A new propeller casting structure

A technology of propellers and molds, applied in the direction of molds, mold components, cores, etc., can solve problems such as difficult, complicated operations, and cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is not only suitable for casting molds of various types of propellers, the following describes the embodiments of the present invention applicable to impellers.

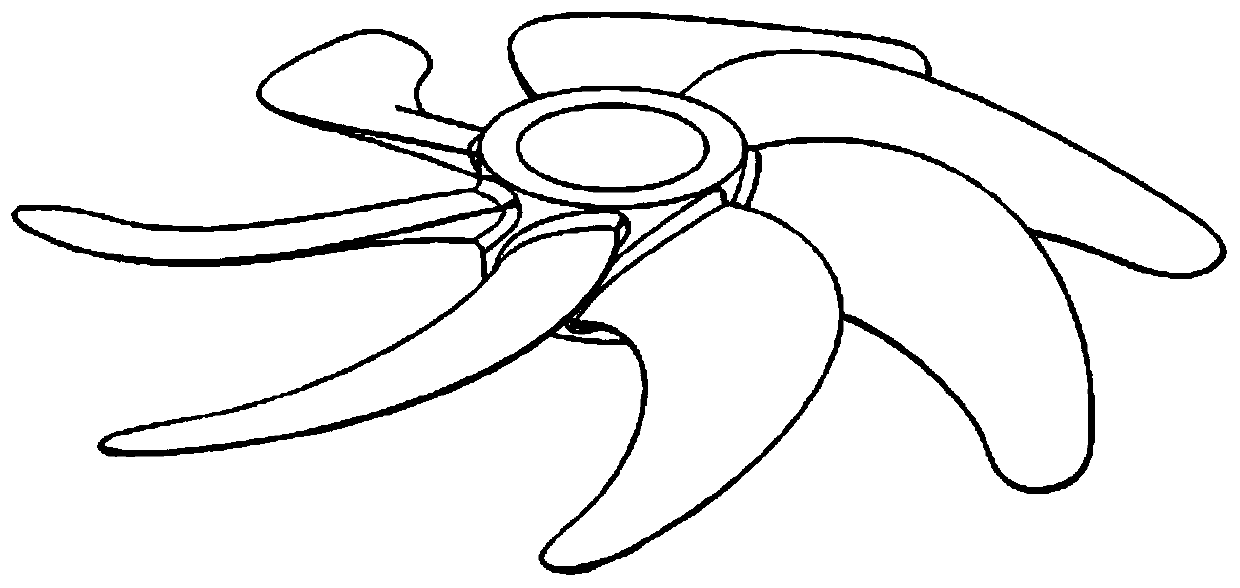

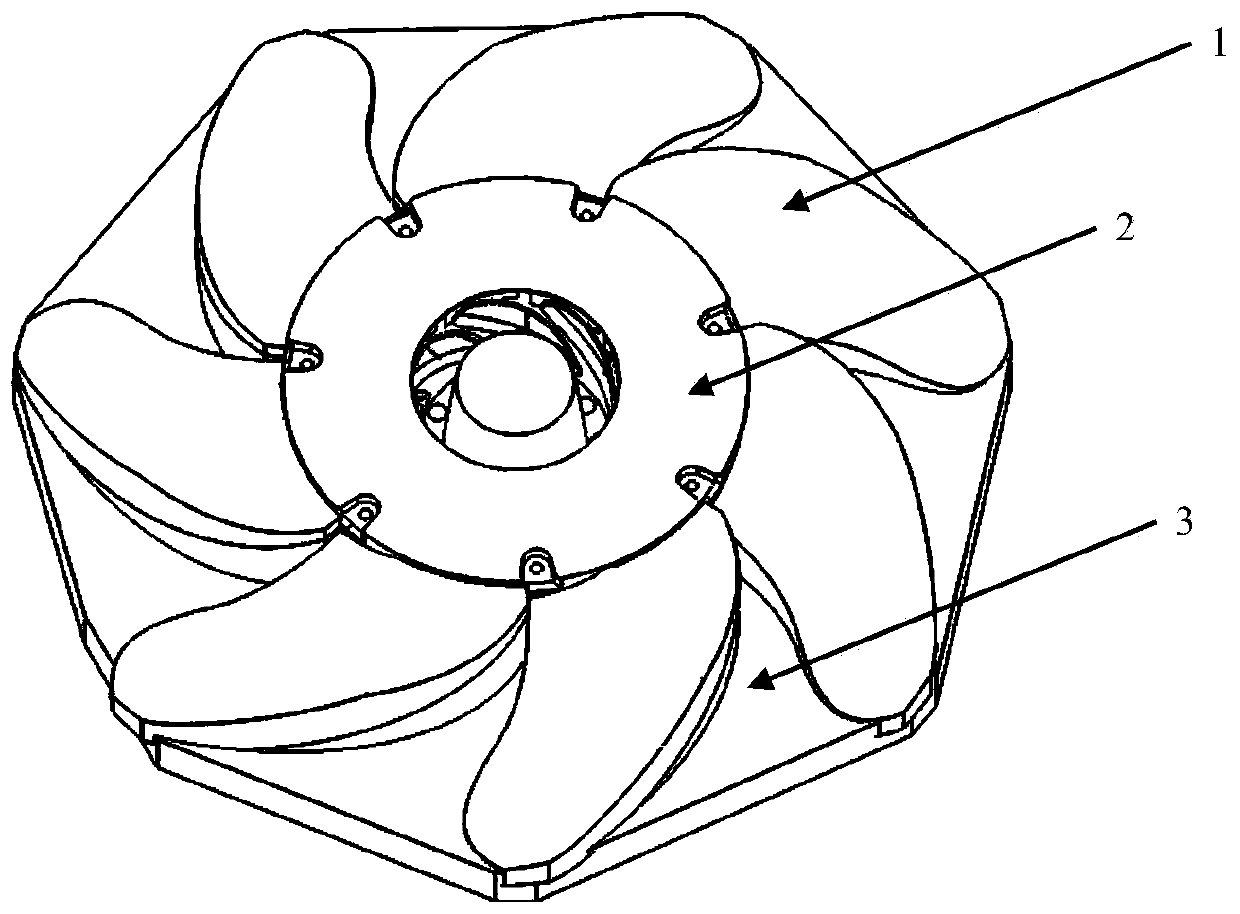

[0018] A new propeller mold structure, including three parts: an upper mold 1 having the same number as the number of blades, an integral center core 2, and an integral lower mold 3. The details are as follows:

