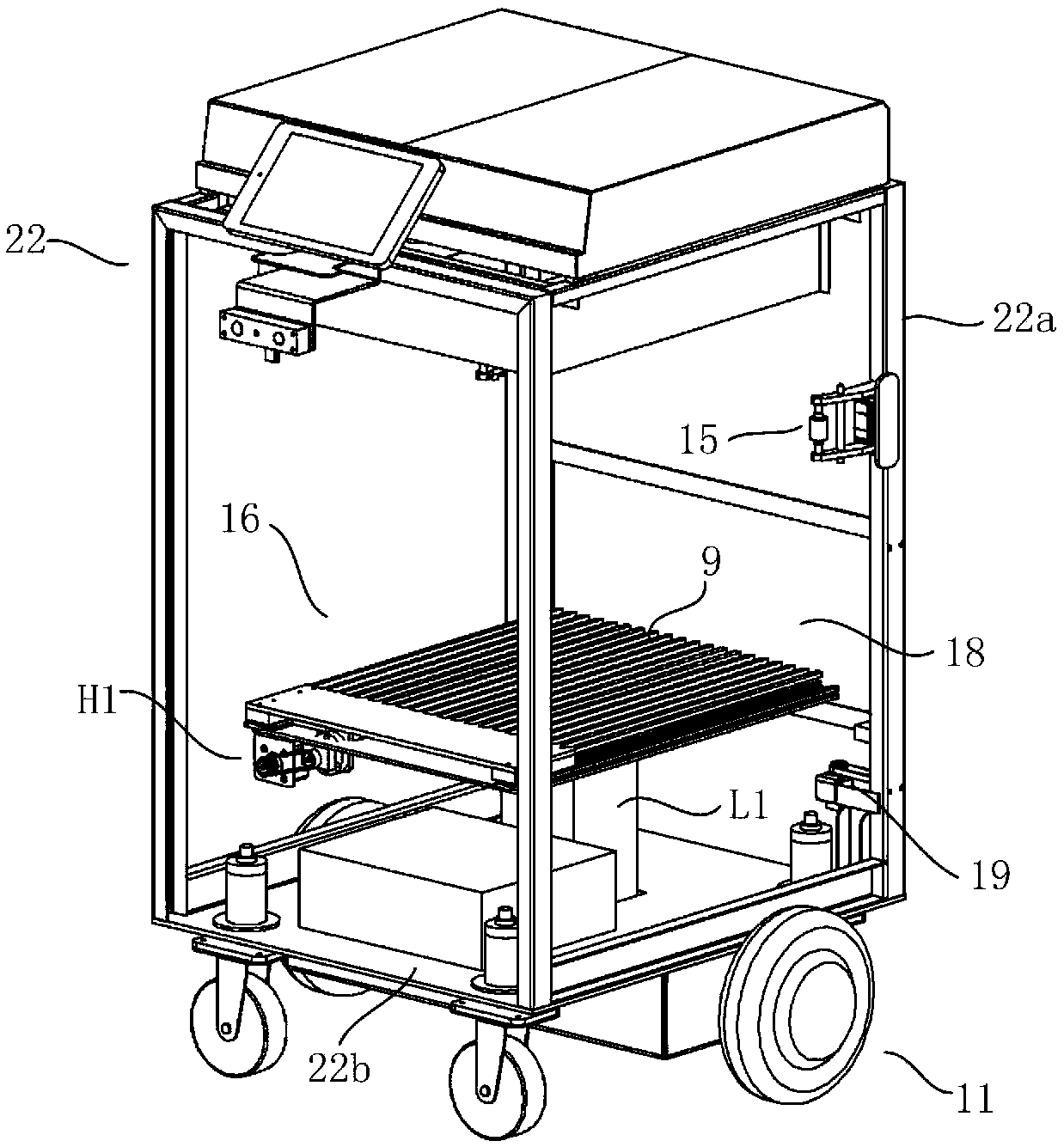

[0063] recombine Figure 6, as shown in Figure 7(a) and Figure 7(b), this embodiment provides a mobile robot automatic access system, which includes a mobile robot and a storage device, the structure of the two is basically the same as that of Embodiment 1, and its main The difference is that the pick-and-place device in this embodiment is different from the structure of the pick-and-place device in Embodiment 1.

[0064] The picking and placing device 16 of this embodiment mainly includes: a first lifting module L1 as a lifting mechanism, a conveyor belt translation linear module H2 as a translation mechanism, a friction roller and a conveyor belt assembly T2 as a conveying mechanism. Wherein, the front end of the conveyor belt translation linear module H2 is provided with a friction roller 60, which can protrude from the horizontal opening 14; correspondingly, the storage box 4 is provided with a passive conveyor belt 7, and the passive conveyor belt 7 includes The mounting...

Embodiment 2

[0070] The action process of embodiment 2 when picking and placing parts is basically the same as that of embodiment 1, except that the way of conveying the items is different, mainly relying on the translation of the conveyor belt linear module H2 with the friction roller and the conveyor belt assembly T2 after translation, so that the friction roller 60 With the passive conveyor belt 7, the article 3 is moved from the storage box grid 4 to the storage cavity of the robot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com