Explosion blocking and venting device for pipeline

A technology of relief device and pipeline, applied in the direction of valve operation/release device, valve device, valve details, etc., can solve problems such as rapid recovery of unfavorable production, increased production cost input, long closing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

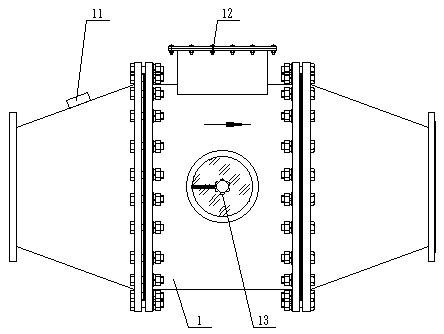

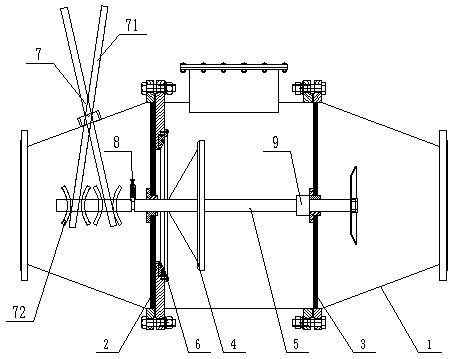

[0031] Such as figure 1 , figure 2 with Figure 5 As shown, the explosion blocking and releasing device for pipelines of the present invention includes: a device main body 1, a front support frame 2, a rear support frame 3, a sealing plate 4, a main shaft 5, a sealing ring 6 and a reset device 7; The main body 1 is a tubular structure with openings at both ends. The front support frame 2 and the rear support frame 3 are fixed in the main body 1 of the device. It consists of pipe sleeves, a sealing plate 4 is arranged between the front support frame 2 and the rear support frame 3, and a main shaft 5 is arranged on the sealing plate 4, and the main shaft 5 runs through the tubes of the front support frame 2 and the rear support frame 3. sleeve, and the main shaft 5 can reciprocally slide relative to the pipe sleeve, and the inner wall of the device main body 1 between the front support frame 2 and the sealing plate 4 is provided with a sealing ring 6, and the sealing plate 4 ...

Embodiment 2

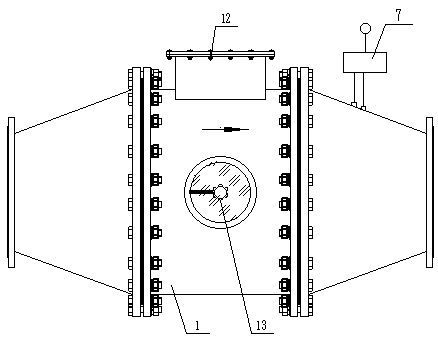

[0046] Such as Figure 3 to Figure 5 Shown: the explosion blocking and releasing device for the pipeline of the present invention, comprising: the device main body 1, the front support frame 2, the rear support frame 3, the sealing plate 4, the main shaft 5, the sealing ring 6 and the reset device 7; the device The main body 1 is a tubular structure with openings at both ends. The front support frame 2 and the rear support frame 3 are fixed in the main body 1 of the device. It consists of pipe sleeves, a sealing plate 4 is arranged between the front support frame 2 and the rear support frame 3, and a main shaft 5 is arranged on the sealing plate 4, and the main shaft 5 runs through the tubes of the front support frame 2 and the rear support frame 3. sleeve, and the main shaft 5 can reciprocally slide relative to the pipe sleeve, and the inner wall of the device main body 1 between the front support frame 2 and the sealing plate 4 is provided with a sealing ring 6, and the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com