Textile product production waste material recycle cleaning device

A technology for producing waste materials and cleaning devices, which is applied in textiles and papermaking, electromechanical devices, mechanical cleaning, etc. It can solve the problems of poor recycling and cleaning effect of textile waste cloth, disregarding the flatness of the cloth surface, and affecting the working efficiency of the device, etc., to achieve Increase practicability, better effect and prolong service life

Pending Publication Date: 2019-01-29

江苏四方纺线有限责任公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The cleaning device for waste recycling in textile products does not consider the surface smoothness of the textile waste cloth, and does not perform drying treatment on the cleaned textile waste cloth, resulting in a comparison of the recycling and cleaning effects of the textile waste cloth. Poor, such textile waste fabrics cannot be put into reprocessing. In the process of cleaning textile waste fabrics, the water after use is directly poured into the water tank through the water pump, and the water body is not filtered. There must be some impurities in the water body, recycling will lead to poor cleaning effect, long-term use of this water body will also lead to blockage of the pipeline, affecting the working efficiency of the device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

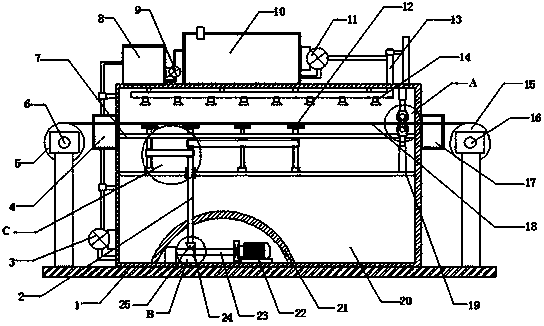

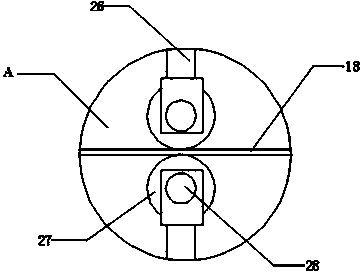

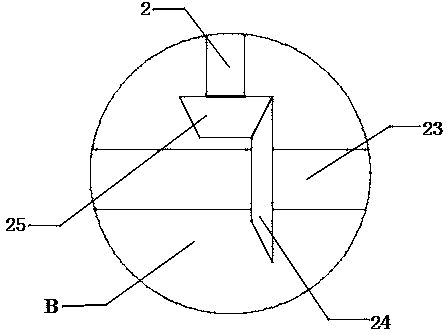

The invention discloses a textile product production waste material recycle cleaning device comprising a pedestal; a cleaning box is arranged on the outer wall of the top of the pedestal; two supportpoles are respectively arranged on the pedestal top outer wall on two ends of a cleaning box; the top outer walls of the four support poles are respectively provided with a first bearing seat; opposite outer walls of the first bearing seat are respectively fixedly connected with a second rotary shaft and a third rotary shaft via a bearing; a cloth release roller is sleeved on the outer wall of thesecond rotary shaft; a cloth retrieve roller is sleeved on the outer wall of the third rotary shaft; a textile waste cloth is sleeved on the outer wall of the cloth release roller and the cloth retrieve roller; a first water pump is arranged on the outer wall of one side of the cleaning box; a cloth feed pipe is arranged on the outer wall on one side, above the first water pump, of the cleaning box. The recycle cleaning device has extrusion rollers and an electric telescopic rod, and the gap between the extrusion rollers can be adjusted according to the original thickness of the textile wastecloth, thus providing a better flatting and extrusion dehydrated effect, improving the device cleaning effect, and increasing the device practicality.

Description

technical field [0001] The invention relates to the technical field of cleaning devices, in particular to a cleaning device for recycling waste materials produced in textile products. Background technique [0002] my country is a big fabric producing country, and it is also a big fabric practical country. The market demand for fabrics is huge, and the amount of waste fabrics is also huge. The market demand leads to waste fabrics that must be recycled and processed to continue to be used. [0003] The cleaning device for waste recycling in textile production does not consider the surface smoothness of the textile waste cloth, and does not perform drying operations on the cleaned textile waste cloth, resulting in a comparison of the recycling and cleaning effects of the textile waste cloth. Poor, such textile waste fabrics cannot be put into reprocessing. In the process of cleaning textile waste fabrics, the water after use is pumped directly into the water tank through the wa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D06G1/00C02F1/00H02K5/10

CPCH02K5/10D06G1/00C02F1/001

Inventor 田海亮

Owner 江苏四方纺线有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com