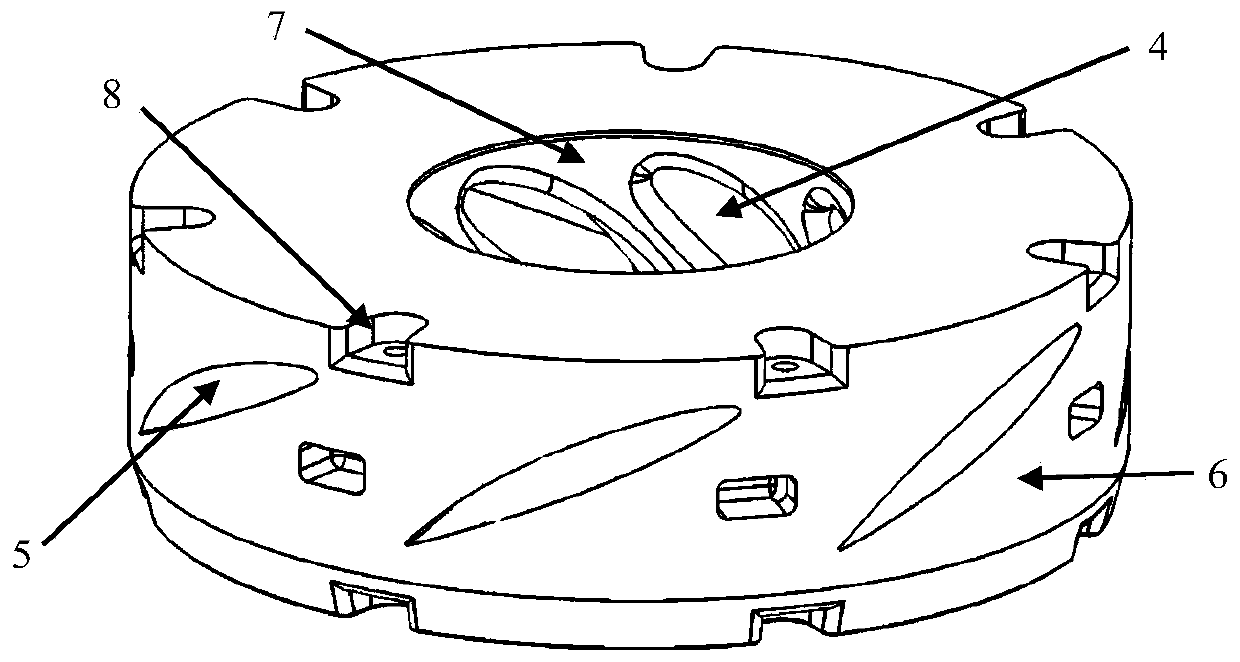

[0019] The center core 2 is a hollow cylindrical structure, which is arranged above the central boss of the lower type 3; including the pressure surface 4 at the blade root, the suction surface 5 at the blade root, the outer cylindrical parting surface 6, and the hub surface 7 , hoisting hole 8, center core positioning concave platform 9, and the casting mold includes overlapping areas at the blades and some non-overlapping areas of the blades, as shown in Figure 3 . The pressure surface 4 at the blade root is arranged below the suction surface, and its number is consistent with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com